Dehydrating agent, preparation method thereof, organic fertilizer and preparation method thereof

A dehydrating agent, Portland cement technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and biological organic part treatment, etc. Effectiveness and social benefit, the effect of promoting the adjustment of agricultural industry structure, and solving the problem of organic fertilizer shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the dehydrating agent of the present invention includes mixing the raw materials uniformly, and is characterized in that the raw materials include furnace ash and / or Portland cement, quicklime, calcium chloride and / or magnesium chloride, and the furnace ash and / or silicic acid The weight of cement: the weight of the quicklime: the weight of the calcium chloride and / or magnesium chloride is 4-12:3-8:1, preferably 5-10:4-6:1.

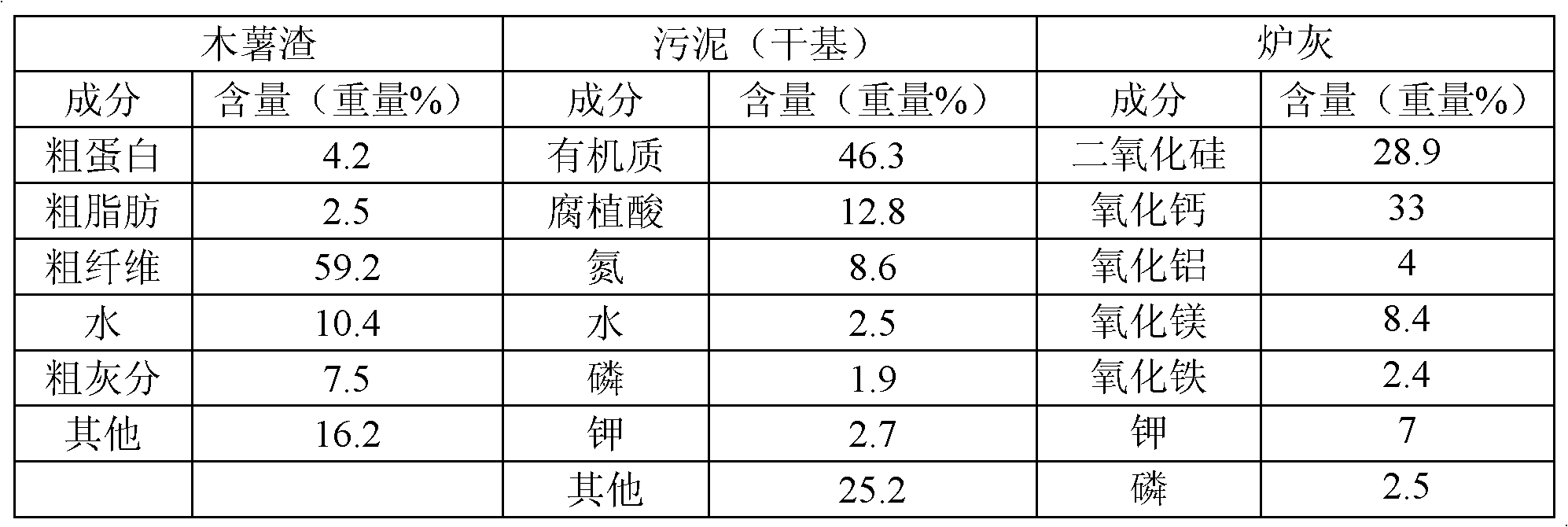

[0016] Wherein, the ash may be ash from various sources, for example, it may be the residue after burning plants or coal. The main components of the furnace ash may include silicon dioxide, calcium oxide, aluminum oxide, magnesium oxide, and iron oxide.

[0017] Based on the total weight of the furnace ash, the content of silica may be 18.2-37.6% by weight, the content of calcium oxide may be 21.5-40.8% by weight, and the content of alumina may be 2.1-8.3% by weight %, the content of the magnesium oxide may be 6.8-14.1% by wei...

