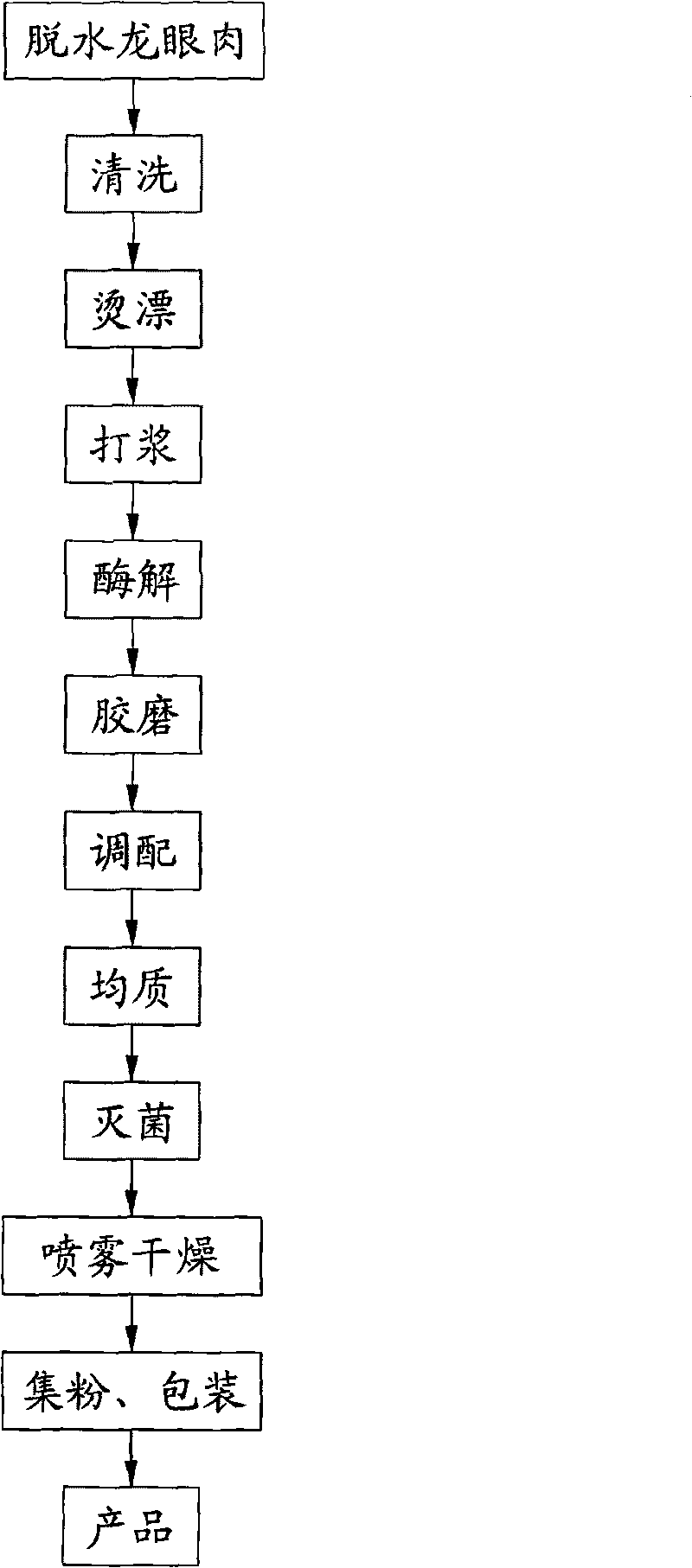

Method for making natural longan powder

A production method and technology of longan powder, which can be used in medical preparations containing active ingredients, pharmaceutical formulas, food preparations, etc., can solve the problems of loss of color and poor solubility, and achieve natural color, long storage period and high solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Concrete implementation steps: (1) select the dehydrated longan meat with good quality and moisture content of about 8%, remove inedible parts such as residual husks, and weigh 100kg of net weight. The raw materials are rinsed with clean water to remove most of the pesticide residues and microorganisms on the surface of the longan. (2) Add the longan meat into 250kg of water, heat to boil, keep for 3 minutes and then cool to 35°C. (3) Use a beater to beat into a coarse pulp with a fineness below 1mm. (4) Add 70 g of pectin and cellulose compound enzyme preparation. Incubate at 20-30°C for 60-90 minutes. (5) Add 150 kg of water to the enzymatically hydrolyzed longan meat and stir evenly into the colloid mill, and adjust the gap between the grinding discs to 30 μm to further refine the material into a uniform and delicate feed liquid. The slurry produced by the colloid mill is filtered by an 80-mesh slurry separator to separate crude fibers and other substances. Store...

Embodiment 2

[0021] Its preparation method is basically the same as that of Example 1, and the different process steps are as follows: (4) 100 g of pectin and cellulose compound enzyme preparation are added. Incubate at 20-30°C for 60-90 minutes. (5) Add 150 kg of water to the enzymatically hydrolyzed longan meat and stir evenly into the colloid mill, and adjust the gap between the grinding discs to 30 μm to further refine the material into a uniform and delicate feed liquid. The slurry produced by the colloid mill is filtered by an 80-mesh slurry separator to separate crude fibers and other substances. Store the separated coarse slag separately. (6) Pump 500 kg of the obtained longan pulp into a jacketed pot with a stirrer, add 100 kg of maltodextrin, add water and stir evenly, add an appropriate amount of water to fully dissolve it, and stir evenly. (9) Use a spray dryer to dry, the condition is: the pressure of the high pressure pump is controlled at 12.5MPa. Inlet air temperature: 1...

Embodiment 3

[0023] Its production method is basically the same as Example 1, and the different process steps are as follows: (6) 500 kg of longan pulp is pumped into a jacketed pot with a stirrer, 150 kg of maltodextrin is added, and an appropriate amount of water is added to fully dissolve it, Stir well. (9) Drying with a spray dryer, the condition is: the pressure of the high pressure pump is controlled at 14.0 MPa. Inlet air temperature: 175°C, exhaust air temperature: 75°C, after drying, a finished product with a moisture content of 5% will be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com