Dyeing process of modified terylene

A technology of polyester modification, applied in the field of dyeing process of modified polyester, which can solve the problems of great difficulty, and achieve the effect of solving the problem of easy color and poor spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Modified polyester top dyed rose red, weighing 120 kg.

[0020] 1. Dye:

[0021] Cationic pink PG, the dosage is 0.26% of the weight of the modified polyester top;

[0022] Cationic red 3R, the dosage is 0.14% of the weight of the modified polyester top.

[0023] 2. Additives:

[0024] Acetic acid, consumption is 2% of modified polyester wool top weight;

[0025] Antistatic agent SN (octadecyl dimethyl nitrate), consumption is 1% of modified polyester top weight;

[0026] Bulking agent SF (fatty acid polyoxyethylene ester), consumption is 2% of modified polyester wool top weight;

[0027] The softener ES (formed by emulsification of stearic acid, diethylenetriamine amide, epichlorohydrin and acetic acid) has an amount of 2% of the weight of the modified polyester top.

[0028] 3. Dyeing equipment: top dyeing machine N371.

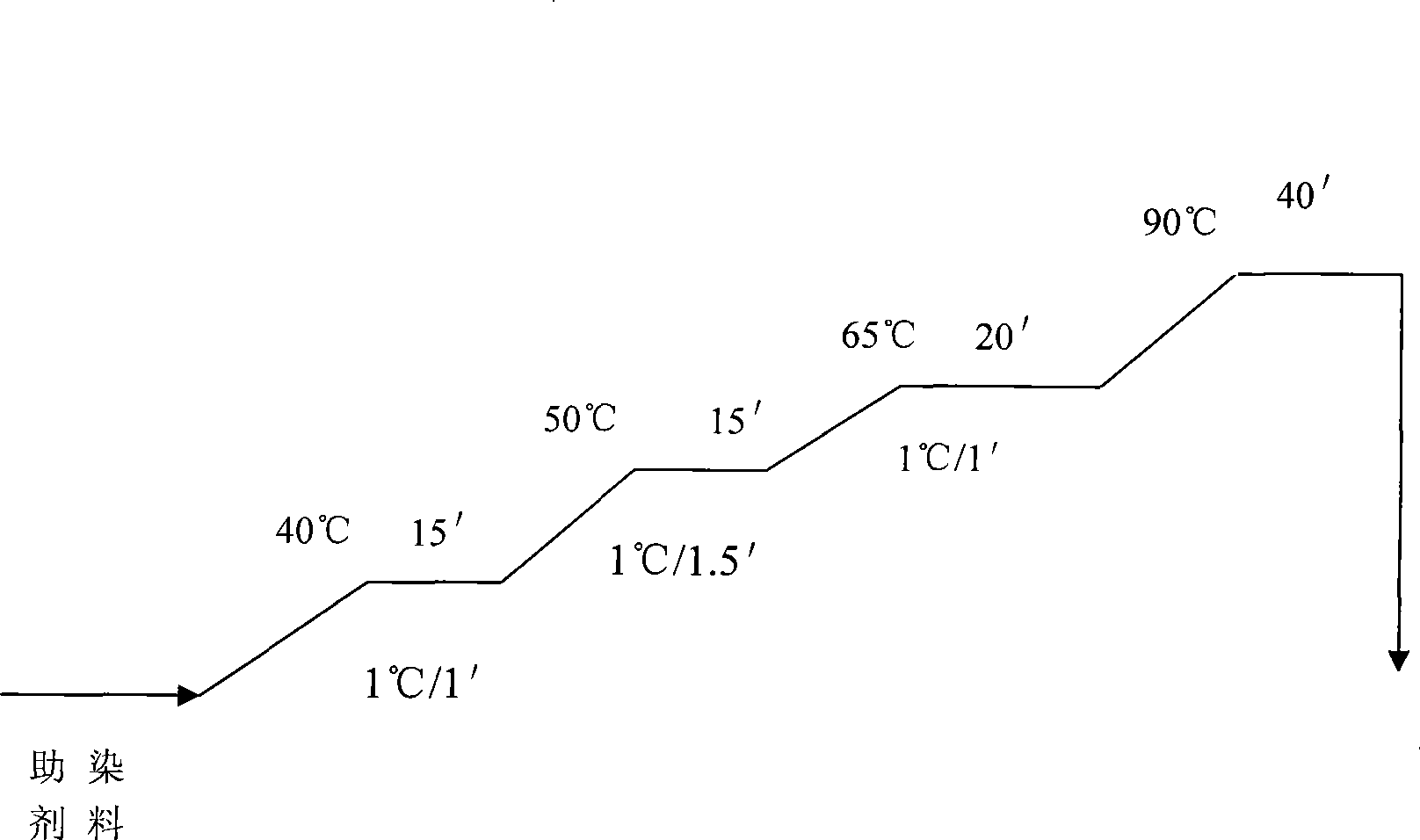

[0029] 4. Dyeing process:

[0030] (1) After the tops are put into the machine at normal temperature, first fill up the water and fully soak ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com