Method for recycling low-zinc flue dust from iron and steel plant

A steel plant and resource-based technology, applied in chemical instruments and methods, improvement of process efficiency, photographic process, etc., can solve the problems of low recovery rate of low-zinc smoke and dust, large pollution, etc., achieve good economic benefits, less equipment investment, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

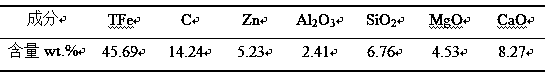

[0020] Embodiment 1: In this embodiment, a low-zinc fume from a steel plant in Sichuan is selected. The Zn content in the low-zinc fume is 5.23%, the TFe content is 45.69%, and the C content is 14.24% (see Table 1);

[0021] Table 1 Analysis of main components of low-zinc fumes from a steel plant in Sichuan

[0022]

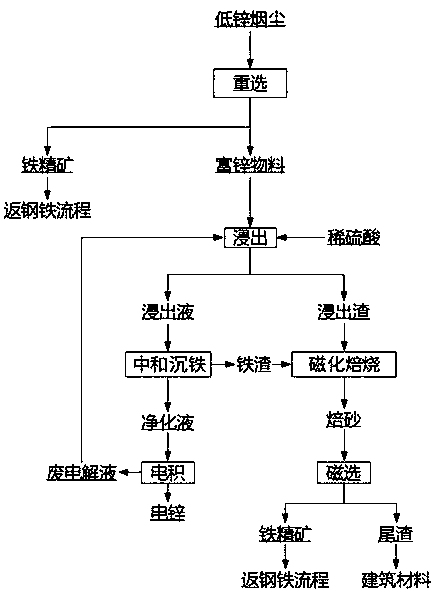

[0023] A method for resource utilization of low-zinc smoke dust in iron and steel plants (see figure 1 ),Specific steps are as follows:

[0024] (1) Iron concentrate and zinc-rich materials are obtained by conventional gravity separation of low-zinc dust from iron and steel plants. Zn13.5% and Fe25.8% in zinc-rich materials, 52.6% Fe and Zn1.8% in iron concentrate, iron concentrate Mine returns to steel process;

[0025] (2) Put the zinc-rich material in step (1) into the leaching tank, and carry out leaching with a dilute sulfuric acid solution at a temperature of 50°C and a stirring rate of 200r / min, wherein the mass concentration of the dilute sulfuric ac...

Embodiment 2

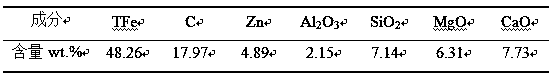

[0027] Embodiment 2: this embodiment selects the low-zinc soot of a certain iron and steel plant in Yunnan, and the Zn content is 4.89%, the TFe content is 48.26%, and the C content is 17.97% (see Table 2) in the low-zinc soot;

[0028] Table 2 Analysis of main components of low-zinc fumes from a steel plant in Yunnan

[0029]

[0030] A method for resource utilization of low-zinc smoke dust in iron and steel plants (see figure 1 ),Specific steps are as follows:

[0031] (1) Iron concentrate and zinc-rich materials are obtained by conventional gravity separation of low-zinc dust from iron and steel plants. Zn12.1% and Fe28.3% in zinc-rich materials, 50.9% Fe and Zn1.4% in iron concentrate, iron concentrate Mine returns to steel process;

[0032] (2) Put the zinc-rich material in step (1) into the leaching tank, and carry out dilute sulfuric acid solution leaching at a temperature of 55°C and a stirring rate of 200r / min, wherein the mass concentration of the dilute sulfuri...

Embodiment 3

[0034] Embodiment 3: the low-zinc soot of a steel factory in Guizhou in this embodiment, the Zn content is 6.23%, the TFe content is 47.87%, and the C content is 21.39% (see Table 3) in the low-zinc fume;

[0035] Table 3 Analysis of main components of low-zinc fumes from a steel plant in Guizhou

[0036]

[0037] A method for resource utilization of low-zinc smoke dust in iron and steel plants (see figure 1 ),Specific steps are as follows:

[0038](1) Iron concentrate and zinc-rich materials are obtained by conventional gravity separation of low-zinc dust from iron and steel plants. Zn11.5% and Fe23.2% in zinc-rich materials, 55% Fe and Zn1.1% in iron concentrate, iron concentrate Mine returns to steel process;

[0039] (2) Put the zinc-rich material in step (1) into the leaching tank, and carry out leaching with a dilute sulfuric acid solution at a temperature of 45°C and a stirring rate of 200r / min, wherein the mass concentration of the dilute sulfuric acid solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com