Patents

Literature

169results about How to "Large market capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

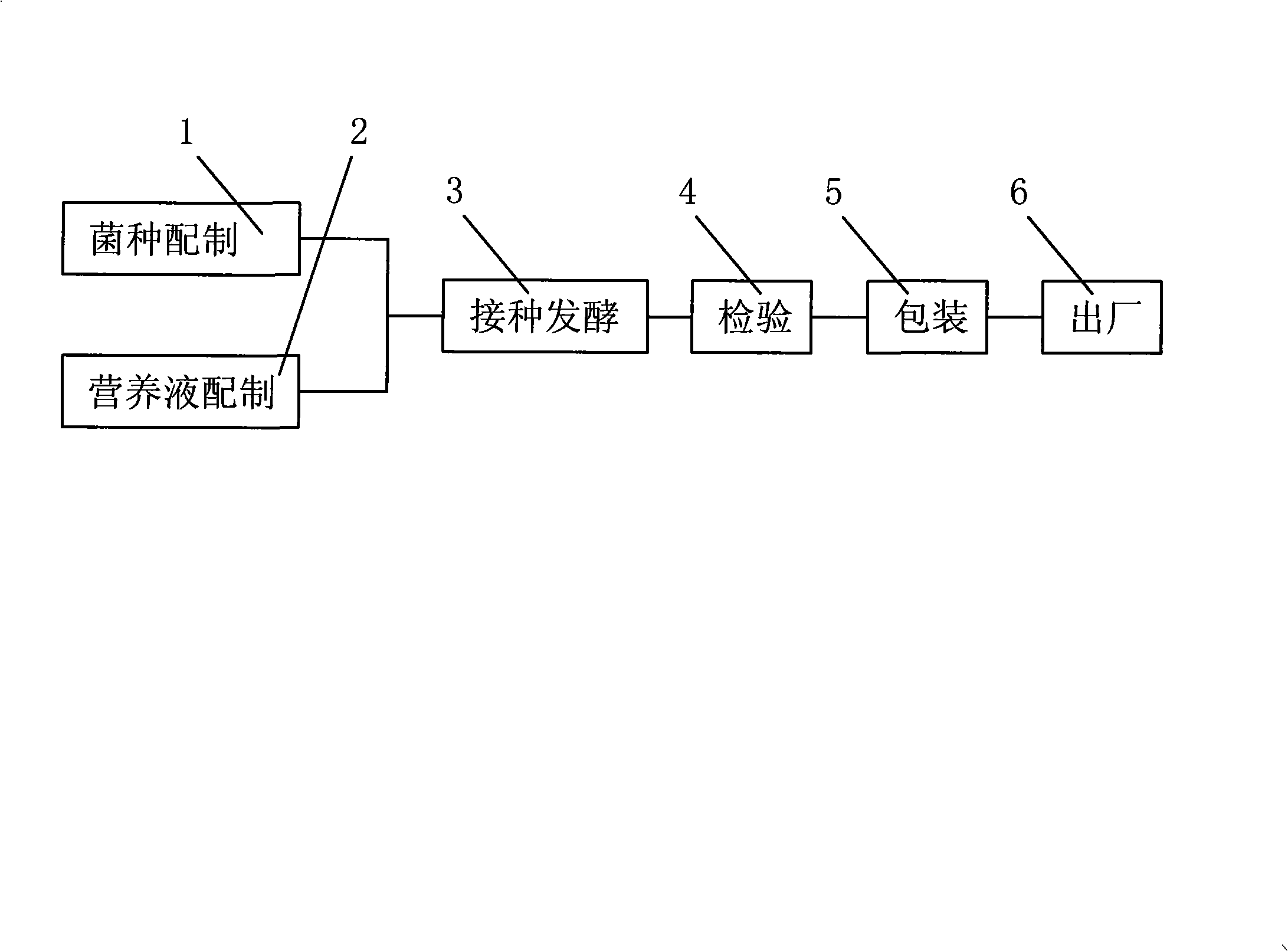

Microbial feed additive liquid agent for pig and preparation technique

InactiveCN101341927APromote digestion and absorptionImprove conversion rateAnimal feeding stuffBacillus licheniformisNutrient broth

The invention discloses microbial feed additive used for pigs, and a preparation process thereof; the prescription is as follows: 1 portion of bacillus licheniformis, 1 portion of bacillus subtilis, 2 portions of bifidobacterium, 2 portions of enterococcus faecalis, 2 portions of enterococcus faecium, 1 portion of boas-oppler bacillus, 1 portion of lactobacillus casei, 1 portion of lactobacillus lactis, 1 portion of plant lactobacillus, 1 portion of candida utilis, 1 portion of saccharomyces cerevisiae, 80kg to 100kg of panela, 3kg to 5kg of salt, 5kg to 8kg of vinegar, 3kg to 5kg of lysine, 1kg to 2kg of methionine, and 1000L of pure water; the weight of each portion of strain is 2g to 5g. The preparation process is as follows: strain preparation, nutrient broth preparation, inoculated fermentation and check. The invention reduces the quantity of the used individual strain, and the strain quality is safe and reliable. The production process is simple and feasible, the effect is obvious; therefore, the invention has promotion value.

Owner:罗志诣

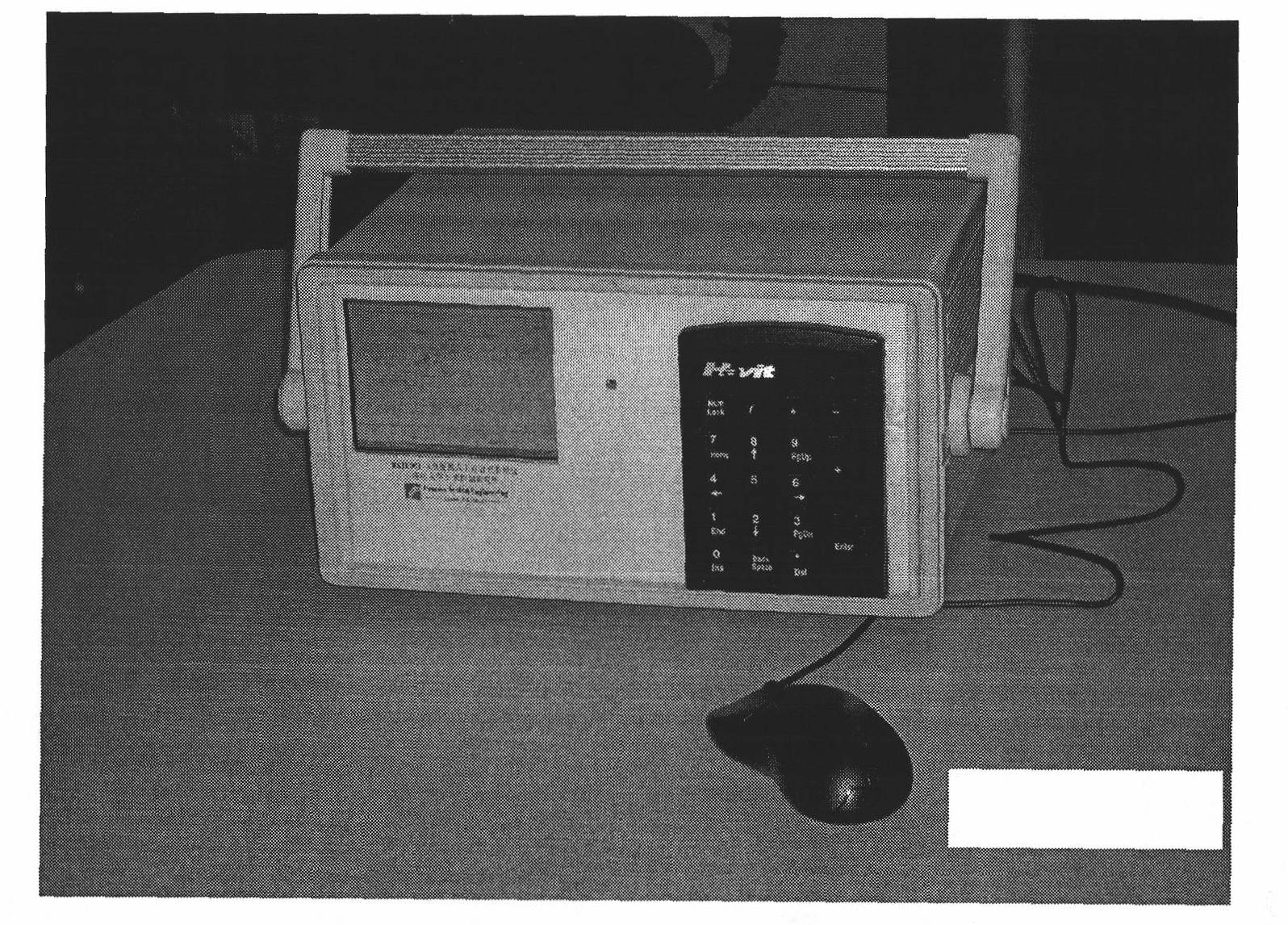

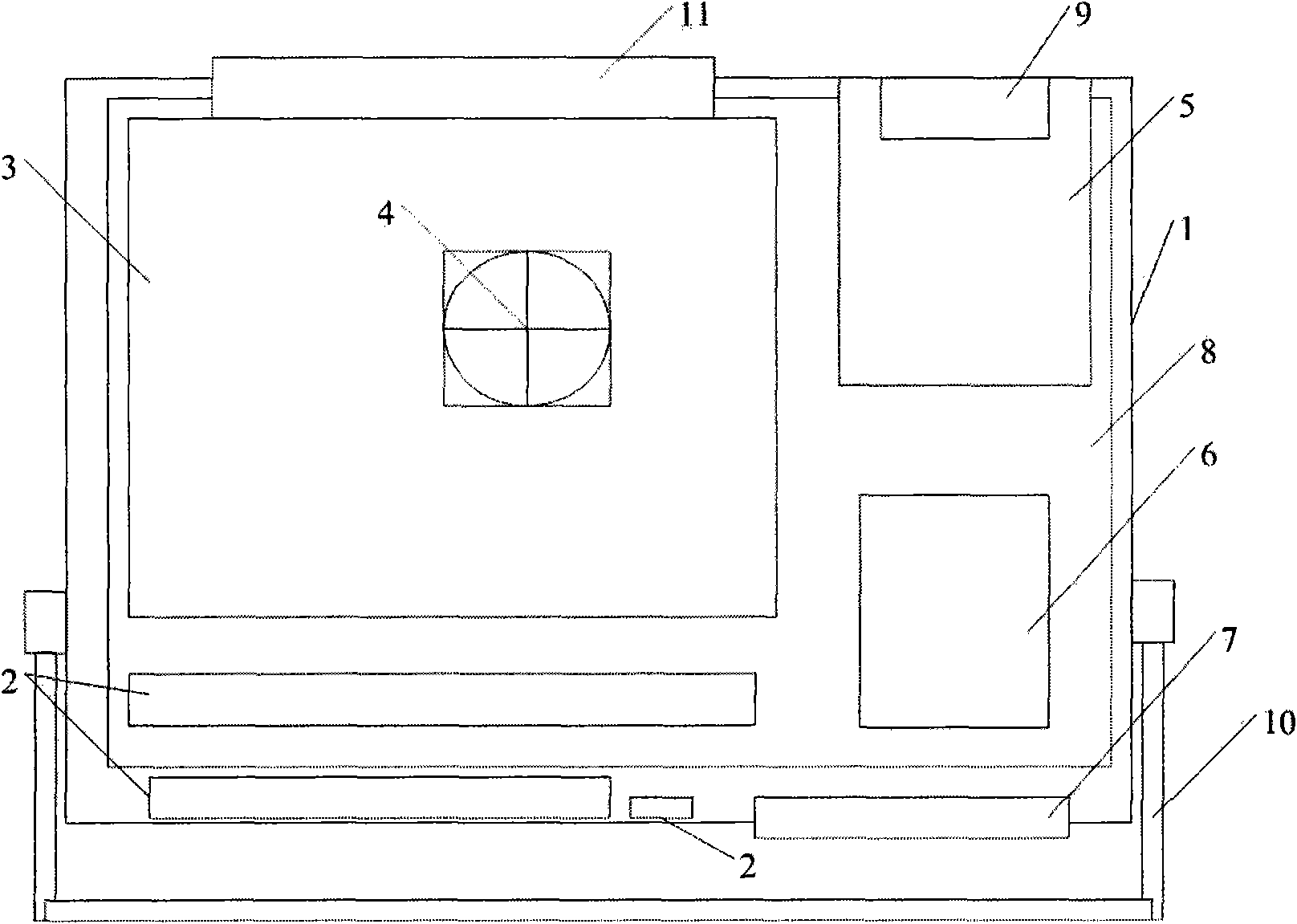

Portable fault diagnosis tester applied to petrochemical production device

InactiveCN101825876AFunction increaseReduce volumeProgramme controlComputer controlCommunication interfaceLiquid-crystal display

The invention discloses a portable fault diagnosis tester applied to a petrochemical production device, comprising an instrument shell, a hardware mainboard, a CPU (Central Processing Unit), a memory, a hard disk, a power supply, a rechargeable battery, a minisize liquid crystal display, a display card, a minisize keyboard, various communication interfaces, a plugin multi-path AD / DA data collector and the like. The fault diagnosis tester can uninterruptedly collect on-site data all day long through simple system arrangement, and the sampling frequency can be set. The invention has small volume, light weight and convenient carrying, solves the bottleneck problem that the fault diagnosis technology is applied to a practical industrial field, has the advantage that the fault diagnosis testercan be used after a network cable is plugged especially for a petrochemical production device provided with a DCS system or a PLC (Programmable Logic Controller) or an intelligent instrument, therebythe invention is very convenient to use.

Owner:ZHEJIANG UNIV

Method for producing architectural gypsum powder by using phosphogypsum

This invention relates to a method for producing construction gypsum powder from ardealite. The method comprises: (1) prehomogenizing ardealite waste residue, placing in a continuous high-efficiency calcining kiln, and calcining; (2) taking out and aging naturally for 7-15 d; (3) milling into 100-200 mesh powder. This invention uses a unique calcination technique to produce high performance construction gypsum from ardealite waste residue, and has such advantages as no secondary pollution and saved water resource.

