Patents

Literature

194results about How to "Realize inner loop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste plastic film decolouring regeneration method and system

ActiveCN102873787AEffective and efficient processingEffective and Efficient Processing CapabilitiesPlastic recyclingMetal coatingChemical reaction

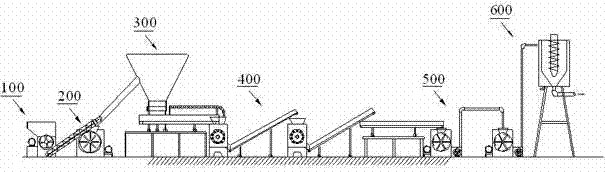

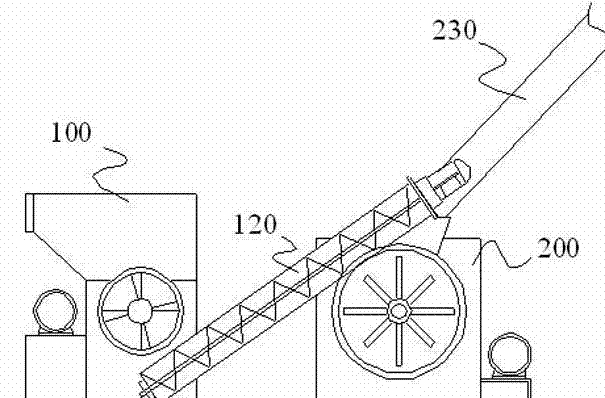

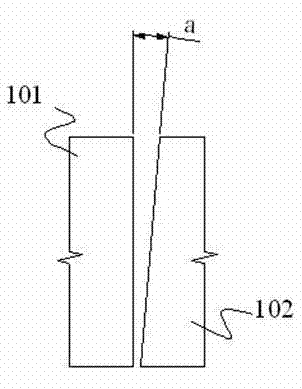

The invention belongs to the field of waste plastic regeneration, and particularly relates to a waste plastic film decolouring regeneration method and a waste plastic film decolouring regeneration system which are pollution-free, efficient and high in treatment ability. Waste plastic films are processed by a physical method, the colour or metal coating covered on the surface of the film is fallen off in a mechanical flapping or mechanical friction manner. In order to completely remove the colour or metal coating covered on the film in a physical manner, the recovered waste film is firstly crushed into small blocks, and the coating on the film fragment is more likely to fall off in the high-speed mechanical flapping and friction process. By the method, the defect that long-time chemical reaction is required according to the conventional chemical method is overcome, the colour or metal coating on the film can be efficiently removed, and the method is suitable for batch industrial process and can be used for treating a large amount of waste plastic garbage.

Owner:SHENZHEN JUYUANTIANCHENG TECH

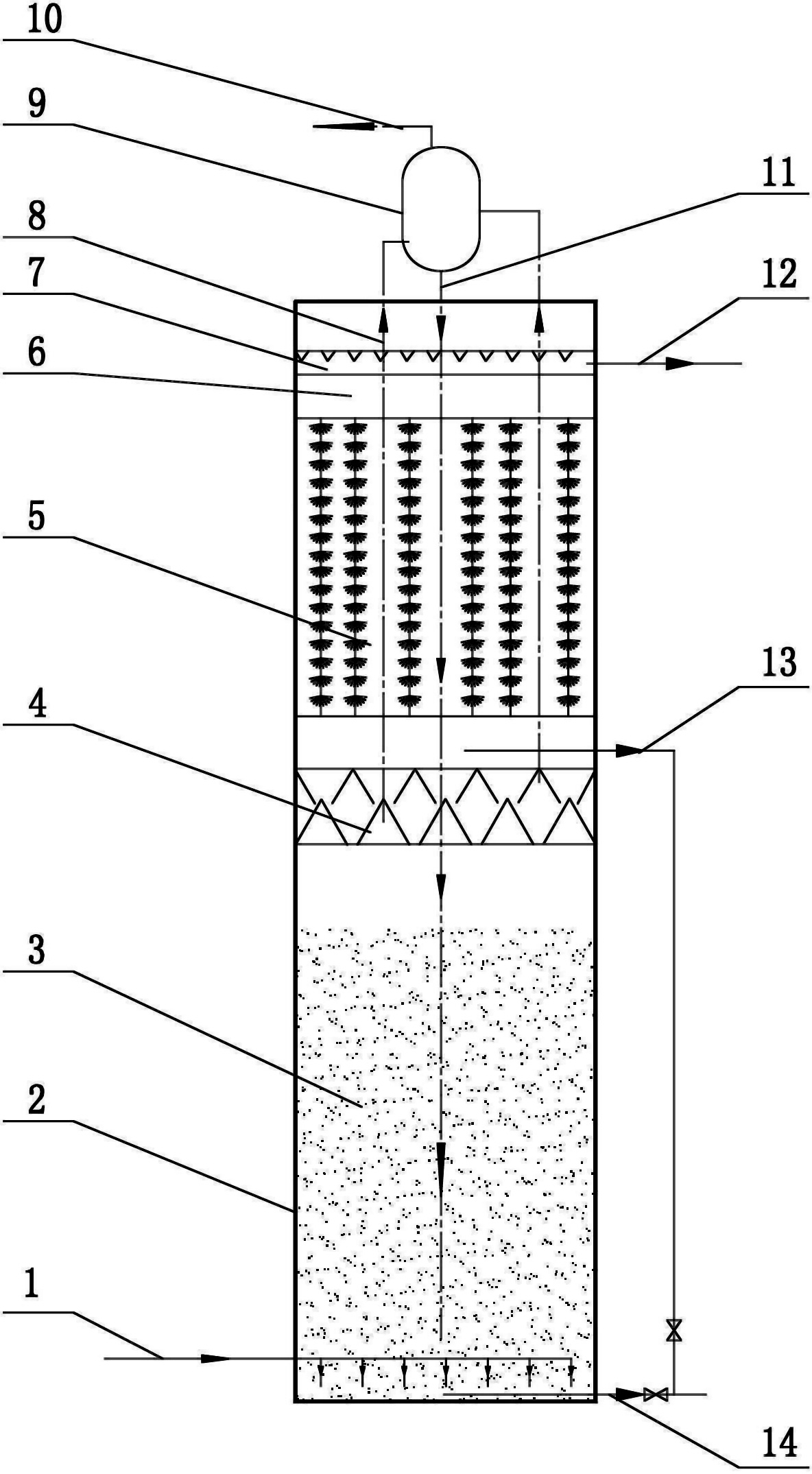

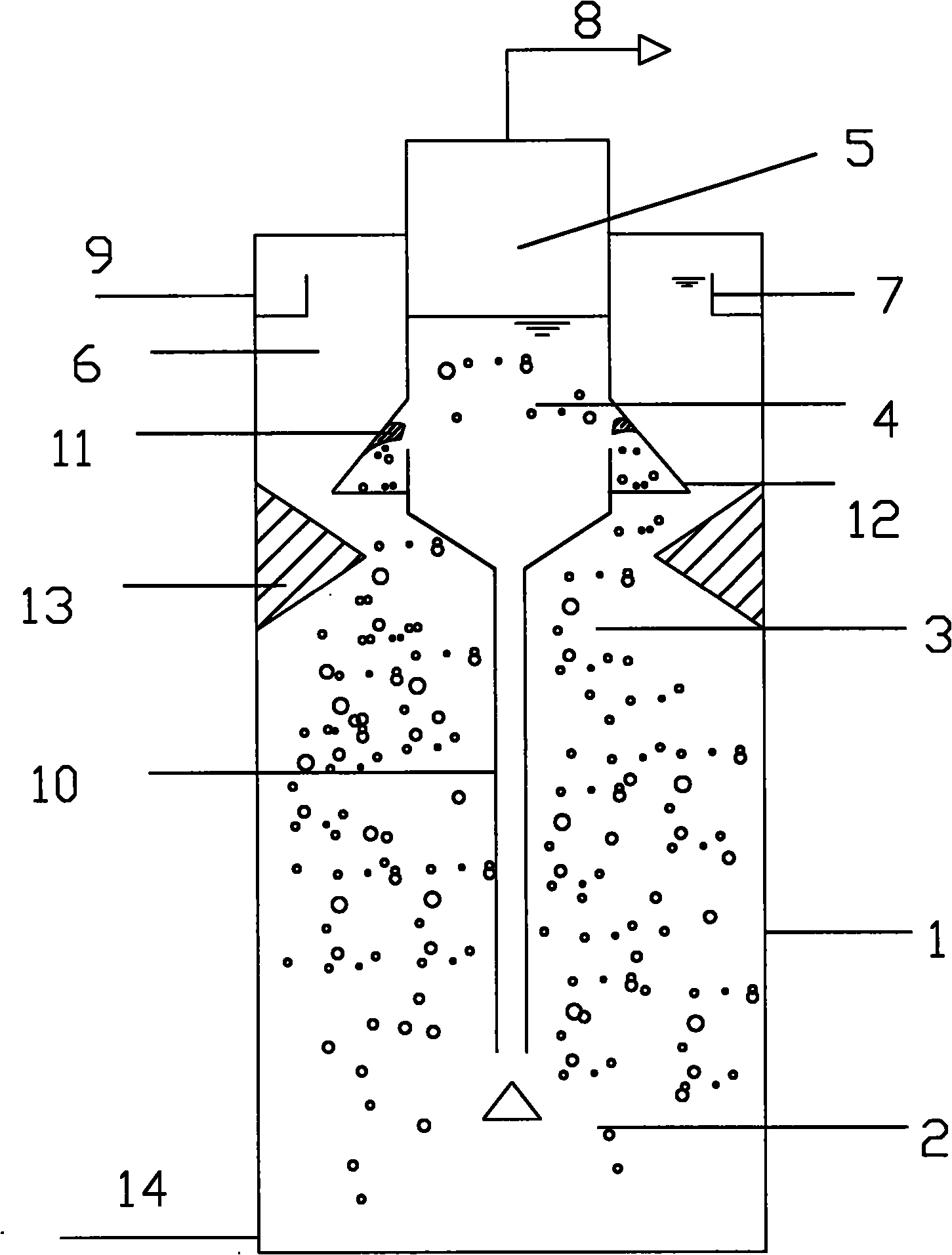

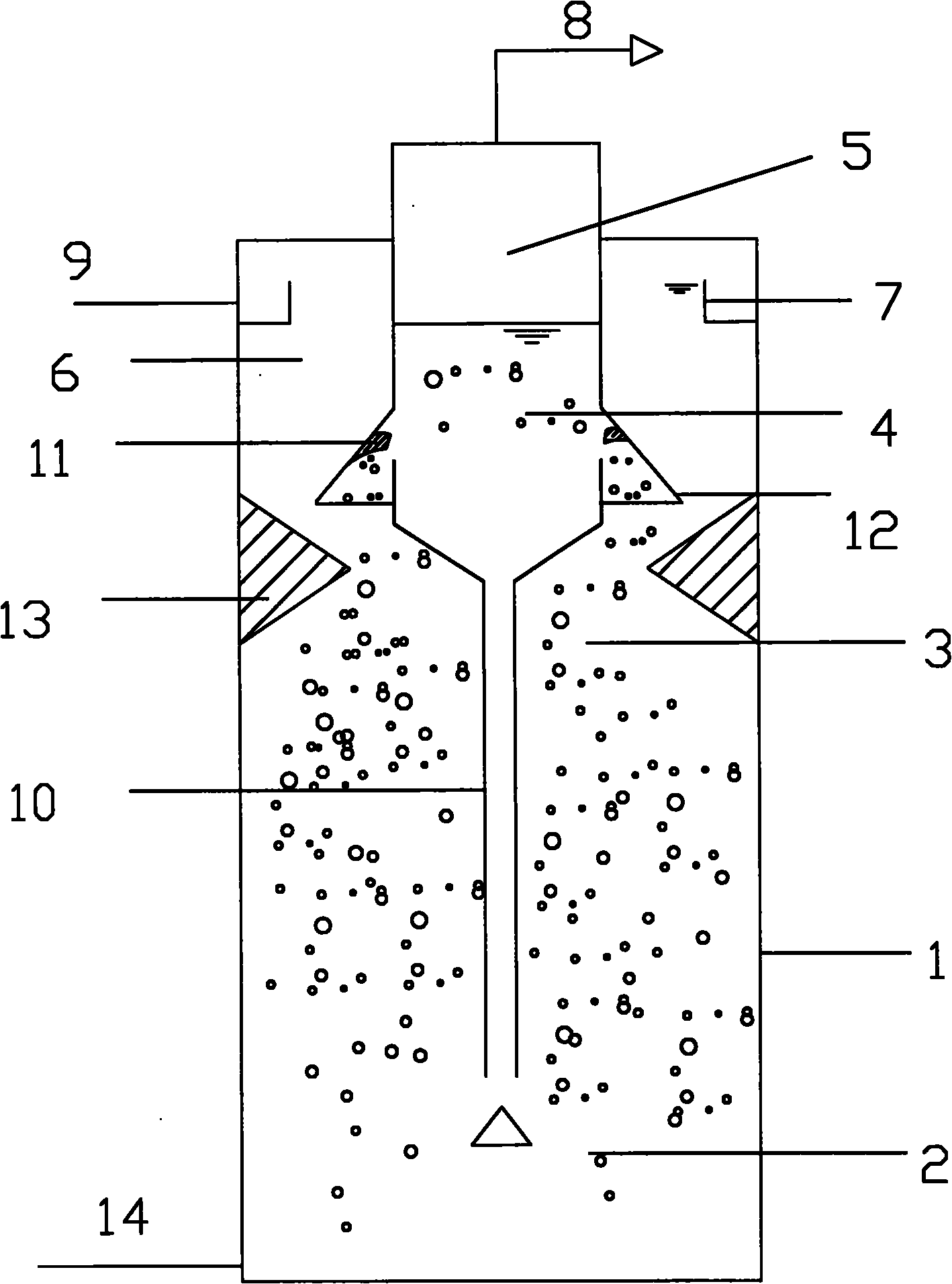

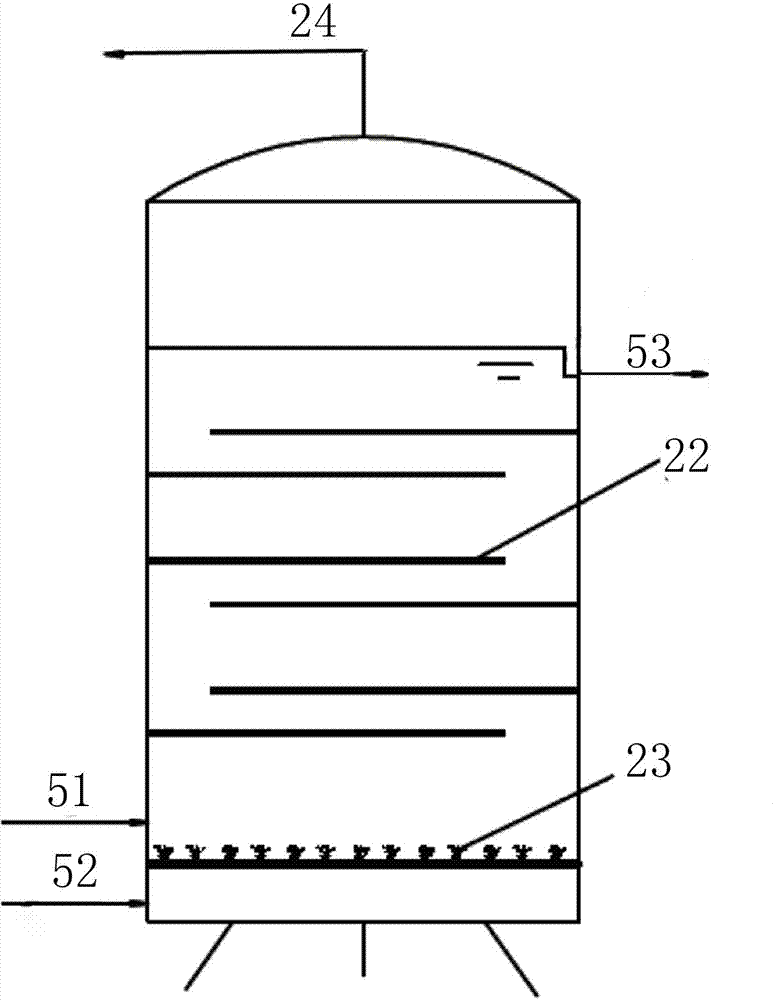

Upflow blanket filter (UBF) anaerobic reactor with filter layer at top and for treating chemical wastewater

InactiveCN102674544ARealize inner loopFully contactedWaste based fuelTreatment with anaerobic digestion processesMicroorganismBiofilm

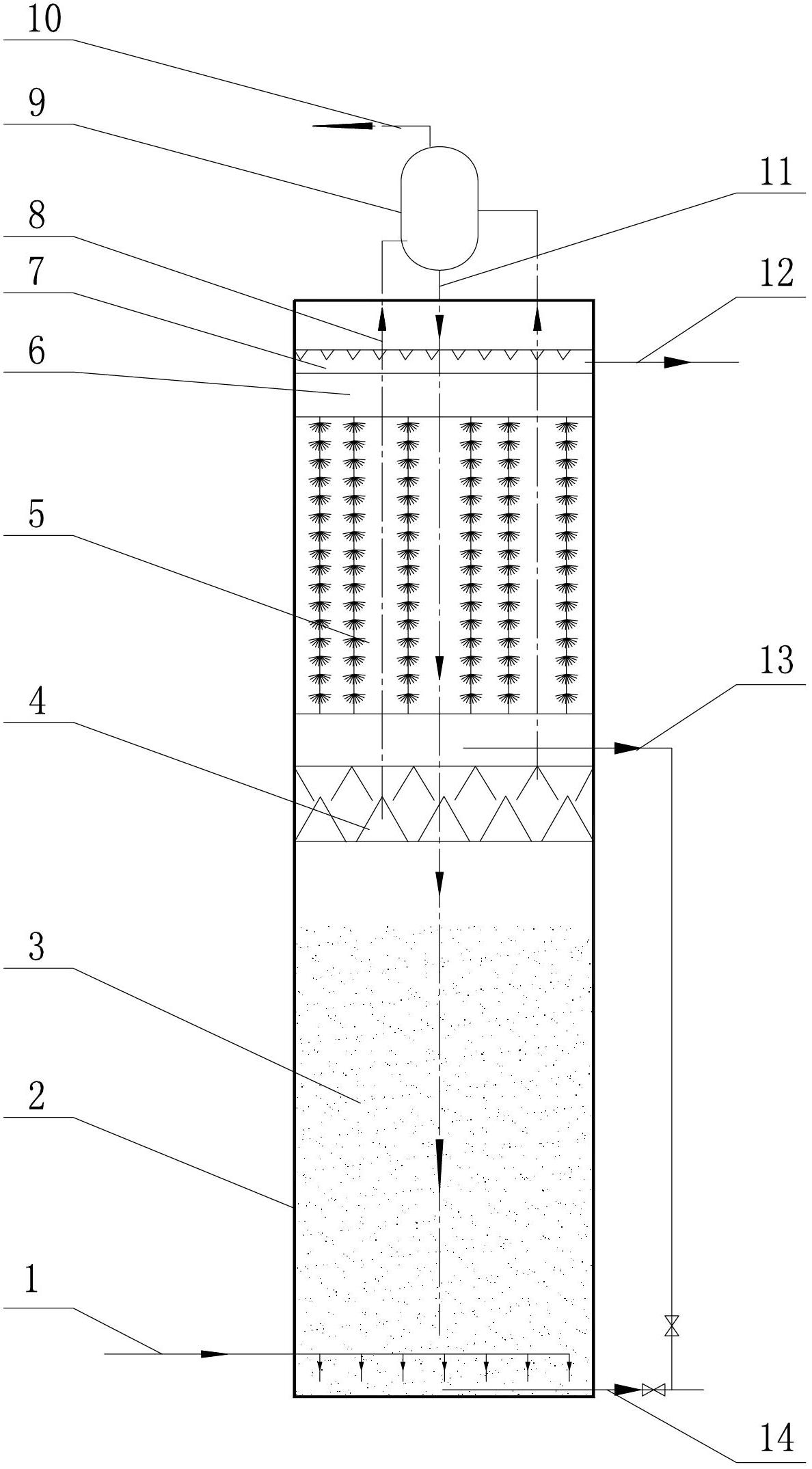

The invention discloses an upflow blanket filter (UBF) anaerobic reactor with a filter layer on the top and for treating chemical wastewater. The UBF anaerobic reactor comprises a reactor, a water distribution device, a sludge expanded bed, a three-phase separator, an effluent collecting device and a methane circulating device and is characterized in that the three-phase separator is arranged in the middle of the reactor; the sludge expanded bed is arranged at the lower part of the three-phase separator; a biological filling region is arranged at the upper part of the three-phase separator; the biological filling region comprises filling and a biological membrane; and the biological membrane is formed by attaching anaerobic microorganisms to the surface of the filling. The UBF anaerobic reactor is suitable for treating the chemical wastewater which has high salt content and low suspended matter content and is difficult to degrade; and gas lift internal circulation is adopted, namely methane generated in the reactor is collected by the three-phase separator and internal circulation is realized by using the methane as the lifting powder and without external mechanical power.

