Method for producing sulfuric acid and co-producing calcium carbide by phosphogypsum

A technology of phosphogypsum and calcium carbide, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problem of low comprehensive utilization rate of phosphogypsum, achieve good environmental protection and social benefits, reduce emissions, and solve comprehensive utilization problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

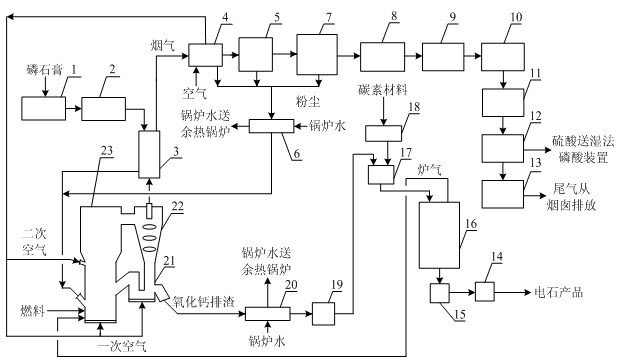

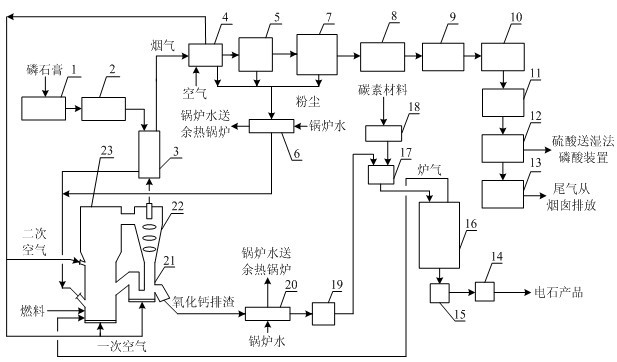

Embodiment 1

[0033] Example 1. Taking the production line of 100,000 tons / year calcium carbide supporting 180,000 tons / year sulfuric acid production line as an example, the following figure 1 process flow. Enter the circulating fluidized bed decomposition furnace to purify phosphogypsum (dry basis) 32t / h, the temperature is 700℃; the air volume into the furnace is 18000m 3 / h, temperature 300°C, primary air volume 14400m 3 / h, secondary air volume 3600m 3 / h (secondary air accounts for 20.0% of the total air volume); the gas volume of the sealed calcium carbide furnace entering the furnace is 5600m 3 / h, the temperature is 700℃; the fuel coal into the furnace is 3.48t / h. The gas temperature out of the calciner is 1200°C, the decomposition rate of gypsum is 99.3%, and the composition of the furnace gas (dry basis) is SO 2 Volume fraction 14.65%, O 2 Volume fraction 10.06%, CO 2 Volume fraction 33.27%, N 2 The volume fraction is 42.02%. The amount of slag discharged from the calcine...

Embodiment 2

[0034] Example 2. Also take the 100,000 tons / year calcium carbide production line with 180,000 tons / year sulfuric acid production line as an example. figure 1 process flow. Enter the circulating fluidized bed decomposition furnace to purify phosphogypsum (dry basis) 32t / h, the temperature is 500℃; the air volume into the furnace is 20000m 3 / h, temperature 250°C, primary air volume 16000m 3 / h, secondary air volume 4000m 3 / h (secondary air accounts for 20.0% of the total air volume); the gas volume of the sealed calcium carbide furnace entering the furnace is 5600m 3 / h, the temperature is 650℃; the fuel coal into the furnace is 3.52t / h. The gas temperature out of the calciner is 1000°C, the gypsum decomposition rate is 99.1%, and the furnace gas component (dry basis) is SO 2 Volume fraction 13.82%, O 2 Volume fraction 9.60%, CO 2 Volume fraction 31.64%, N 2 The volume fraction is 44.94%. The amount of slag discharged from the calciner is 14.11t / h, of which the mass ...

Embodiment 3

[0035] Example 3. Also take the 100,000 tons / year calcium carbide production line with 180,000 tons / year sulfuric acid production line as an example. figure 1 process flow. Enter the circulating fluidized bed decomposition furnace to purify phosphogypsum (dry basis) 32t / h, the temperature is 400℃; the air volume into the furnace is 30000m 3 / h, temperature 250°C, primary air volume 20000m 3 / h, secondary air volume 5000m 3 / h (secondary air accounts for 20.0% of the total air volume); the gas volume of the sealed calcium carbide furnace entering the furnace is 5600m 3 / h, the temperature is 600℃; the fuel coal into the furnace is 3.7t / h. The temperature of the gas exiting the calciner is 950°C, the decomposition rate of gypsum is 99.0%, and the composition of the furnace gas (dry basis) is SO 2 Volume fraction 10.80%, O 2 Volume fraction 7.50%, CO 2 Volume fraction 30.00%, N 2 The volume fraction is 51.70%. The amount of slag discharged from the calciner is 14.13t / h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com