Owner:宁夏建筑材料研究院(有限公司)

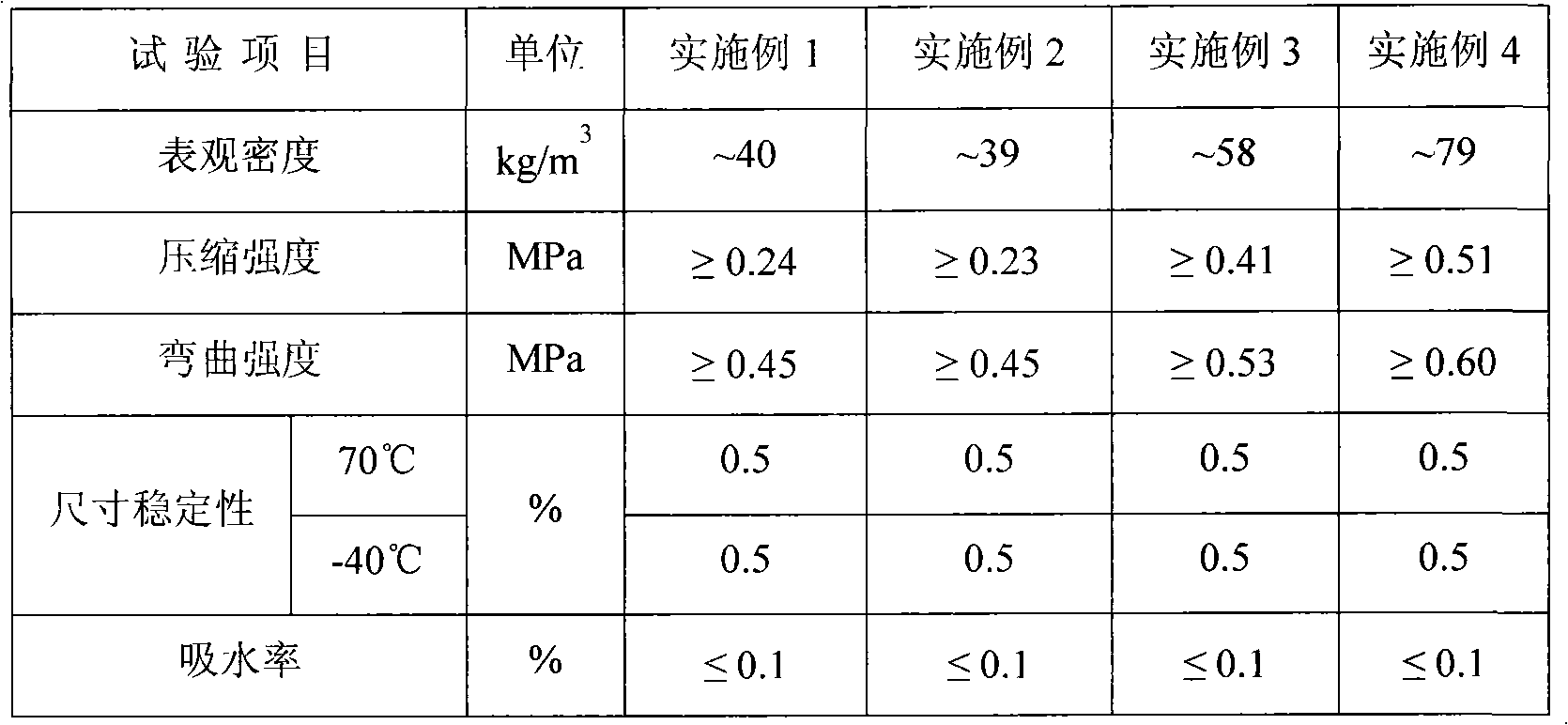

Biodegradation expanded plastic and method for manufacturing same

InactiveCN101245175ANo difficult recycling issuesNo atmosphere damage problemThermal insulationCopolymer

The invention relates to a biological degradation foamed plastic which comprises the following components and contents: polylactic acid resin: 100 portions; polylactic acid plasticizer: 10 to 20 portions; polyhydroxy alkanoates multipolymer: 10 to 50 portions; corn starch: 20 to 60 portions; foaming agent: 8 to 17 portions; blowing promoter: 2 to 4 portions; lubricant: 0.8 to 1.2 portions; antiager: 0.45 to 0.70 portion, and the amount is calculated by weight. The biological degradation foamed plastic of the invention also provides a manufacturing method for manufacturing the biological degradation foamed plastic. The biological degradation foamed plastic is characterized by low density, high specific strength, good shock absorption performance and complete biological degradation, can be applied not only in the shock absorption packages of industrial products, such as domestic appliances, electron, instruments, industrial fittings and glass / ceramic etc., but also in a field that needs heat preservation and thermal insulation, thus the biological degradation foamed plastic of the invention is a new environmental-friendly packaging material.

Owner:陈俭秋

Oolong tea processing method

The invention discloses an oolong tea processing method. According to the processing method, a deterioration process is combined with a fermentation process to prepare the oolong tea which is light orange yellow in soup, aromatic in fruit flavor, sweet in taste, and continuously pleasant in taste. The processing method comprises the following technological steps: picking of fresh tea leaves; deterioration; cooling of the tea leaves; fine manipulation of the tea leaves; re-deterioration; rolling; fermentation; drying; finishing. The processing method disclosed by the invention can be used for breaking through the conventional processing method and reducing the content of tea polyphenol and caffeine in the tea; due to content reduction of the tea polyphenol, the fresh degree of the tea is reduced, so that the mellowness of the tea is improved; due to the content reduction of the caffeine, the sweet degree of the tea is improved, so that the tea preferably satisfies the taste requirements of people in drinking.

Owner:YANGSHAN COUNTY DIYIFENG TEA

Microemulsion

InactiveCN101036457AGood synergistic effectGood environmental compatibilityBiocideAnimal repellantsMicroemulsionBULK ACTIVE INGREDIENT

The invention relates to a pesticidal microemulsion, comprising agricultural active ingredients and synergy and / or toxicity antagonistic effective amount of natural (macromolecular) materials. The invention also relates to the preparation method of the pesticidal microemulsion and the application of the natural (macromolecular) material in the pesticidal microemulsion used as synergist and / or toxicity antagon. The pesticidal microemulsion in the invention is provided with remarkable synergistic effect and improved safety property in utilization.

Owner:北京华京五方实用纳米科技开发有限公司

Bayer process red mud processing method

The invention discloses a treatment method of Bayer method red mud, comprising the following steps: (a) the red mud is sorted by a beneficiation method and divided into three parts, namely, rough sand, fine sand and soil mortar; (b) milling grinding and settling separation are carried out to the rough sand in the step (a) to obtain rough sand one and tailing ore slurry one; (c) after the rough sand one in the step (b) and the fine sand in the step (a) are mixed, magnetic separation is carried out to obtain iron powder and quartz powder; (d) the iron powder obtained in the step (c) is refined and sorted by a magnetic separator to obtain fine iron powder F and fine iron powder P; and (e) the soil mortar in step (a) is pulse magnetic separated to obtain tailing ore slurry and fine iron powder PI. The method can reduce 35-40 percent of red mud discharge, the iron element effective utilization rate can reach more than 70 percent, and the monomer quartz extraction yield can reach 80 percent. The method optimizes the production flow of alumina by using a combination method, reduces the red mud discharge, protects the environment, reduces the production cost of alumina and improves the alumina production capacity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

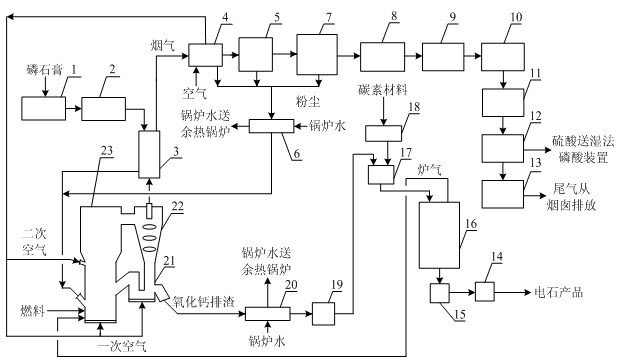

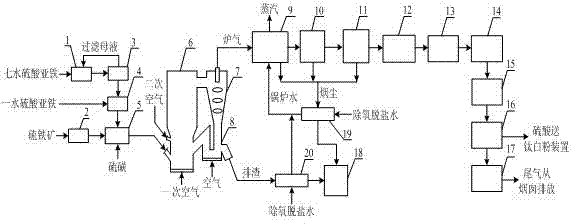

Method for producing sulfuric acid and co-producing calcium carbide by phosphogypsum

ActiveCN102442650ASolve the problem of difficult resource utilizationAchieve recyclingSulfur compoundsEnergy inputCycloneDecomposition

The invention relates to a method for producing sulfuric acid and co-producing calcium carbide by phosphogypsum, and belongs to the technical field of environmental protection. According to the method, phosphogypsum is subjected to a water washing and purification pretreatment by a multi-stage cyclone; then the pretreated phosphogypsum is dried and dewatered; the dewatered phosphogypsum enters a multi-stage suspension heat exchanger to carry out preheating; the hot state gypsum enters a circulating fluidized bed decomposing furnace, then primary air and secondary air are respectively introduced to carry out decompositions; high temperature sulfur dioxide-containing flue gas discharged from the top of the circulating fluidized bed decomposing furnace enters the multi-stage suspension heat exchanger to carry out heat exchanging and cooling with the cold state gypsum; dust in the cooled hot flue gas is removed by a multi-stage dust removing device; the dust-removed flue gas enters an acid washing and purification system to further remove the dust and the gaseous impurities in the flue gas; the purified and cleaned flue gas is conveyed into an acid preparation system to produce the sulfuric acid product; the hot state calcium oxide discharged from the bottom of the circulating fluidized bed decomposing furnace is cooled, and conveyed into a sealed calcium carbide furnace to carry out an electrical arc reaction with a carbon material to generate the calcium carbide product; the high temperature furnace gas discharged from the top of the sealed calcium carbide furnace is directly conveyed into the decomposing furnace, wherein the high temperature furnace gas is adopted as a fuel and a reducing agent. The method of the present invention has good environmental protection benefits and strong economic advantages.