Owner:苏州苏水环境工程有限公司

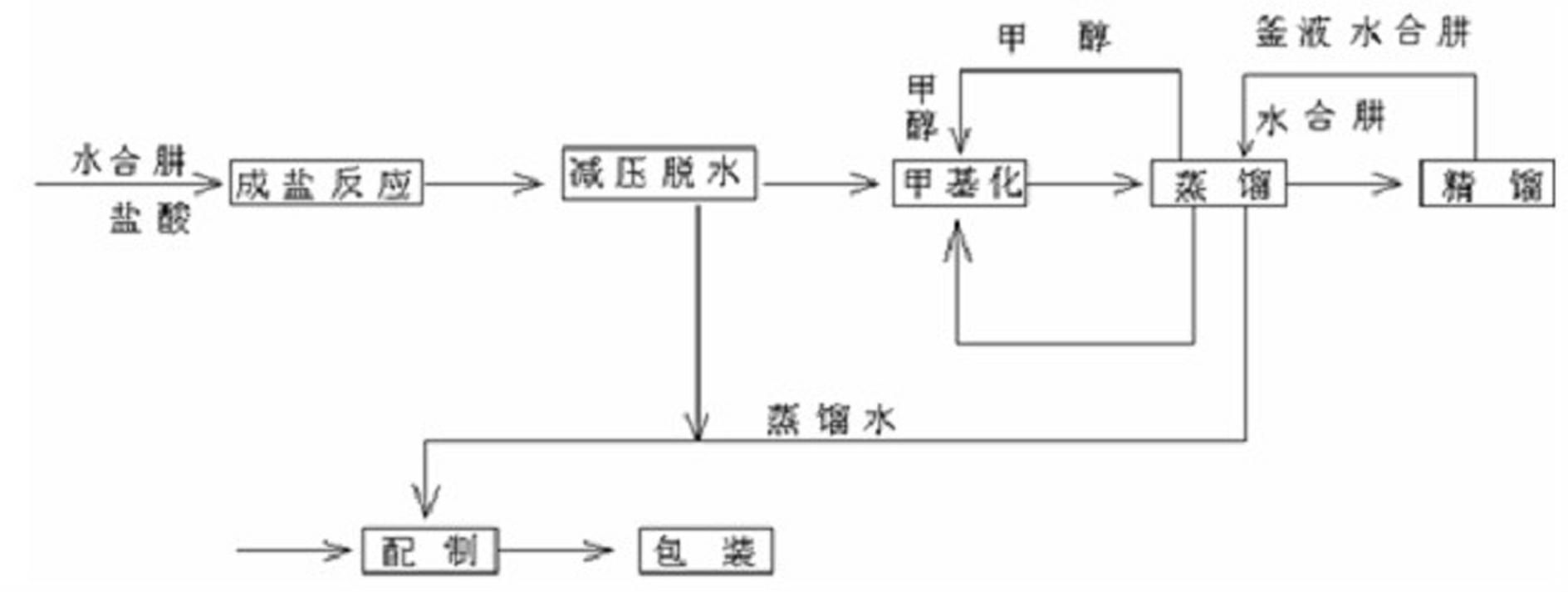

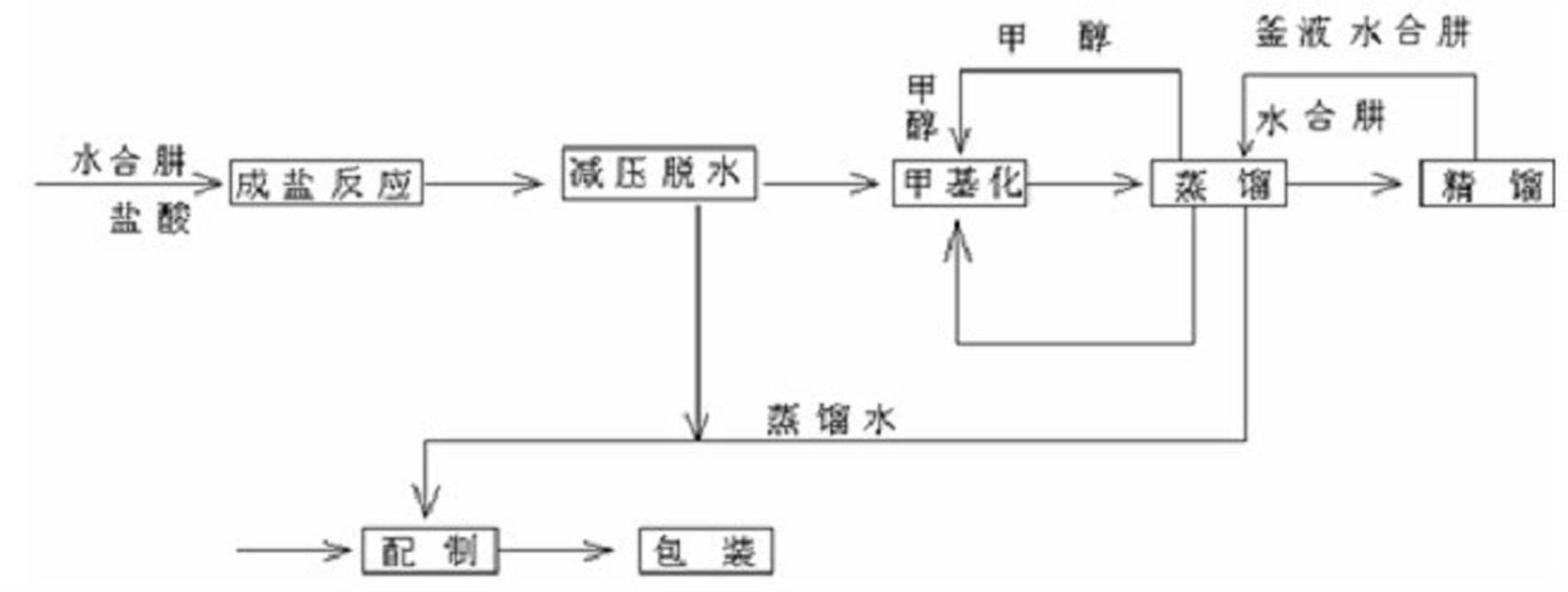

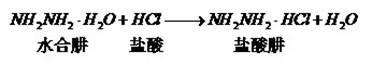

Process for producing methyl hydrazine with hydrazine hydrate method

ActiveCN102516117AEmission reductionReduce consumptionHydrazine preparationChemical oxygen demandHydrazine compound

The invention discloses a process for producing methyl hydrazine with a hydrazine hydrate method. The process is characterized by comprising the following steps of: reacting hydrazine chloride with methanol under the protection of an inert gas; isolating methyl hydrazine hydrochloride by using a hydrazine hydrate; and undergoing distilling and rectifying processes to obtain the methyl hydrazine. The process has the advantages of saving in energy, reduction in the emission of waste water, waste gas, waste residues and COD (Chemical Oxygen Demand) emission and high environmental friendliness. Internal circulation and continuous production is realized, the labor intensity of workers is lowered, reaction pressure is lowered from 0.7-1.3 MPa to 0.5-0.7 MPa, and the safe coefficient is increased.

Owner:DONGLI NANTONG CHEM

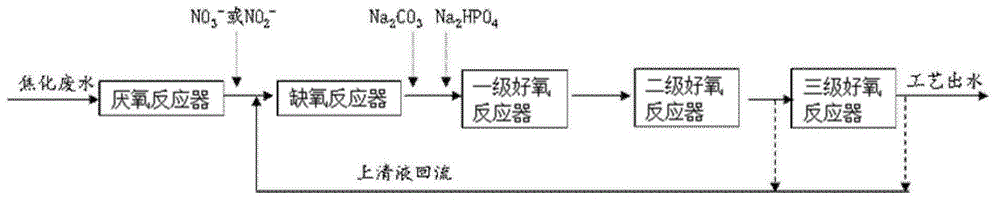

Biological treatment method, biological treatment system and bioreactor of coal chemical wastewater

ActiveCN102874927AHigh N/C valueIncrease concentrationTreatment with aerobic and anaerobic processesAnaerobic reactorOxygen

The invention relates to a biological treatment method of coal chemical wastewater, which adopts a biological reaction-muddy water separation integrated bioreactor. The method comprises the following steps of: sequentially feeding materialized and pre-treated coal chemical wastewater into an anaerobic bioreactor, an anoxic bioreactor, a first-stage aerobiotic bioreactor, a second-stage aerobiotic bioreactor and a third-stage aerobiotic bioreactor, selecting each aerobiotic bioreactor to discharge water and inflow into the anoxic bioreactor; and carrying out anaerobic acidification treatment by the anaerobic reactor, reinforcing a biological denitrification reaction in the anoxic reactor to remove non-gradable organic matters, completely decarbonizing by the first-stage aerobiotic bioreactor, and realizing the short-course nitratlon reaction and the whole-course nitratlon reaction by the second-stage aerobiotic bioreactor and the third-stage aerobiotic bioreactor, wherein the sludge concentration in the reactor can be guaranteed to be greater than 8mg / L due to the biological reaction-muddy water separation integrated bioreactor, the sludge age is greater than 60 days, the specific strains can be preferably cultured, and the function realization of a novel method can be guaranteed. The coal chemical wastewater is treated by the method, so that the discharged water can reach the requirement of the national wastewater comprehensive discharge standard.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

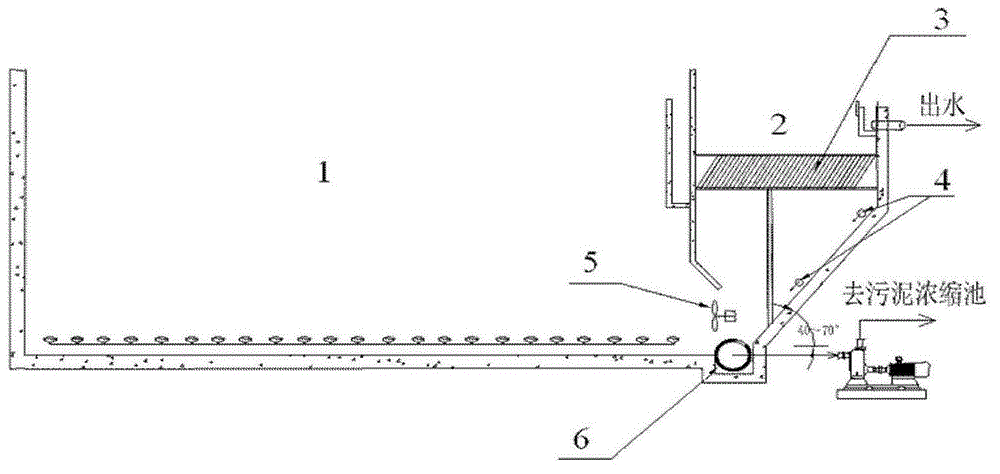

Internal circulation upflow anaerobic sludge blanket reactor

InactiveCN101891302ARealize inner loopNovel structureWaste based fuelTreatment with anaerobic digestion processesSuspended matterSedimentation

The invention relates to an internal circulation upflow anaerobic sludge blanket (UASB) reactor, which effectively solves the following problems: triphase separators are too large, suspended substances in the effluent are higher, additional power is needed and the operation cost is high. The reactor is characterized in that a suspension zone is arranged above a sludge blanket zone on the lower part of a reactor body; a triphase separator with upper part stretching out of the reactor body is arranged on the upper part of the suspension zone; sedimentation zones are formed between the outside of the triphase separator and the inner walls of the reactor body; a return pipe on the lower part of the triphase separator runs through the suspension zone and then stretches into the sludge blanket zone; a gas outlet pipe is arranged on the upper part of a collection chamber; a wastewater inlet pipe is arranged on the lower side wall of the reactor body; a raised weir is arranged on the inner wall; the wall on the raised weir is shaped like a horn and forms a channel communicated with the upper part of the suspension zone with the funneled wall at the upper end of the return pipe; baffles are arranged on the inner walls of the reactor body on the lower parts of the sedimentation zones and form channels communicated with the sedimentation zones with the outer walls of the triphase separator; overflow effluent weirs are arranged on the inner walls of the reactor body on the upper parts of the sedimentation zones; and outlet pipes are arranged on the vertical side walls of the reactor body on the upper parts of the overflow effluent weirs. The reactor is low in cost, stable and reliable in operation and high in efficiency.

Owner:ZHENGZHOU UNIV

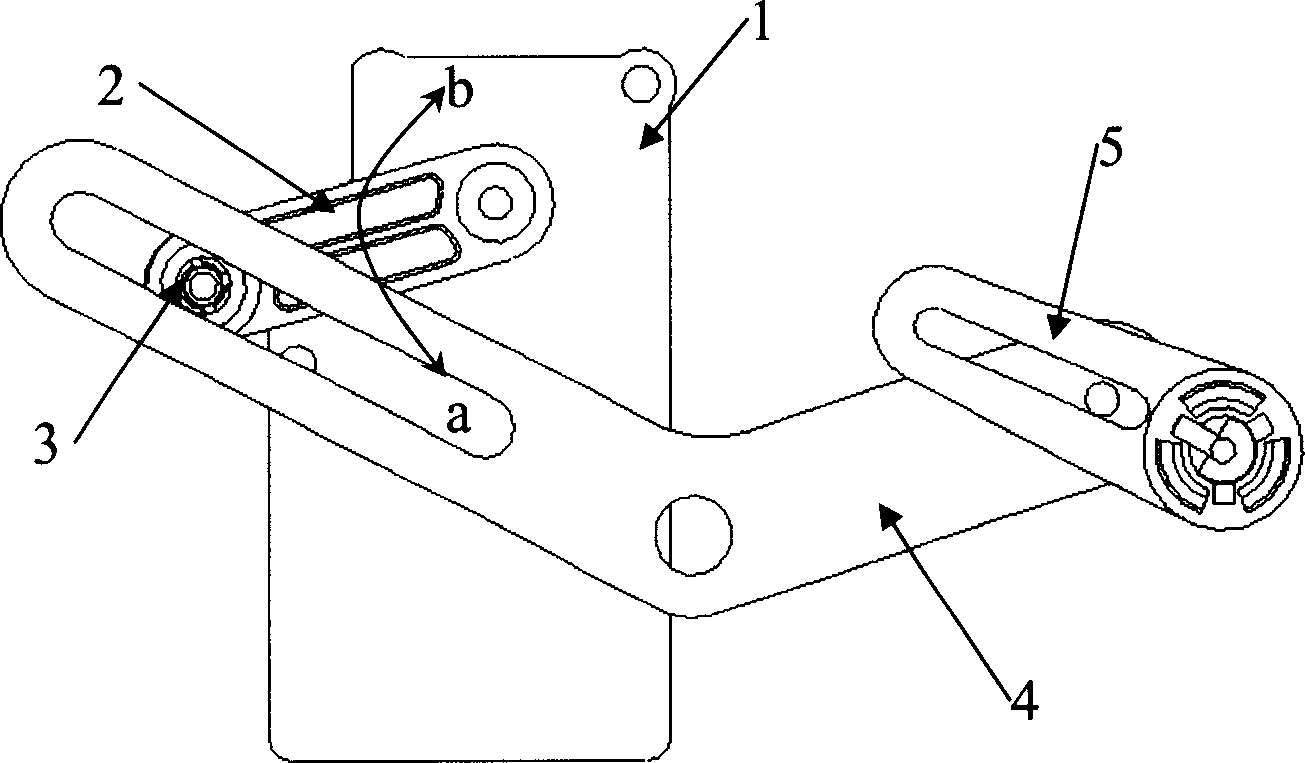

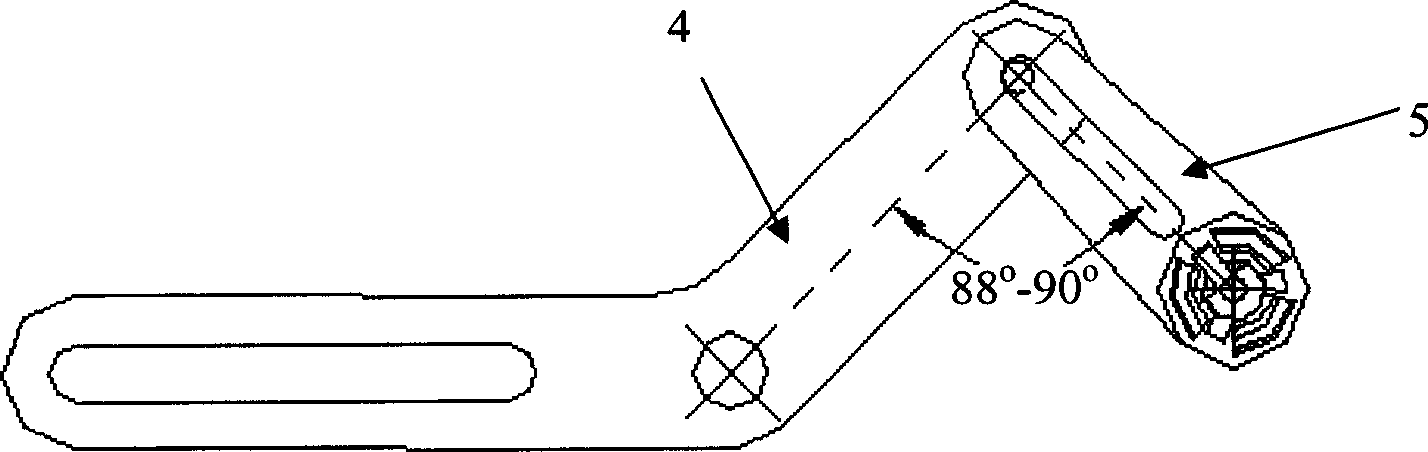

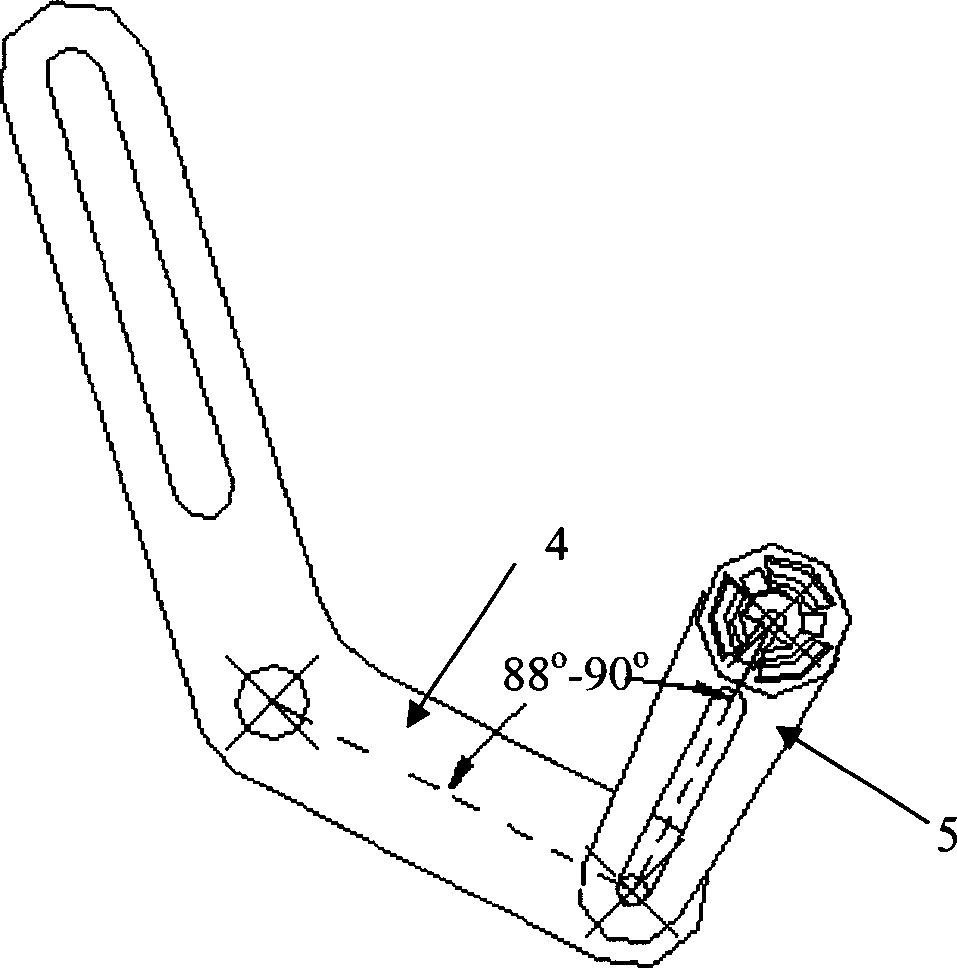

Automobile air conditioner air door device

ActiveCN1899864AImprove sealingSimple structureAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningReduced size

The automobile air conditioner air door device includes an executor, a transmission mechanism, an air door baffle, and an air intake box, and the transmission mechanism includes an executor rotation arm, a driving rack and an air door rotation arm. The air door baffle is made to switch the position between the inner air intake and the outer air intake for realizing the inside circulation and the outer circulation of the air inside the automobile to ensure the ventilation and comfort effectively. The simple structure of the transmission mechanism and the small size of the air door device result in greatly reduced size of the whole air intake. In addition, the air door baffle has self-locking effect and the air door has excellent sealing performance.

Owner:BYD CO LTD

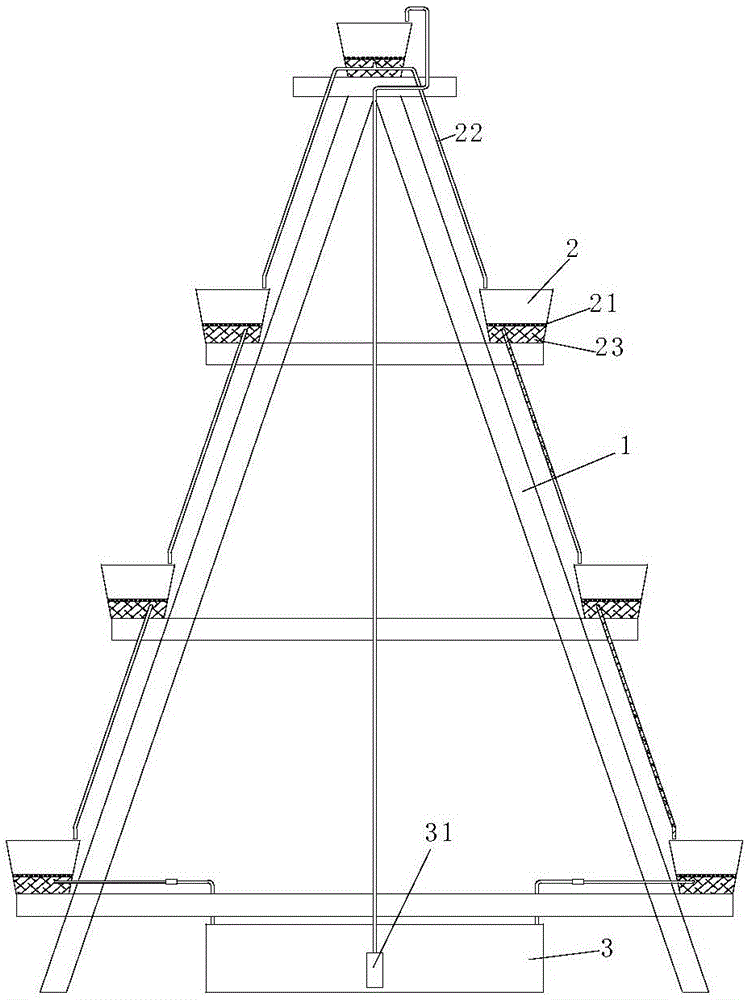

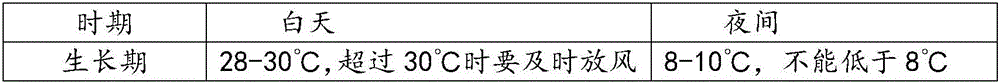

Strawberry cultivation pattern

The invention relates to the technical field of plant cultivation and specifically relates to a strawberry cultivation pattern. The strawberry cultivation pattern comprises shed frame construction, variety selection, planting management and planting post-management, wherein planting management comprises disinfection of a greenhouse, disinfection of a matrix, planting processing, and management in a planting date. The strawberry cultivation pattern has the advantages that the scientific controllable management is implemented, the space is efficiently utilized, water and a fertilizer are saved, meanwhile, the yield of a strawberry is high, and the quality of strawberry is good.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

