Closed-circuit recycling process of waste gas and waste residue generated during production of brown fused alumina and calcium carbide

A closed-loop, brown corundum technology, used in waste treatment, solid waste removal, inorganic chemistry, etc., to achieve the effect of huge market capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

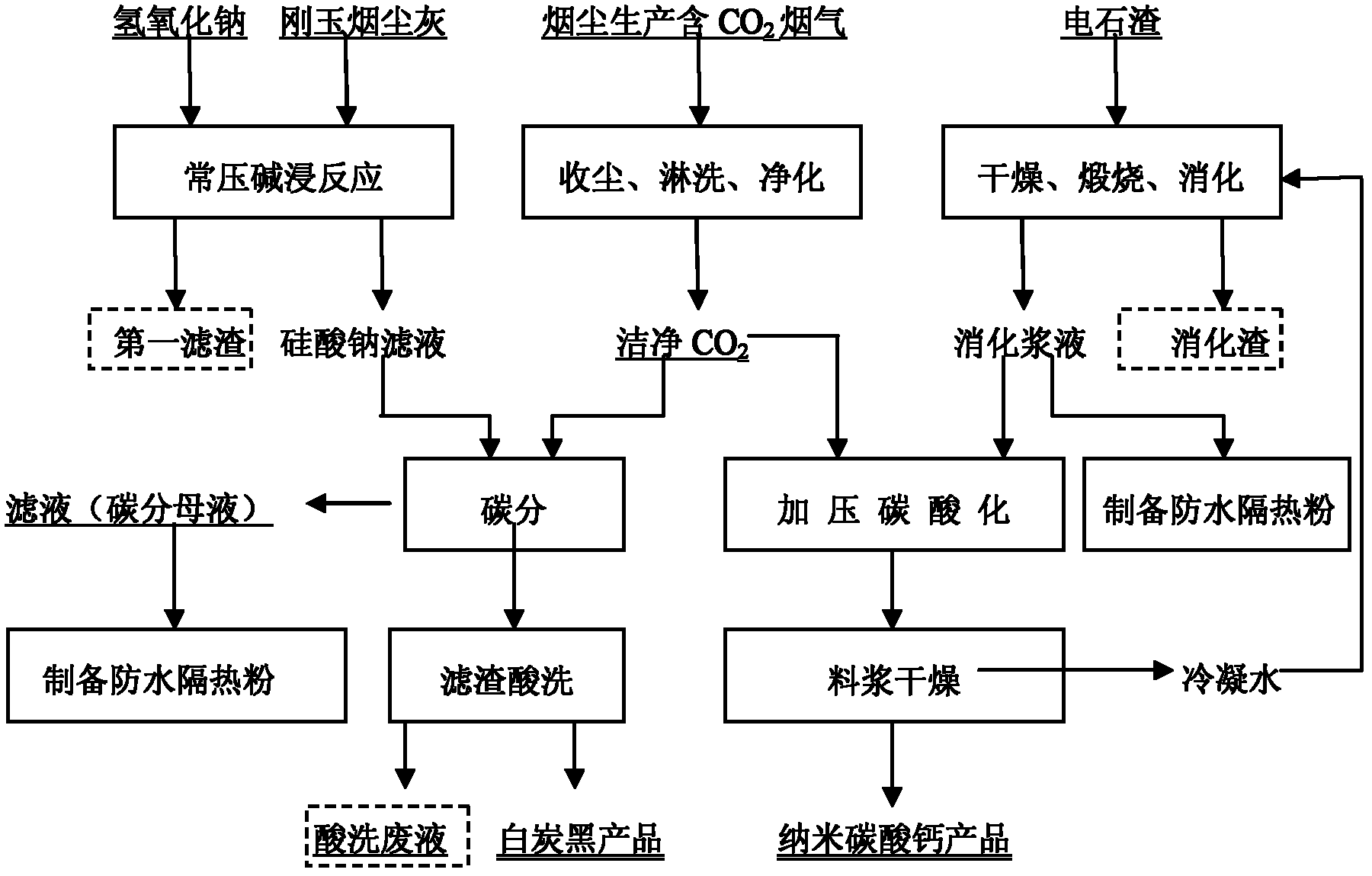

[0023] The dust collected in the production of brown fused alumina, the calcium carbide slag generated in the calcium carbide industry, and the CO contained in the production process of brown fused alumina 2 Flue gas is used as raw material to produce high-grade aluminum-containing silica and nano-calcium carbonate.

[0024] The technological process of this embodiment sees attached figure 1 .

[0025] In the first step, the CO containing CO produced in the production of brown corundum and calcium carbide 2 The flue gas is purified and recovered, and is ready for use. The flue gas purification is to purify the flue gas through the gravity dust collector, cyclone dust collector, and leaching tower in sequence, and then enter the gas-water separator to remove most of the water and then store it. in CO 2 Stand-by in the gas storage tank;

[0026] In the second step, the soot ash produced in the production of brown corundum is mixed with sodium hydroxide solution, and then fil...

Embodiment approach 2

[0030] In the first step, the CO containing CO produced in the production of brown corundum and calcium carbide 2 The flue gas is purified and recovered, and is ready for use. The flue gas purification is to purify the flue gas through the gravity dust collector, cyclone dust collector, and leaching tower in sequence, and then enter the gas-water separator to remove most of the water and then store it. in CO 2 Stand-by in the gas storage tank;

[0031]In the second step, the soot ash produced in the production of brown corundum is mixed with sodium hydroxide solution, and then filtered after alkali leaching reaction under normal pressure to obtain a low aluminum sodium silicate solution and the first filter residue, which is used for later use; the alkali The liquid-solid ratio of the soaking reaction system is 4: 1, the mass percentage concentration of sodium hydroxide solution is 25%, 110 ℃ of reaction temperature, 2 hours of reaction time; The first step is stored in CO 2...

Embodiment 3

[0035] In the first step, the CO containing CO produced in the production of brown corundum and calcium carbide 2 The flue gas is purified and recovered, and is ready for use. The flue gas purification is to purify the flue gas through the gravity dust collector, cyclone dust collector, and leaching tower in sequence, and then enter the gas-water separator to remove most of the water and then store it. in CO 2 Stand-by in the gas storage tank;

[0036] In the second step, the soot ash produced in the production of brown corundum is mixed with sodium hydroxide solution, and then filtered after alkali leaching reaction under normal pressure to obtain a low aluminum sodium silicate solution and the first filter residue, which is used for later use; the alkali The liquid-solid ratio of the immersion reaction system is 3: 1, the mass percent concentration of sodium hydroxide solution is 50%, 120 ℃ of reaction temperatures, 1.5 hours of reaction time; The first step is stored in CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com