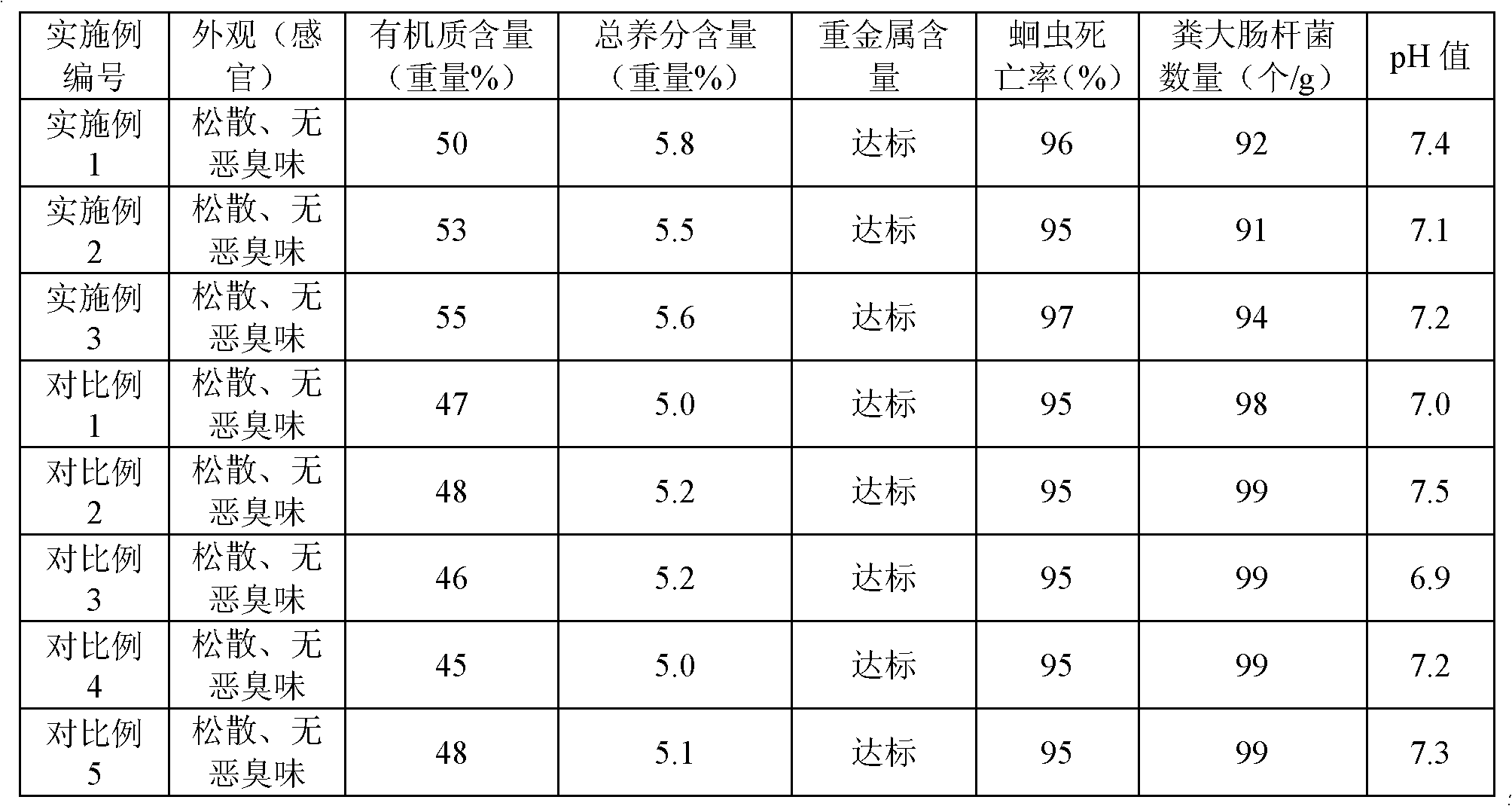

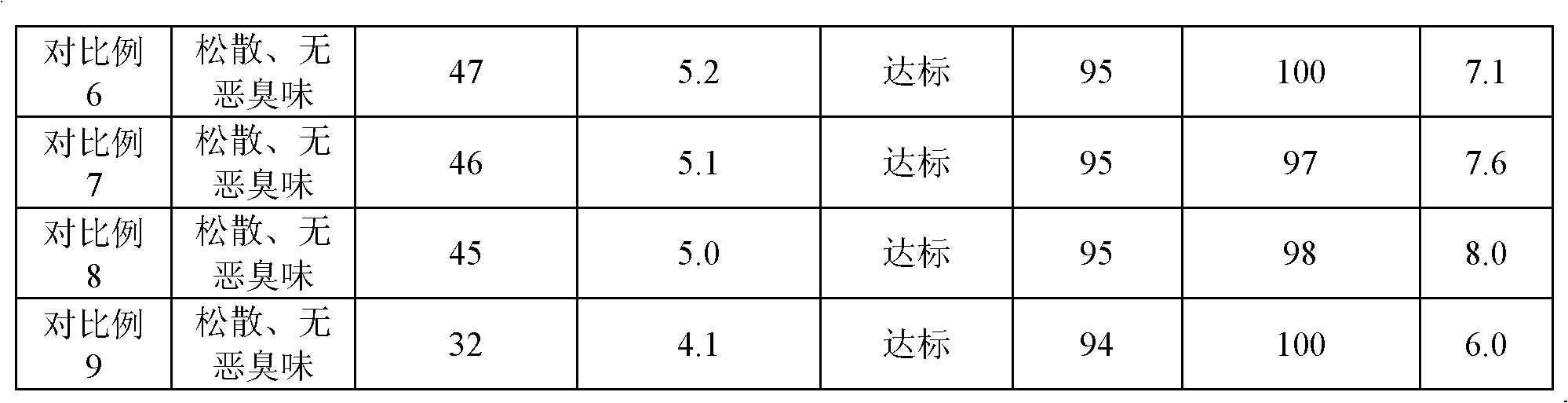

Embodiment 1

[0041] The sludge, cassava residue and dehydrating agent are mixed in a weight ratio of 1:2:0.02. The dehydrating agent contains furnace ash, quicklime and calcium chloride, and the weight ratio of the three is 4:8:1, and inoculated with Bacillus subtilis ( Guangzhou Huayuan Biological Technology Co., Ltd.) (inoculate about 200 million cassava residues per kilogram), mix well and pile into a stereo trapezoid stack (upper bottom area is 1×2m 2 , The bottom area is 2×3m 2 , Height is 1m) for stacking fermentation, turning the stack twice a day to keep the stacking temperature at about 60°C, and stopping turning after 10 days. The moisture content of the mixture at this time is measured to be 30% by weight. Use natural ventilation to keep the stacking temperature at about 35℃ for 7 days, then place the product in a direct heating rotary drum dryer (Zhengzhou Dingli Drying Equipment Co., Ltd.), and dry it at 80℃ to reduce the moisture content to 20% by weight or less, the organic fe...

Embodiment 2

[0043] The sludge, cassava residue and dehydrating agent are mixed in a weight ratio of 1:2:0.1. The dehydrating agent contains Portland cement, quicklime and magnesium chloride, the weight ratio of the three is 12:3:1, and the inoculation of Bacillus natto ( Guangzhou Huayuan Biological Technology Co., Ltd.) (inoculate about 200 million cassava residues per kilogram), mix well and pile into a stereo trapezoidal stack (upper bottom area is 1×2m 2 , The bottom area is 2×3m 2 , Height is 1m) for stacking fermentation, turning the stack twice a day to keep the stacking temperature at about 60°C, stopping turning after 15 days, and measuring the moisture content of the mixture at this time to be 30% by weight. Use natural ventilation to keep the stacking temperature at about 35℃ for 7 days, then place the product in a direct heating rotary drum dryer (Zhengzhou Dingli Drying Equipment Co., Ltd.), and dry it at 80℃ to reduce the moisture content to 20% by weight or less, the organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com