Owner:CHINA PETROCHEMICAL CORP +1

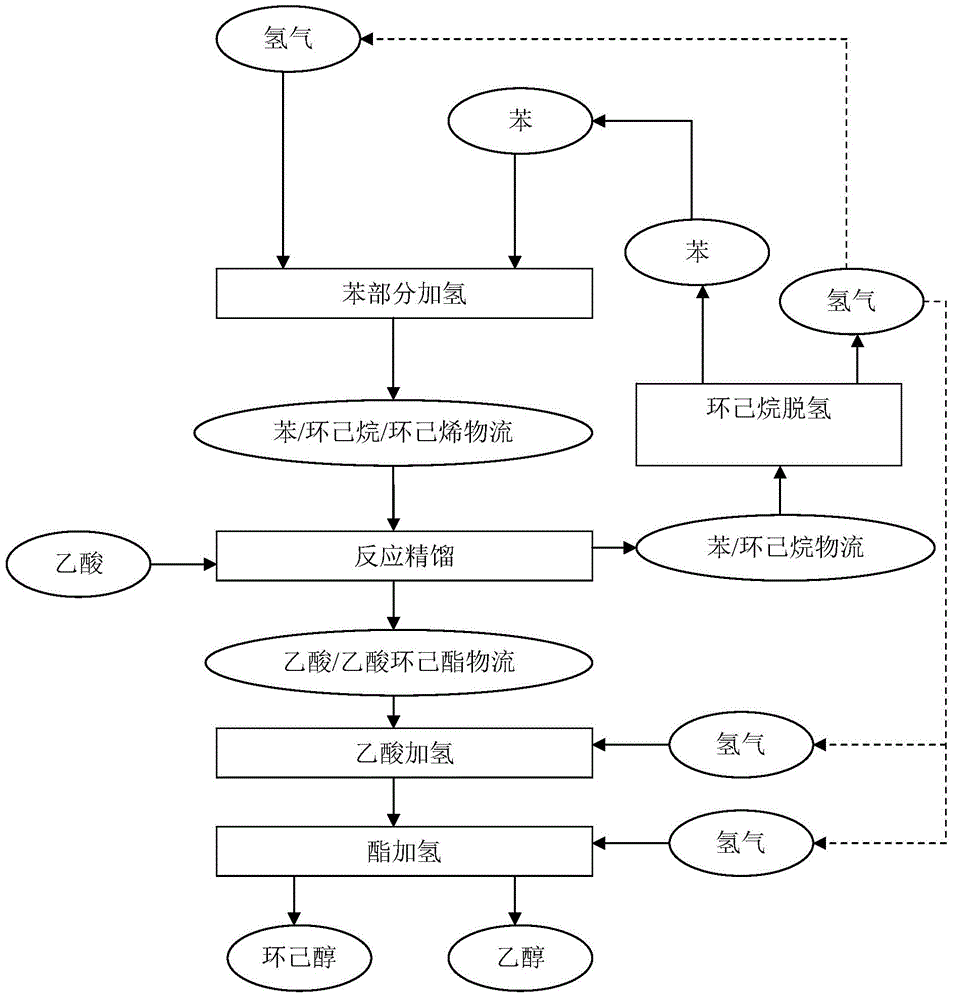

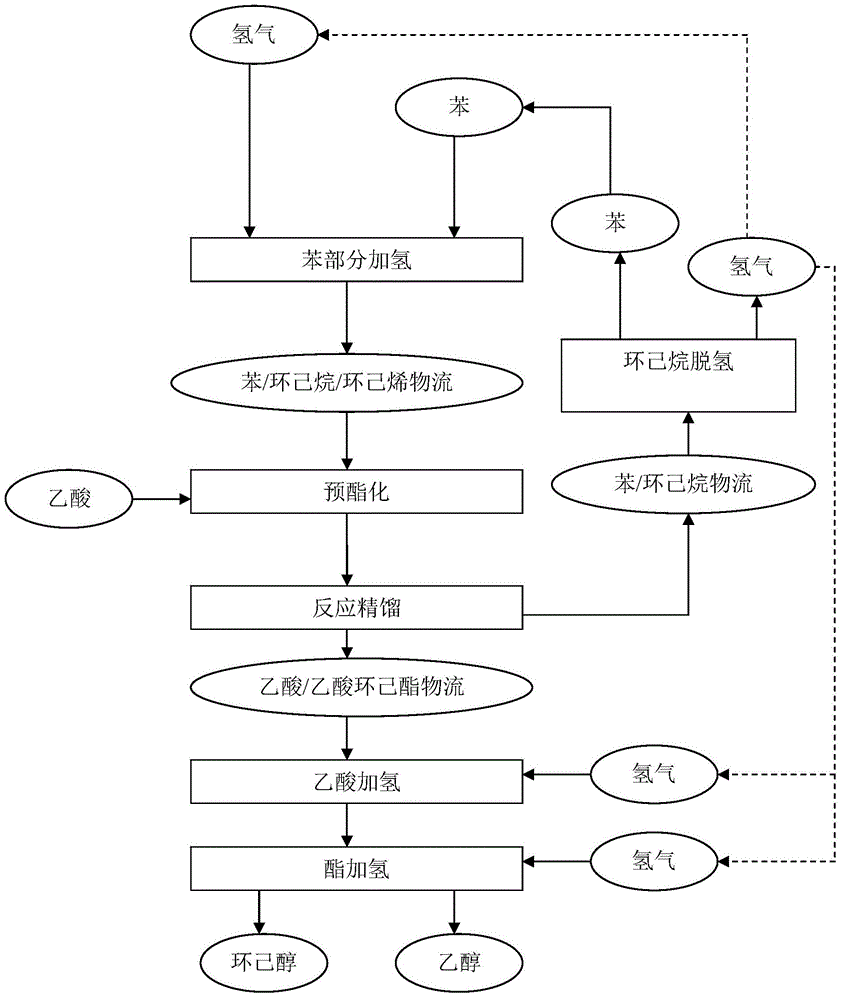

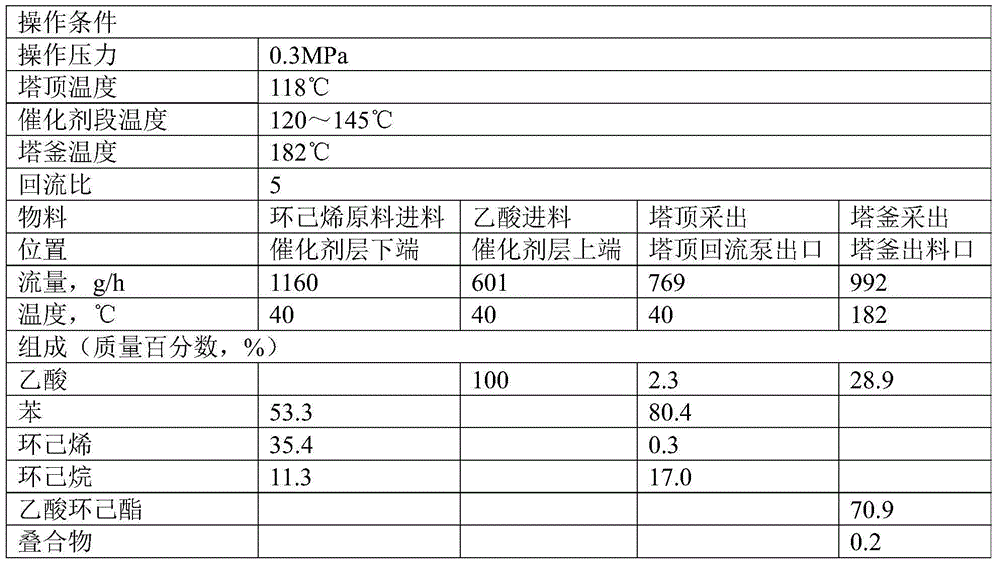

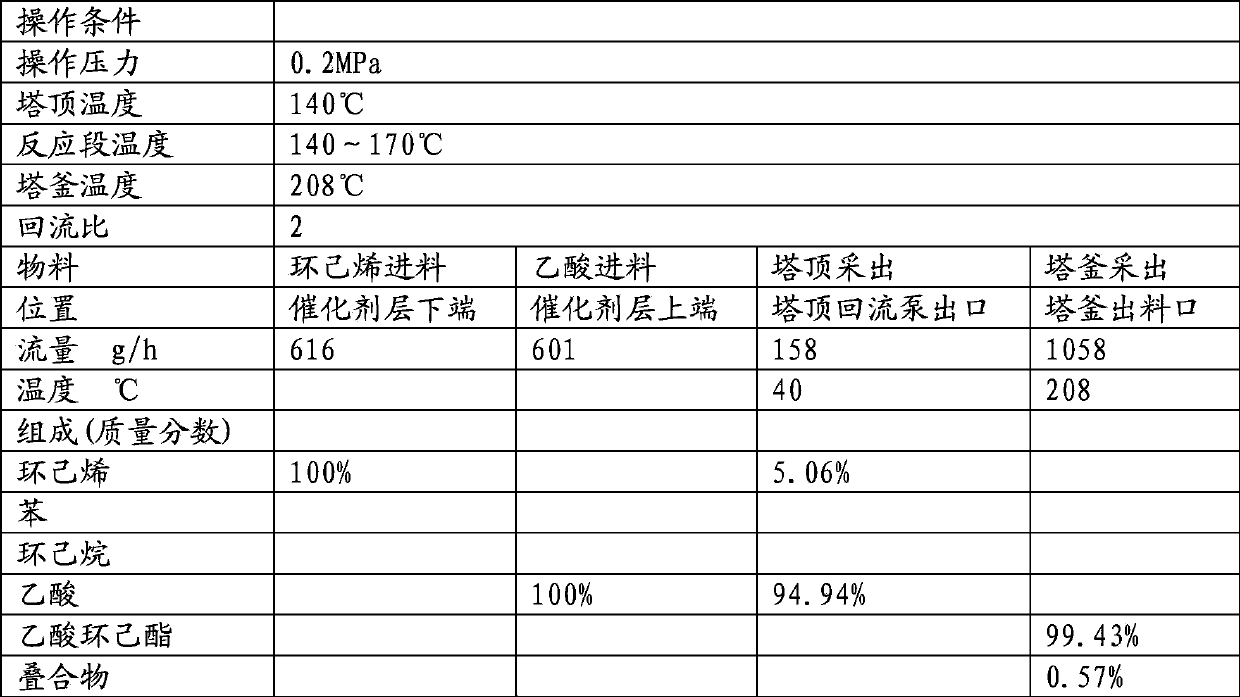

Method for coproducing cyclohexanol and alkanol

InactiveCN104557465AImprove efficiencyLow costOrganic compound preparationCarboxylic acid esters preparationBenzeneAcetic acid

The invention provides a method for coproducing cyclohexanol and alkanol. The method comprises the following steps: preparing benzene and / or cyclohexane into cyclohexene, carrying out addition-esterification on the cyclohexene in a catalytic distillation tower, obtaining carboxylic acid / cyclohexyl carboxylate material flow at the bottom of the tower, hydrogenating the material flow to obtain the cyclohexanol and the alkanol. The esterification and hydrogenation reactions in the method have high conversion rate and selectivity, and high atom economy; the process is environment-friendly; the alkanol is coproduced when the cyclohexanol is produced, in particular, when acetic acid is used, the cheap acetic acid is converted into ethanol with high cost and large market capacity in an indirect manner, so as to increase the economical efficiency of the process.

Owner:CHINA PETROLEUM & CHEM CORP +1

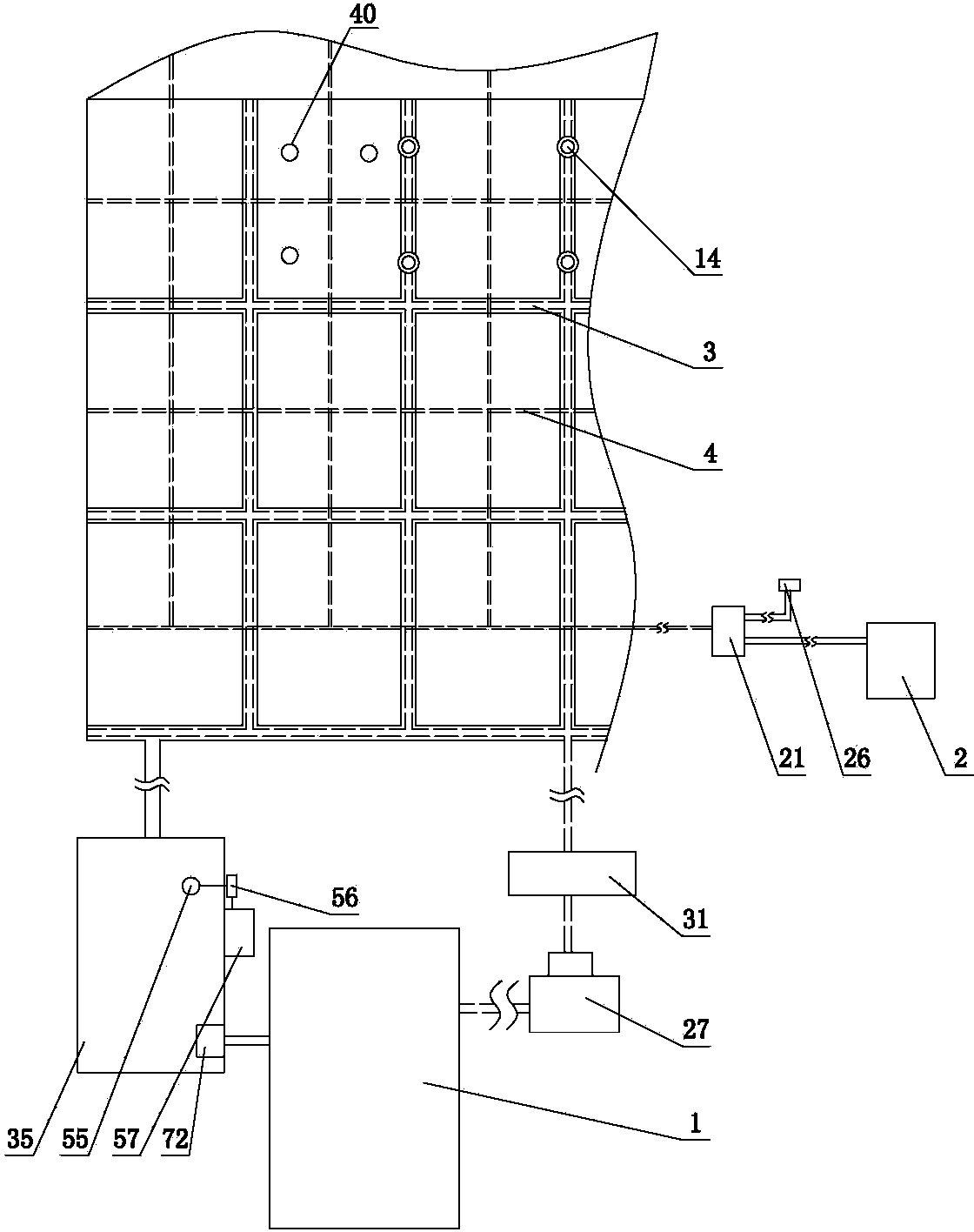

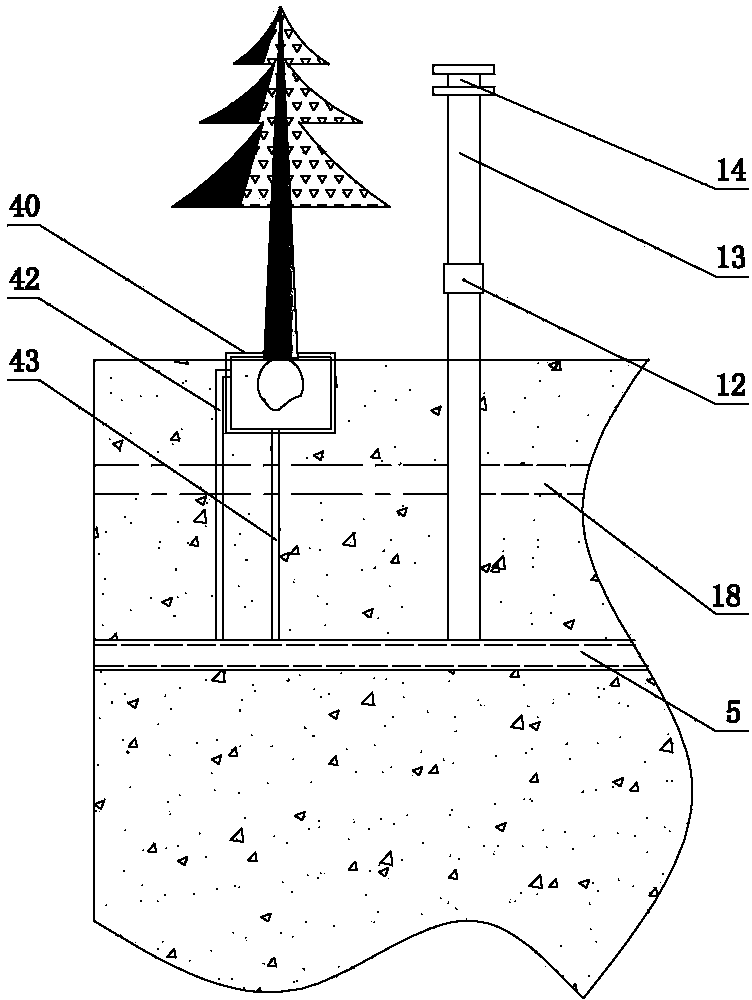

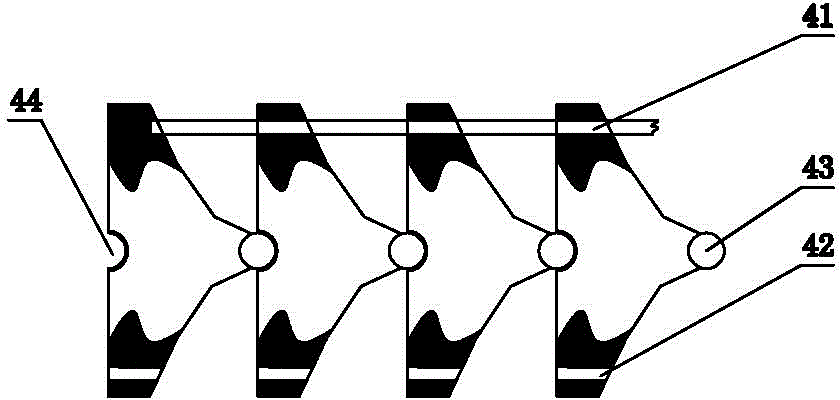

Inferior land green vegetation ecological reconstruction system

ActiveCN104255108AEcologically goodThe renovation plan is reasonableWatering devicesDirect liquid fertiliser deliveryWater storageAlkali soil

An inferior land green vegetation ecological reconstruction system comprises a water storage pond, an organic nutrient solution pond, a water supply and discharge pipe network, a soil fertility improving pipe network and a tree variety transplantation protection device; the tree variety transplantation protection device is arranged inside grids of the water supply and discharging pipe network; nodes of the soil fertility improving pipe network are arranged inside grids of the water supply and discharging pipe network. The inferior land green vegetation ecological reconstruction system has the advantages of being reasonable in structure and reliable in performance and achieving water resource recycling due to recycle washing of the saline-alkali soil through water feeding and discharging of the system, overcoming disadvantages of other discharging pipes, improving the soil, reducing salt and alkali performance and being outstanding in zoology vegetation construction of salt and alkali areas and large in market capacity, wide in prospect and having great market and social values.

