Piezoelectric inkjet head and printing device comprising same

An ink head and nozzle technology, applied in the fields of printing equipment and piezoelectric inkjet heads, can solve the problems of easy blockage of fluid grooves and/or micro-nozzle holes, low working efficiency of piezoelectric inkjet heads, and small space for material selection, etc. Achieve the effect of improving work efficiency, low processing cost, and large space for material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

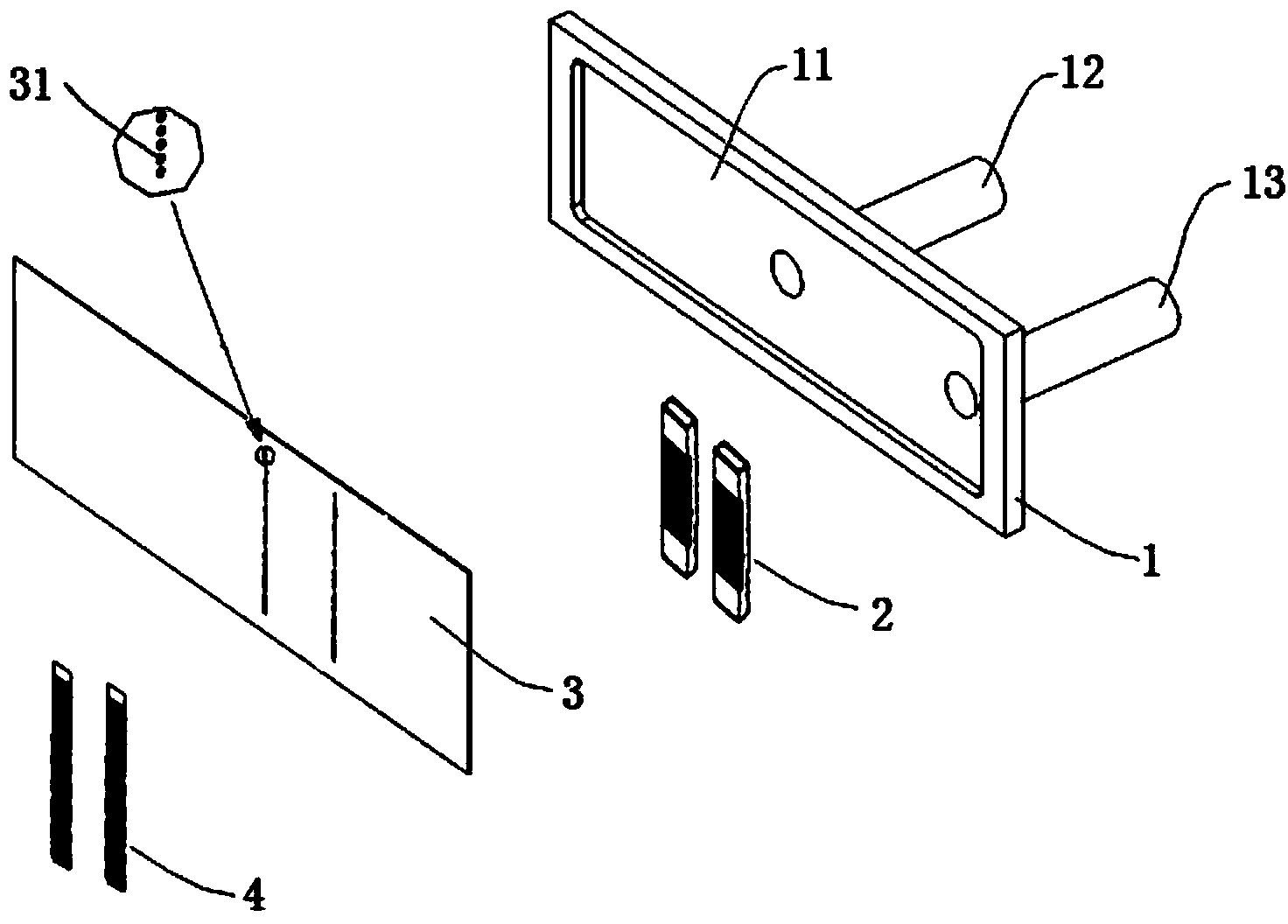

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

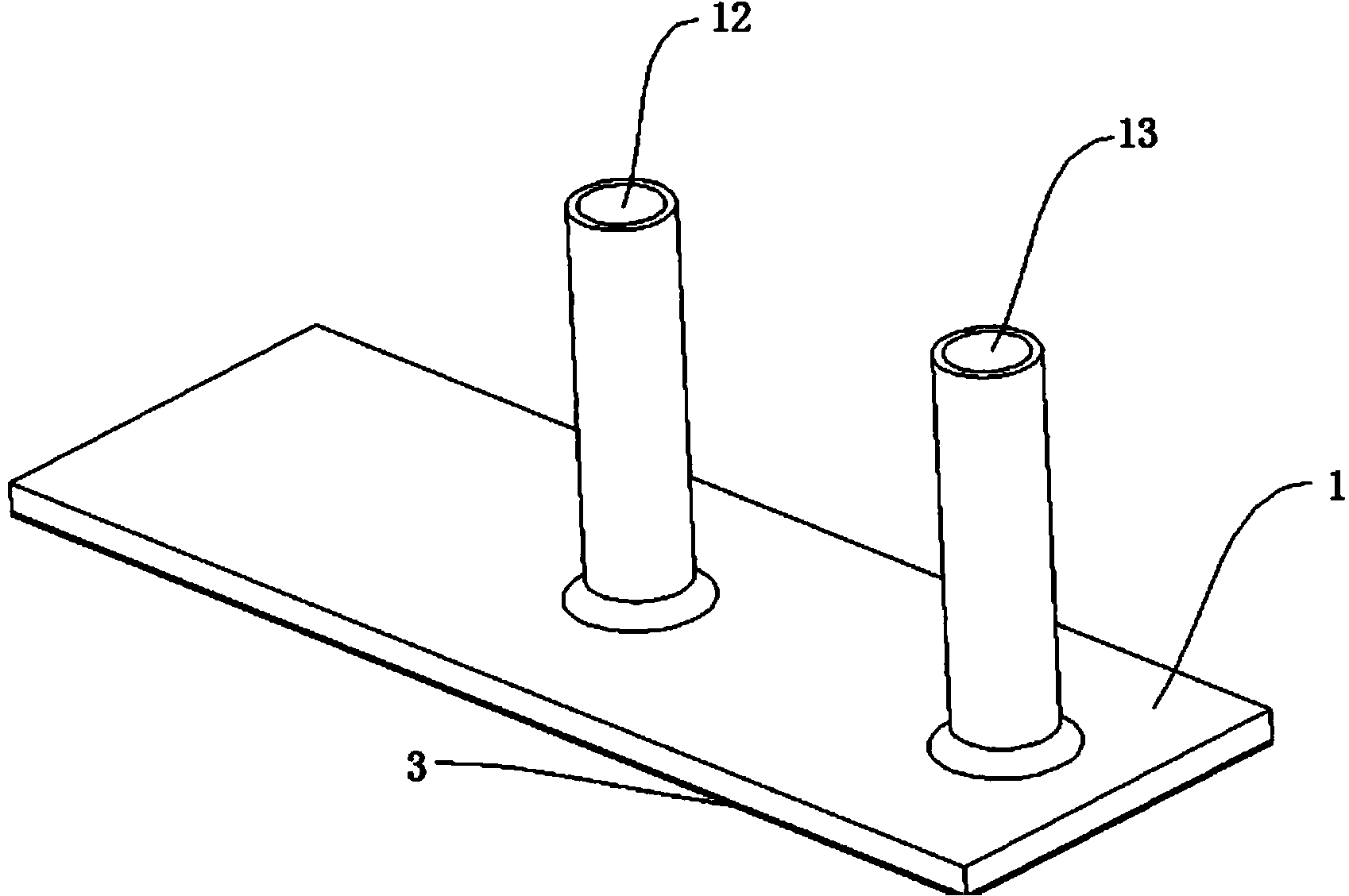

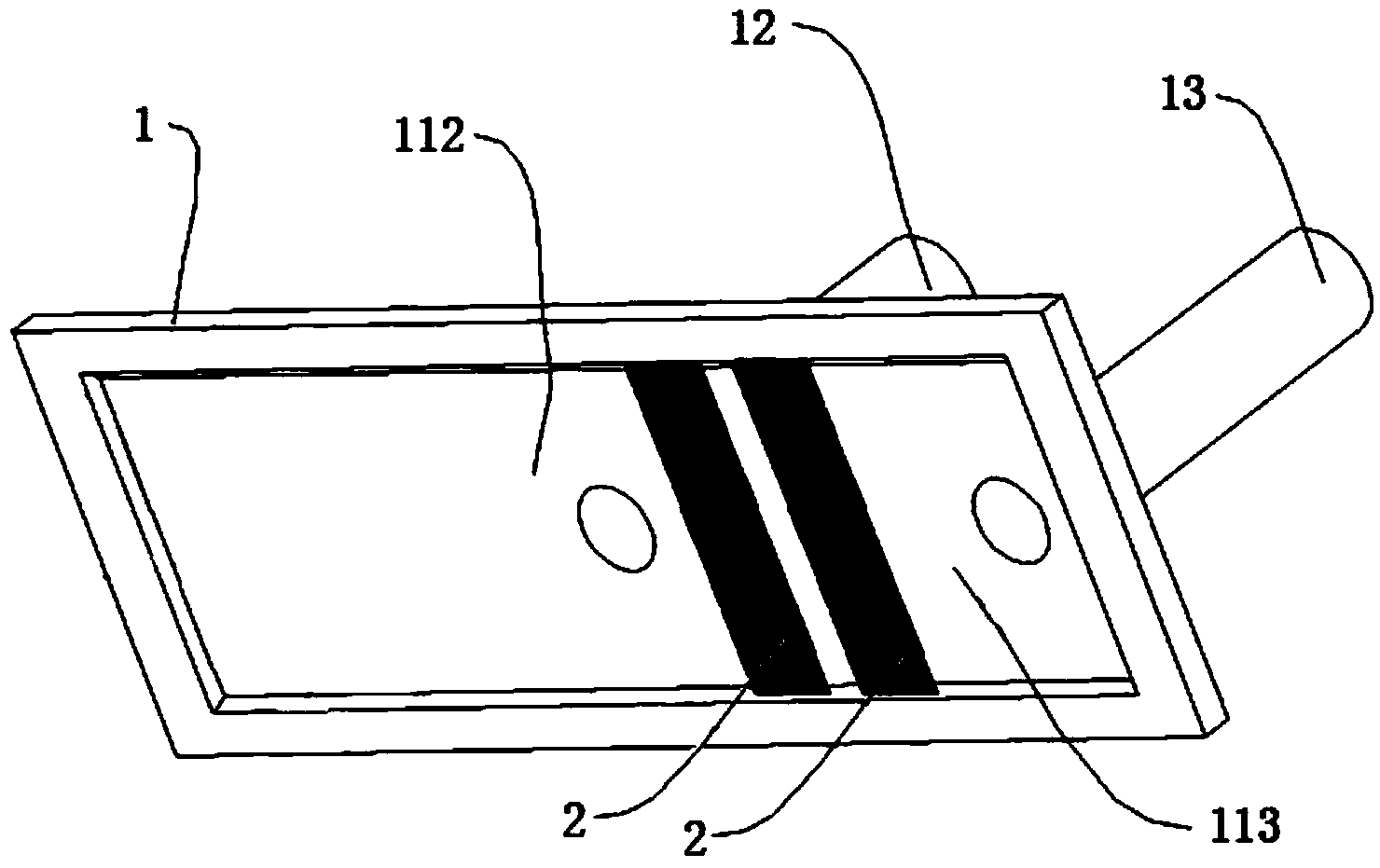

[0036] In one aspect, the present invention provides a piezoelectric inkjet head, such as Figure 1 to Figure 7 As shown, it includes a nozzle base 1, a fluid tank plate 2, a nozzle plate 3 (or 3’), a piezoelectric ceramic driver 4 and a drive circuit device (not shown), wherein:

[0037] There is a groove on the lower end surface of the nozzle base 1, and the nozzle plate 3 (or 3') is covered on the groove to form an ink chamber 11, and the upper end surface of the nozzle base 1 is provided with ink communicating with the ink chamber 11. The inflow pipeline 12, the ink outflow pipeline 13, and the nozzle base 1 can be injection molded, which is completed at one time, and the process is simple and reliable;

[0038] The fluid tank pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com