Waste SCR catalyst-containing titanium-containing pellet and preparation method thereof

A technology of SCR catalyst and catalyst, which is applied in blast furnaces, furnace types, furnaces, etc., can solve the problems of impact on pellet performance and difficulty in forming pellets, and achieve the effects of good static pelletization, strong water absorption, and excellent metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

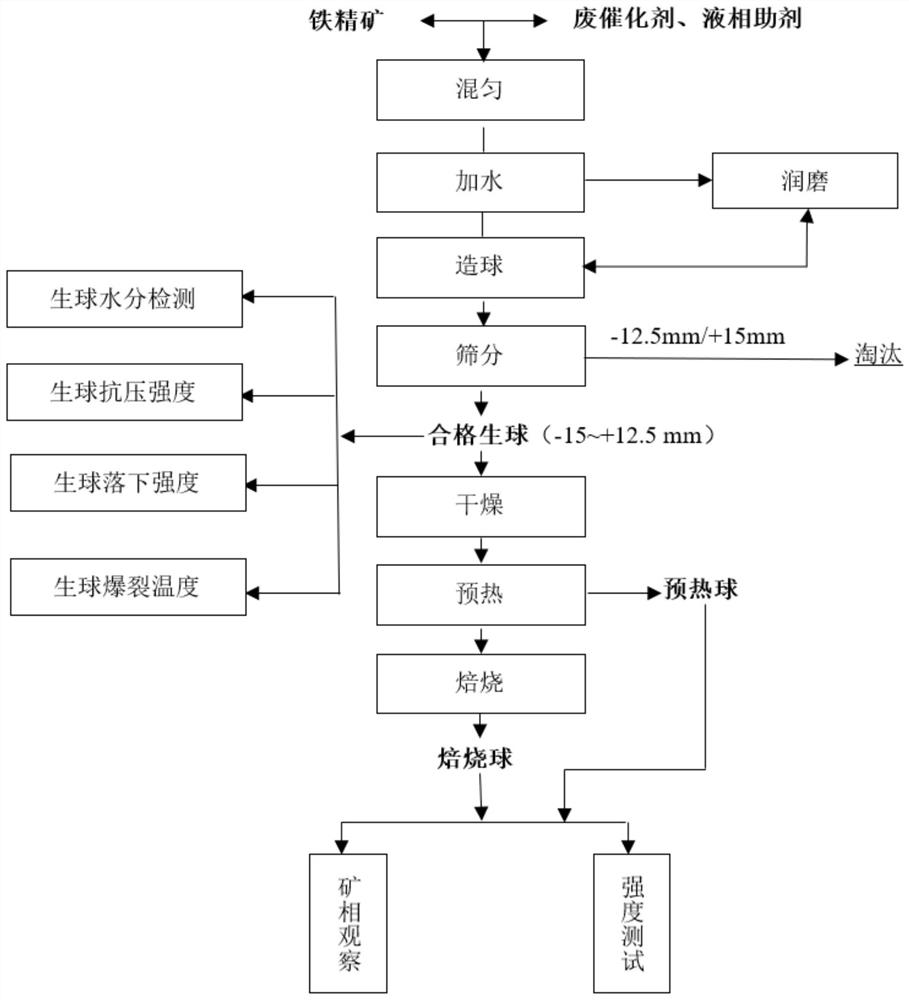

Method used

Image

Examples

Embodiment 1

[0073] The present invention proposes a method for preparing titanium-containing pellets containing waste SCR catalysts, which can properly solve the problems that the current waste SCR catalysts are produced in large quantities and difficult to recycle, the traditional production process of titanium-containing pellets is difficult to form into pellets, and the technology of pellets has poor performance question. The pellets produced by this method can meet the various performance indicators of the pellets required by the blast furnace, and can also provide a new treatment method for the harmless and efficient utilization of waste SCR denitrification catalysts.

[0074] Concrete experimental steps of the present invention are as follows:

[0075] Step 1: Raw material pretreatment

[0076] (1) Waste catalyst preparation: take the waste SCR catalyst, pre-treat to remove the blockage fly ash in the waste catalyst, then crush and grind to obtain -200 mesh catalyst powder;

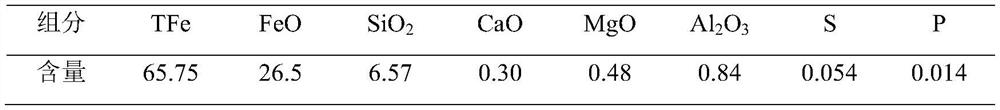

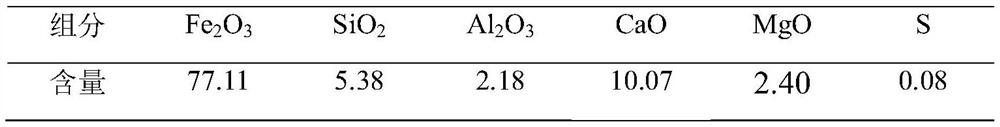

[007...

Embodiment 2

[0110] In this embodiment, the basic process of using the waste SCR catalyst as a binder to produce titanium-containing pellets is the same as that in Embodiment 1, the difference is that the proportion of waste catalyst added in the waste catalyst pellets of this embodiment accounts for the total amount of iron-containing raw materials. The mass percentage is 2.5%, and the addition ratio of the liquid phase additive accounts for 2.5% of the total mass percentage of the iron-containing raw materials. After mixing, add water to the disc pelletizer to produce pellets. After the pelletization is completed, the performance of the green pellets (drop strength, compressive strength, burst temperature) is tested, and the resistance to the pellets after roasting is tested. The compressive strength was measured, and the experimental results are recorded in Table 3.

Embodiment 3

[0112] In this embodiment, the basic process of using the waste SCR catalyst as a binder to produce titanium-containing pellets is the same as that in Embodiment 1, the difference is that the proportion of waste catalyst added in the waste catalyst pellets of this embodiment accounts for the total amount of iron-containing raw materials. The mass percentage is 7.5%, and the addition ratio of the liquid phase additive accounts for 7.5% of the total mass percentage of the iron-containing raw material. After mixing, it is added to the disc pelletizer to replenish water to produce pellets. After the pelletization is completed, the pellet performance ( Green pellet drop strength, compressive strength, burst temperature) detection, and the compressive strength of the pellets after roasting were measured, the experimental results are recorded in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com