Lining plate for packaging surgical suture needles and threads

A technique for surgical suturing and packaging, applied in surgical instruments, applications, trocars, etc., can solve problems such as easy knotting, and achieve the effects of improving production efficiency, simple structural design, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

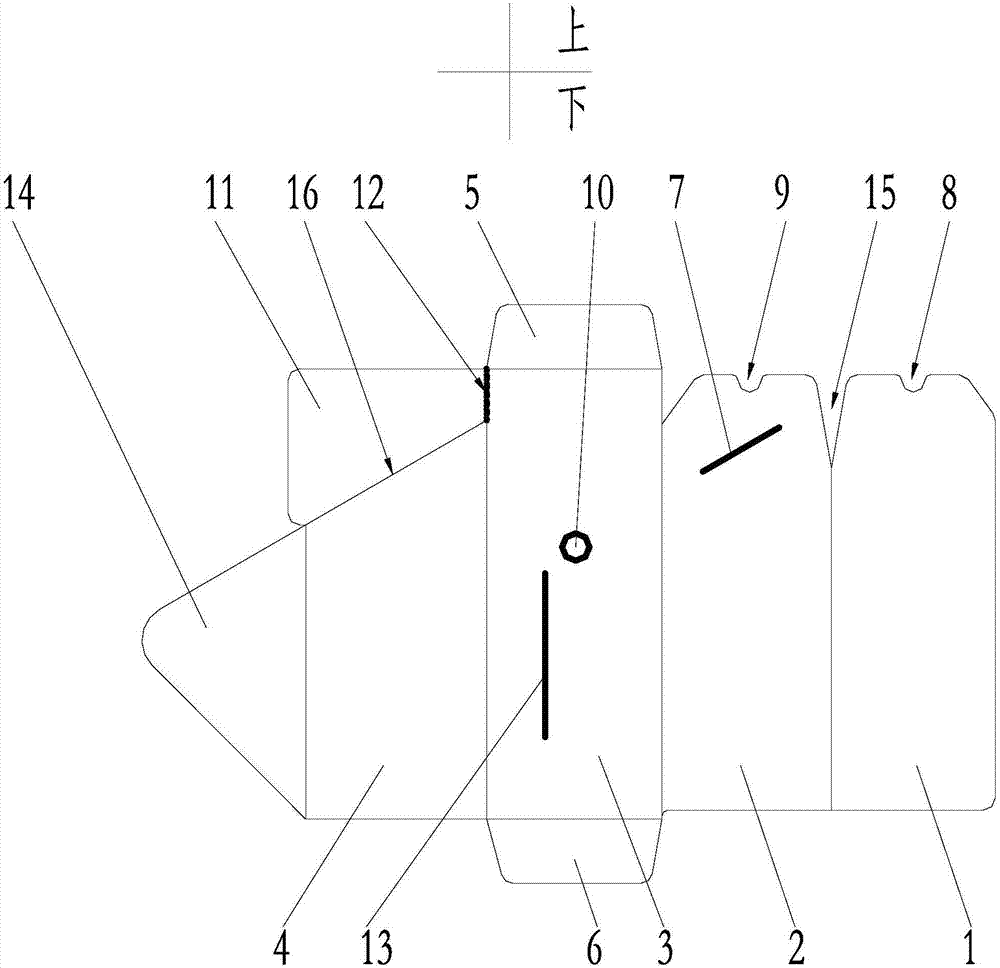

[0021] Embodiment 1 of the present invention: as figure 1 As shown, a lining board for surgical suture needlework packaging includes a first part 1, a second part 2, a third part 3 and a fourth part 4 connected as one, the first part 1, the second part 2, the third part 3 and the width dimensions of the fourth component 4 are successively increasing. This kind of size arrangement makes it unnecessary to set up double-press tangent line folding between adjacent parts during the production process of the packaging liner, and can also achieve the purpose of easy packaging, avoiding unnecessary mold opening in the production process, and reducing the process steps and production costs. The middle part of the short side on the top of the first part 1 is provided with a first notch 8, the middle part of the short side on the top of the second part 2 is provided with a second notch 9, and the top of the third part 3 is connected with a first side cover plate 5, namely The first sid...

Embodiment 2

[0024] Embodiment 2: as figure 1As shown, a liner for surgical suture needlework packaging includes a first part 1, a second part 2, a third part 3 and a fourth part 4 connected as one, the first part 1, the second part 2, the third part 3 and the width dimensions of the fourth component 4 are successively increasing. This kind of size arrangement makes it unnecessary to set up double-press tangent line folding between adjacent parts during the production process of the packaging liner, and can also achieve the purpose of easy packaging, avoid unnecessary mold opening in the production process, and reduce the process steps and production costs. The middle part of the short side on the top of the first part 1 is provided with a first notch 8, the middle part of the short side on the top of the second part 2 is provided with a second notch 9, and the top of the third part 3 is connected with a first side cover plate 5, namely The first side cover 5 , the first notch 8 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com