Owner:湖北天蓝地绿生态科技股份有限公司

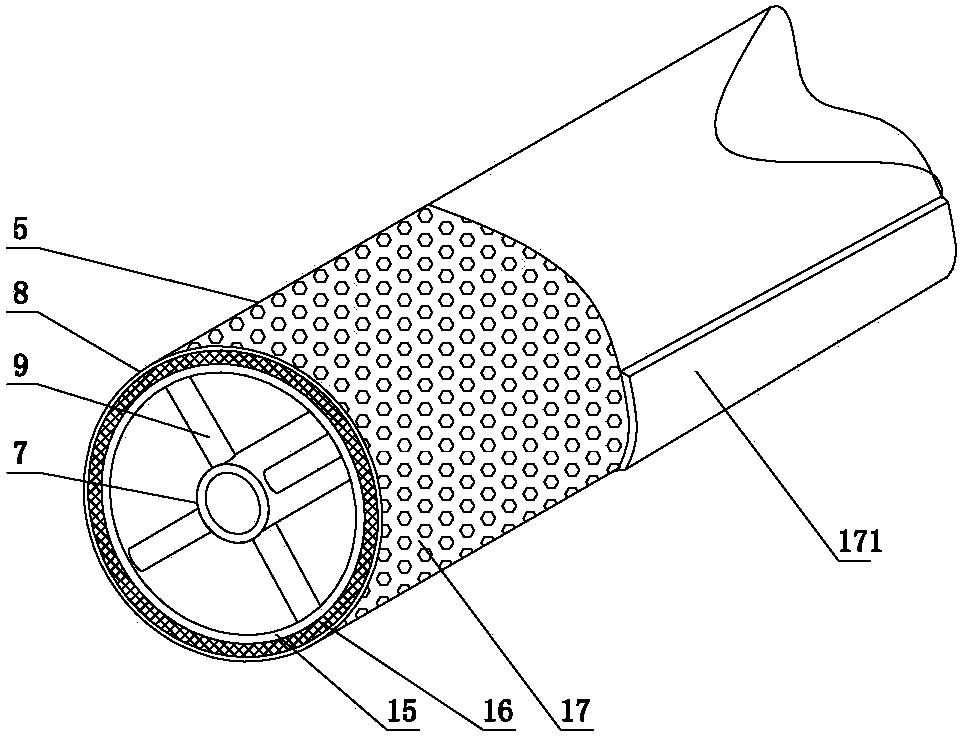

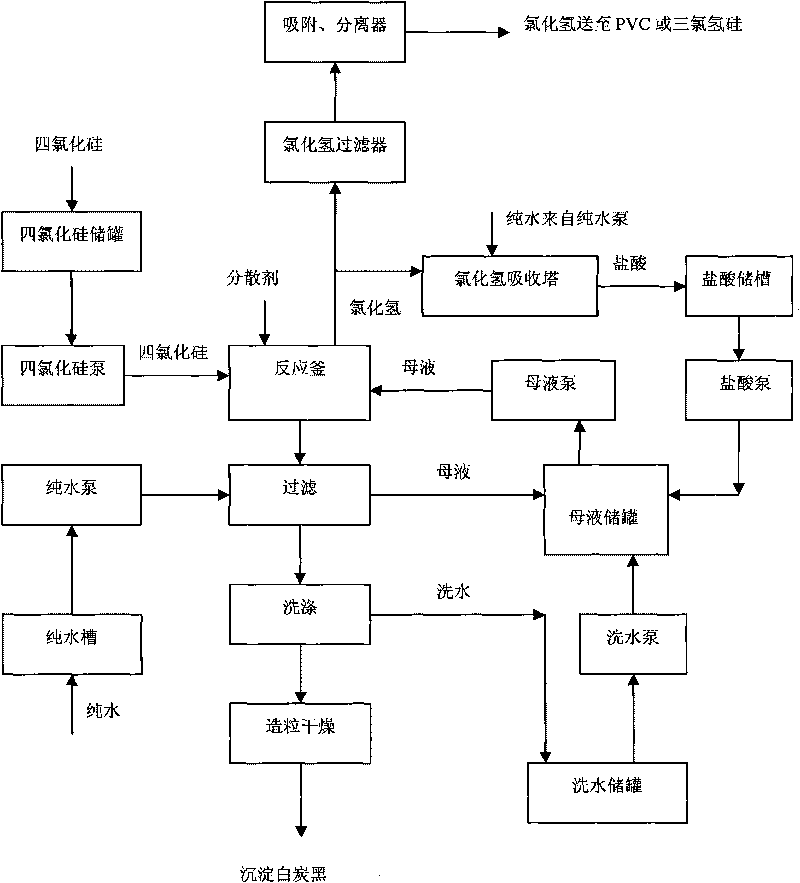

Process for producing precipitated white carbon black by silicon tetrachloride

InactiveCN101734667AIncrease porositySolve the pollution of the environmentSilicaHydrideRaw material

The invention belongs to a process for preparing white carbon black and in particular relates to a process for producing precipitated white carbon black by silicon tetrachloride. The process comprises the following steps: adding the silicon tetrachloride into 29 to 33 mass percent hydrochloric acid aqueous solution which contains a dispersant, controlling the temperature to between 28 and 45 DEG C for reaction to generate silica sol and chlorine hydride gas, standing and ageing the silica sol to form colloidal white flocculent sediment, filtering, separating and washing the sediment, and pelletizing and drying the sediment to obtain the precipitated white carbon black. The process has short flow, relatively simple production equipment and process control, and available raw materials, effectively utilizes the silicon tetrachloride, totally reclaims the product chlorine hydride, reduces the processing expense, the amount of waste acid and the environmental pollution, and has low production cost, wide application and large market capacity.

Owner:昊华宇航化工有限责任公司

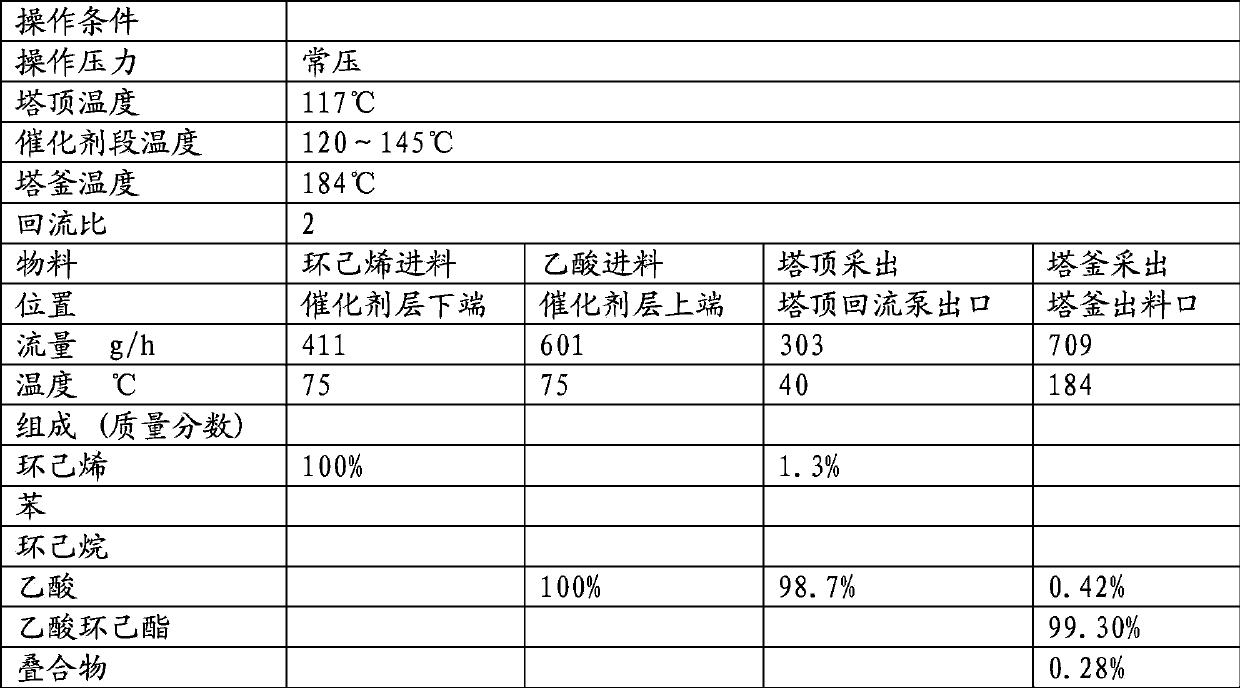

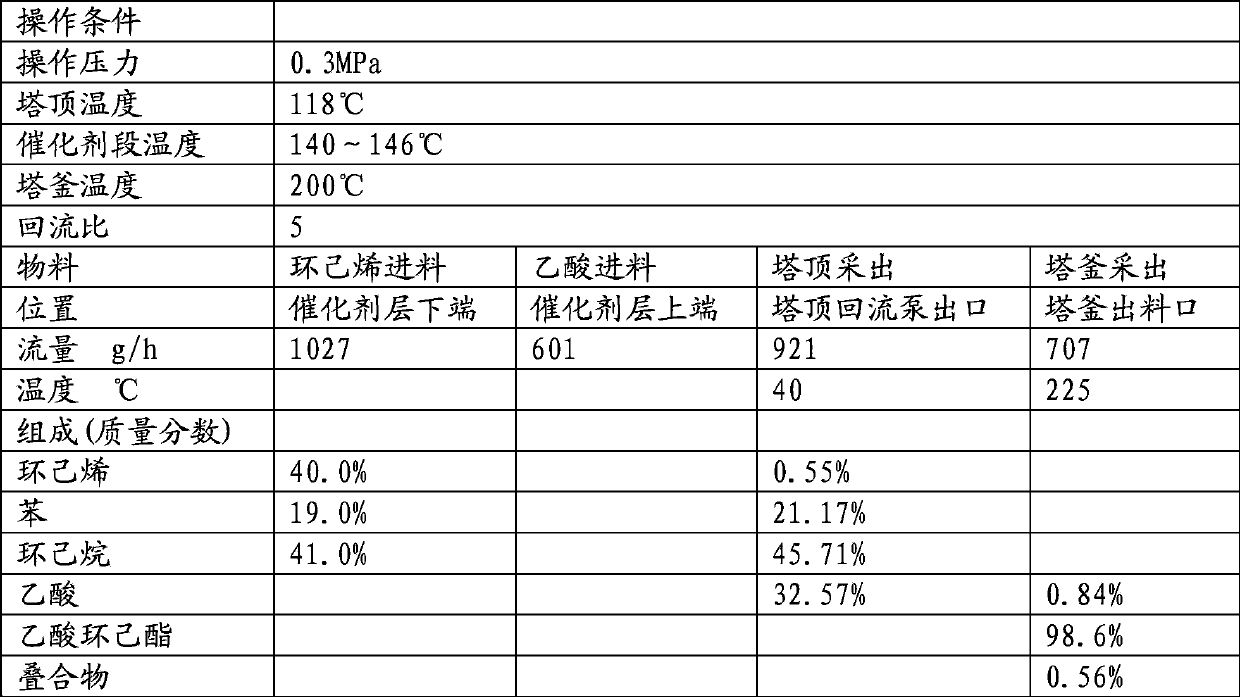

Method for coproducing cyclohexanol and ethanol

ActiveCN103664529AHigh selectivityAtom utilization is highOrganic compound preparationCarboxylic acid esters preparationAcetic acidCyclohexene

The invention relates to a method for coproducing cyclohexanol and ethanol, which comprises the following steps: carrying out addition esterification reaction on acetic acid and cyclohexene by using reaction rectification to prepare cyclohexyl acetate; and hydrogenating the cyclohexyl acetate to coproduce the cyclohexanol and ethanol. The method can be used for coproducing the cyclohexanol and ethanol at high efficiency and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cyclohexanol and epoxide

The present invention relates to a method of preparing the cyclohexyl alcohol epoxide. The method is characterized in that the amount of the organic compound catalyst containing the transition metal is only 5 to 500 ppm of the total weight of materials; the olefin is added in the cyclohexyl oxide compound containing the cyclohexyl hydrogen peroxide; the molar ratio between the olefin and the cyclohexyl hydrogen peroxide is between 0.2 and 20 to 1; under the pressure of 0.1MPa to 6.0MPa and at the temperature between 0 and 200 DEG C, the epoxidation reaction is done for 10 to 20 minutes to prepare the cyclohexyl alcohol and epoxide. The present invention uses the oxygen decomposed from the cyclohexyl hydrogen peroxide for the epoxidation; thus the present invention not only saves the cost of the oxidant of the epoxidation of olefin, but also obviously improves the collection rate of the cyclohexanol and cyclohexanone decomposed from the cyclohexyl hydrogen peroxide. In particular, the dosage of the selected catalyst is minimal so as not to be recycled; the process is simple and the cost is low.

Owner:YUEYANG CHANGDE CHEM IND

Method for recycling titanium, silicon, aluminum, calcium and magnesium from titaniferous blast furnace slag by multistage acid leaching

InactiveCN103952567ALow costQuality improvementRecycling and recovery technologiesProcess efficiency improvementSlagManganese

The invention discloses a method for recycling titanium, silicon, aluminum, calcium and magnesium from titaniferous blast furnace slag by multistage acid leaching. The titaniferous blast furnace slag is especially titaniferous blast furnace slag obtained by carrying out iron making on vanadium titanomagnetite in Panzhihua regions. The method comprises the following steps: carrying out acid leaching (especially multistage acid leaching) on furnace slag to obtain an acid leaching solution and white carbon black; and carrying out an extraction technique on the acid leaching solution to obtain titanium, aluminum, calcium, magnesium, manganese, iron, chromium, vanadium and other useful metals. On the premise of recycling resources, the method implements cyclic utilization of waste (using waste of one technique as a raw material of another technique), eliminates waste discharge, obviously lowers the cost and enhances the recycling efficiency.

