Method for producing concentrated apricot juice and natural fruit acid

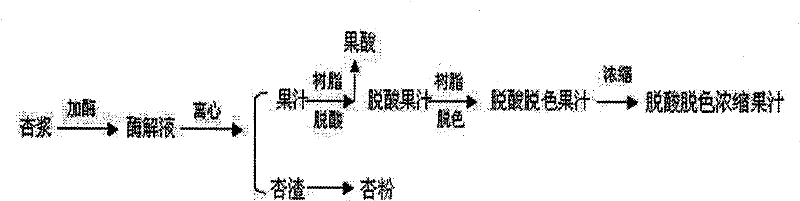

A production method and fruit acid technology, applied in the field of concentrated apricot juice and natural fruit acid production, can solve the problems of low development and utilization of apricot resources, narrow application range, low technical content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 3000g of apricots, wash and drain, remove the pits, and obtain 2750g of apricot pulp, beat the apricot pulp into apricot pulp, add pectinase and enzymolyze it at 45-55°C for 30min. Then the rotating speed is 7000rpm under the condition of centrifugation for 20min, and after the centrifugation, the supernatant (apricot juice) is boiled for 2 minutes to kill the enzyme. Leave the enzyme-inactivated apricot juice through the D380 column at 3 mL / min, and then collect 2.5 liters of apricot juice after deacidification; elute with a mixed solution of ammonia water and 50% ethanol at a volume ratio of 1:18, and then dry to obtain 3 g of fruit acid . Concentrate the deacidified apricot juice and put it on an AB-8 resin column to obtain 2 liters of deacidified and decolorized apricot juice. Concentrate the deacidified and decolorized apricot juice to obtain 330 milliliters of apricot juice with a sugar content of 70%.

Embodiment 2

[0019] Take 6000g of apricots, wash and drain and remove the pits to obtain 2750g of apricot pulp. The apricot pulp is beaten into apricot pulp, and pectinase is added to enzymolyze it at 45-55°C for 30 minutes. Then, the rotating speed is 4000rpm under the condition of centrifugation for 30min, and after the centrifugation, the supernatant (apricot juice) is boiled for 2 minutes to kill the enzyme. Leave the enzyme-inactivated apricot juice through the D380 column at 3 mL / min, and then collect 4.6 liters of apricot juice after deacidification; elute with a mixed solution of ammonia water and 50% ethanol at a volume ratio of 1:20, and then dry to obtain 5.8 fruit acids . The deacidified and decolorized apricot juice was concentrated and put on an AB-8 resin column to obtain 3.7 liters of deacidified and decolorized apricot juice, and the deacidified and decolorized apricot juice was concentrated to obtain 650 milliliters of apricot juice with a sugar content of 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com