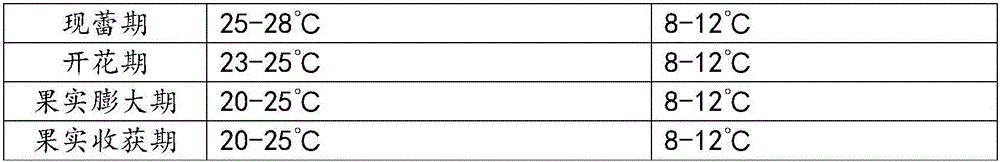

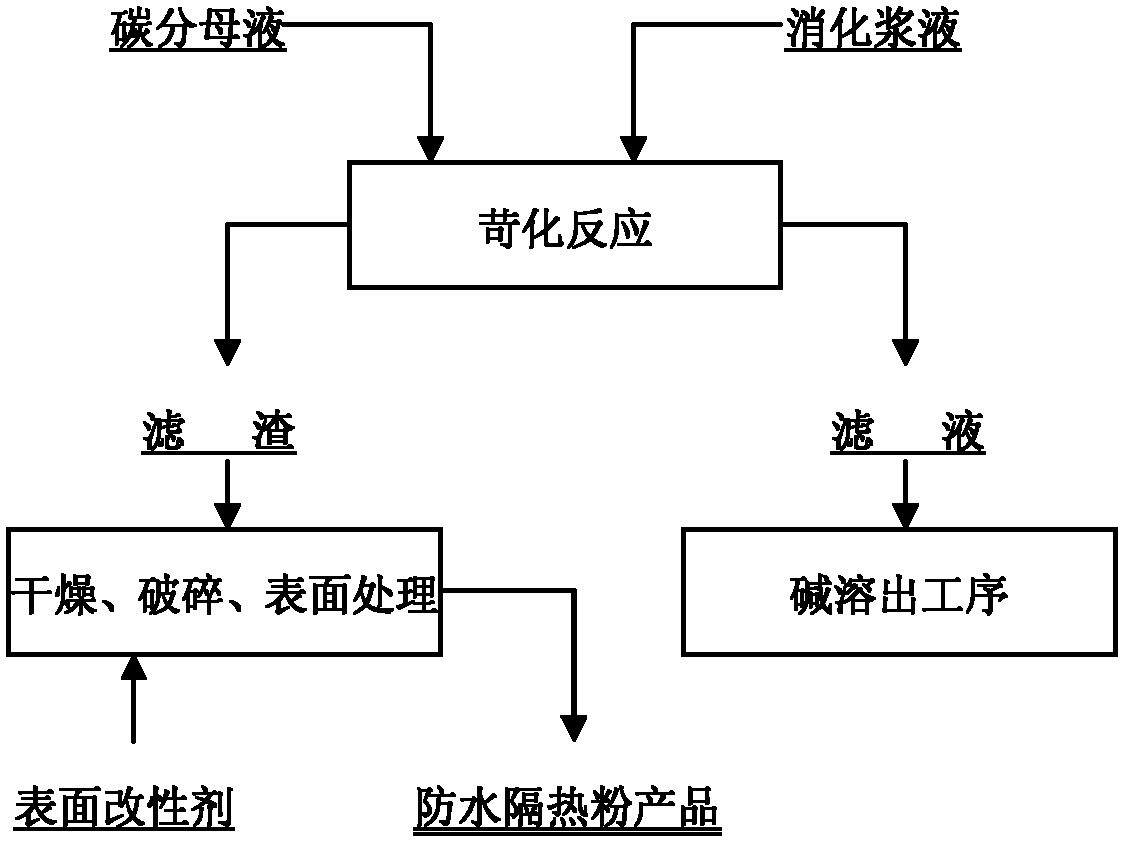

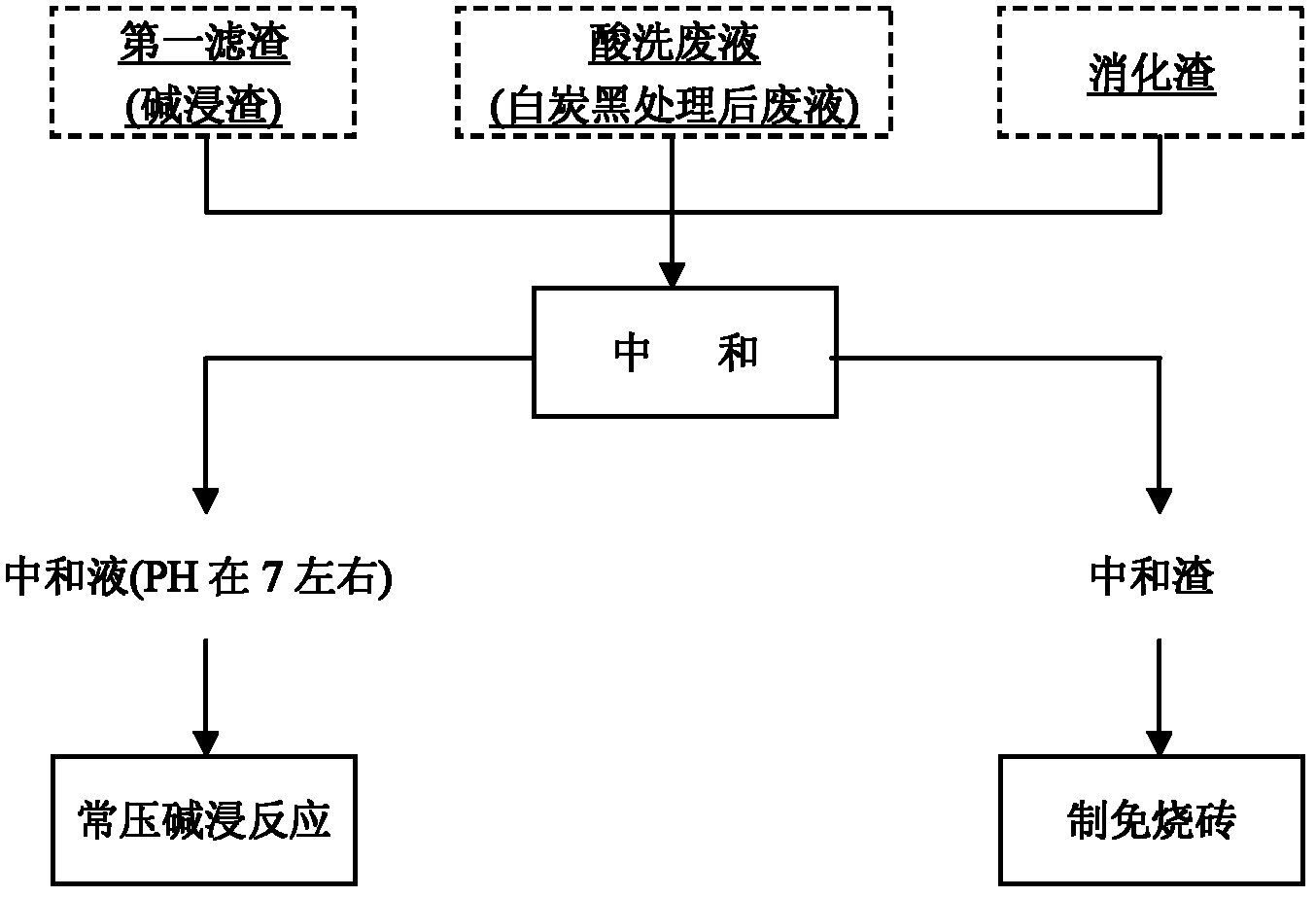

Closed-circuit recycling process of waste gas and waste residue generated during production of brown fused alumina and calcium carbide

InactiveCN102500184ALarge market capacityRealize inner loopCalcium/strontium/barium carbonatesCombination devicesFlue gasChemical products

A closed-circuit recycling process of waste gas and waste residue generated during the production of brown fused alumina and calcium carbide is a closed-circuit recycling process which utilizes flue dust and flue gas containing carbon dioxide collected when brown fused alumina is produced as well as calcium carbide residue and flue gas containing carbon dioxide when calcium carbide is produced toproduce high-grade silica, high-grade nanometer calcium carbonate and waterproof heat insulation powder. The closed-circuit recycling process comprises the following steps: fused alumina flue dust isimmerged in alkali and dissolved out in normal pressure; calcium carbide residue is calcined and nitrated; and carbon dioxide obtained when the flue gas is purified is used for carbonating alkali immersion liquid of fused alumina flue dust and nitrating serum. By adoption of the process provided by the invention, waste gas and waste residue generated when brown fused alumina and calcium carbide are produced are transformed into valuable chemical products, so that internal cycling of material is realized, three wastes are emitted outside no longer, and secondary pollution is avoided. The process is suitable for industrial application.

Owner:CENT SOUTH UNIV +1

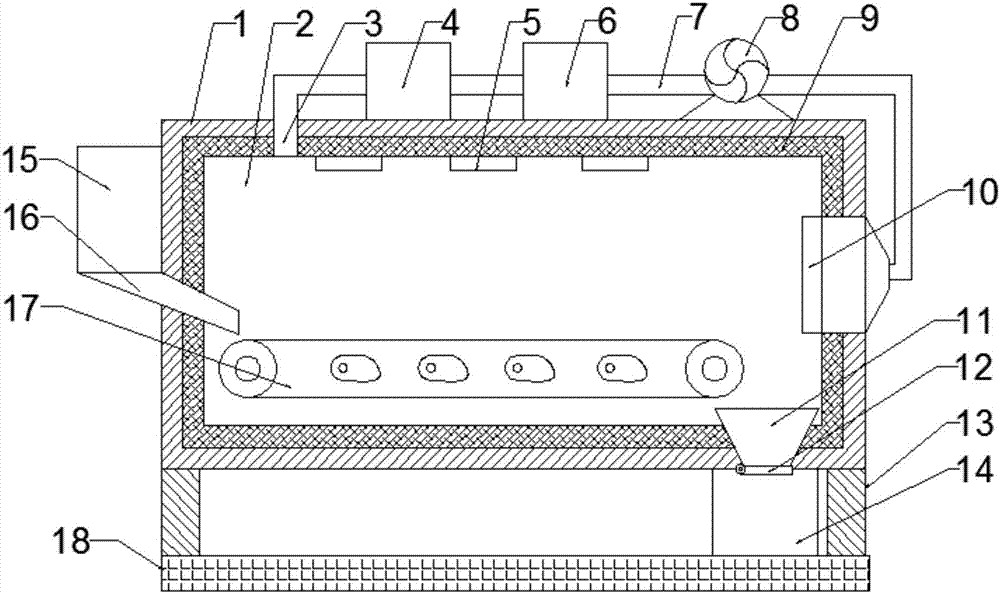

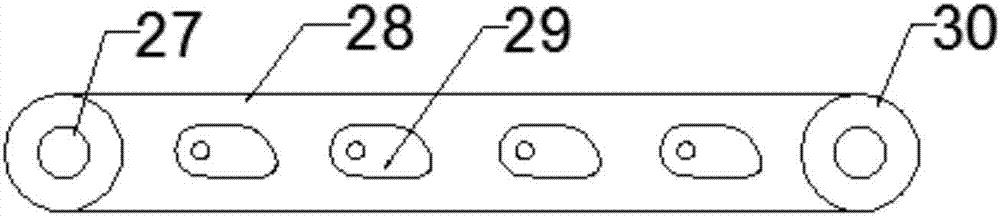

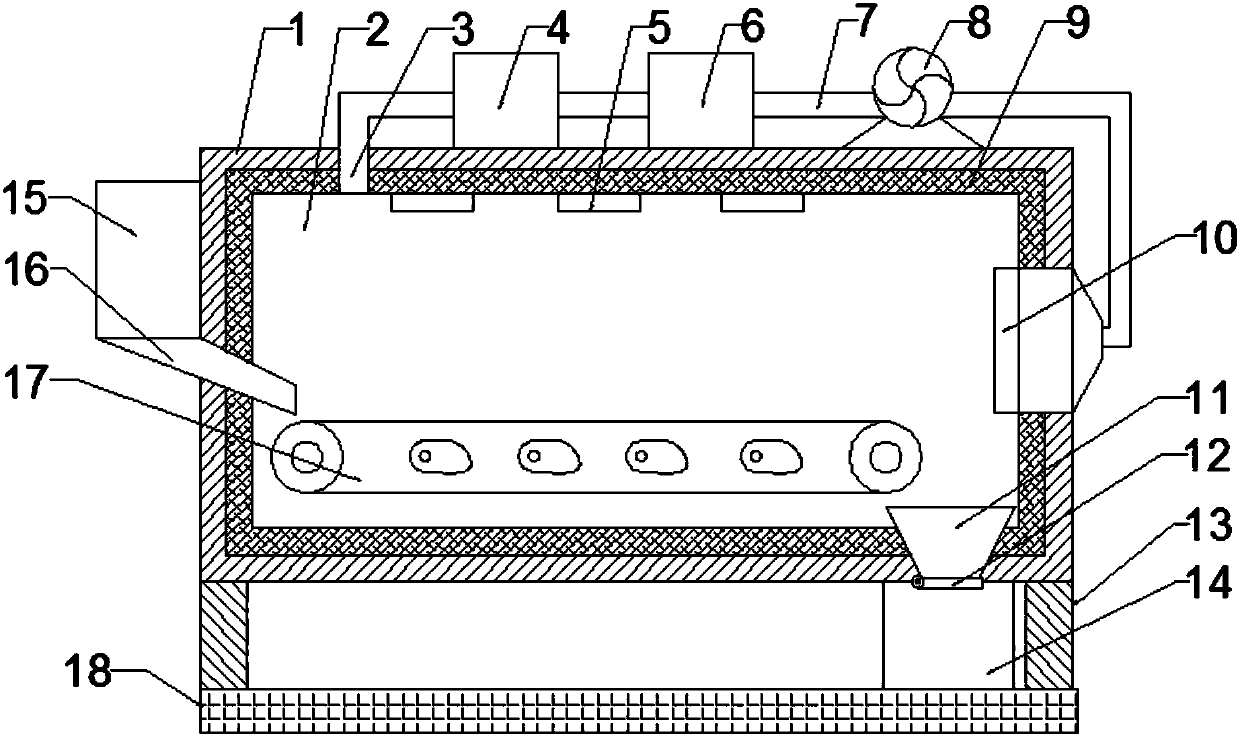

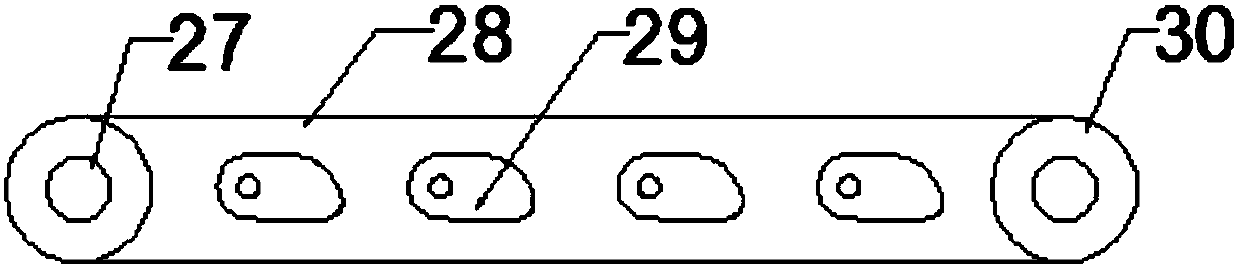

Energy-saving type poultry feed drying device

InactiveCN107388780AEasy to dryImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsEnvironmental resistanceInsulation layer

The invention discloses an energy-saving type poultry feed drying device and belongs to the field of poultry feed production equipment. The energy-saving type poultry feed drying device comprises a shell, a drying cavity, an air outlet, a dehumidifying box, an ultraviolet radiator, a heating box, a circulation air guide pipe, a circulating fan, a heat insulation layer, an air uniformizing cover, a collection hopper, a movable baffle, a support, a collection box, a feeding device, a discharging hopper, a conveying device and a base. The shell is a hollow cylinder which is horizontally arranged and is made of stainless steel materials, and the heat insulation layer is arranged on the surface of the inner wall of the shell. The feeding device is fixedly arranged on the left side of the shell, and the discharging hopper is arranged on the bottom of the feeding device. The circulation air guide pipe is arranged between an air inlet of the air uniformizing cover and the air outlet, the circulation guide pipe sequentially penetrates the dehumidifying box, the heating box and the circulating fan from left to right, and the dehumidifying box is internally provided with dehumidifying cotton. The energy-saving type poultry feed drying device is reasonable in structural design, the drying effect of feed is good, the situation that hot air leaks and pollutes the working environment is avoided, the loss of heat is also avoided, and then the energy-saving and environmental-friendly effects are achieved.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

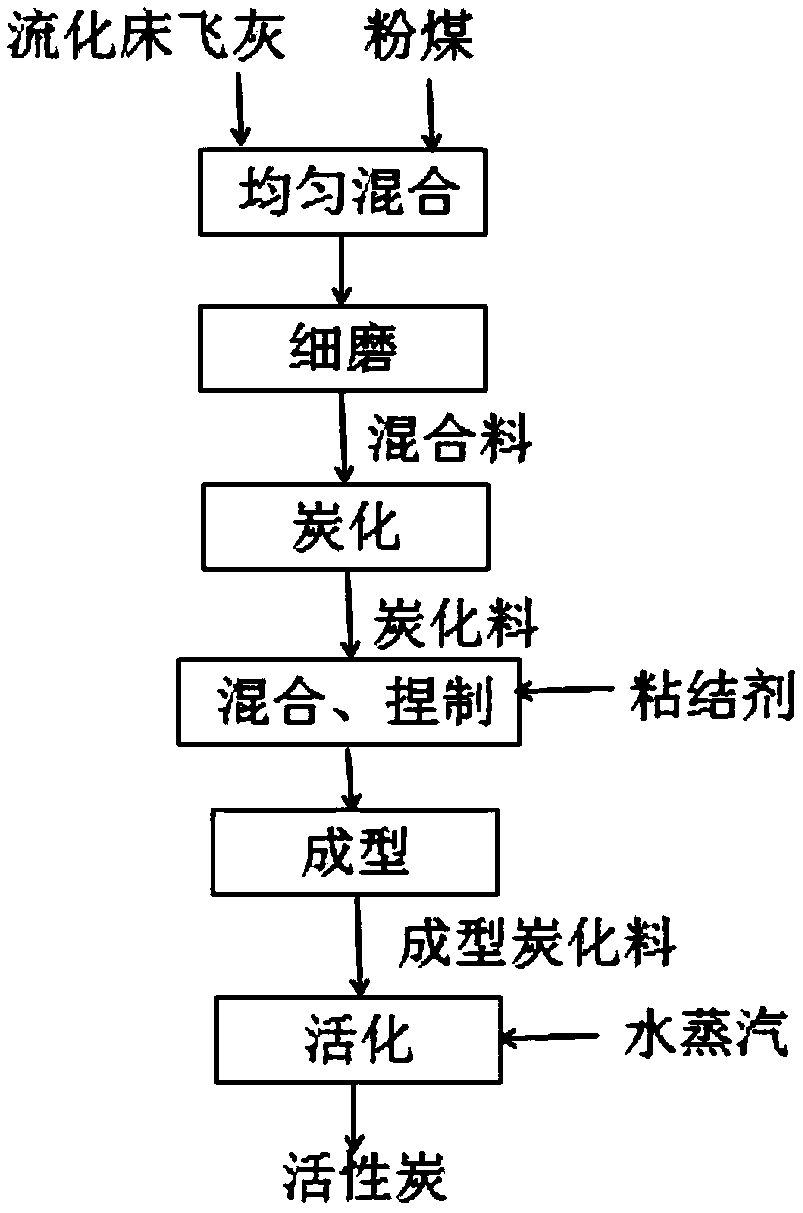

Petroleum hydrocarbon catalytic conversion method

ActiveCN1766043ALarge circulationImprove gas-solid contact efficiencyCatalytic crackingReaction temperatureMixed materials

The catalysis conversion method for petroleum hydrocarbon comprises: in a reactor with a mixing zone, a first and second reaction zone, forcing regenerative agent and carry-carbon agent from second zone into mixing zone and flow into first zone by pre-hoisting medium; in the first zone, contacting and reacting between the material oil and said mixed agents, making the oil-agent mixed material up to second zone for continuing reaction; returning some reacted carry-carbon agent to mixing zone for recycle; separating reacted oil-gas to send to subsequent separation system and other catalysts for recycle after steam stripping. This invention reduces dry gas yield, strengens the hydrogen-transfer reaction, and decreases the olefin content.

Owner:CHINA PETROLEUM & CHEM CORP +1

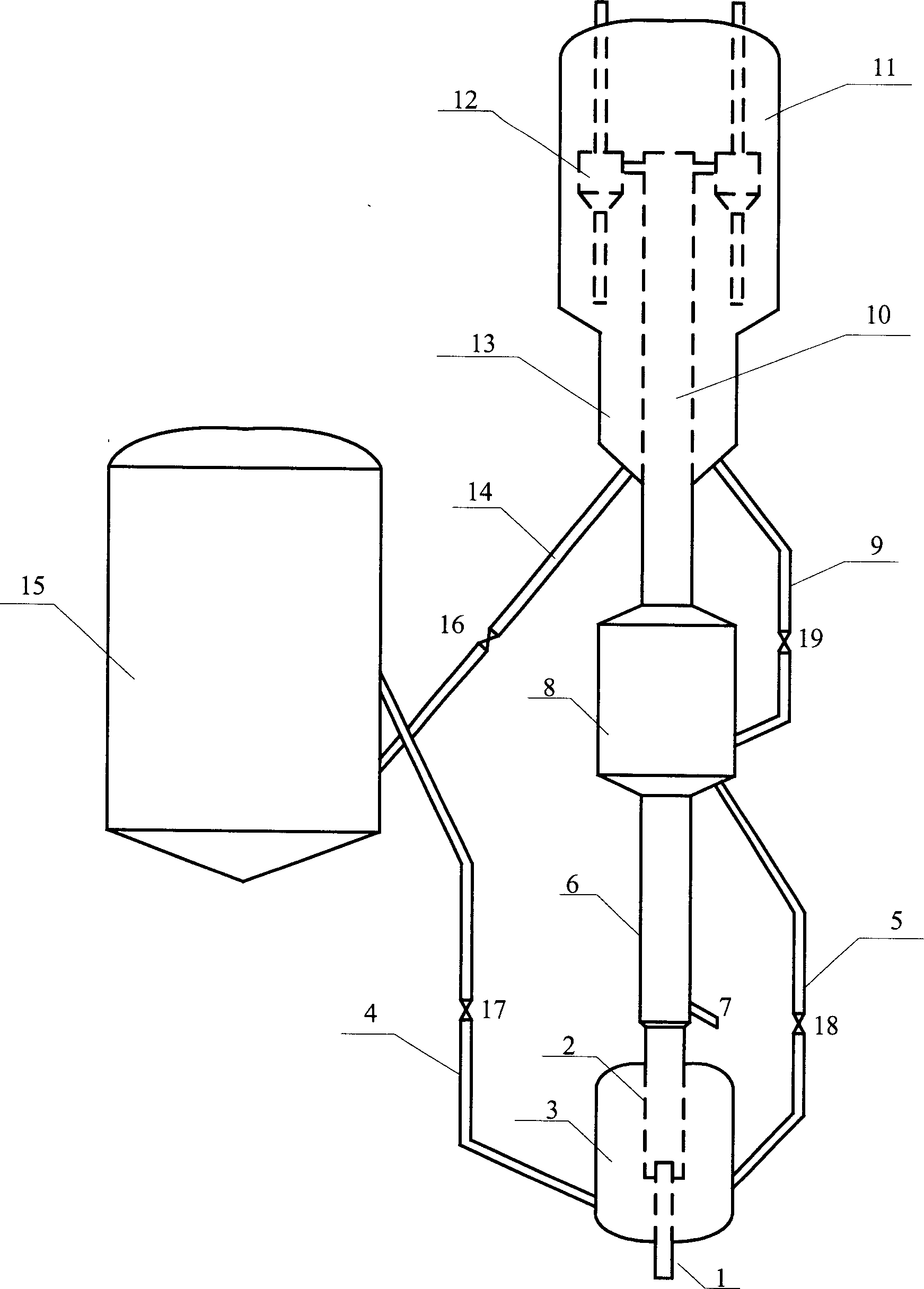

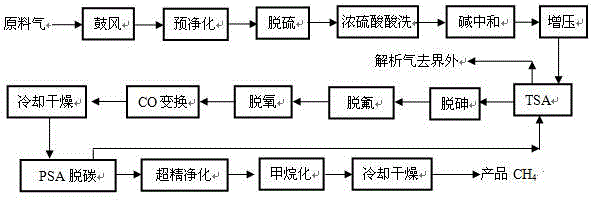

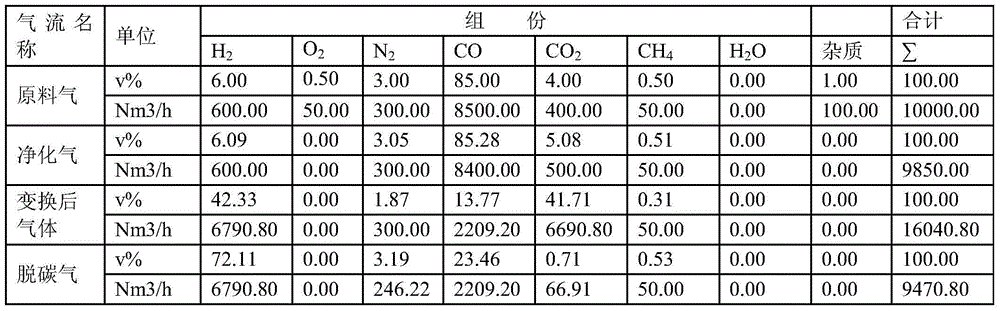

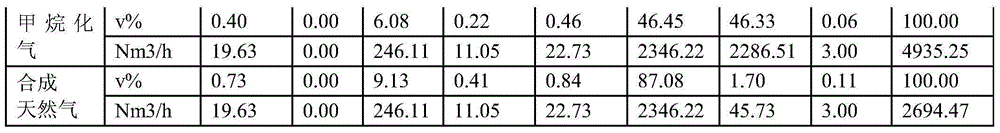

Process of preparing synthetic natural gas by using yellow phosphorus tail gas

The invention belongs to the field of resource recycling of industrial tail gases and particularly relates to a process of preparing synthetic natural gas by using yellow phosphorus tail gas. The process comprises the following steps: carrying out blowing and pressurization, pre-cleaning, desulfuration, pickling by concentrated sulfuric acid, alkali neutralization, pressurization, temperature swing adsorption purification, dearsenification, defluorination, deoxygenation, CO conversion, cooling and drying, decarbonization, superfine purification, methanation and cooling and drying on raw material yellow phosphorus tail gas, and thus finally preparing a natural gas product. The process provided by the invention is a yellow phosphorus tail gas purifying and synthetic natural gas preparing packaged technology suitable for industrial scale application and can prepare high purity methane gas by taking the yellow phosphorus tail gas containing various impurities as fuel gases or chemical materials for users to use.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