Owner:衡阳市金铭环境科技有限公司

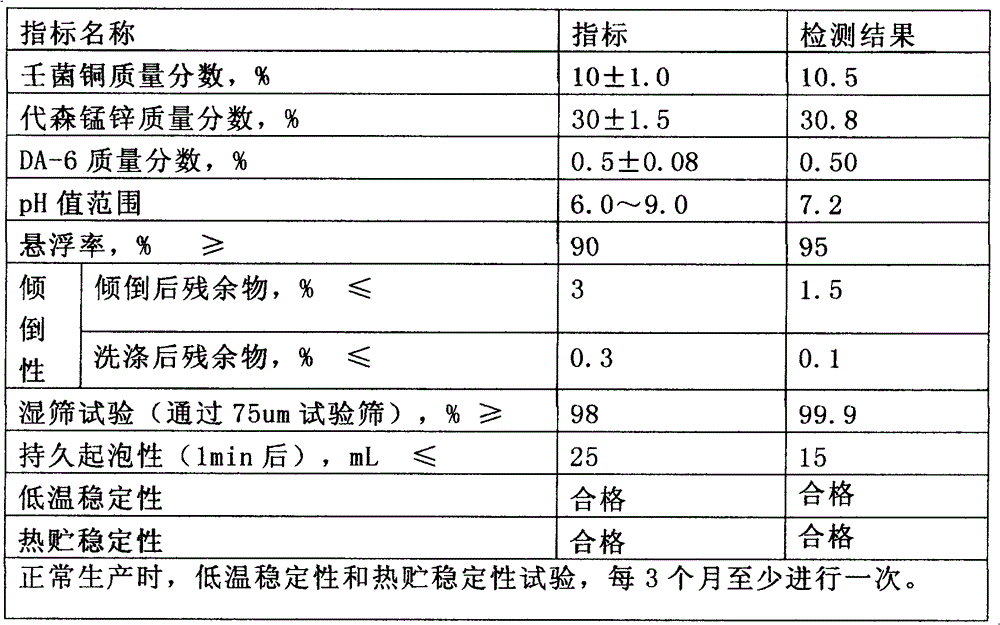

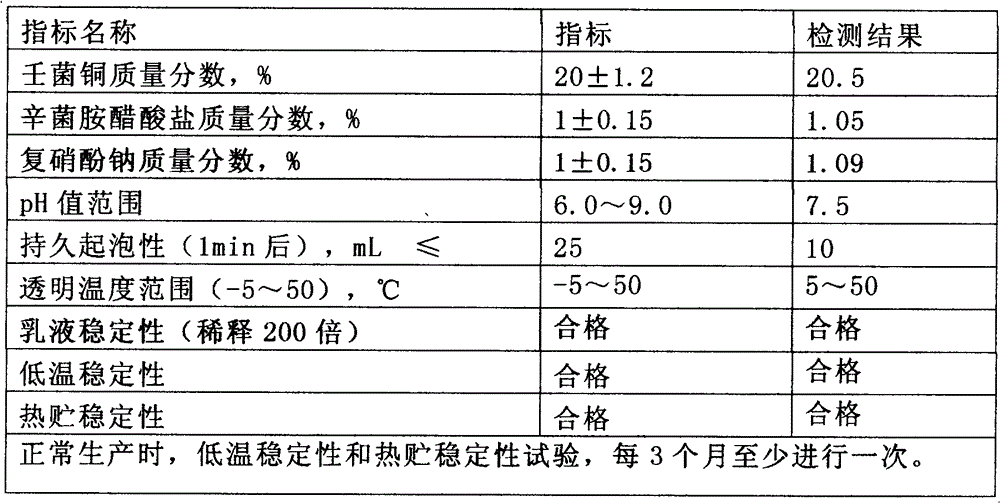

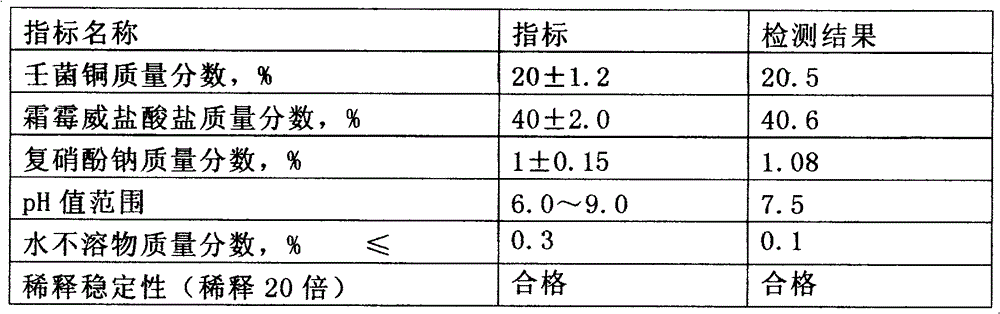

Cuppric nonyl phenolsulfonate-containing compound water-based pesticide and preparation method as well as application thereof

ActiveCN102742571AResidue reductionSolve residual problemsPlant growth regulatorsBiocideWater basedAnti freezing

The invention relates to a cuppric nonyl phenolsulfonate-containing compound water-based pesticide and a preparation method as well as application thereof. The cuppric nonyl phenolsulfonate-containing compound water-based pesticide contains cuppric nonyl phenolsulfonate, other pesticide active ingredients, auxiliary agents and water, wherein the auxiliary agents comprise solvent, cosolvent, an emulsifier, a dispersant, a wetting agent, a stabilizer, a penetrant, an anti-freezing agent, an anti-foaming agent and the like. The cuppric nonyl phenolsulfonate-containing compound water-based pesticide has an obvious synergistic effect; the problems of difficulty in compounding and difficulty in mixing in actual use of the cuppric nonyl phenolsulfonate are solved; the prevention and treatment range is expanded; various acting mechanisms are effectively combined to realize high-efficiency, quick and lasting treatment and prevention; and the safety in use is improved. The water-based pesticide has the advantages of low toxicity, high efficiency and environmental friendliness.

Owner:XIAN MODERN PESTICIDE

Aqueous antiseptic heat-insulating temperature keeping coating and its making method

The invention discloses a water-based antiseptic insulating paint, which comprises a substratum layer, an intermediate layer and a face layer, the formulation, process for preparation and use are provided for each layer of the paint. The paint has good antiseptic and heat insulation effects.

Owner:辽宁舜德国泰科工贸有限公司

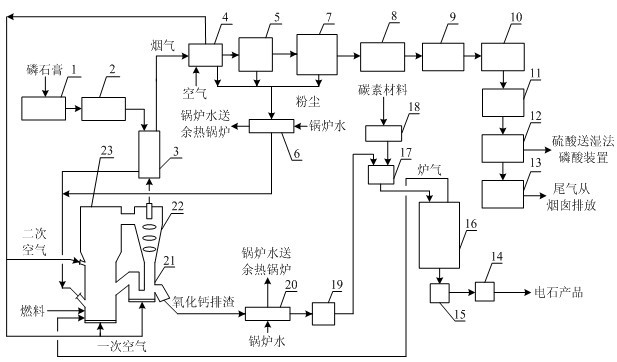

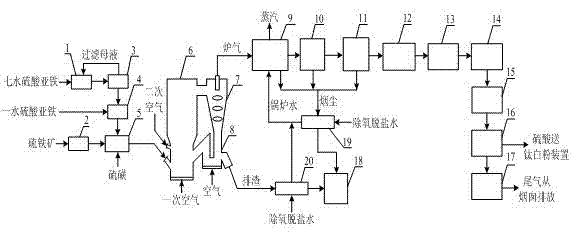

Method for joint production of sulfuric acid and refined iron powder by mixed burning of ferrous sulfate and pyrite

ActiveCN102502527AAchieve recyclingSolve the problem of difficult resource utilizationSulfur compoundsEnergy inputThermal stateFiltration

The invention discloses a method for joint production of sulfuric acid and refined iron powder by mixed burning of ferrous sulfate and pyrite and belongs to the technical field of environmental protection. The method comprises the following steps of: preparing ferrous sulfate monohydrate from ferrous sulfate heptahydrate by high-temperature crystal transformation, filtration and drying; drying and then feeding to drying equipment for free water removal together with ferrous sulfate monohydrate which is separated by concentrating waste acids from titanium dioxide production; drying and then feeding the mixture of ferrous sulfate monohydrate, pyrite and solid sulfur to a circulating fluid bed decomposition furnace; and introducing primary and secondary air for cyclic thermal decomposition. The high-temperature sulfur dioxide-containing flue gas discharged from the top of the circulating fluid bed decomposition furnace is subjected to cooling and dedusting treatment by a waste heat boiler, a cyclone dust collector and an electric dust collector and then fed into a dilute acid washing and purifying system and a double-transformation double-suction acid making system to produce sulfuric acid. The refined iron powder discharged from the circulating fluid bed decomposition furnace and the refined iron powder collected by the waste heat boiler, the cyclone dust collector and the electric dust collector, which have a thermal state w (Fe) of more than or equal to 60%, are cooled by a hot-material cooler and then fed into a refined iron powder bin. The method has good environmental and social benefits.

Owner:CHINA PETROCHEMICAL CORP +1

Method for producing jerusalem artichoke whole powder

The invention relates to the deep processing technology of jerusalem artichoke, in particular to a method for producing jerusalem artichoke whole powder, which solves the problems of simple process in the conventional method for producing the jerusalem artichoke whole powder, poor dissolubility and a large number of impurities of the jerusalem artichoke powder due to the single enzyme, damaged nutritional ingredients and flavor of products and the like. In the method, powder is prepared from natural and fresh jerusalem artichoke serving as a main raw material through the steps of cleaning, blanching, mashing, colloid milling, enzymolysis, homogenizing, sterilizing, centrifugation, micro-filtration, drying, powder collecting, sieving, packaging and product warehousing. In the method, a wet process is adopted, and the processes of blanching, enzymolysis and spray drying are introduced, so the problems of poor color and luster, mouthfeel and dissolubility of the conventional products are solved, the quality and yield of the products are improved, and the production cost is reduced.

Owner:山西金绿禾燕麦研究所

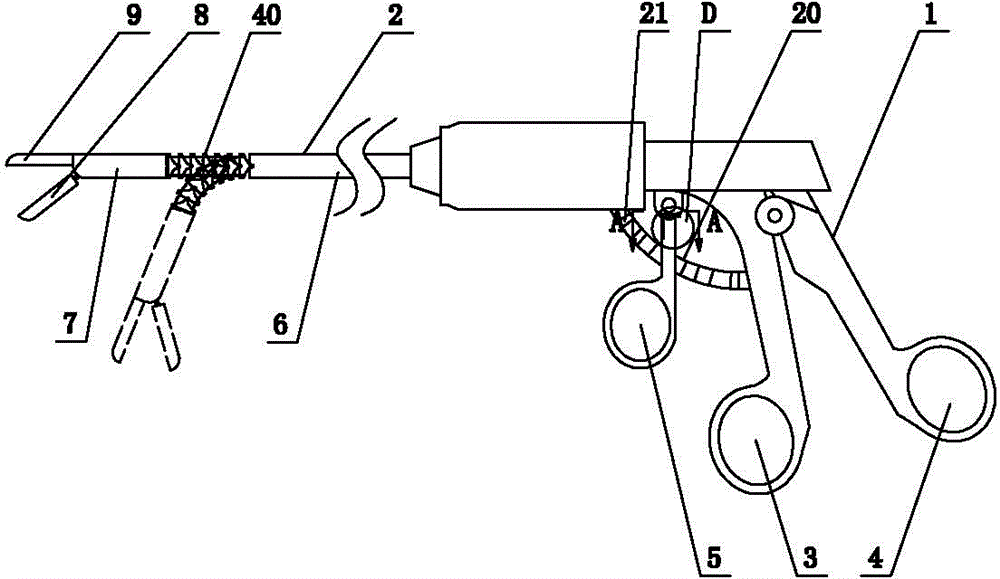

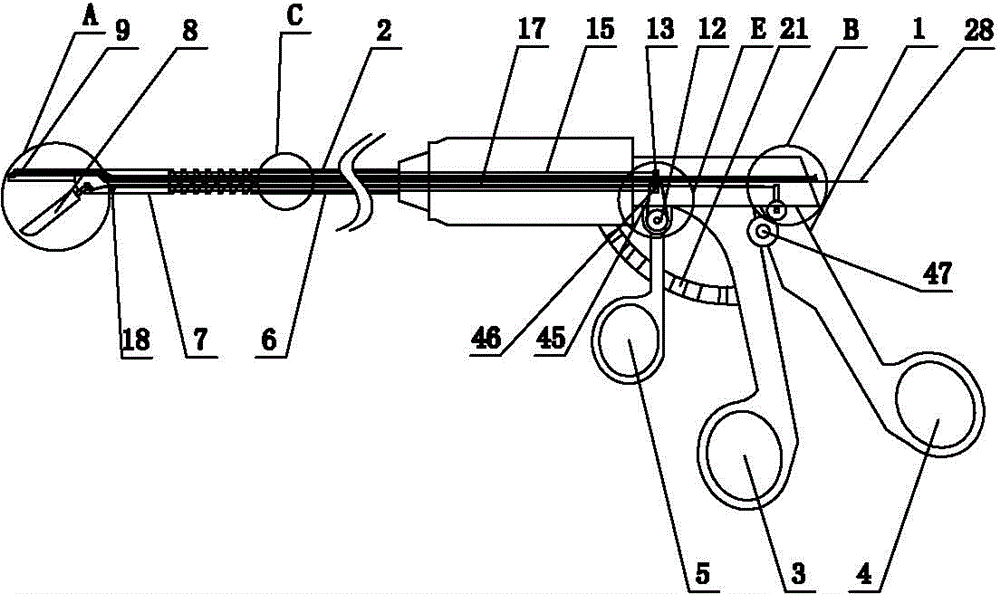

Operating forceps capable of being bent

The invention discloses a pair of precision forceps for exploring a bile duct. The precision forceps for exploring the bile duct comprise an exploration lever, wherein a fixed forceps head is arranged on the front end of the exploration lever, a fixed finger ring handle is arranged on the back end of the exploration lever, a groove is formed in the fixed forceps head, a miniature camera and an LED (light-emitting diode) lamp are arranged in the groove, a movable forceps head in parallel with the fixed forceps head is also hinged to the front end of the exploration lever, and a movable finger ring handle in parallel with the fixed finger ring handle is hinged to the back end of the exploration lever. The precision forceps are novel in design, simple in structure and convenient to operate. When a doctor conducts a surgery, the instrument can be used to flush the bloodiness in a surgical wound with clean water, so that the doctor can observe the situation of the surgical wound through the camera more clearly, further, the infection of the wound is also avoided, when the cleaning is over, the sewage can be sucked outside via a suction port, the sewage is then prevented from staying in the body, and the risk of being infected is radically eliminated.

