High-temperature heat pipe working medium filling device and method

A high-temperature heat pipe and working medium technology, applied in the field of heat pipes, can solve the problems of affecting the purity of the working medium, complicated operation, and difficulty in measuring the filling amount of the working medium, and achieve the effects of avoiding human contact, convenient operation, and reducing the risk of pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

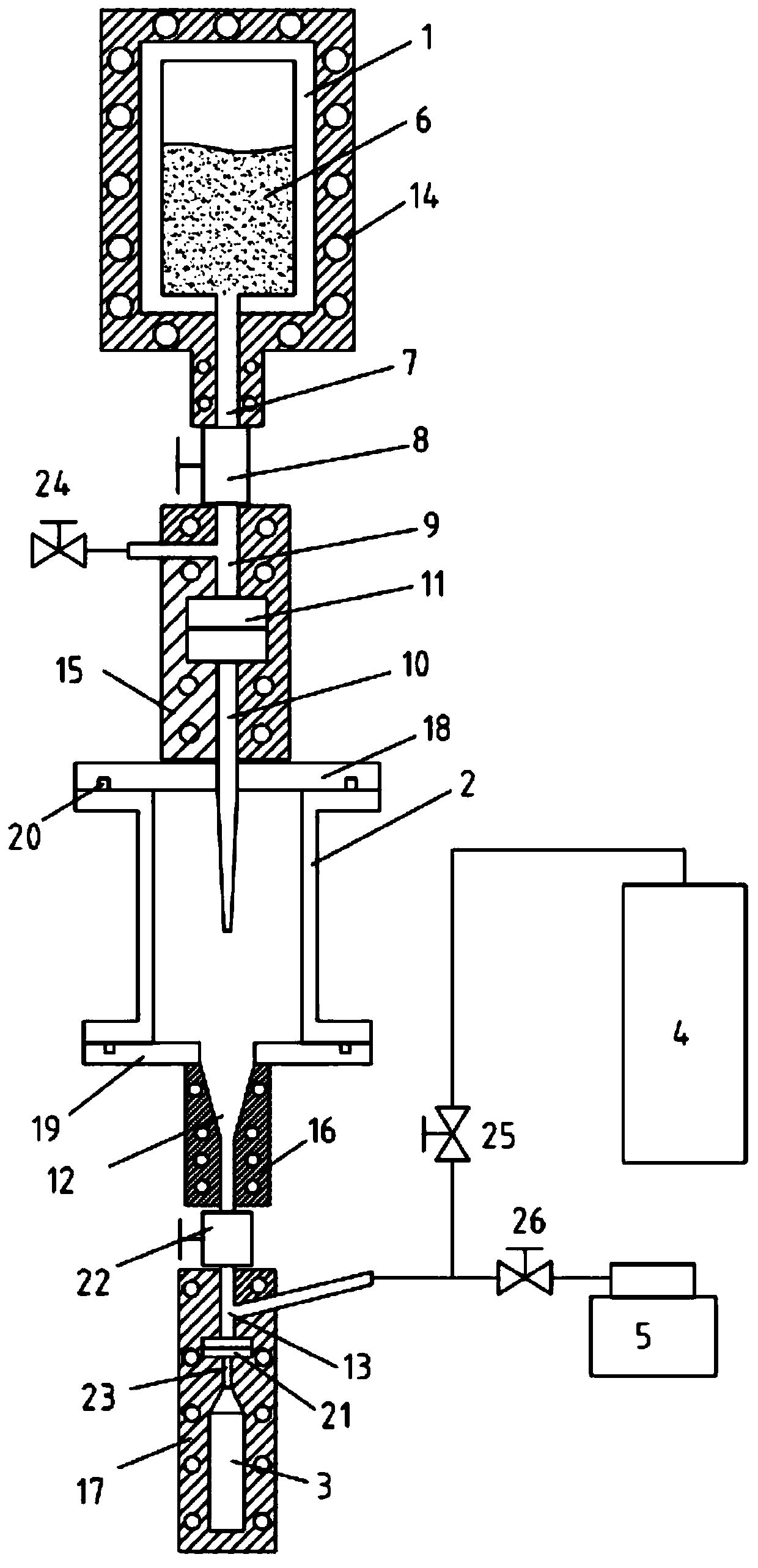

[0034] Such as figure 1 As shown, the present invention provides a high-temperature heat pipe working medium filling device, which includes a working medium container 1, a first pipeline 7, a first valve 8, a second pipeline 9, a first joint 11, Conical pipe 10 , quartz container, funnel 12 , second valve 22 , tee pipe 13 , second joint 21 , packaging pipe 23 and high temperature heat pipe 3 . Wherein, the quartz container includes a quartz tube 2, a first flange 18 and a second flange 19, the top and bottom of the quartz tube 2 are respectively connected with the first flange 18 and the second flange 19 through a sealing groove 20, and the working fluid container 1 A high-purity working medium 6 is set in the medium, and a high vacuum is kept in the working medium container 1, that is, 10 -3 ~10 -5Pa. The first end of the tapered tube 10 is connected to the first joint 11, the second end passes through the first flange 18 and extends into the lumen of the quartz tube 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com