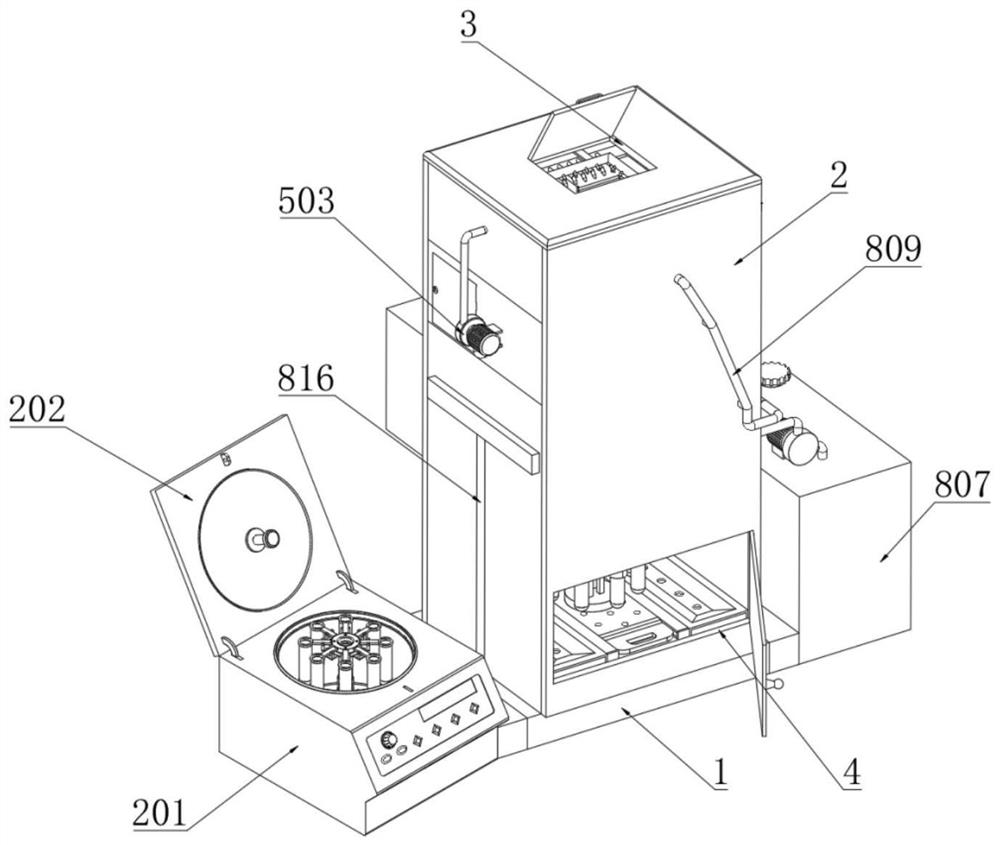

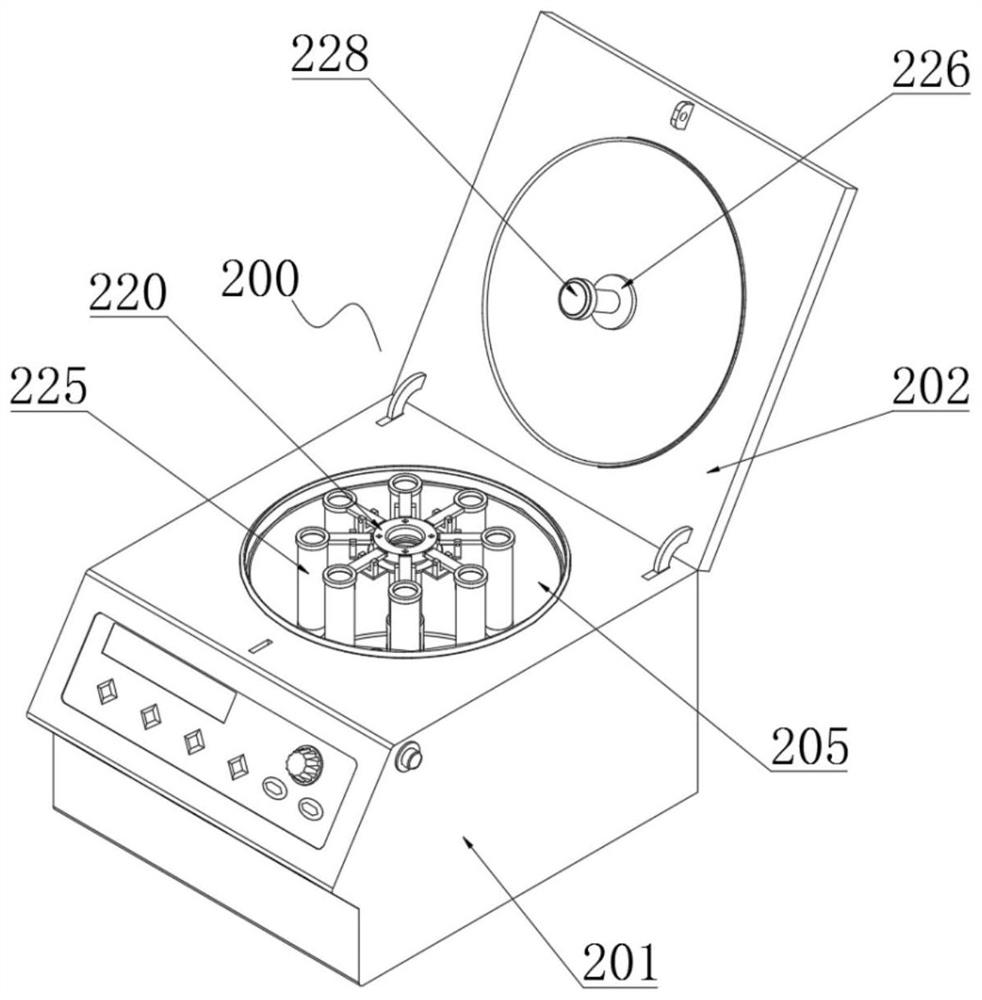

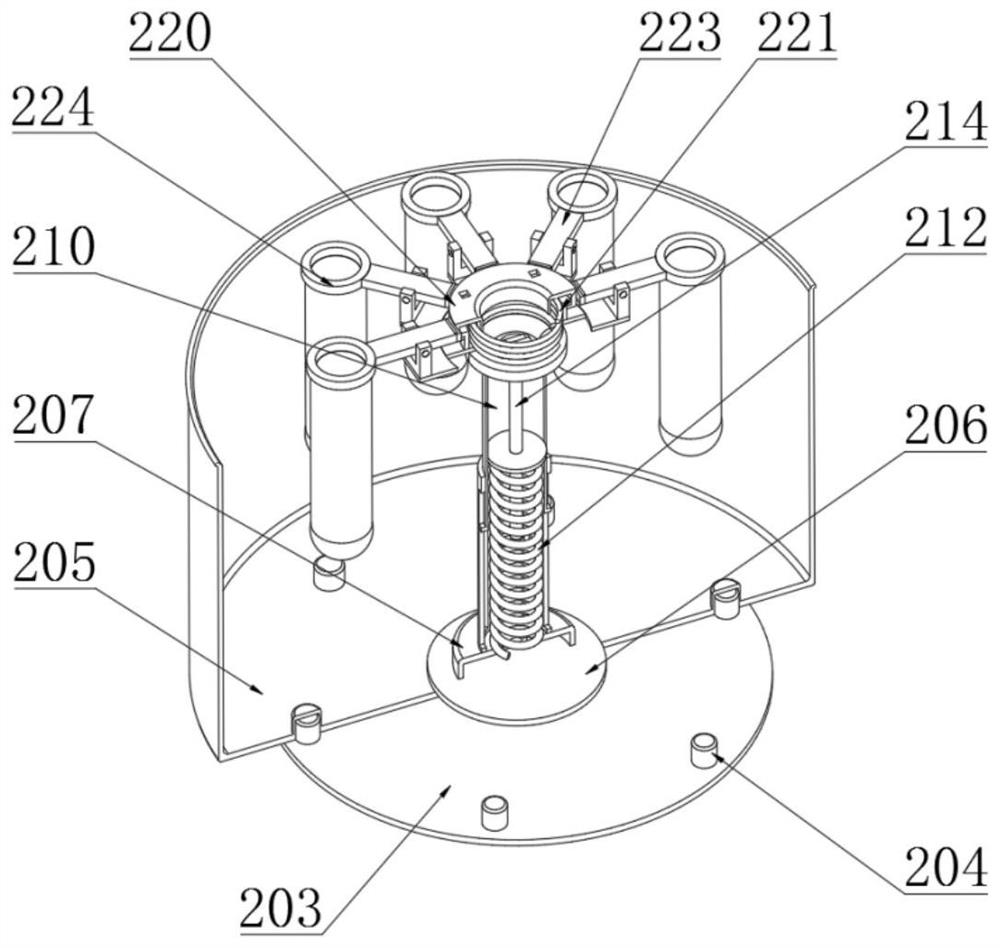

Stem cell culture system

InactiveCN112111400AGuaranteed levelEasy to take outBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringStem cell culture

The invention discloses a stem cell culture system. The stem cell culture system comprises a mounting box, a pretreatment mechanism, a cell dispersing mechanism, an isolating and cleaning mechanism, aconvenient test tube picking and placing mechanism, a temperature control mechanism and a cell centrifugation mechanism, wherein the bottom end of the mounting box is fixedly connected with a mounting bottom plate, the cell centrifugation mechanism is arranged on one side face of the outside of the mounting box and comprises a centrifuge main body, and a sealing cover is hinged to one side of oneside face, where the centrifuge main body is placed, of the outside of the mounting box. According to the stem cell culture system, a lifting outer tube can be lifted from the top of a lifting circular tube through an offsetting spring, a top end plane of a connecting flip plate can restores horizontal, thus, a fixing ring and a top end plane of a placement tube can be horizontal, then, the placement tube can correspond to a test tube position of the convenient test tube picking and placing mechanism, thus, a test tube can be more easily placed inside the placement tube, and thus, a cell dispersing device and a stem cell centrifugation mechanism can be more conveniently used in a matched manner.

Owner:孙震颖

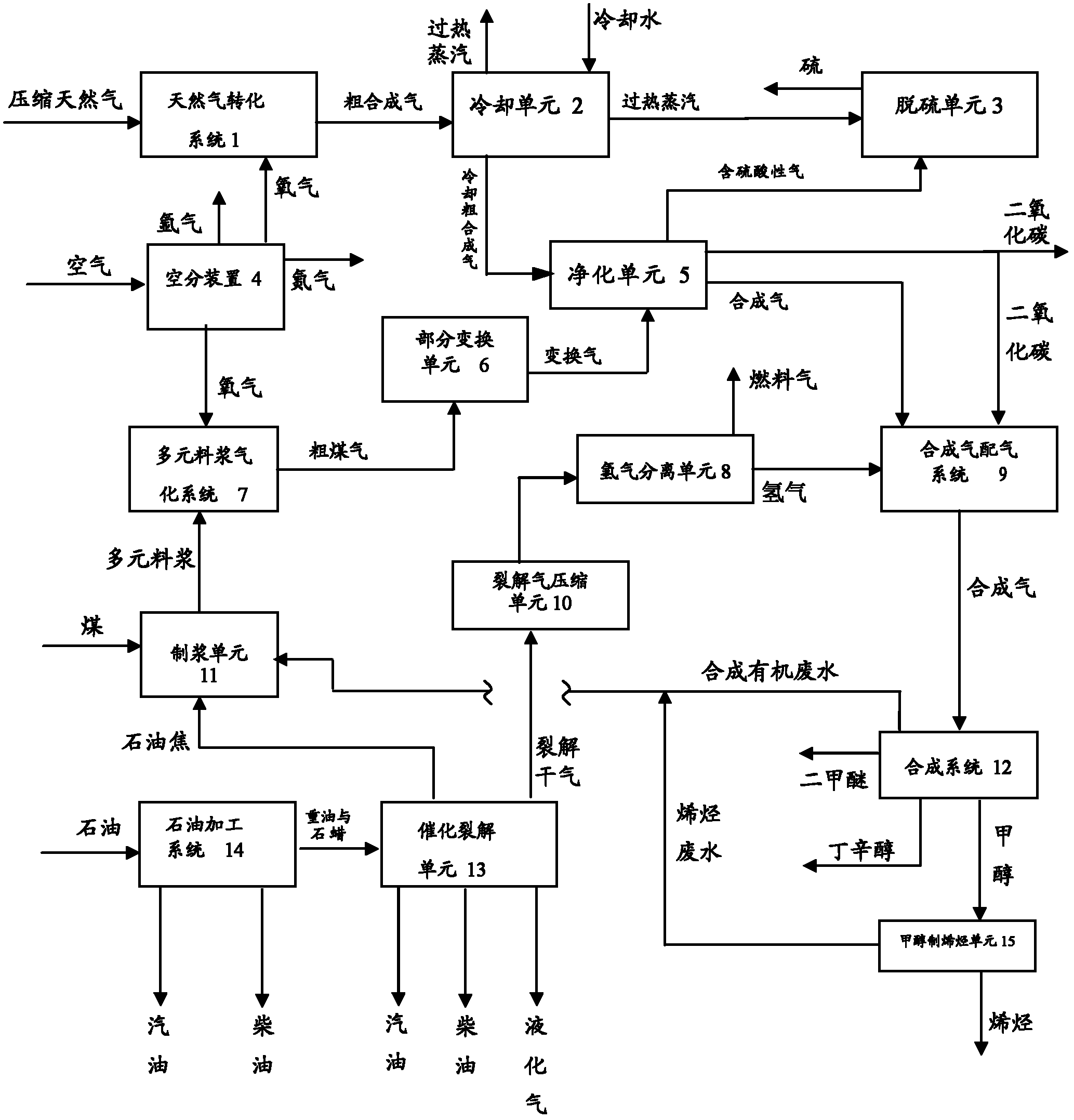

Method for co-production of various chemical products from natural gas, coal and petroleum

ActiveCN102659076AIncrease productionReduce the degree of transformationHydrogenOrganic compound preparationUnit deviceAdditional values

The invention relates to a method for co-production of various chemical products from natural gas, coal and petroleum. The method includes steps of natural gas conversion, slurry gasification, petroleum refining, synthesis gas distribution and chemical product synthesis. The method has the advantages of high comprehensive raw material utilization efficiency, low waste discharge, matured technology of unit devices, more end products, high additional value of the products, obvious scale merit, and the like.

Owner:SHAANXI YANCHANG PETROLEUM GRP +1

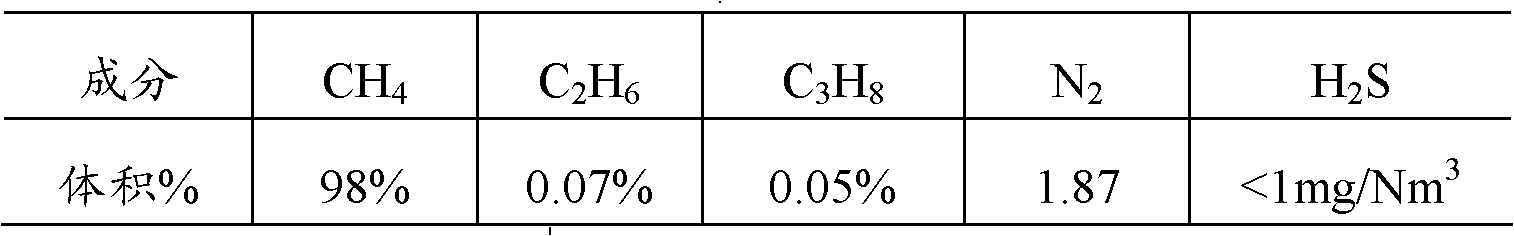

Method for preparing activated carbon from fluidized bed flying ash and pulverized coal

PendingCN108046255AReduce manufacturing costRealize resource utilizationCarbon compoundsActivated carbonFluidized bed

The invention relates to a method for preparing activated carbon from fluidized bed flying ash and pulverized coal. The method comprises the following steps: uniformly mixing fluidized bed flying ashand pulverized coal, and finely grinding so as to obtain a mixed material; carbonizing the mixed material so as to obtain a carbonized material; putting an adhesive into the carbonized material, mixing and kneading under a heating condition, and performing molding and drying treatment so as to obtain a molded carbonized material; feeding the molded carbonized material into an activation device, introducing steam into the activation device, and performing activation treatment on the molded carbonized material with steam, therein obtaining activated carbon. By adopting the method provided by theinvention, the fluidized bed flying ash can be directly adopted to prepare activated carbon without floating separation, recycling of flying ash is achieved, and the preparation cost of the activatedcarbon is reduced; in addition, activated carbon can be also prepared from pulverized coal generated from a fluidized bed standby coal system, recycling treatment of coal ash is achieved, later dustcollection burden of a fluidized bed is reduced, the operation cost is reduced, and equipment operation can be relatively simple to implement.

Owner:BEIJING QUNYOU NEW ENERGY TECH CO LTD

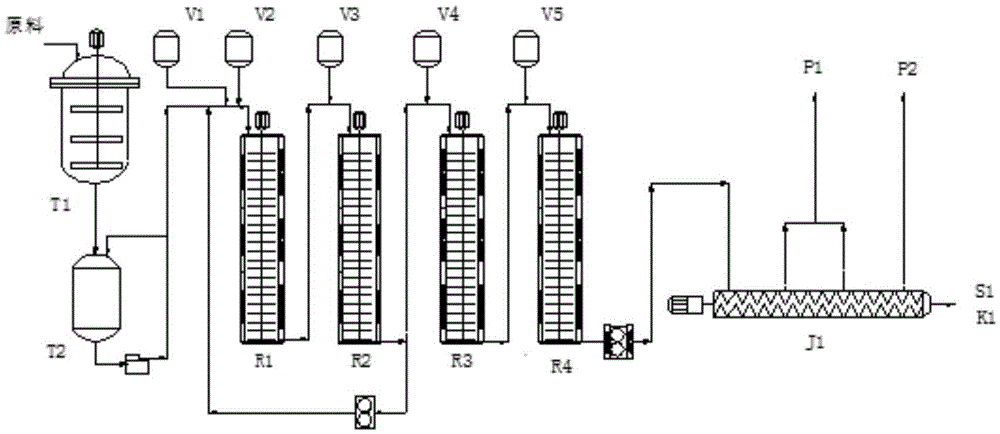

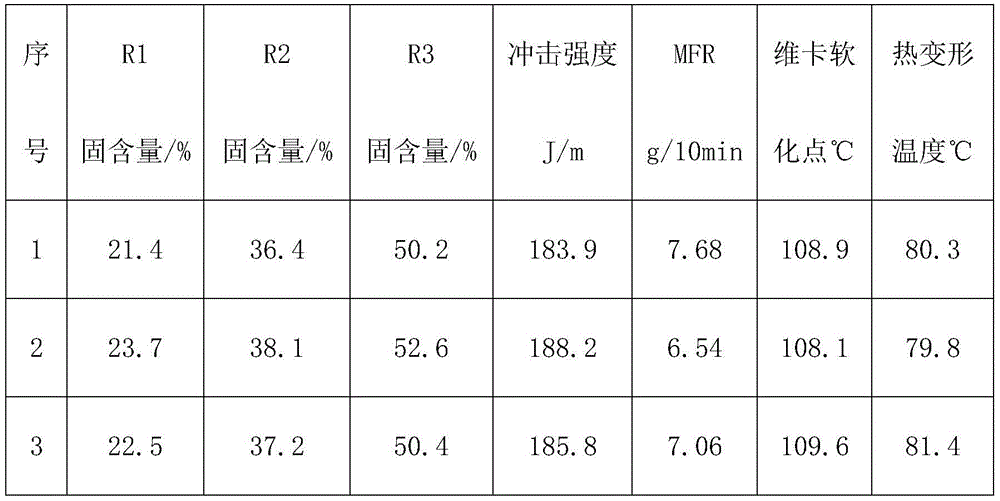

Method for preparing heat-resistant bulk ABS resin

InactiveCN105482045AImprove heat resistanceNarrow molecular weight distributionHeat resistanceReaction system

The invention relates to a method for preparing heat-resistant bulk ABS resin. The prominent problem that the stability of the reaction technology of a multistage reactor in the common bulk ABS production technology at present is poor is mainly solved. The technological process is performed through a raw material preparing system, a polymerization reaction system and a devolatilization prilling system. The reaction system is composed of four plug flow reactors connected in series, and each plug flow reactor is internally provided with a plurality of flow guide plates, a plurality of flat-paddle shaft stirrers and a reactor conduction-oil heating and cooling system. According to the technology, azophenyl maleimide is used as a heat resistant agent, and the produced ABS resin has excellent heat resistance, excellent impact resistance and excellent processing performance.

