Upflow blanket filter (UBF) anaerobic reactor with filter layer at top and for treating chemical wastewater

An anaerobic reactor and chemical wastewater technology, applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as complex equipment, shorten the start-up period, reduce sludge loss, The effect of improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

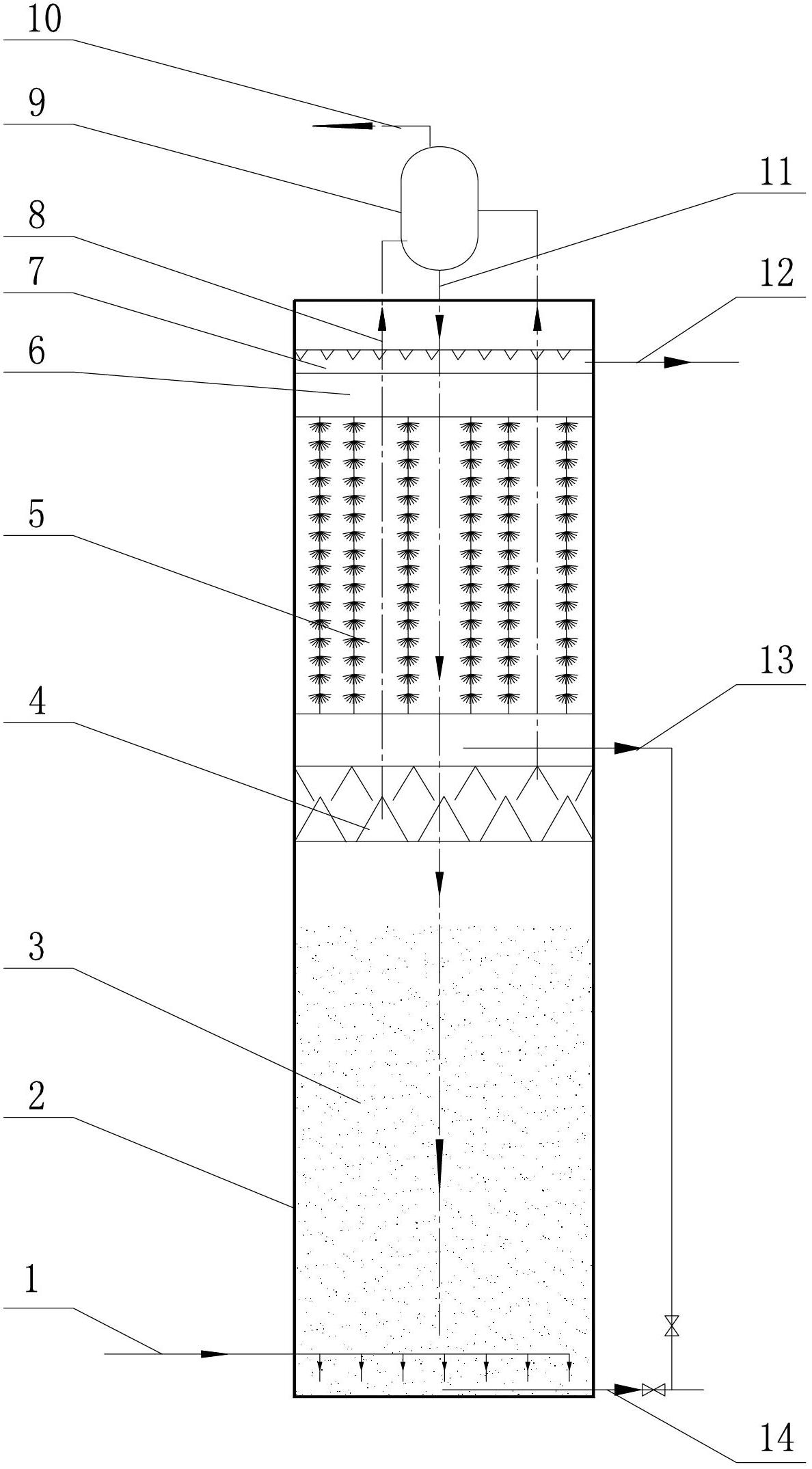

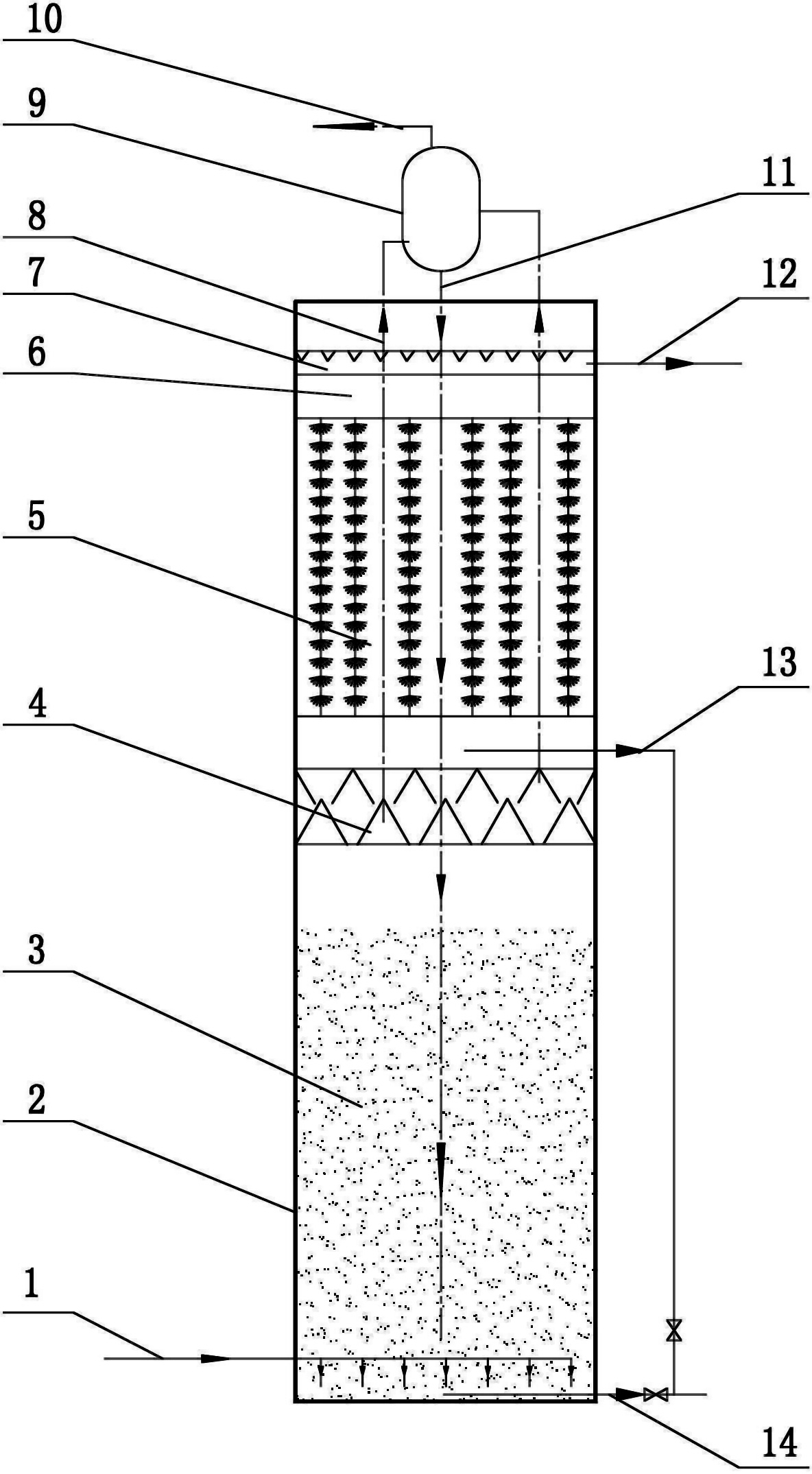

[0030] Such as figure 1 The UBF anaerobic reactor for treating chemical wastewater with a filter layer on the top of a preferred embodiment of the present invention shown includes reactor 2, water distribution device 1, sludge expanded bed 3, three-phase separator 4, and effluent collection device and biogas circulation device, a three-phase separator 4 is installed in the middle of the reactor 2, the lower part of the three-phase separator 4 is a sludge expanded bed 3, and the upper part of the three-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com