Owner:白少华

Technique for extracting titanium slag form red mud

ActiveCN101054628AReduce production linksReduce manufacturing costRecycling and recovery technologiesProcess efficiency improvementRed mudAtmospheric temperature

A technical handling method of cuprum wires cross relates to the annealing process of cuprum wires cross and comprises the following steps: putting cuprum wires cross into a annealing furnace, pumping air in the furnace to form negative-pressure in the furnace, filling the furnace with carbon dioxide protective gas; performing a heating treatment of two stages under pressure, performing a gas releasing decompression processing between stages, then cooling-down slowly in the furnace for 0.3-1 hour, and opening the furnace to cool-down naturally to atmospheric temperature. Therefore, electrical soft wires cross through such annealing treatment has brightening surfaces and excellent finish, without greasy dirt or other soils; exhibits uniform flexibility and strong antioxidant ability, and can be stored for a long time.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

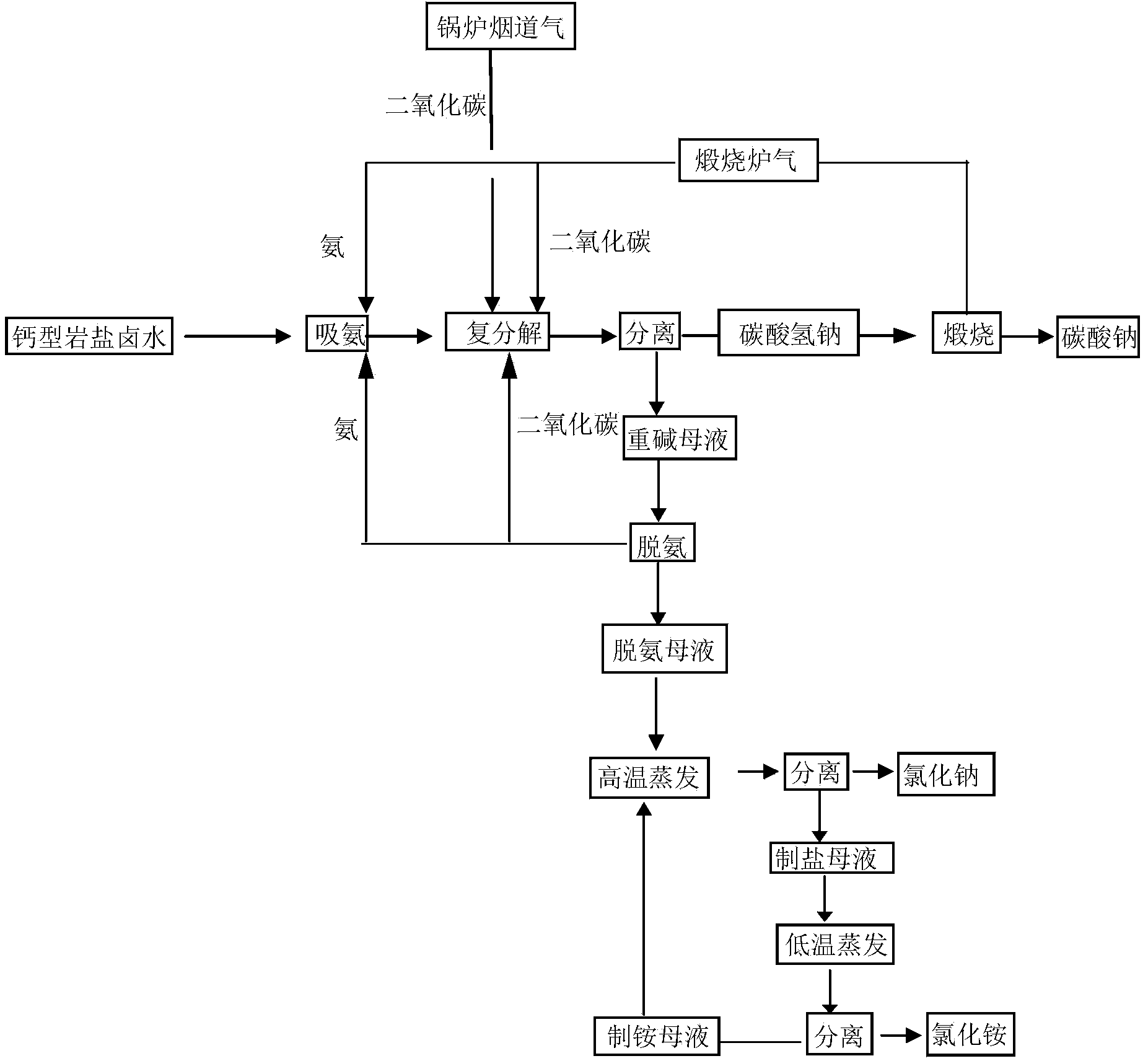

Technology for co-production of sodium carbonate, sodium chloride and ammonium chloride through calcium type rock salt brine and flue gas of boiler

InactiveCN103880046AAchieve protectionLarge market capacityAmmonium halidesAlkali metal chloridesSodium bicarbonateDecomposition

The invention provides a technology for co-production of sodium carbonate, sodium chloride and ammonium chloride through calcium type rock salt brine and flue gas of a boiler. The technology comprises steps of carrying out double decomposition reaction on the raw materials refined calcium type rock salt brine (containing sodium chloride), ammonia and carbon dioxide, and then separating so as to obtain solid sodium bicarbonate and sodium bicarbonate mother liquor; preheating and deaminizing the sodium bicarbonate mother liquor at high temperature, so as to obtain deaminized mother liquor; evaporating the deaminized mother liquor and circulating ammonium-making mother liquor at high temperature so as to separate to obtain solid sodium chloride and salt-making mother liquor; evaporating the salt-making mother liquor at low temperature so as to separate to obtain solid ammonium chloride and ammonium-making mother liquor; circularly evaporating the ammonium-making mother liquor so as to separate to obtain solid sodium chloride and salt-making mother liquor; calcining solid sodium bicarbonate so as to convert into solid sodium carbonate. According to the technology, the use ratio of sodium and chlorine of the raw material rock salt is 100%, energy consumption and production cost are greatly lowered, and the technology has advantages of no emission of 'three wastes' due to the closed cycle, reduction of the carbon emission, environmental friendliness, and large capacity of the market of the main products and by-products.

Owner:CHINA LIGHT IND INT ENG CO LTD

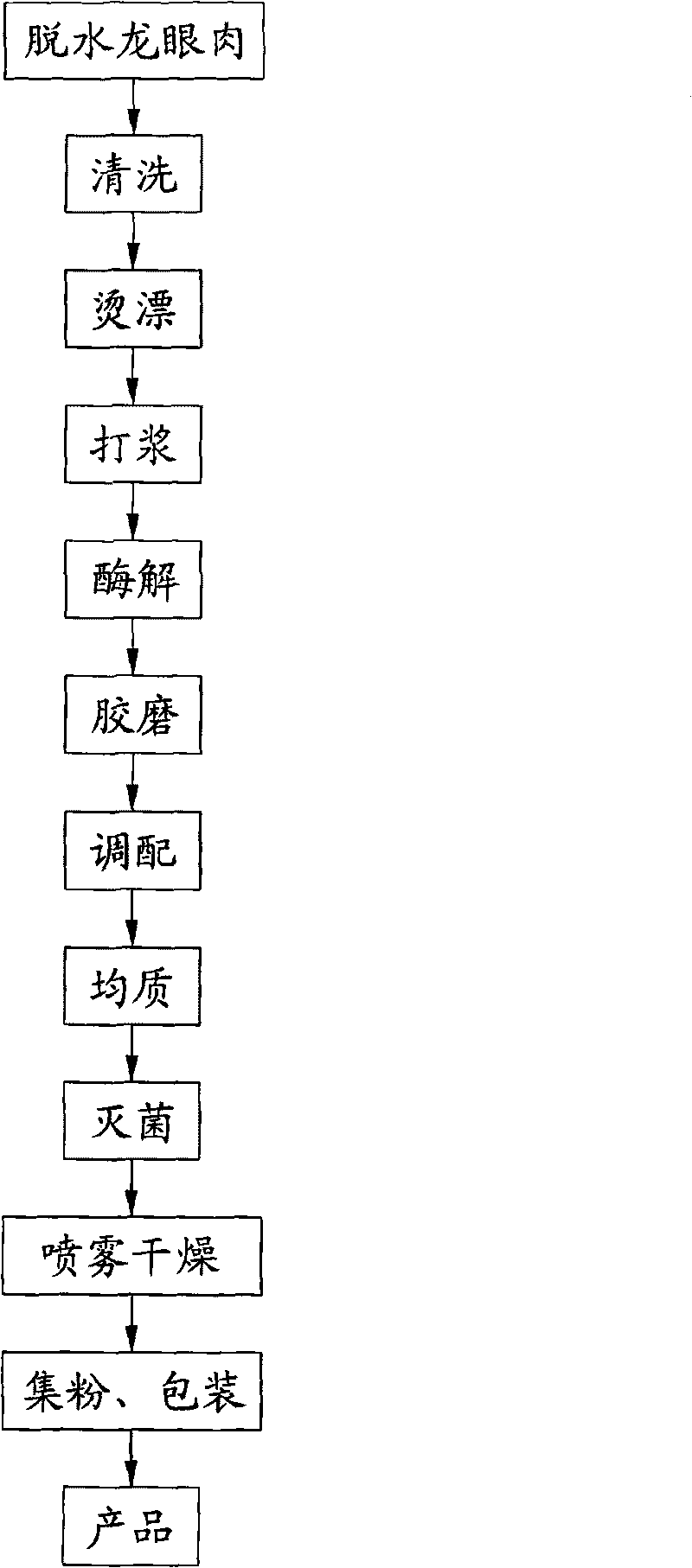

Method for making natural longan powder

InactiveCN101690566ASolve the problem of coloringSolve the taste problemFood shapingFood preparationSolubilityFlavor

The invention discloses a method for making natural longan powder, which carries out the steps of cleaning of dried longan fruit pulp, blanching, beating, enzymatic hydrolysis, colloid milling, blending, homogenizing, sterilization, drying, powder collection, screening and the like, thereby preparing a longan powder product; and the processing is completed by adopting the mechanized continuous operation way. The longan powder prepared by the method can solve the problems of poor color, luster and solubility of the existing products, low product yield and the like. The technical scheme is characterized by introducing the treatment technologies of color protection, enzymatic hydrolysis and spray drying. The product keeps the flavor and the nutritional ingredients of longan and has natural color and luster, high solubility and good taste, and the making process does not add any pigments, essences, preservatives and other chemical substances, thereby having no side effects and being the pure natural fruit powder.

Owner:JIMEI UNIV

Method for producing building gypsum from modified phosphorus gypsum

InactiveCN101265043ACalcination temperature is lowImprove performanceSolid waste managementChemical industryTreatment time

The invention relates to a method for producing construction gypsum from modified phosphogypsum, which belongs to the technology field of phosphorus chemical industry. The raw materials of phosphogypsum and carbide slag are pulverized and then mixed with Al2O3 and rare earth metal as modifiers, at a weight ratio of (76-88) :(5-15):(3-10):(0.5-1.5), the resulted mixture is granulated and modified by calcination process free of water washing, under such conditions that the calcination temperature is controlled at 150-300 DEG C and the calcination time is 20-30 minutes, and then discharged to obtain modified phosphogypsum. The product performance meets and complies with the premium grade in GB9776-88 standards 'Construction Gypsum'. Additionally, the invention has the advantages that: the modification process has short treatment time and low energy consumption, the invention realizes the reasonable utilization of phosphogypsum resources, and the invention is significant in solving the problems of land occupation and environmental pollution in phosphogypsum storage.

Owner:YUNNAN MINZU UNIV

Method for fully recycling municipal solid waste

ActiveCN104128350ANo long-term occupationResource does not existSolid waste disposalPlastic recyclingLand resourcesResource utilization

The invention discloses a method for fully recycling municipal solid waste. The method includes steps of garbage classification, garbage stabilization and catalytic cracking. The municipal solid waste is fully recovered and recycled. A harmless and resource-utilization treatment is achieved. Defects of long-period occupying land and polluting land resource in municipal solid waste incineration and landfill are avoided. Discharges of waste water, waste residue and waste gas are avoided. A Defect that landfill leachate and stink in the landfill seriously pollute the environment is avoided. A highest temperature during a production process is not higher than 180 DEG C and the method is free of generation of dioxin. A finished product can be a building product without generation of organic fertilizers. The defect that heavy metal in garbage compost harms human and livestock through food chain is avoided. All the environmental-protection indexes of the building product generated in the method reach requirements in national relative standard. The building product is huge in a market capacity. A problem that the building product is turned into new garbage since the product is lack of outlet is avoided.