Owner:NORTH HUAJIN CHEM IND CO LTD

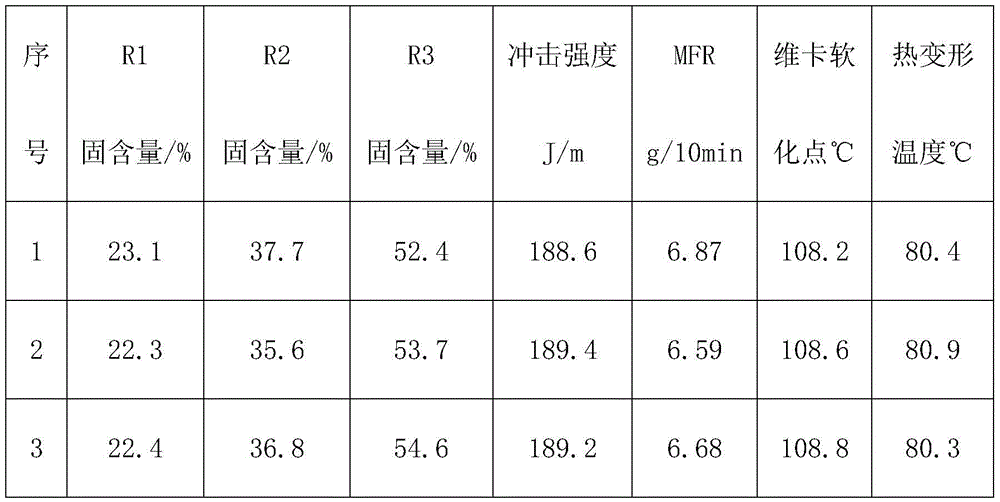

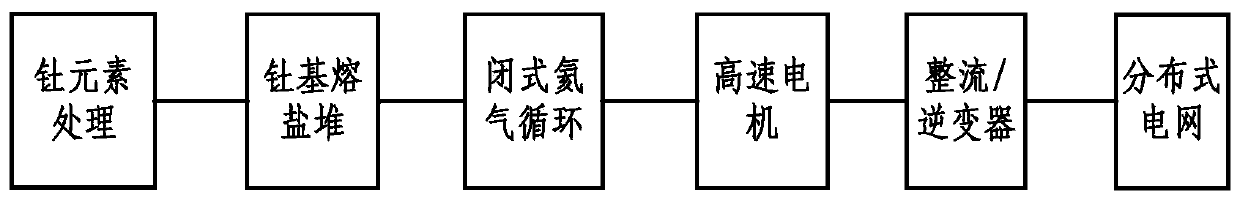

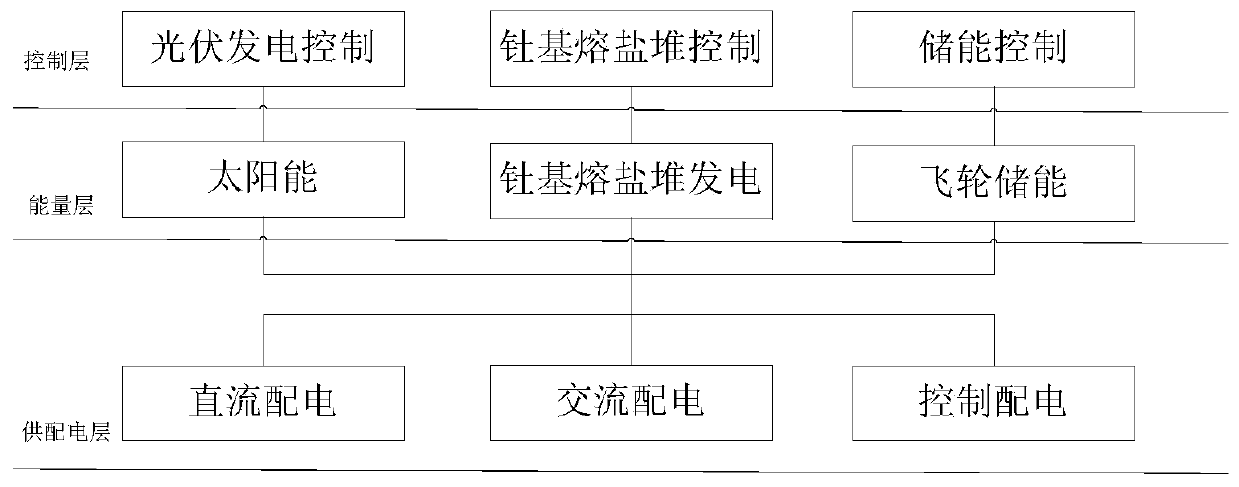

Power supply system for generating power by utilizing moon in-situ energy

InactiveCN110660497AIn situ utilizationReduce the difficulty of transportationNuclear energy generationPV power plantsGas compressorGamma ray

The invention relates to a power supply system for generating power by utilizing moon in-situ energy. The power supply system comprises a nuclear reaction power generation system, and the nuclear reaction power generation system comprises a nuclear reactor, an intermediate molten salt ring, a turbine, a high-speed motor, a gas compressor, a heat regenerator and a heat radiator. According to the power supply system, moon surface thorium-rich Kreep rock is collected and refined, so that in-situ utilization of energy is realized, and the transportation difficulty and cost of primary ore are greatly reduced; on the basis of maintaining the neutrons of the nuclear reactor not to escape, released gamma rays are subjected to photoelectric reaction to further generate electric energy, so that theworking efficiency of the nuclear reactor is further improved. The power generation scheme is based on closed helium circulation, and compared with traditional thermoelectric power generation, the advantages are that: the efficiency of power generation can reach 25-40%; internal circulation of a circulating working medium can be realized, no substance is exchanged with the outside, and the environmental adaptability is good; meanwhile, due to the rotary working characteristic, the energy density is high, and miniaturization is easy; based on the characteristics of large day and night temperature difference, vacuum and low-gravity environment on the surface of the moon, a power station energy storage mode taking a rotary flywheel as an energy storage link is provided.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

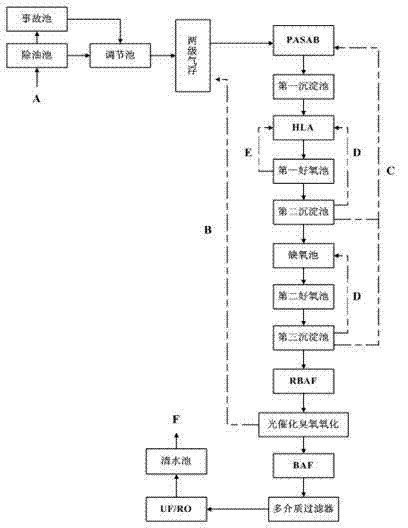

Decarbonization and total nitrogen removal treating process for semi-coking wastewater

ActiveCN104724886APromote decompositionEasy to separateMultistage water/sewage treatmentCavitationSludge

The invention discloses a decarbonization and total nitrogen removal treating process for semi-coking wastewater. The process comprises a pretreatment system, a biochemical treatment system and a deep treatment system, wherein the pretreatment system comprises an oil separation tank and second-stage air flotation treatment, the biochemical treatment system comprises a multifunctional denitrification tank, a first aerobic pool, a second precipitation tank, an anoxic tank, a second aerobic pool and a third precipitation tank, an HSBEMBM environmental management microbial preparation is added to the multifunctional denitrification tank, the first aerobic pool, the anoxic tank and the second aerobic pool respectively, a mixed solution of the first aerobic pool partially flows back to the multifunctional denitrification tank, the deep treatment system comprises a photocatalytic ozone oxidation reaction tower, the biochemical treatment system further comprises a sludge adsorption bed reaction tank, the first aerobic pool is provided with a plurality of reflux inlets in the flow direction, and a gas collecting pipe is arranged at the top of the photocatalytic ozone oxidation reaction tower and is used for collecting residual ozone overflowing from a water surface and then leading the collected residual ozone into a first-stage cavitation air flotation tank. Through treating with the systems of the process disclosed by the invention, a very good treatment effect for the semi-coking wastewater can be achieved, meanwhile, the adaptability is strong, and the operation is convenient.

