Chromium-niobium-boron alloy rare earth casting grinding ball and production process method thereof

A technology for casting grinding balls and production processes, applied in the field of metal grinding media, can solve the problems of increasing the manufacturing cost of grinding ball products, difficult to master micro-alloying technology, and reducing the amount of chromium used, and achieves grain refinement and dense organization. , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

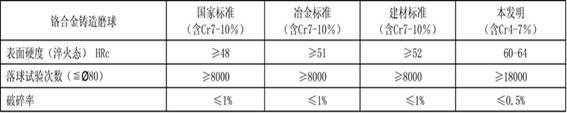

Image

Examples

Embodiment 1

[0041] Specification ? 25mm chromium-niobium-boron alloy rare earth cast grinding ball, its chemical composition is as follows:

[0042] Carbon (C): 2.63 % Silicon (Si): 0.58 %, Manganese (Mn): 0.38 %,

[0043] Chromium (Cr): 4.32%, Phosphorus (P): 0.064%, Sulfur (S): 0.055%;

[0044] Niobium (Nb): 0.055%, Boron (B): 0.12%, Compound Rare Earth Modifier (Re): 0.18%,

[0045] Iron (Fe): 91.39%.

[0046] The manufacturing process of ?25mm chromium-niobium-boron alloy rare earth casting grinding ball is as follows:

[0047] The main raw material used is scrap steel. According to the above formula, the scrap steel is first melted in an intermediate frequency induction furnace, and the temperature is raised to 1480-1520°C, and then chromium (Cr), silicon (Si), manganese (Mn), niobium (Nb), boron ( B) The alloy reaches the required chemical composition. Then put the massive composite rare earth modifier into the molten iron ladle, melt it with molten iron and let it stand for 4 m...

Embodiment 2

[0053] The chemical composition of 60mm chromium-niobium-boron alloy rare earth casting grinding balls is as follows:

[0054] Carbon (C): 1.81%, Silicon (Si): 0.62%, Manganese (Mn): 0.65%,

[0055] Chromium (Cr): 6.32%, Phosphorus (P): 0.059%, Sulfur (S): 0.058%;

[0056] Niobium (Nb): 0.058%, Boron (B): 0.11%, Compound Rare Earth Modifier (Re): 0.2%,

[0057] Iron (Fe): 90.12%.

[0058] The manufacturing process of ?60mm chromium-niobium-boron alloy rare earth casting grinding ball is as follows:

[0059] According to the recipe, the scrap steel is first melted in an intermediate frequency induction furnace, and the temperature is raised to 1480-1520°C, and then chromium (Cr), silicon (Si), manganese (Mn), niobium (Nb), and boron (B) alloys are added to achieve the desired temperature. required chemical composition. Then put the composite heavy rare earth modifier into the molten iron ladle, melt it with molten iron and let it stand for 5 minutes to carry out modificatio...

Embodiment 3

[0065] The chemical composition of 90mm chromium-niobium-boron alloy rare earth casting grinding balls is as follows:

[0066] Carbon (C): 1.52%, Silicon (Si): 0.68%, Manganese (Mn): 0.72%,

[0067] Chromium (Cr): 7.1%, Phosphorus (P): 0.058%, Sulfur (S): 0.055%;

[0068] Niobium (Nb): 0.060%, Boron (B): 0.13%, Compound Rare Earth Modifier (Re): 0.25%,

[0069] Iron (Fe): 89.43%.

[0070] The manufacturing process of 90mm chromium-niobium-boron alloy rare earth casting grinding ball is as follows:

[0071] According to the formula, the steel scrap is first melted in an intermediate frequency induction furnace, and the temperature is raised to 1510-1560°C, and then chromium (Cr), silicon (Si), manganese (Mn), niobium (Nb), and boron (B) alloys are added to achieve the desired temperature. required chemical composition. Then put the composite heavy rare earth modifier into the molten iron ladle, melt it with molten iron and let it stand for 5 minutes to carry out modificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com