Owner:广州同欣体育股份有限公司

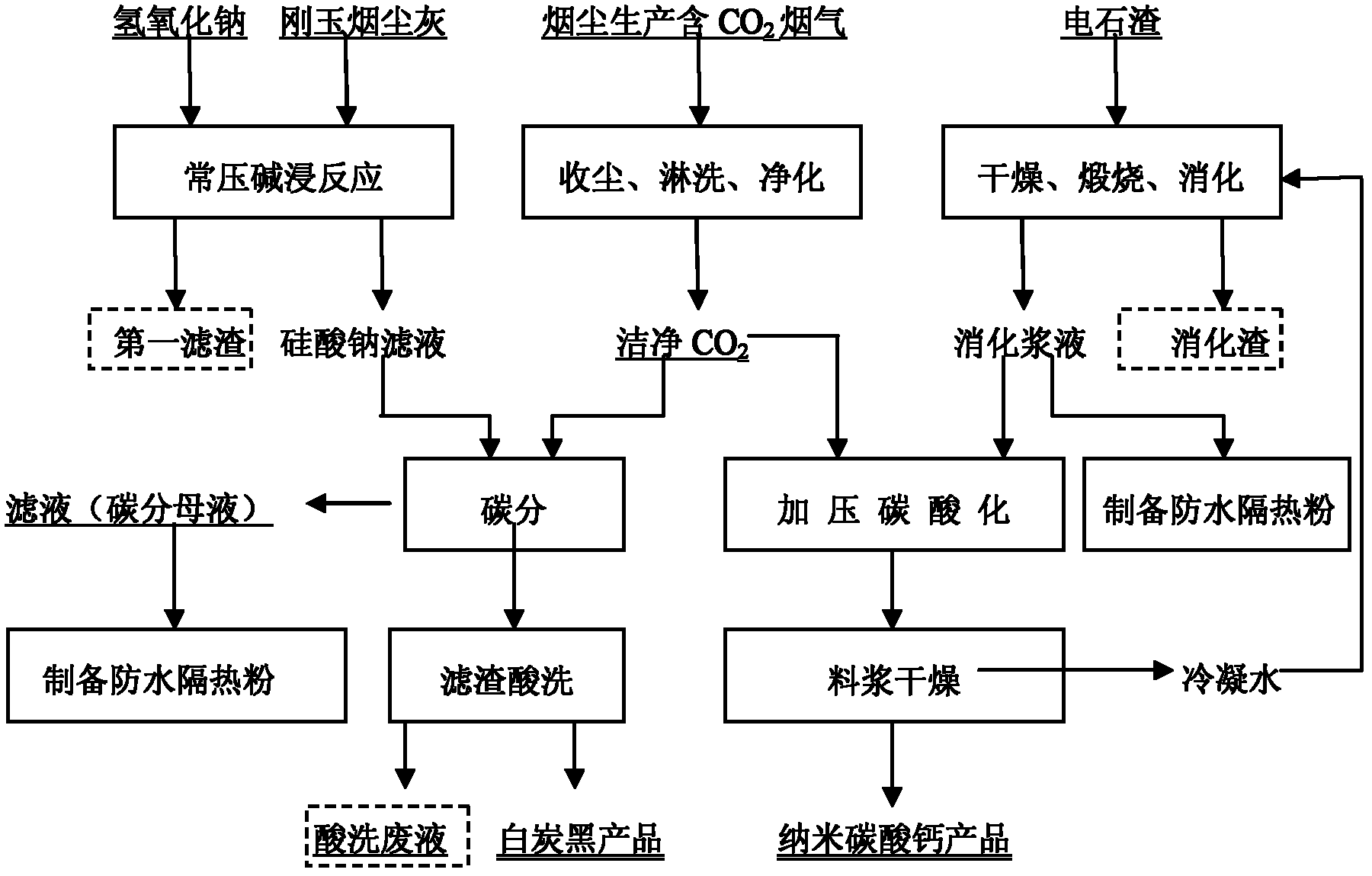

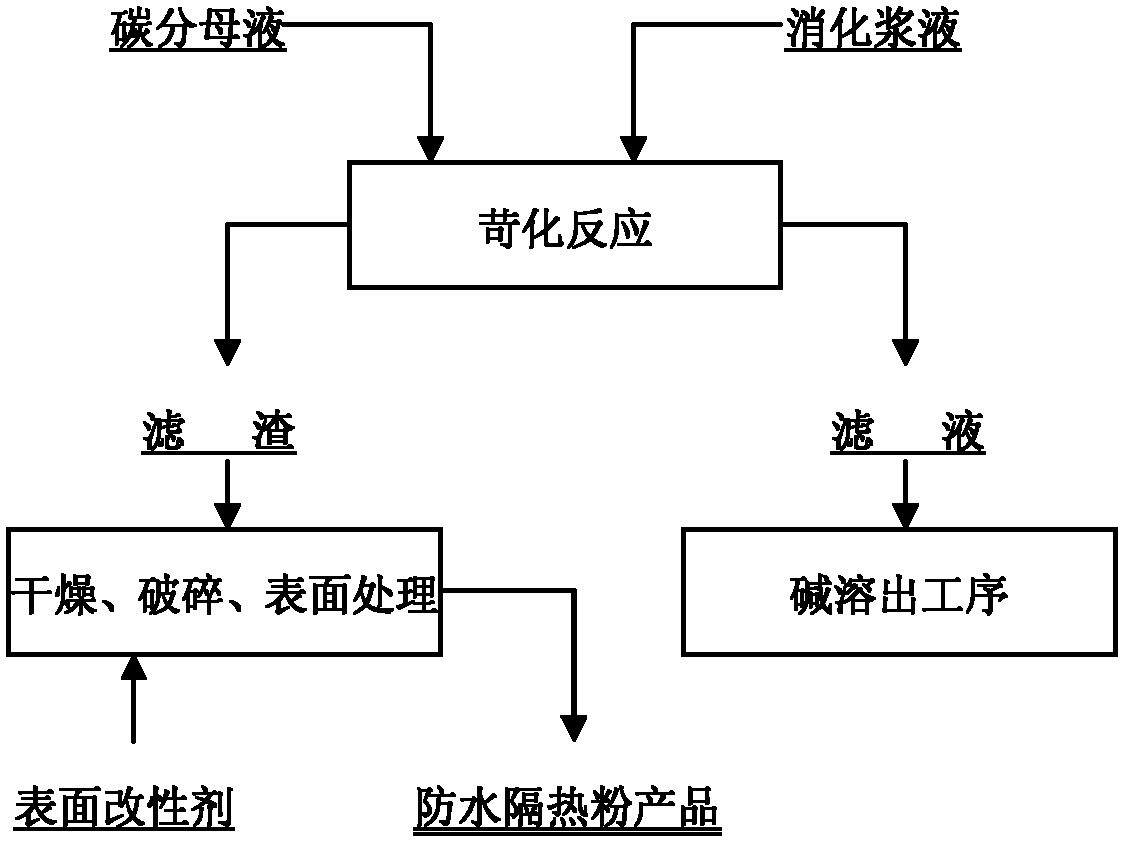

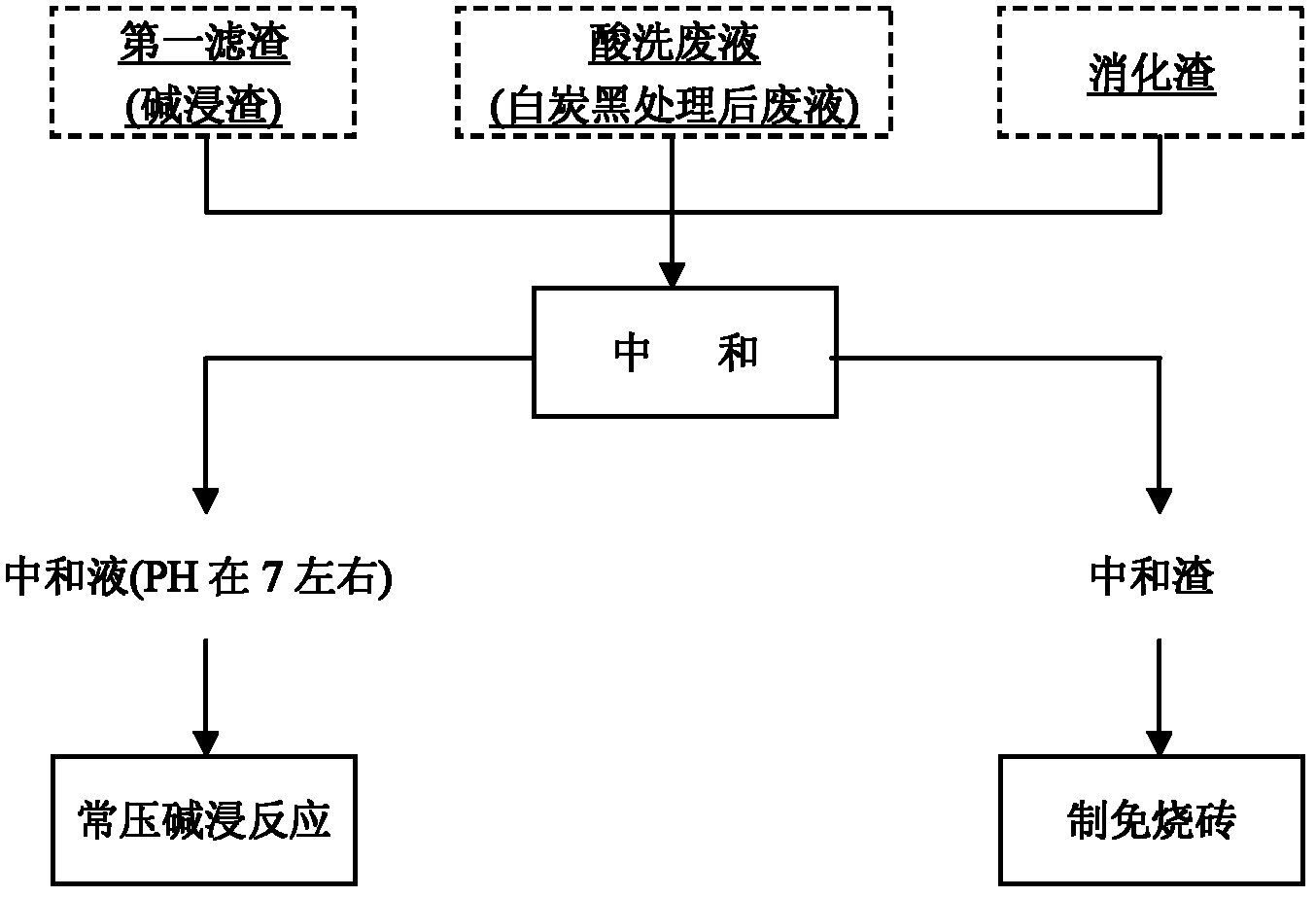

Closed-circuit recycling process of waste gas and waste residue generated during production of brown fused alumina and calcium carbide

InactiveCN102500184ALarge market capacityRealize inner loopCalcium/strontium/barium carbonatesCombination devicesFlue gasChemical products

A closed-circuit recycling process of waste gas and waste residue generated during the production of brown fused alumina and calcium carbide is a closed-circuit recycling process which utilizes flue dust and flue gas containing carbon dioxide collected when brown fused alumina is produced as well as calcium carbide residue and flue gas containing carbon dioxide when calcium carbide is produced toproduce high-grade silica, high-grade nanometer calcium carbonate and waterproof heat insulation powder. The closed-circuit recycling process comprises the following steps: fused alumina flue dust isimmerged in alkali and dissolved out in normal pressure; calcium carbide residue is calcined and nitrated; and carbon dioxide obtained when the flue gas is purified is used for carbonating alkali immersion liquid of fused alumina flue dust and nitrating serum. By adoption of the process provided by the invention, waste gas and waste residue generated when brown fused alumina and calcium carbide are produced are transformed into valuable chemical products, so that internal cycling of material is realized, three wastes are emitted outside no longer, and secondary pollution is avoided. The process is suitable for industrial application.

Owner:CENT SOUTH UNIV +1

A method for reprocessing and comprehensive utilization of red mud

ActiveCN102295396ASimple methodTechnical parameters are easy to controlSludge treatmentRed mudMagnetic separator

The invention discloses a reprocessing and comprehensive utilization method of red mud, comprising the following steps: (1) carrying out mashing on red mud, and carrying out artificial mineral dressing on heavy mineral to respectively obtain coarse sand and mortar; (2) drying the coarse sand, then carrying out magnetic separating to respectively obtain quartz sand and level 1 magnetic material; (3) carrying out magnetic separating on the level 1 magnetic material to respectively obtain magnetite powder and tailing 1; and (4) putting the mortar in a magnet separator for magnetic separating to respectively obtain fine iron ore and tailing 2. The method is simple and practicable and has the advantages of easily controllable technical parameters, little energy consumption and low cost, can process more than 100 Mtpa per year, reduce the discharging capacity of red mud by 35-70 % and reduced the production cost of alumina. The main products of the method are magnetite powder and quartz, and the obtained two tailings can be used in preparing dry cement or in damming, so that the purpose of comprehensive utilization of red mud is achieved.

Owner:中铝山东有限公司

Baking-free brick with waste rubber and coal ash as major raw materials

ActiveCN102976686AImprove brittle defectsLow elastic modulusSolid waste managementWaste rubberFreeze and thaw

The invention discloses a baking-free brick with waste rubber and coal ash as major raw materials. The baking-free brick is composed of the following raw materials in parts by weight: 3-10 parts of waste rubber, 30-45 parts of coal ash, 20-25 parts of yellow sand, 5-10 parts of cement, 10-15 parts of calcium oxide, 3-5 parts of calcium sulfate, 1-2 parts of sodium sulfate, 1.5-2 parts of sodium hydroxide, 0.01-0.05 parts of sodium metaaluminate and 8-15 parts of water. The baking-free brick has the advantages that (1) the major problems that the coal ash baking-free brick is high in water absorption and poor in resistance to freezing and thawing resistance are solved, and the application field and region of the coal-ash baking-free brick are greatly expanded; (2) the production process is simple, the investment is low, the cost is low, the benefit is good, the market competitiveness is strong and the capacity of the market is great; and (3) the solid wastes such as waste tire and coal ash are used for making bricks instead of the traditional clay bricks, so that the baking-free brick is a green novel building material and is an important development project in China.

Owner:河南盖森材料科技有限公司

Method for producing baked brick by using rare-earth metal modified coal gangue

The invention relates to a method for producing a baked brick by using a rare-earth metal modified coal gangue. The method comprises the following steps of: crushing the coal gangue to pelletize with clay and rare-earth metal; feeding the granules into a blender to uniformly blend and mix by adding water; then feeding the mixture into a brick machine for performing compression molding; and finally putting the mixture into a sintering kiln for sintering into a finished product so as to obtain a common baked brick which accords with GB5101-2003 and can be directly used as a building material.