Owner:浙江汉蓝环境科技有限公司

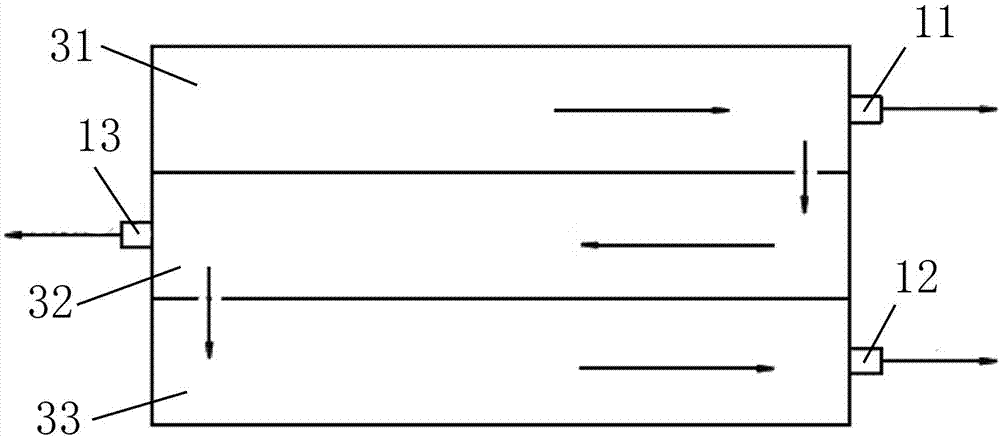

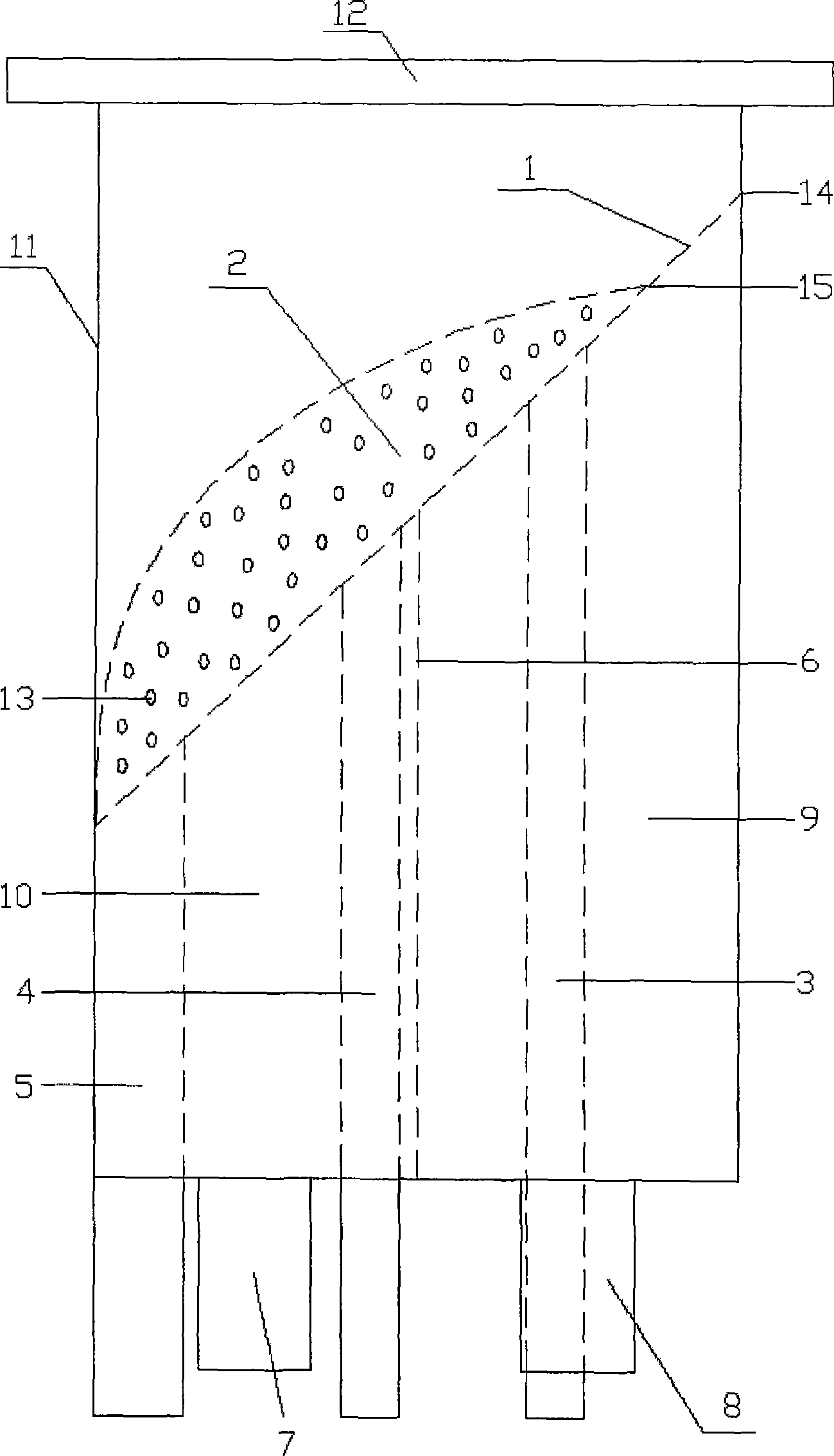

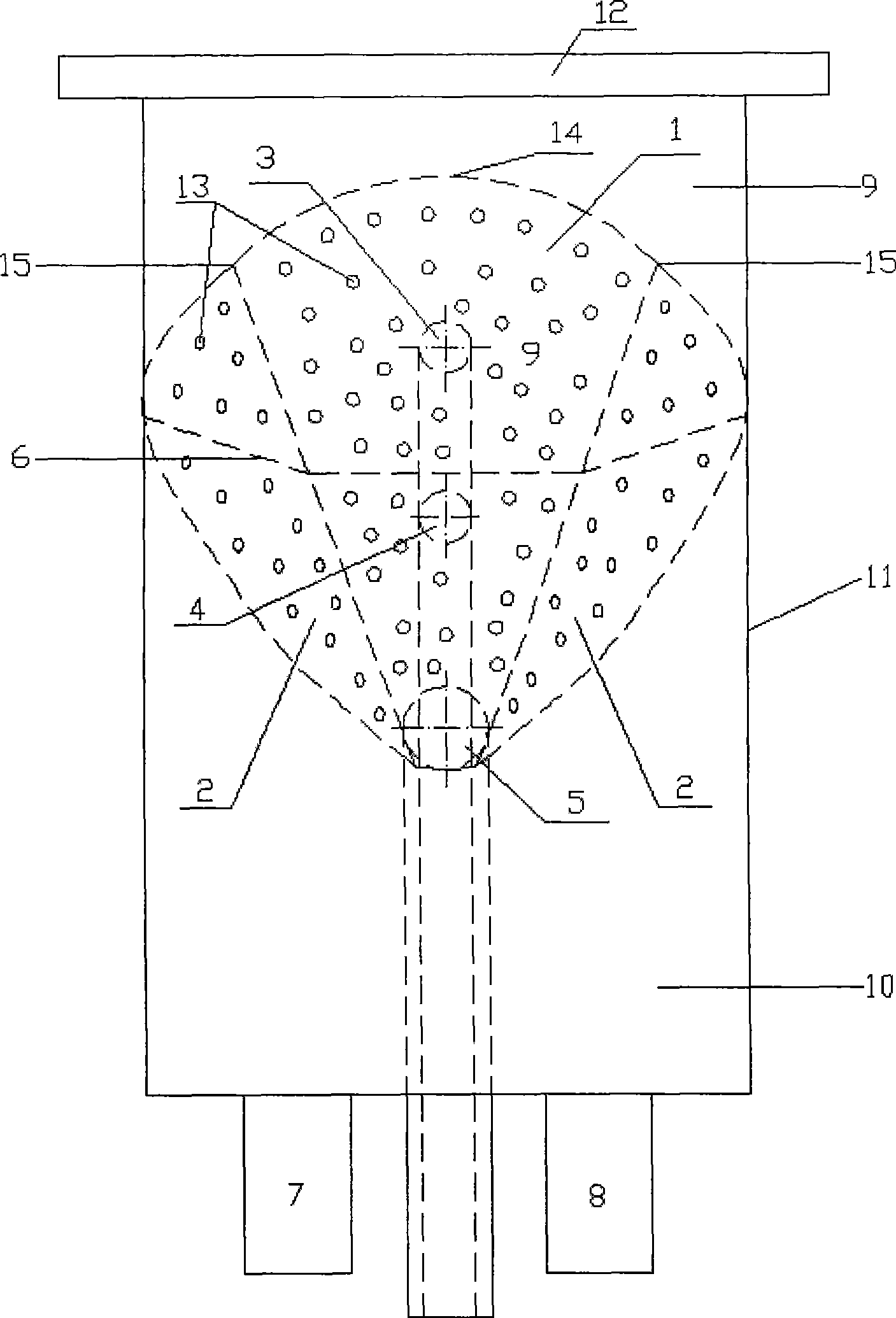

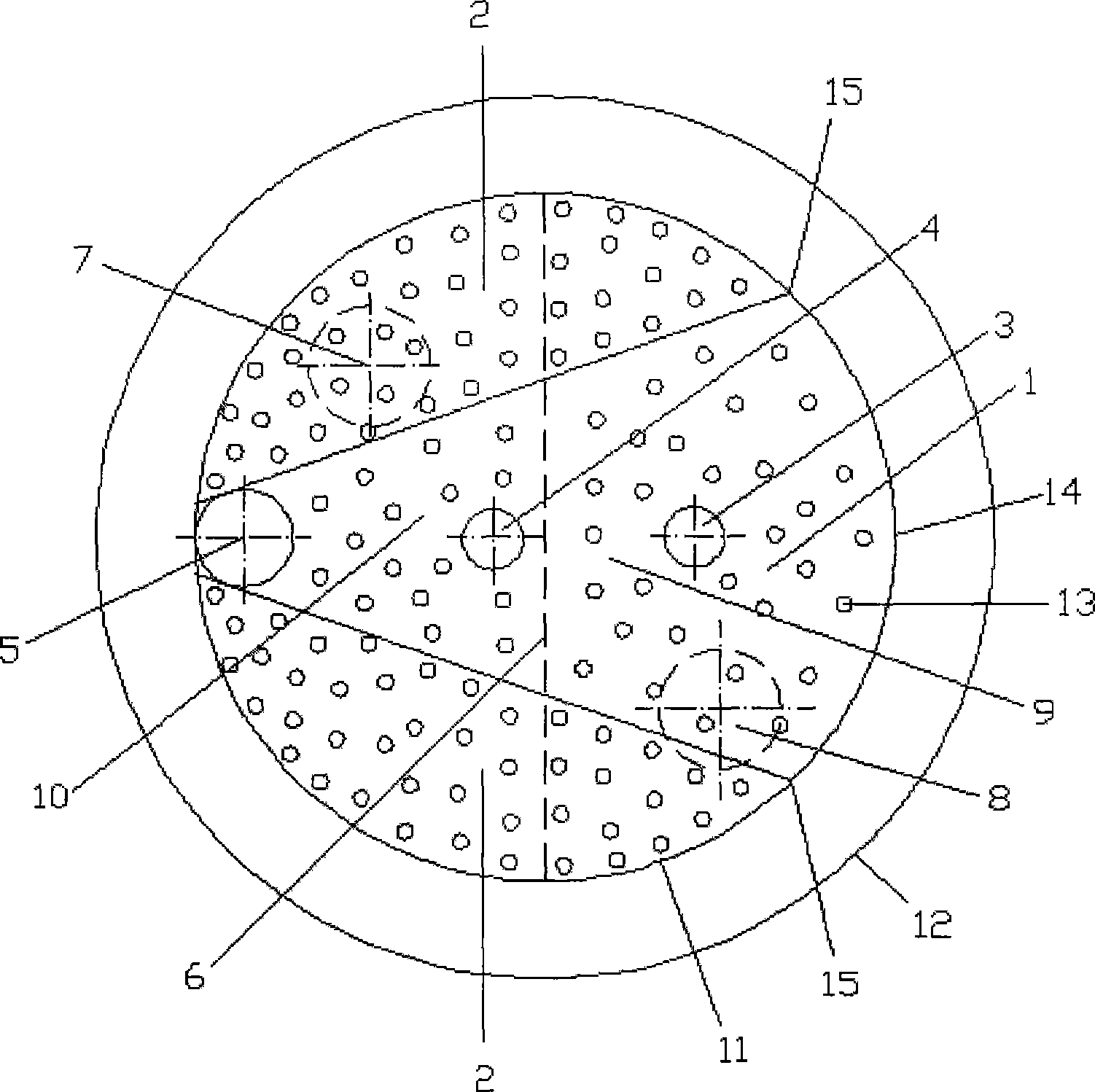

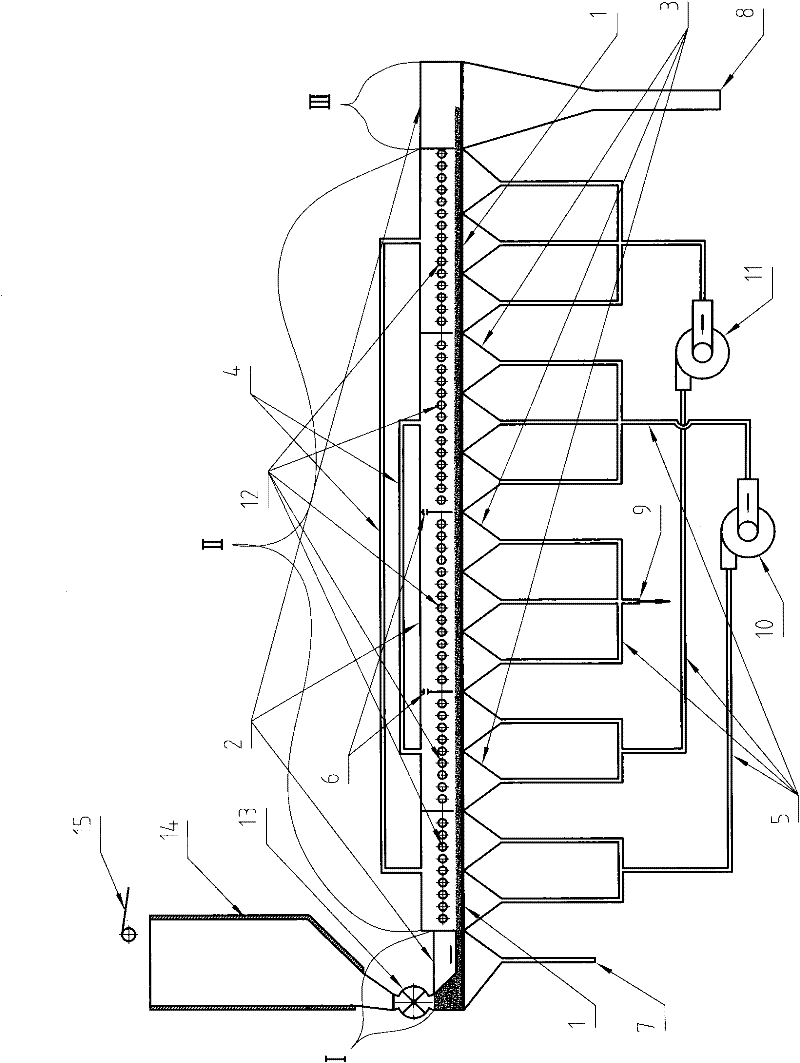

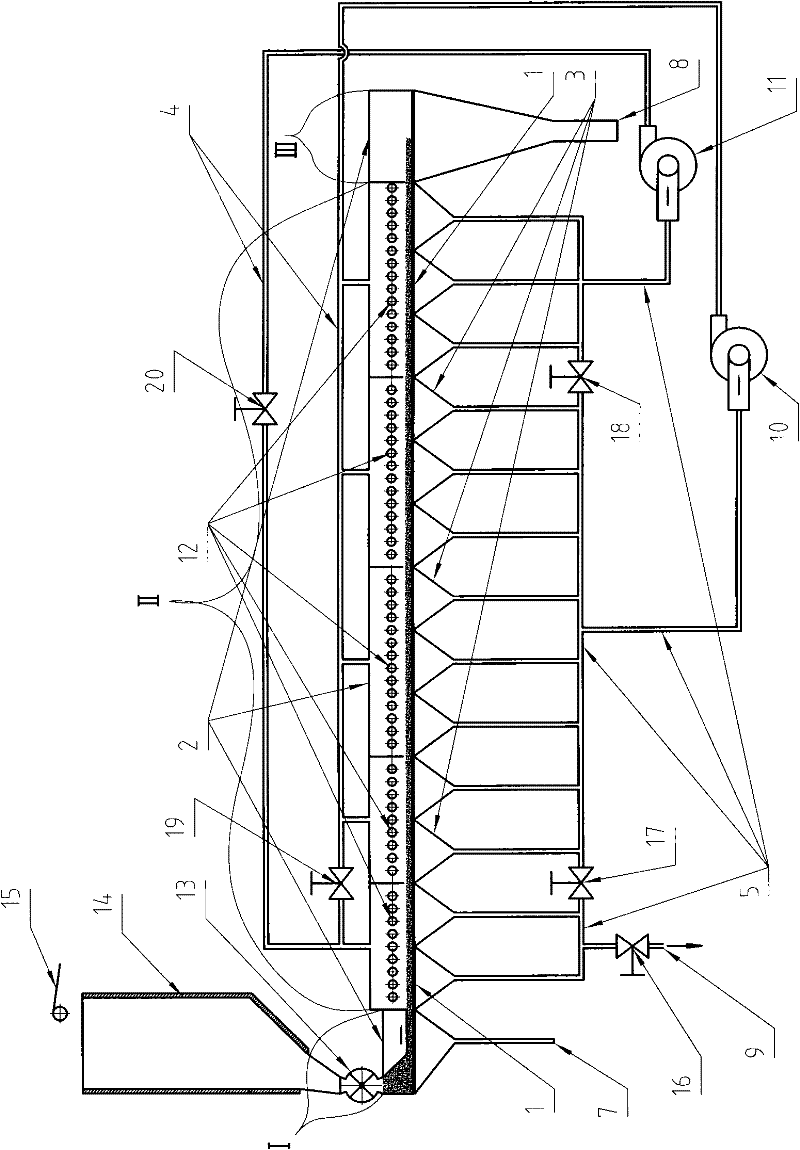

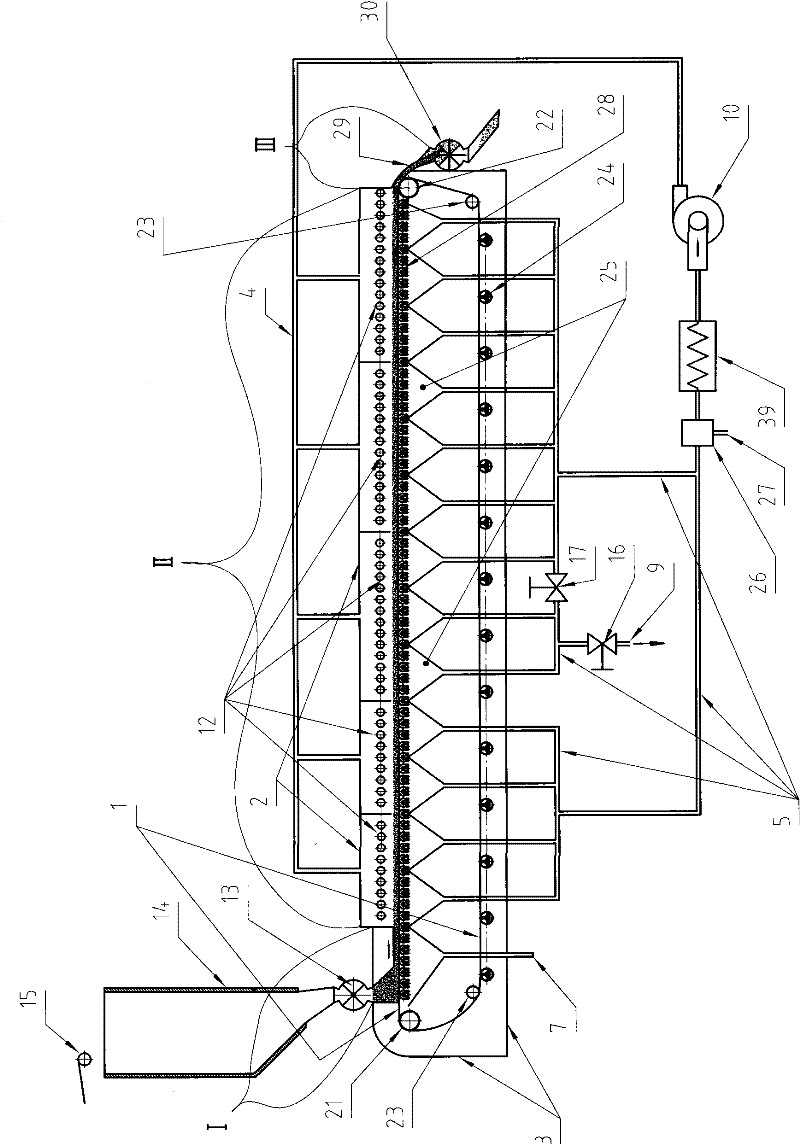

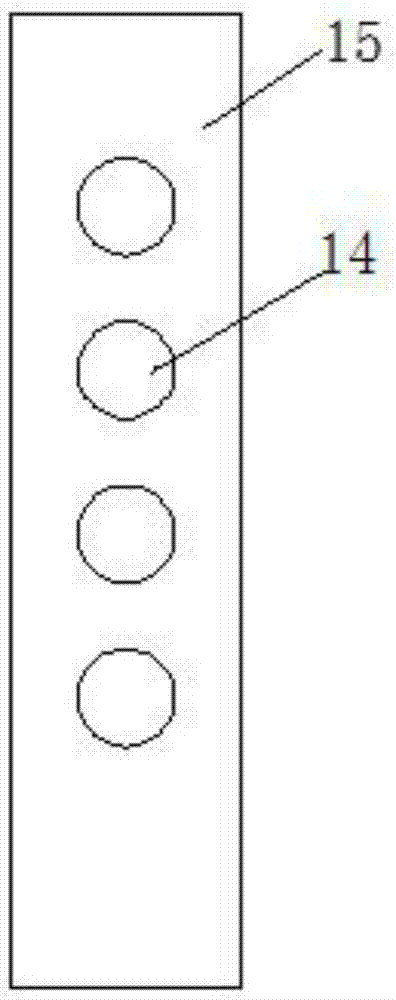

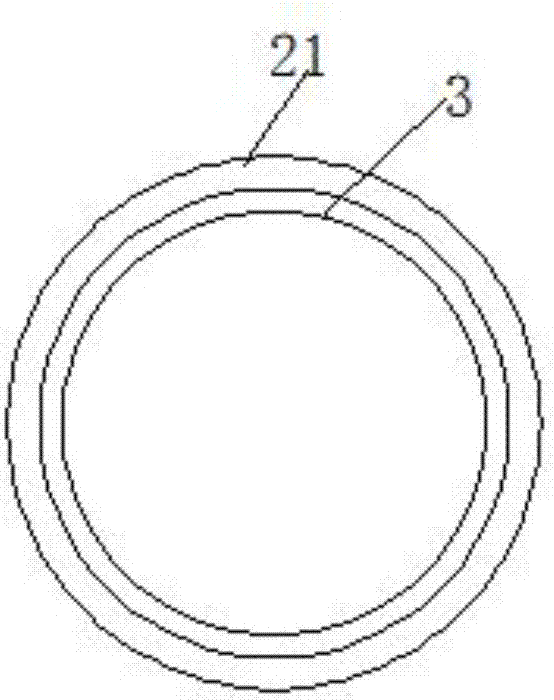

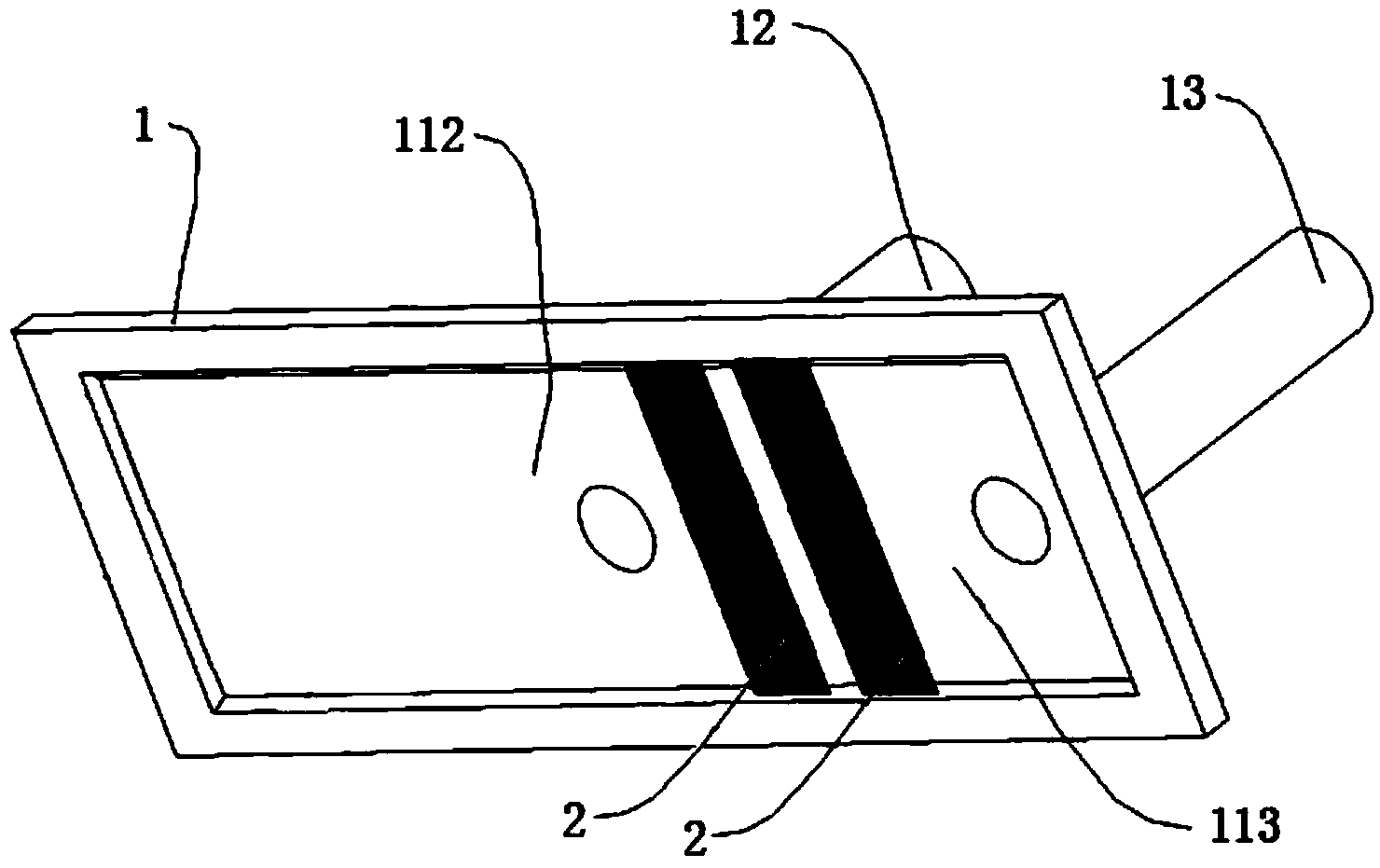

Gas distribution device

ActiveCN101519606AEnhanced lateral mixingExtended stayCombined combustion mitigationGranular/pulverulent flues gasificationEngineeringGas chamber

The invention relates to a gas distribution device which comprises a main board (1), lateral wings (2), a jet pipe ash-exhausting pipe (5), a baffle (6), a gas inlet pipe gas chamber, a cylinder (11) and a flange (12). A gas distribution board is formed by the main board (1) and the lateral wings (2), and the main board (1) forming an angle of 25 degrees to 60 degrees with the horizontal direction is obliquely arranged in the cylinder (11) and is connected with the wall surface of the cylinder (11); vertical upward small holes (13) are respectively arranged on the main board (1) and the lateral wings (2), and the ash-exhausting pipe (5) is communicated with an ash-exhausting hole on the main board (1); two jet pipes (3) and (4) are arranged in the cylinder (11), and the centers are respectively arranged on two equipartition points which uniformly divide the diameter of the cylinder (11) after the diameter of the ash-exhausting pipe (5) is removed; one end of the jet pipe (3) and one end of the jet pipe (4) are communicated with the main board (1), and the baffle (6) which is arranged on a midline in the cylinder (11) divides the gas chamber into two gas chambers (9) and (10) which are communicated with two gas inlet pipes (7) and (8). The invention has the advantages of easy operation, high gasification efficiency and wide material range of application.

Owner:ENN SCI & TECH DEV

Process for preparing chromium oxide from laterite-nickel ores

ActiveCN101723460AHigh value for industrial useIncrease diversityChromium oxides/hydratesSlurryToxic material

The invention provides a process for preparing chromium oxide from laterite-nickel ores. The process comprises the steps of carrying out liquid-solid separation and aluminum removal on roast materials obtained by leading the laterite-nickel ores and alkali metal hydroxide to be in molten salt reaction for obtaining alkaline leaching solution which is rich in chromate and the alkali metal hydroxide, taking the alkaline leaching solution as a raw material, taking hydrogen as a reducing agent, leading the alkaline leaching solution and the hydrogen to be in direct hydrothermal reduction reaction under certain temperature and pressure conditions for generating chromium hydroxide slurry, and carrying out the liquid-solid separation on the slurry for obtaining a chromium hydroxide filter cake and filtrate containing a small quantity of hexavalent chromium. A final product of chromium oxide is obtained by drying, high-temperature calcining and washing the chromium hydroxide filter cake; and the filtrate can be returned to the material mixing procedure for realizing the circulating material mixing. The process can effectively recycle and utilize valuable metal chromium in the laterite-nickel ores, thereby not only realizing the pluralism of a laterite-nickel ore product, but also reducing the emissions of toxic wastes, realizing the internal circulation of materials and media, being in line with the requirements on clean production; furthermore, the reduction process has simple flow process and strong industrial operationality.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

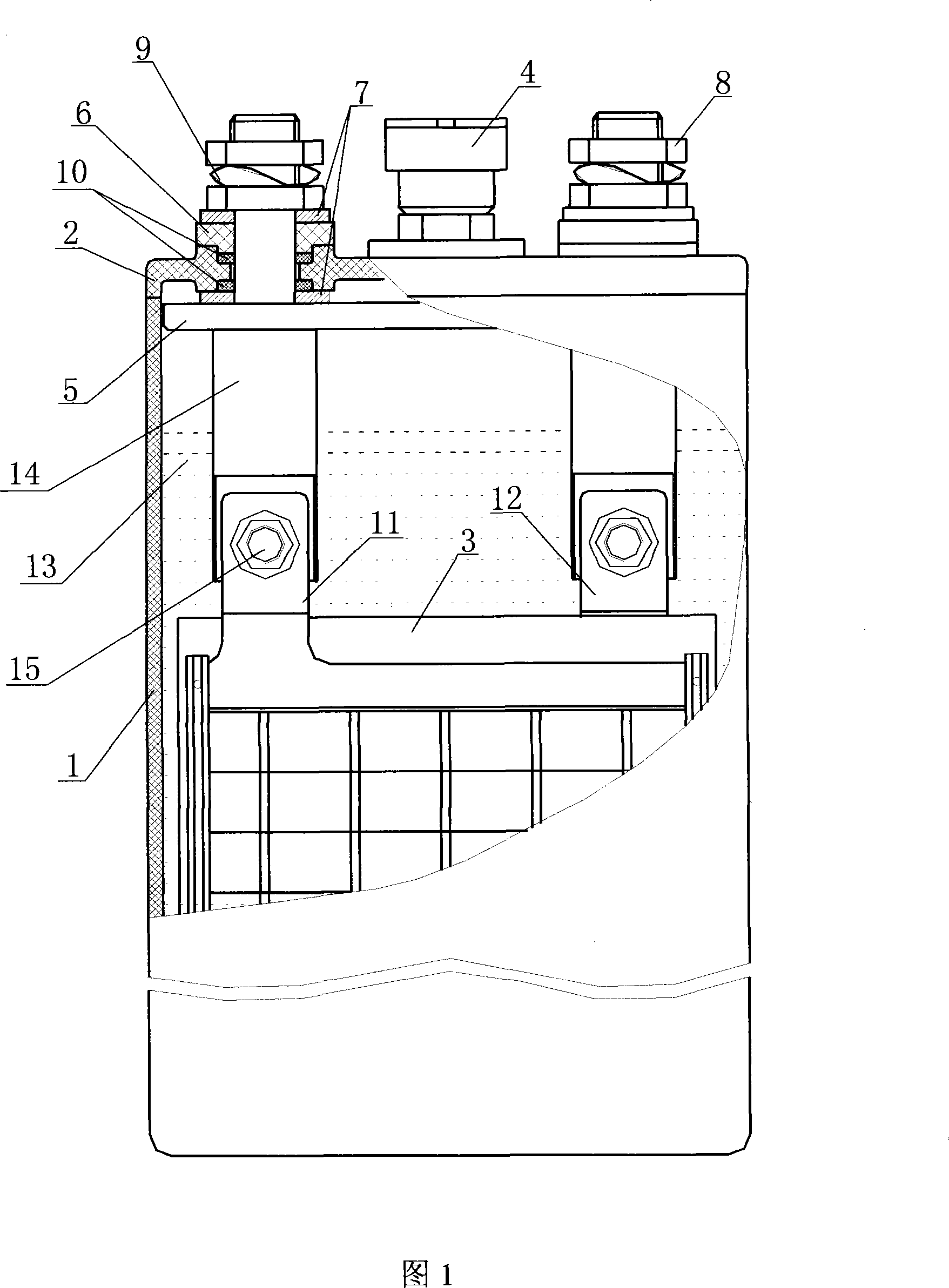

Built-in maintenance-free cadmium nickel alkalescent accumulator

InactiveCN101237065AAchieve maintenance-freeImprove charging efficiencyCell seperators/membranes/diaphragms/spacersSmall-sized cells cases/jacketsDehydrogenationDischarge rate

A built-in maintenance-free Ni-Cd alkaline storage battery mainly comprises a positive plate, a negative plate, a spacer, a battery container, an assembling air plug, auxiliary parts and electrolyte. The storage battery is characterized in that: a pored absorption box with dehydrogenation catalyst arranged inside is also arranged above the electrolyte inside the battery container; the assembling air plug is preferably a valve-controlled assembling air plug. The adoption of the present invention can maintain the advantages of the prior Ni-Cd alkaline storage battery, improve charge efficiency by 20 percent, ensure discharge rate can meet the discharge requirements of a Ni-Cd alkaline storage battery at high, middle and low rate, and guarantee stable discharge voltage as well as safe and reliable quality. Liquid adding maintenance period can reach twenty times more than the prior Ni-Cd storage batteries, so as to realize the real maintenance exemption of Ni-Cd storage batteries.

Owner:四川长虹电源有限责任公司

Oil shale retorting method as well as dynamic grate type retort furnace for realizing same and application thereof

ActiveCN102051188AAvoid wastingSolve the amount of circulationDirect heating destructive distillationSpecial form destructive distillationCombustible gasProduct gas

The invention provides an oil shale retorting method as well as a dynamic grate type retort furnace for realizing the same and application thereof, belonging to the technical fields of the extraction of shale oil gas from oil shale and the extraction of oil and combustible gas from soft coal. The oil shale retorting method comprises the steps of crushing the oil shale, charging into a furnace, heating, collecting shale retorting gas, collecting shale semicokes and the like and the use of heat-carrying gas. The oil shale retorting method is characterized in that the ratio of the circulating amount of the heat-carrying gas for the retorting furnace in the furnace to the processing amount of the heat-carrying gas for oil-gas extraction is not less than 3.5. By means of the invention, the problems on the separation of circulation amount and the processing amount is solved, and the minimization of the processing amount can be realized; the air injection can also be avoided so that the quality of product gas is improved and particularly the unit heat value of the product gas is improved; and moreover, by means of the high-multiple inner circulation of the heat-carrying gas inside the retorting furnace, the heat loss and the like of the heat-carrying gas in the process can be reduced. Therefore, the oil shale retorting method is particularly suitable for the technical fields of the extraction of the shale oil gas from the oil shale and the extraction of the oil and combustible gas from the soft coal.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

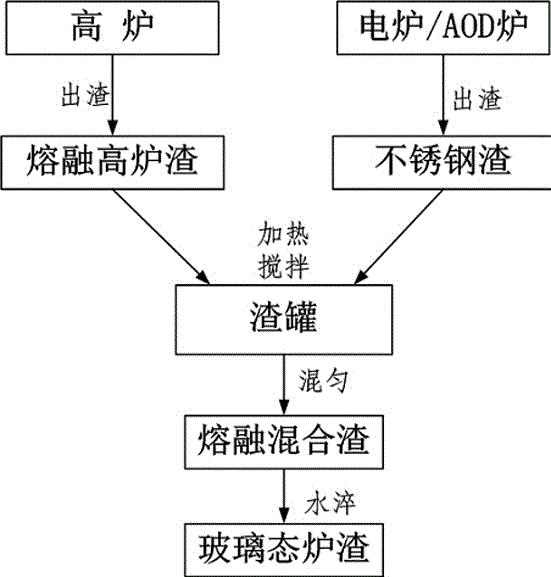

Method for high-temperature harmless treatment of stainless steel slag through molten blast furnace slag

The invention discloses a method for high-temperature harmless treatment of stainless steel slag through molten blast furnace slag. The method comprises the following steps that (1) after blast furnace slag is normally discharged, and the molten blast furnace slag is loaded into a slag ladle to be kept in the molten state through electrical heating; (2) the stainless steel slag is added into the molten blast furnace slag, the slag ladle is powered on for heating, and stirring is conducted; and (3) glassy state furnace slag is obtained through water quenching, and heavy metal Cr is fixed in the glassy state furnace slag. Through the method, mixed slag glass bodies are formed, Cr is stable in the glassy furnace slag, and the environment emission standard is met; and the energy consumption in the treatment process is low, required newly-built devices is little, and resources are further utilized.

Owner:JIANGXI UNIV OF SCI & TECH

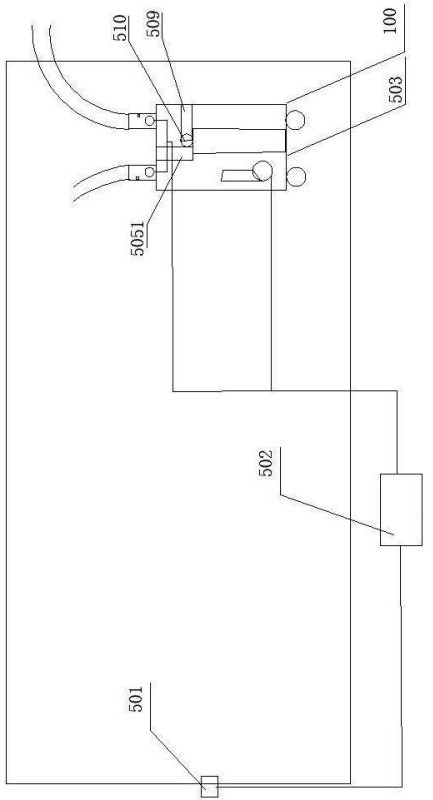

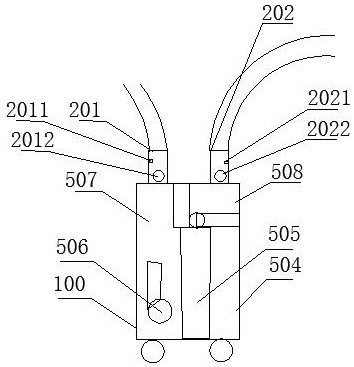

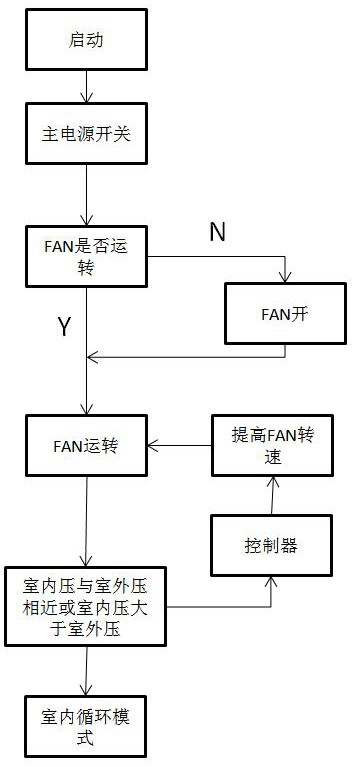

Negative pressure ward exhaust purification system

ActiveCN113218013AAchieve negative pressureSolve the transformation problemMechanical apparatusLighting and heating apparatusThermodynamicsAir volume

The invention discloses a negative pressure ward exhaust purification system. The system comprises a pressure difference sensor, a controller and a negative pressure exhaust purification device. The pressure difference sensor detects the air pressure difference between the internal environment and the external environment of a ward, and the controller adjusts a working mode of the negative pressure exhaust purification device according to the air pressure difference detected by the pressure difference sensor. The exhaust purification device can solve the problem of accelerated exhaust under the special condition, and can selectively adjust the air inlet amount and the air speed ratio in a first exhaust funnel and a second exhaust funnel according to actual conditions, and the problem that the air return amount, the air exhaust amount and the air speed cannot be adjusted by existing purification equipment in the market is solved.

