Biological organic fertilizer and preparation method thereof

A bio-organic fertilizer and mixture technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, can solve problems such as pollution, and achieve the effects of reducing environmental pollution, major economic and social benefits, and high fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The invention provides a method for preparing bio-organic fertilizer, which is characterized in that the method comprises mixing sludge, plant waste and high-temperature-resistant aerobic bacteria, and stacking and fermenting the obtained mixture until the moisture content of the mixture is reduced to 40% by weight % or less, such as 30-40% by weight, and then post-ripen the stacked fermented product, wherein the weight ratio of the sludge to the plant waste is 1:0.3-2, preferably 1:0.5-1, Based on each kilogram of plant waste, the amount of the thermostable aerobic bacteria added is 125-250 million, preferably 150-200 million, and the temperature that the thermostable aerobic bacteria can tolerate is at least 50°C.

[0013] According to the present invention, the object of the present invention can be achieved as long as the thermostable aerobic bacteria can withstand at least a high temperature of 50° C. and are harmless to human body and environment. Preferably, the ...

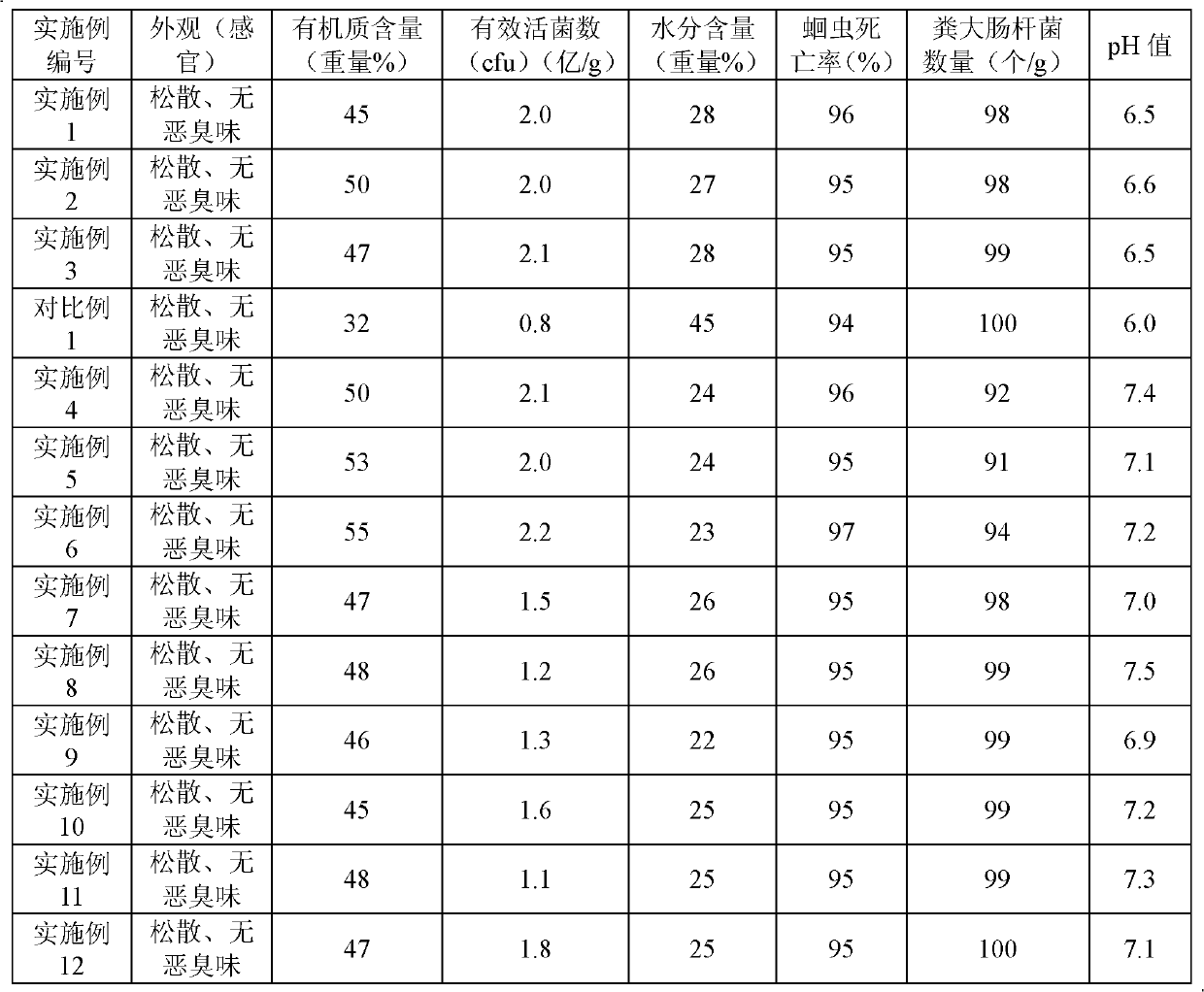

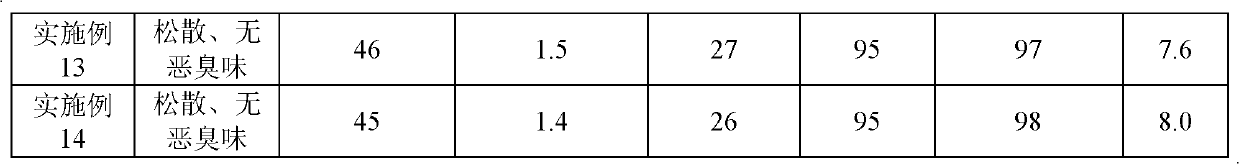

Embodiment 1

[0035] Mix the sludge and cassava residues in a weight ratio of 1:1, and inoculate Bacillus subtilis (Guangzhou Huayuan Biotechnology Co., Ltd.) (about 125 million inoculations per kilogram of cassava residues), and stack them into three-dimensional trapezoidal stacks after mixing evenly (The area of the upper bottom surface is 1×2m 2 , the area of the bottom surface is 2×3m 2 , height is 1m) carry out stacking fermentation, turn over 2 times every day to keep stacking temperature to be about 60 ℃, stop turning over after 25 days, record the moisture content of this moment mixture to be 37% by weight. The method of natural ventilation was used to keep the stacking temperature at about 35°C for 7 days to obtain the bio-organic fertilizer. The technical indicators such as organic matter in the bio-organic fertilizer were measured, and the results are shown in Table 2.

Embodiment 2

[0037] Mix the sludge and straw according to the weight ratio of 1:0.3, and inoculate Bacillus natto (Guangzhou Huayuan Biotechnology Co., Ltd.) (about 250 million cassava residues per kilogram), and stack them into three-dimensional trapezoidal stacks after mixing evenly (The area of the upper bottom surface is 1×2m 2 , the area of the bottom surface is 2×3m 2 , height is 1m) carry out stacking fermentation, turn over 2 times every day to keep stacking temperature to be about 60 ℃, stop turning over after 25 days, record the moisture content of this moment mixture to be 36% by weight. The method of natural ventilation was used to keep the stacking temperature at about 35°C for 7 days to obtain the bio-organic fertilizer. The technical indicators such as organic matter in the bio-organic fertilizer were measured, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com