Owner:YUNNAN MINZU UNIV

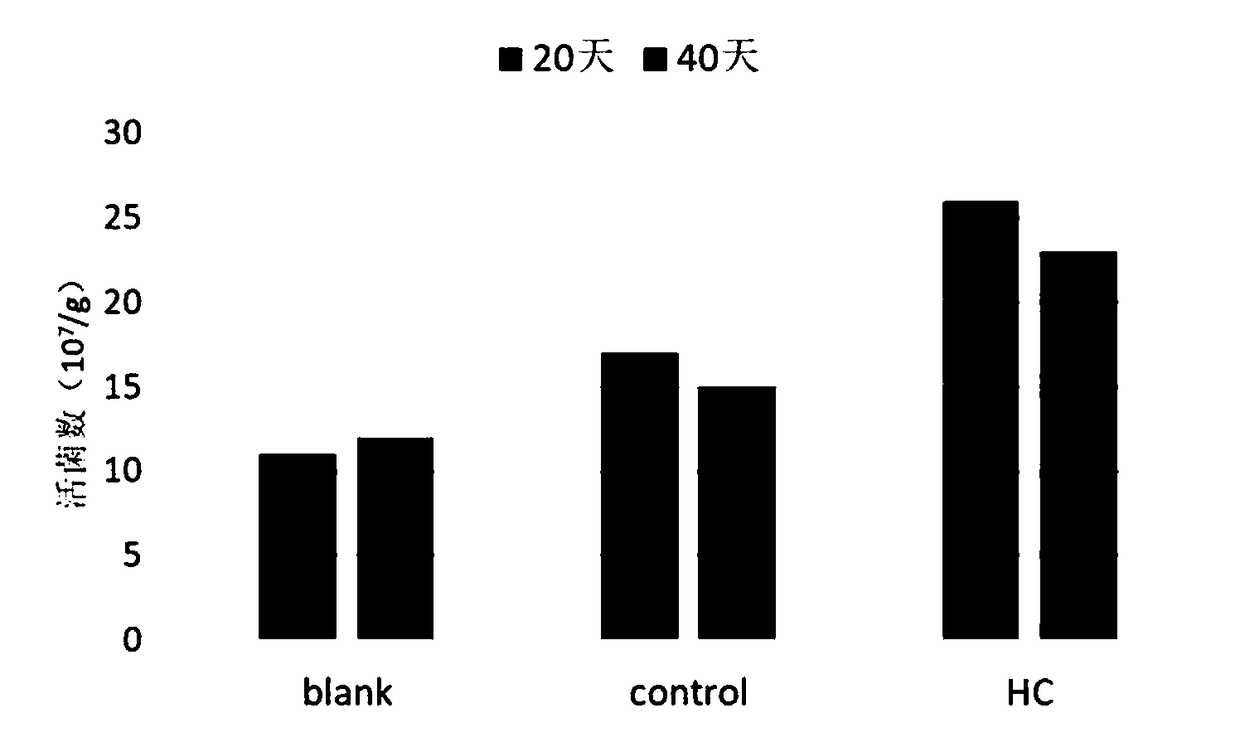

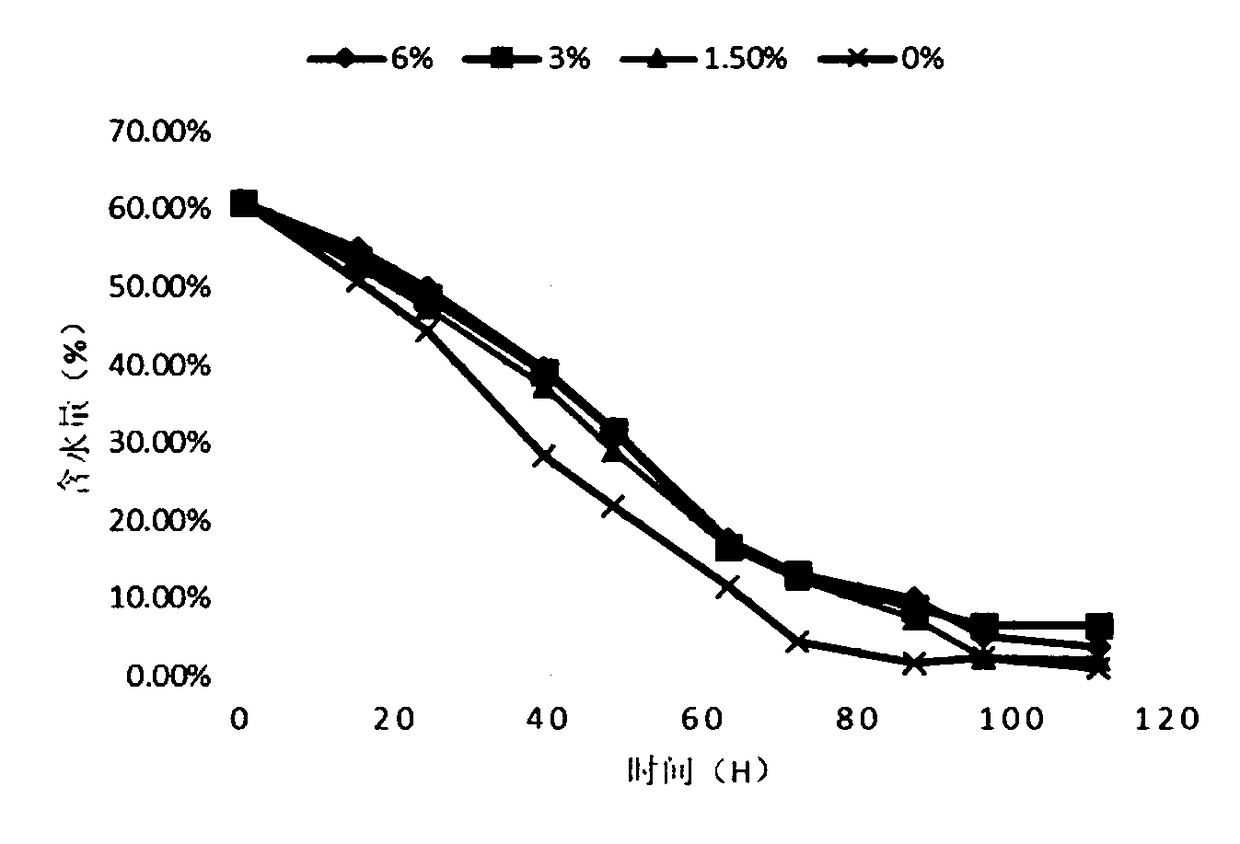

Soil improving hydrogel as well as preparation method thereof and application thereof

ActiveCN108148208ALow costEfficient manufacturingOrganic fertilisersSoil conditioning compositionsFiberHigh energy

The invention belongs to the field of high value conversion and utilization of biological waste, in particular to a soil improving hydrogel, a preparation method thereof and application thereof. The hemicellulose-containing wastewater is used as a solvent, mixed with a hydrogel monomer and a crosslinking agent, and a crosslinked polymer obtained by polymerization is a hydrogel. The water-retainingagent provided by the invention can directly use the hemicellulose-containing wastewater as the solvent, thereby eliminating the high energy consumption and chemical reagent costs of separation and purification of hemicellulose; oligosaccharide rich therein and phosphorus and potassium and other elements added during the preparation process can be used as a supplementary nutrient for crops and soil microorganisms to promote the water retention performance of a soil ecological improving agent and microbial colonization. The other components in by-products are utilized, and no wastewater is discharged during the entire utilization process, thereby providing an economical and environment-friendly route for hemicellulose treatment in the pulping and viscose fiber industries.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

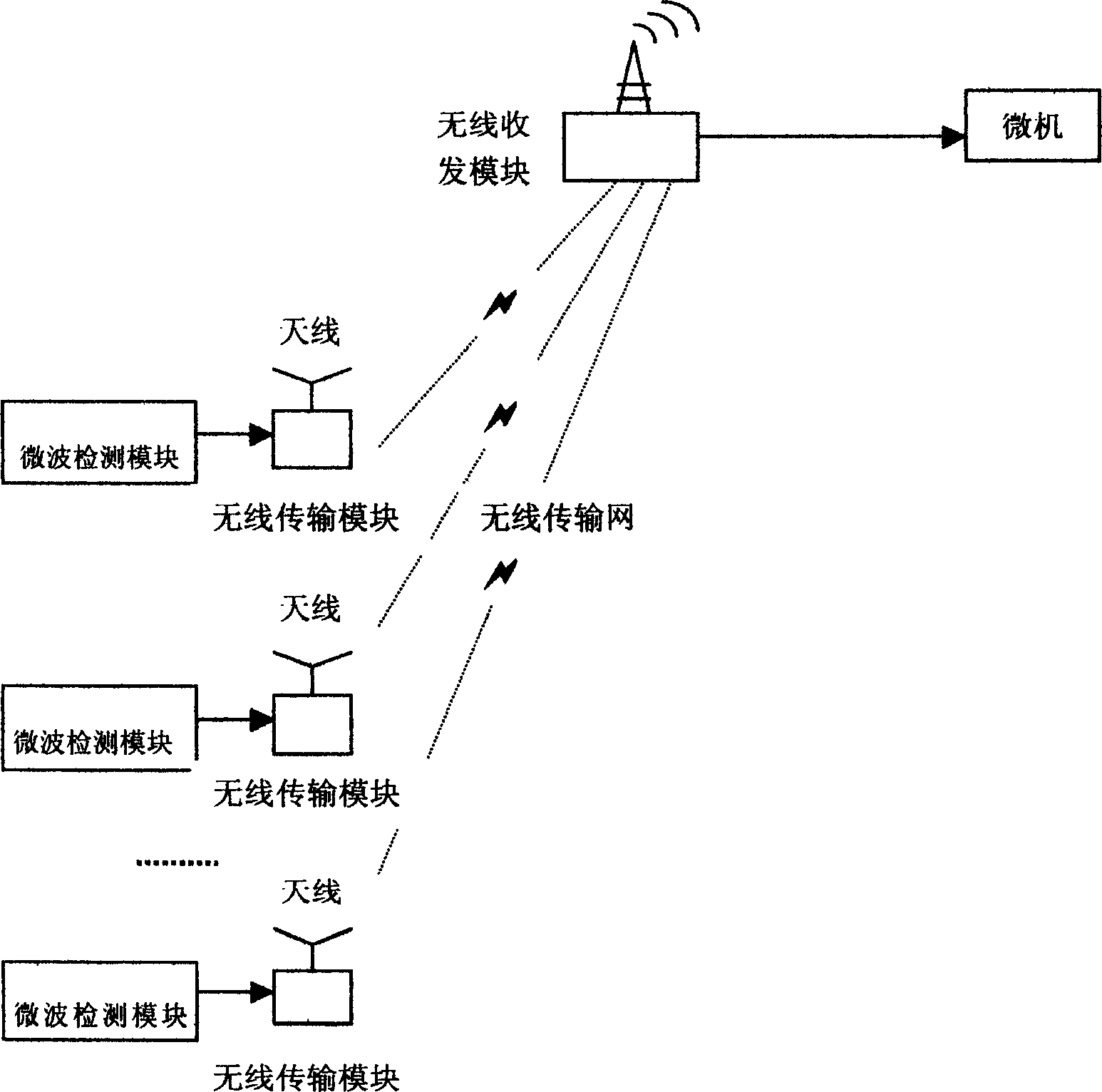

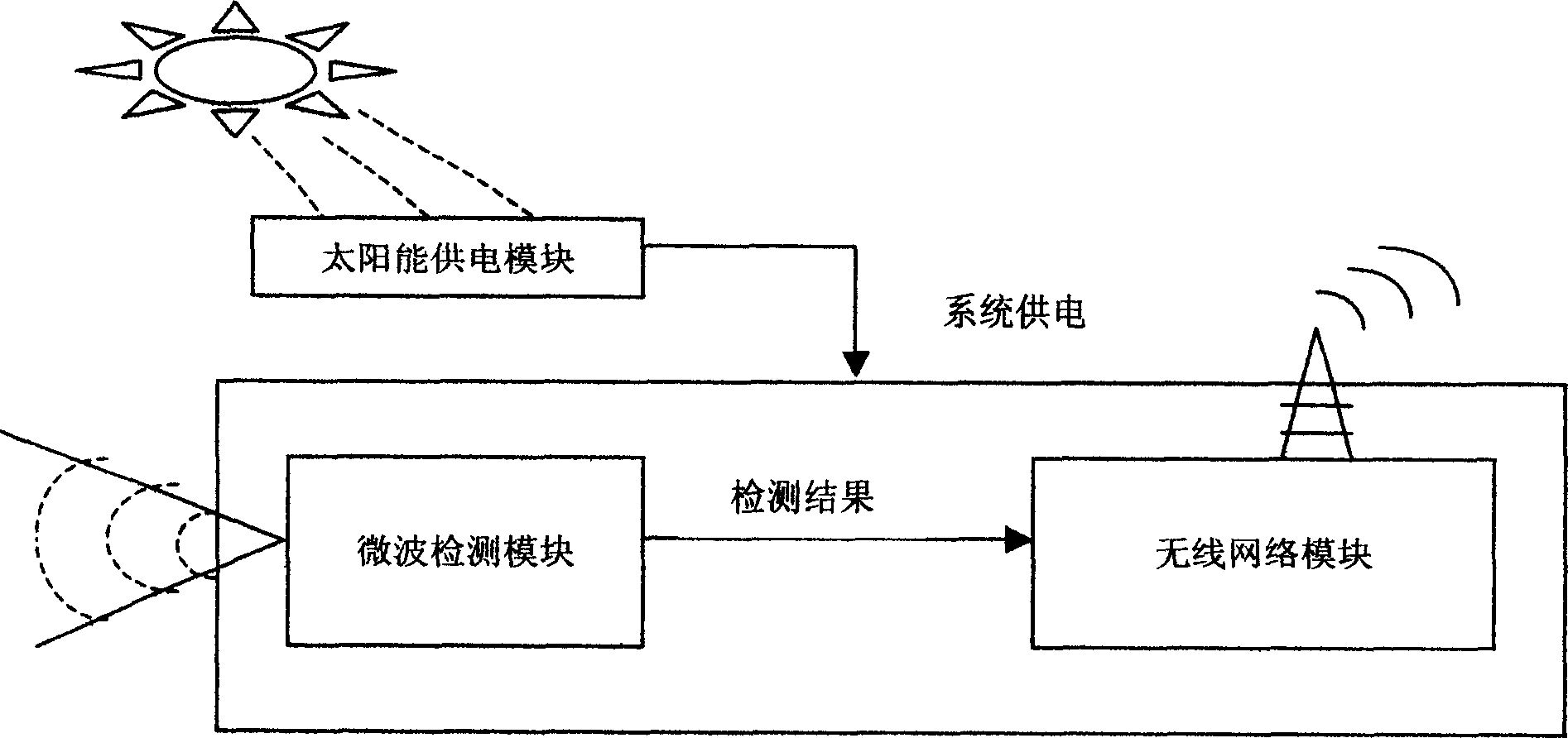

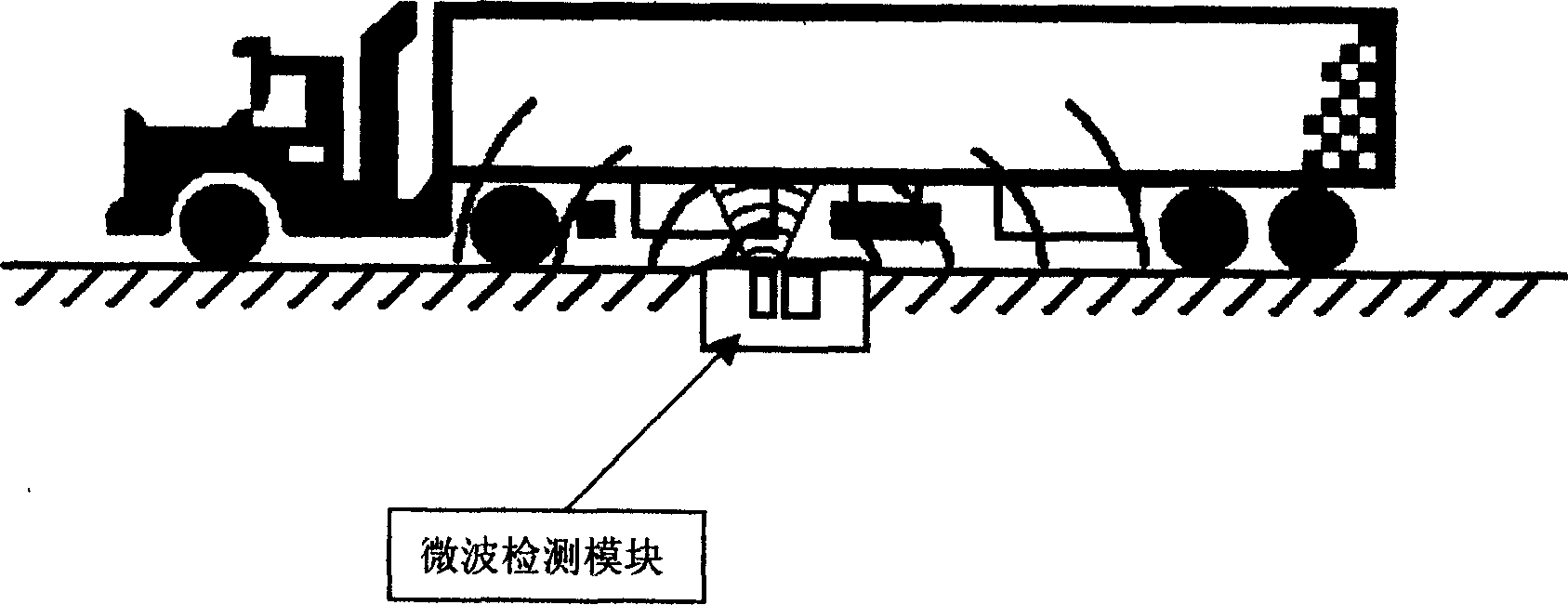

Method for processing parking monitoring system

InactiveCN1707543ALess crowdedEasy constructionRoad vehicles traffic controlMonitoring systemLongwave

The present invention relates to radio RF technology, and is especially one kind of processing method for berth monitoring system. The berth monitoring system includes microwave detection module, radio transmission module, radio transceiving module, radio transmission network, image recognizing detection system, etc. It features the microwave detection system comprising at least one microwave detection module connected to radio transmission module, and the radio transceiving module in long wave digital communication mode. The present invention has the features of simple site construction, convenient installation and maintenance, no need of wiring, etc.

Owner:SHANGHAI SHENTENG INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com