Owner:MAYAIR TECH (CHINA) CO LTD

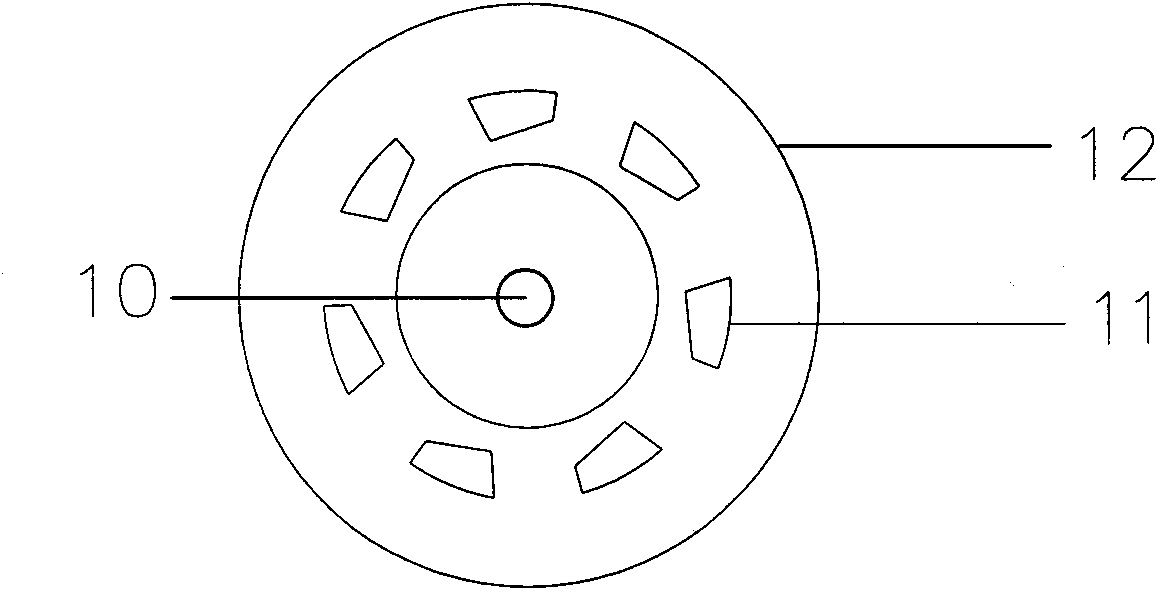

Internal circulation biological desulphurization reactor and method thereof

ActiveCN108905599AEasy to separateImprove efficiencyGas treatmentDispersed particle separationReaction zoneEnvironmental engineering

The invention discloses an internal circulation biological desulphurization reactor and a method thereof. A main body of the reactor is a cylindrical outer wall, which is divided into a sulfur-collection zone, a water-inlet zone and a circulation reaction zone from bottom to top, and a sedimentation zone is arranged on the outer periphery of the upper portion of the cylindrical outer wall. The sulfur-collection zone is provided with a sulfur-discharging pipe, a screw opening, a mud-collecting tank and an annular inclined plate; the water-inlet zone is provided with an inlet pipe, an aeration head, an air-guiding pipe and a limited rod; the circulation reaction zone is provided with an inner cylinder and a bell mouth; and the sedimentation zone is provided with a sedimentation inclined plane, a flushing pipe, a water outlet, an inclined plate and an outlet pipe. The reactor integrates sulfide oxidation and elemental sulfur separation, and has the advantages of compact structure and small land occupation; the efficient internal circulation of the reaction liquid can be achieved by the stripping effect and the Venturi effect through the optimized combination of the inner cylinder withthe bell mouth; effective separation of muddy water and recovery of elemental sulfur can be achieved by providing the inclined plate, the water outlet and the flushing pipe.

Owner:ZHEJIANG UNIV

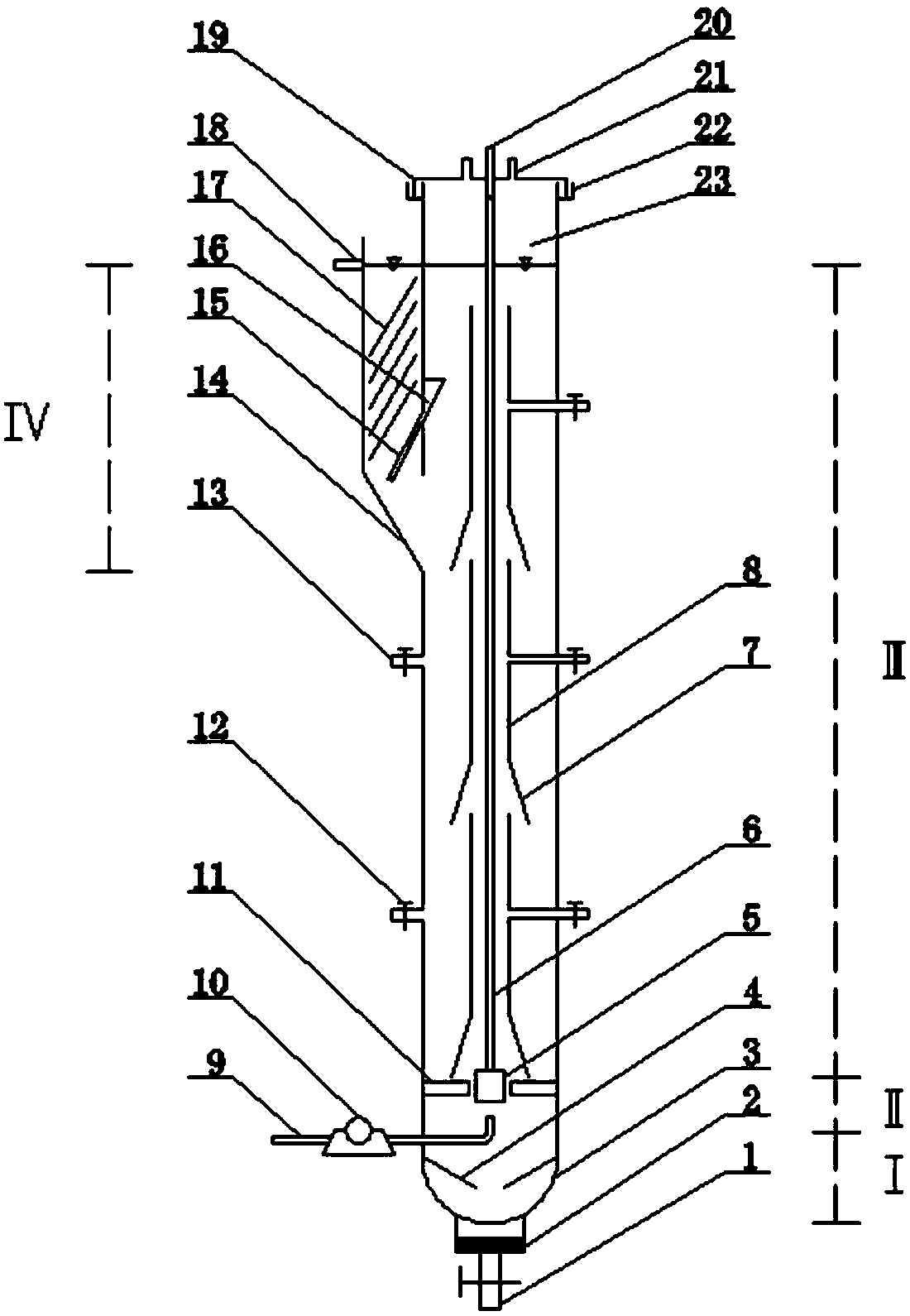

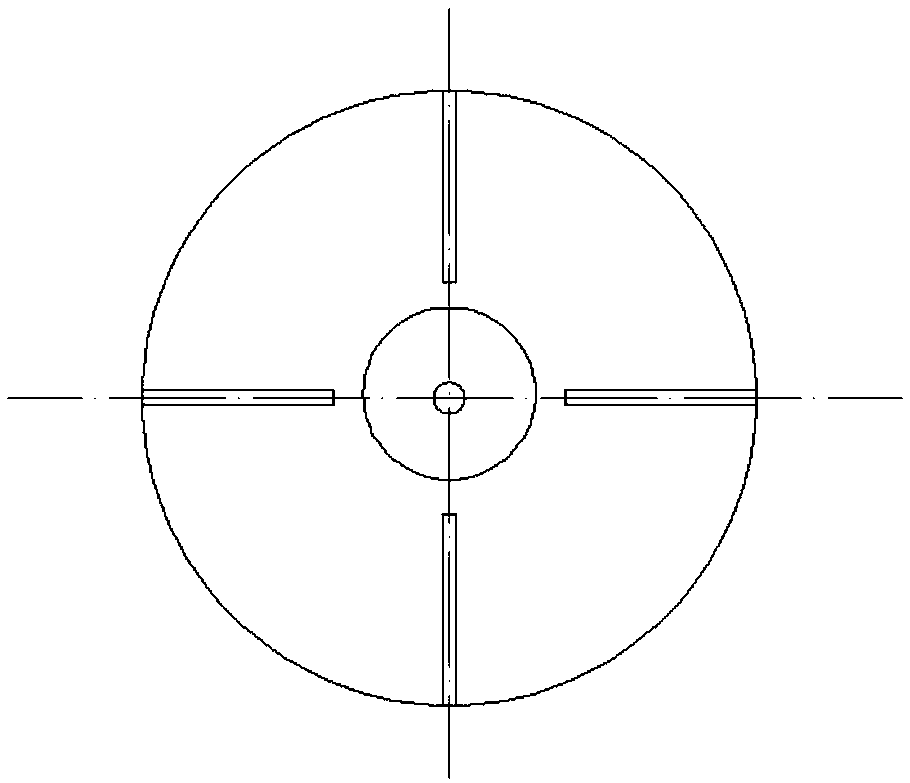

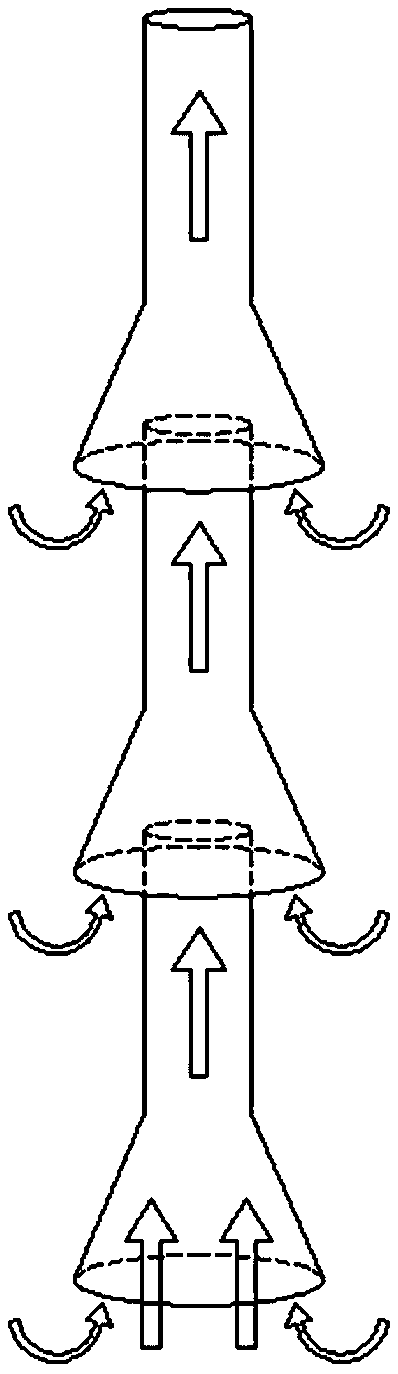

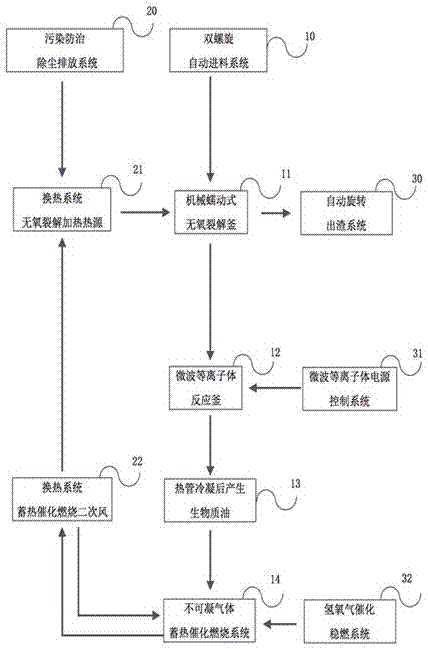

Medical waste microwave plasma anaerobic catalytic cracker

InactiveCN107152689ASolving Pollution Control ProblemsReduce consumptionIncinerator apparatusMicrowavePlasma technology

The microwave plasma anaerobic catalytic cracking device for medical waste combines low-cost pyrolysis gasification technology with advanced microwave plasma technology. Combustible gas is catalytically cracked and burned by gas technology, which doubles equipment investment, greatly reduces energy consumption, and makes it possible to implement the latest technology. The use of microwave plasma + thermal storage catalytic cracking and reprocessing has effectively solved the problem of pollution control in medical waste disposal. Make the disposal process always in a safe, controllable, compliant and legal environment. The combination of continuous technological innovation and technological optimization can realize the complete internal circulation, zero pollution and harmless, reduction and resource utilization of medical waste disposal.

Owner:曹蕴明 +1

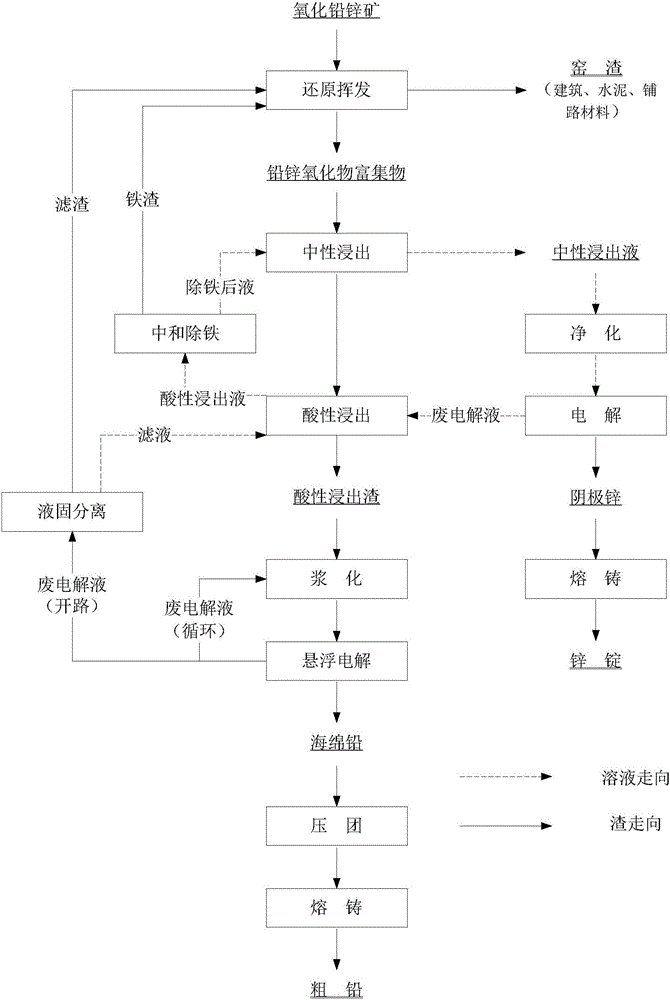

Environment-friendly metallurgy extracting method for lead-zinc oxide ores

InactiveCN106498181AStable in natureQuality improvementPhotography auxillary processesProcess efficiency improvementElectrolysisImpurity

The invention discloses an environment-friendly metallurgy extracting method for lead-zinc oxide ores, and belongs to the field of lead zinc ore metallurgy. The method comprises the following steps: reducing and volatilizing the lead-zinc oxide ores to obtain high-quality lead-zinc oxide enrichment, and separating lead and zinc from other impurities in raw ores; carrying out sulfuric acid leaching-purifying-electrodeposition on the lead-zinc oxide enrichment to obtain cathode zinc, and casting to obtain zinc ingot products; and after slurrying zinc leaching residues, continuously adding in a suspension electrolytic bath for producing lead powder by electrodeposition, and after washing, filtering and briquetting the lead powder, smelting into lead bullion. The lead and the zinc are highly enriched effectively by pyrogenic-process reduction and volatilization, and influence of impurities such as Fe, Si, Ca, Mg and Al to a smelting process is greatly reduced; and the zinc and the lead are effectively extracted in a sulfuric acid system to directly obtain the cathode zinc and the lead bullion, organic circulation of lead and zinc smelting systems is realized, consumption of energy and materials is greatly reduced, meanwhile, 'zero' consumption of sulfuric acid, 'zero emission' of waste water and 'zero' emission of smelting wastes are realized simultaneously, and the environment-friendly metallurgy extracting method for the lead-zinc oxide ores is environment-friendly.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

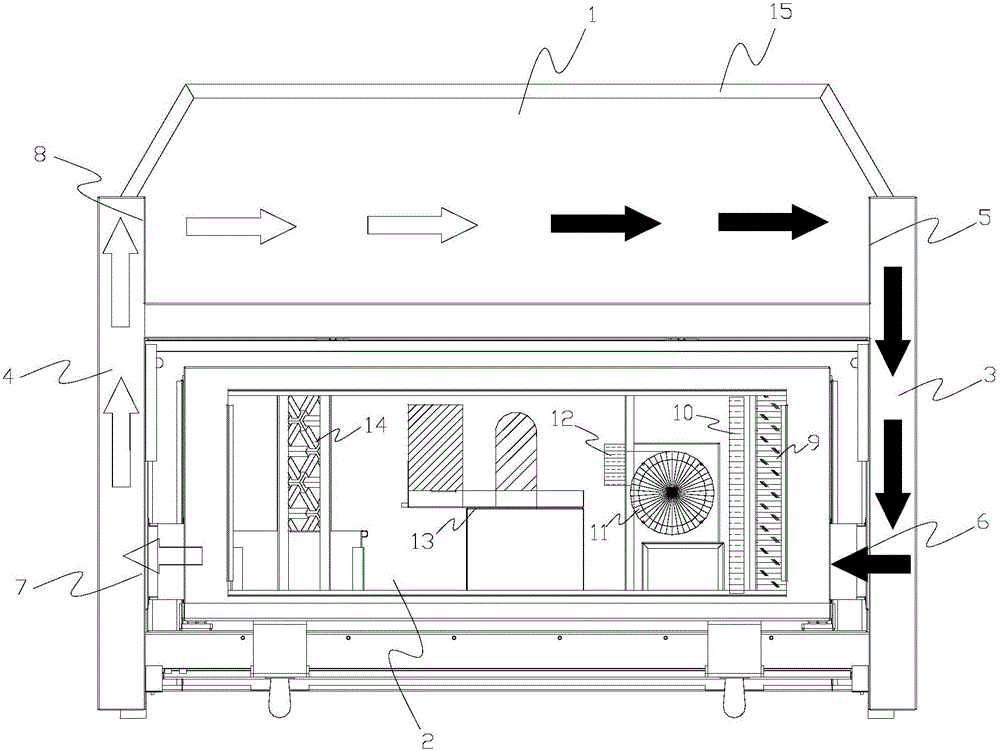

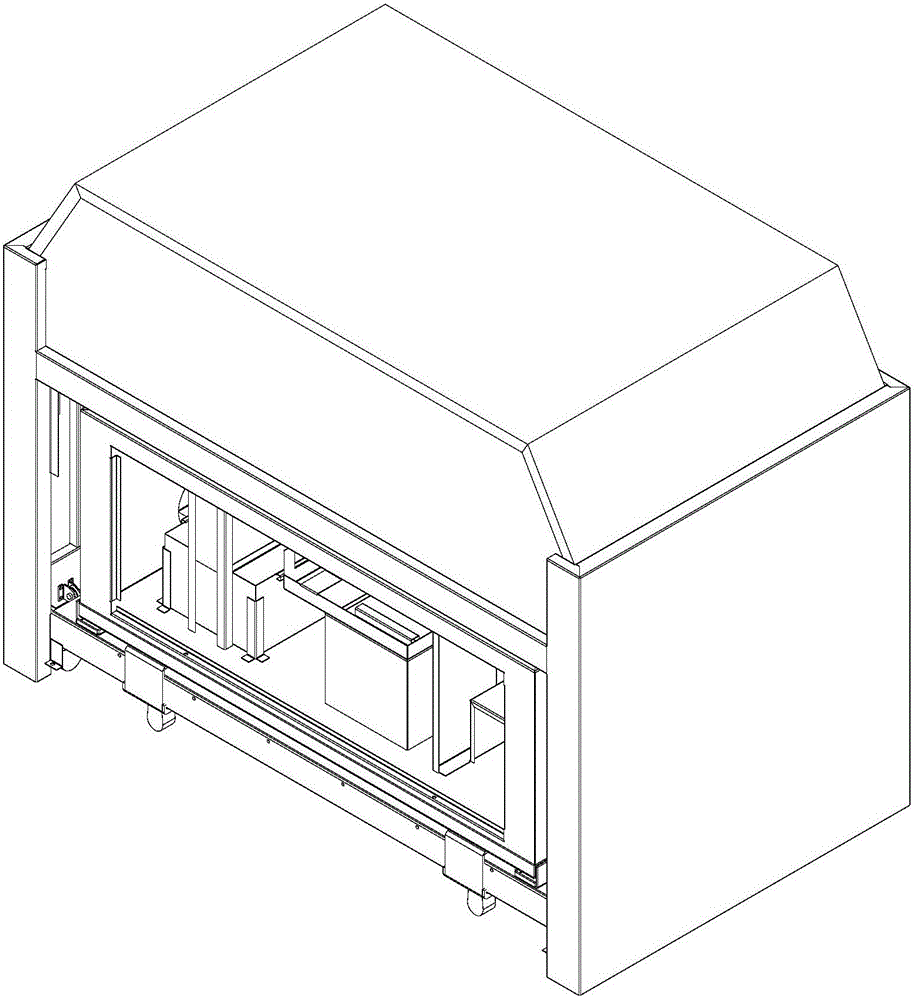

Deacidification type constant-temperature and constant-humidity purification display cabinet

The invention discloses a deacidification type constant-temperature and constant-humidity purification display cabinet. The deacidification type constant-temperature and constant-humidity purification display cabinet comprises a display chamber (1) for storing an object to be displayed, and an air treatment chamber (2) for adjusting the inner environment of the display chamber (1), wherein the display chamber (1) and the air treatment chamber (2) are mutually independently arranged and are in fluid connection through an air pipeline; the air treatment chamber (2) is internally provided with a temperature adjusting assembly, a humidity adjusting assembly and a mixed type filter (10) capable of carrying out deacidification treatment on air; the air in the display chamber (1) flows into the air treatment chamber (2) to be treated; and the treated air flows back into the display chamber (1). The inner part of the deacidification type constant-temperature and constant-humidity purification display cabinet disclosed by the invention is a sealed type space, and the display region is communicated with side plates on the two sides and is connected with a constant-temperature and constant-humidity box at the bottom, so that inner circulation of the air is realized.

Owner:北京融安特智能科技股份有限公司

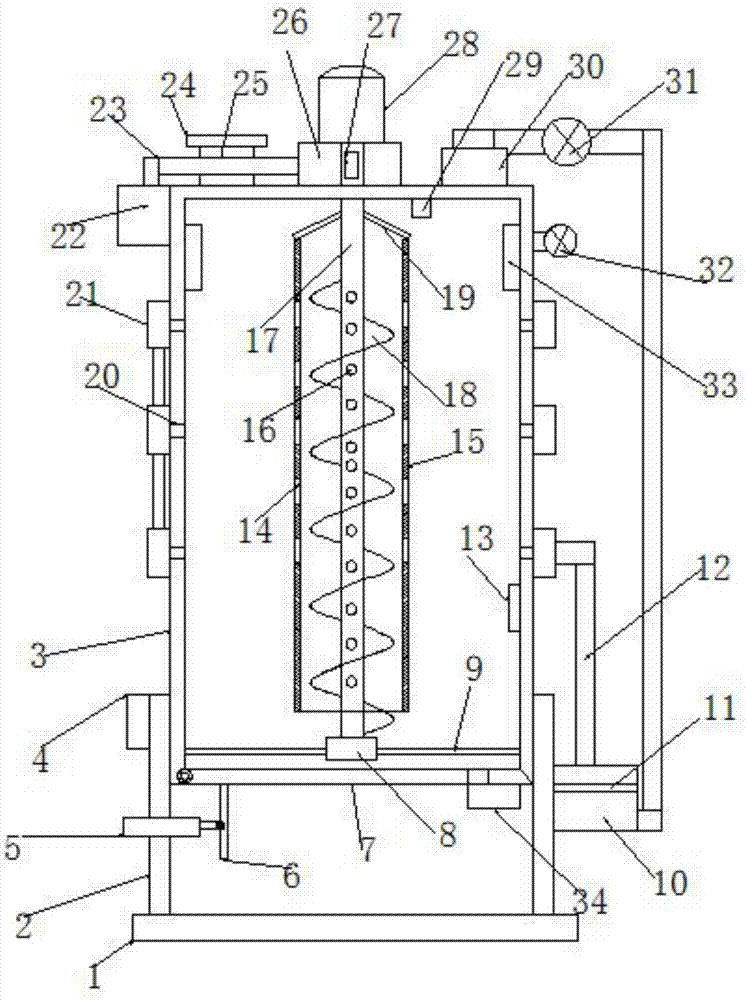

Energy-saving mushroom smashing and drying device

InactiveCN108020061AEasy to dryImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsWorking environmentEngineering

The invention discloses an energy-saving mushroom smashing and drying device, and belongs to the field of food processing equipment. The energy-saving mushroom smashing and drying device comprises a shell, ultraviolet lamps, a collection hopper, a movable baffle plate, a collection box and a feeding device, wherein the shell is a horizontally arranged hollow cylinder and is made from a stainless steel material; an insulating layer is arranged on the surface of the inner wall of the shell; a drying chamber is arranged in the shell; the shell is fixedly arranged above a base through supports; the feeding device is fixedly arranged on the left side of the shell; a discharge hopper is arranged at the bottom of the feeding device; the ultraviolet lamps are fixedly arranged at the top of the drying chamber; the collection box is arranged on the base; and the collection box is positioned right under the collection hopper. According to the energy-saving mushroom smashing and drying device, structural design is reasonable, mushrooms are dried after being smashed, the drying effect is good, hot gases are prevented from leaking outwards to pollute the working environment, loss of heat is avoided as well, and energy-saving and environmentally-friendly functions are achieved.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

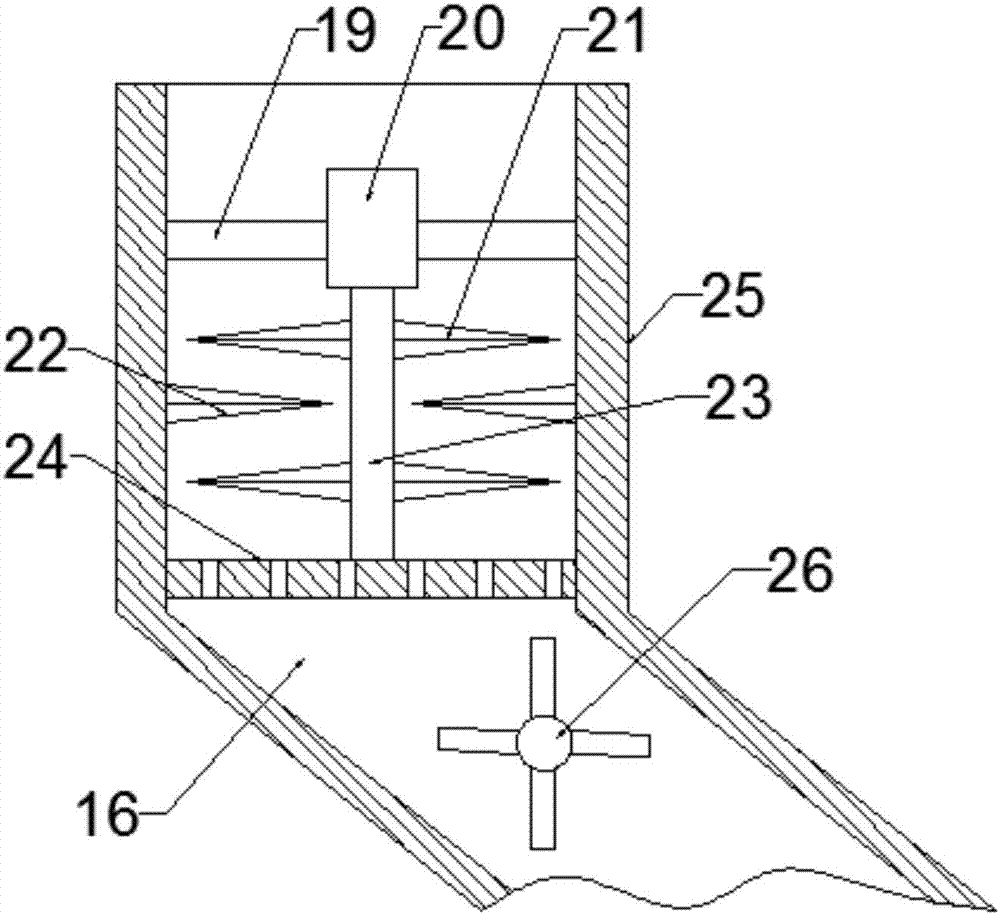

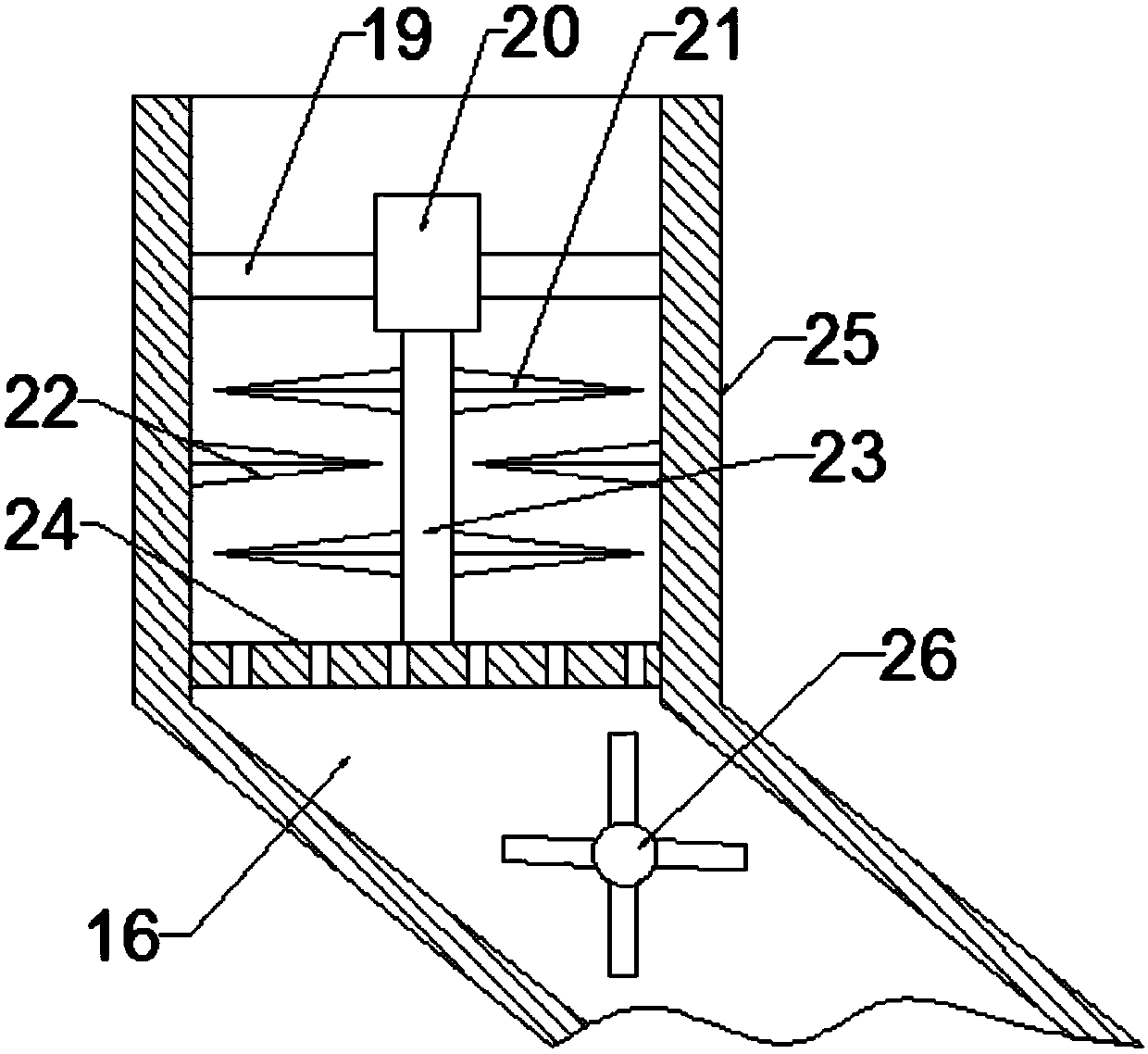

Centrifugal dispersing type traditional Chinese medicine drying and sterilizing device

InactiveCN107242975ARealize inner loopAchieve bactericidal effectPharmaceutical product form changeRadiationDrive shaftBuffer tank

The invention discloses a centrifugal dispersing type traditional Chinese medicine drying and sterilizing device, which comprises a base and a processing box. A processing box is arranged above the base. Both sides of the lower end of the processing box are connected and fixed to the base through legs. The processing box is a cylinder Type cylinder, the inside of the processing box is vertically equipped with a lifting cylinder, and the driving shaft is pierced through the lifting cylinder. The driving shaft is a hollow structure. The upper end of the driving shaft and the lifting cylinder are connected and fixed by a connecting rod, and the upper end of the driving shaft passes through the processing box The top is connected and fixed with the output end of the driving motor. The driving shaft in the lifting cylinder is provided with a pushing blade, and a buffer box is provided between the driving motor and the processing box. The structure of the invention is simple and reasonable, and the The integrated setting of wetting medicine and drying helps to improve the processing efficiency of medicinal materials. At the same time, the device realizes the internal circulation of materials, which greatly improves the discrete effect of materials, helps the sterilization and drying of medicinal materials, and improves the practicality of the device. sex.

Owner:赵志坚

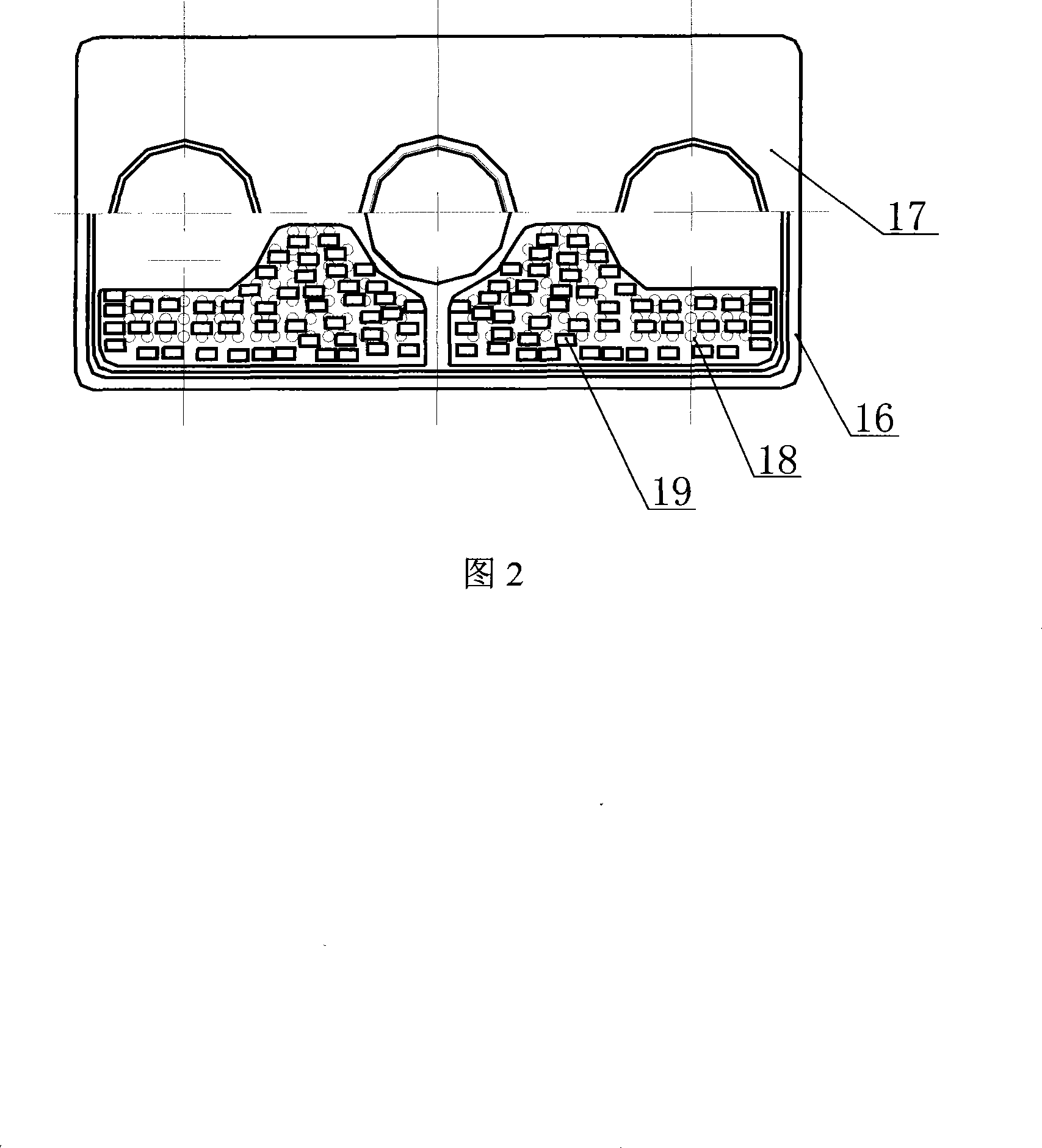

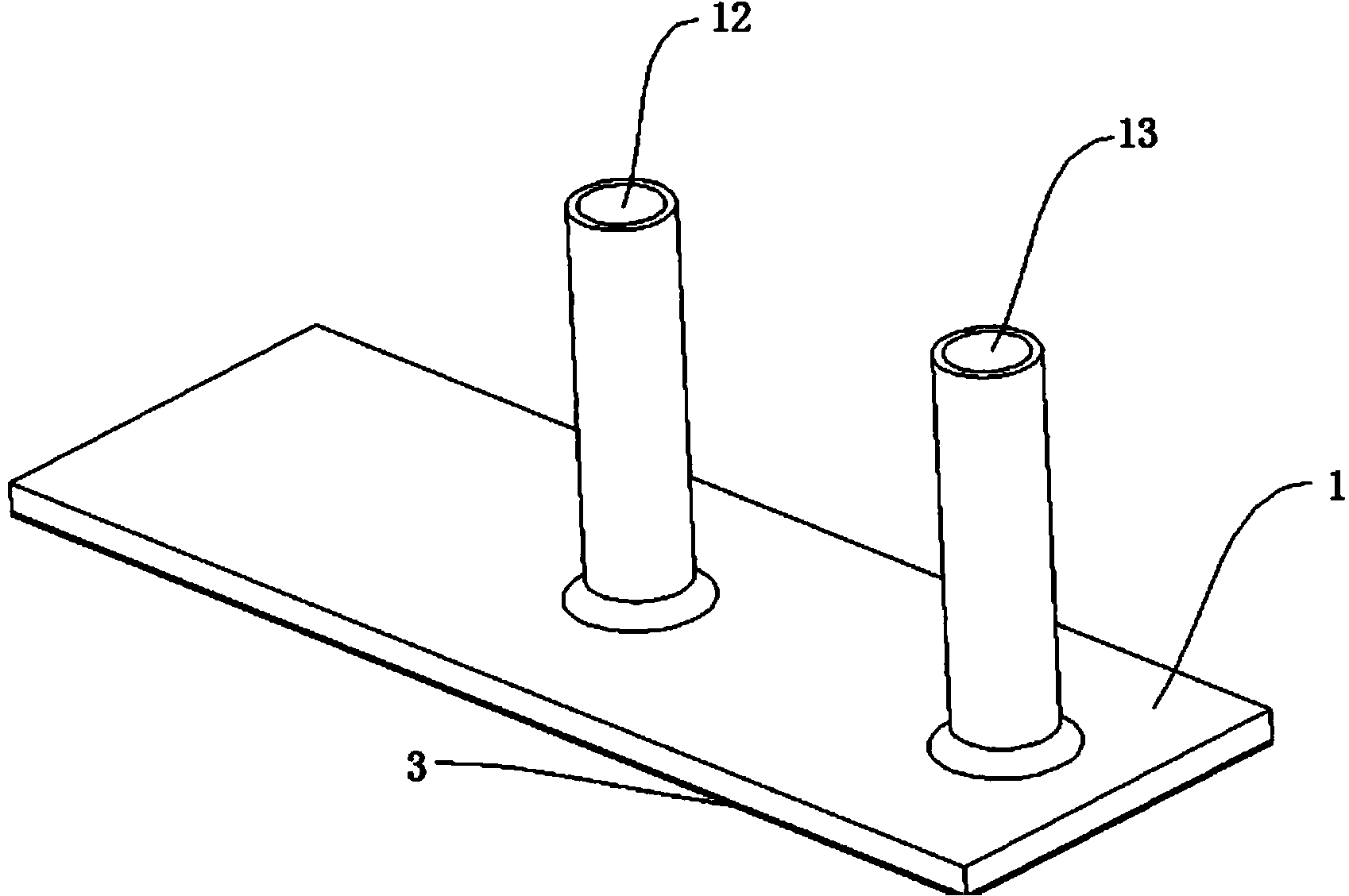

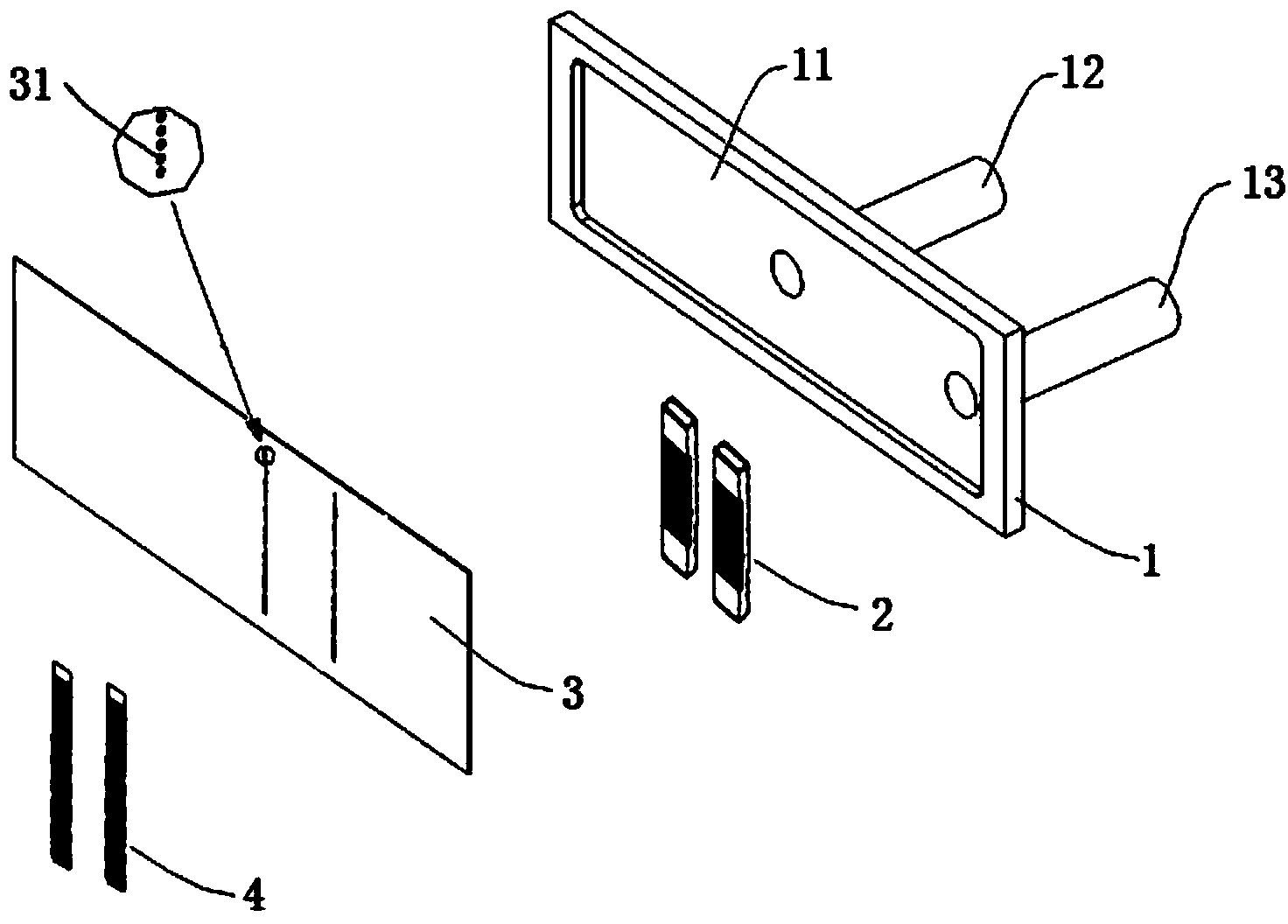

Piezoelectric inkjet head and printing device comprising same

ActiveCN103963468AImprove work efficiencyGood plastic deformation abilityPrintingSpray nozzleCeramic

The invention discloses a piezoelectric inkjet head and a printing device comprising the piezoelectric inkjet head and belongs to the technical field of inkjet printing. The piezoelectric inkjet head comprises a spray head base, a fluid groove plate, a spray nozzle plate, a piezoelectric ceramic driver and a driving circuit device. The spray head base comprises an ink cavity, an ink inflow pipeline and an ink outflow pipeline. A plurality of fluid grooves are formed in the fluid groove plate, and the fluid groove plate divides the ink cavity into an ink inflow cavity and an ink outflow cavity. A plurality of micro-jet holes are formed in the spray nozzle plate, and each micro-jet hole corresponds to the position of the concave part of one fluid groove. The piezoelectric ceramic driver comprises a plurality of piezoelectric ceramic micro-units, and each piezoelectric ceramic micro-unit corresponds to the position of the concave part of one fluid groove. The driving circuit device is electrically connected with the piezoelectric ceramic driver. The piezoelectric inkjet head effectively solves the problems that an existing piezoelectric inkjet head is low in working efficiency, small in material selection space and high in machining cost and fluid grooves and / or micro-jet holes are blocked easily.

Owner:PAIHE SCI & TECH HLDG CO LTD BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com