Patents

Literature

42results about How to "Improve brittle defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified glass fiber reinforced polylactic acid composite material and preparation method thereof

The invention relates to a modified glass fiber reinforced polylactic acid composite material and a preparation method thereof, relating to the field of composite materials. The composite material comprises the following components in parts by weight: 100 parts of polylactic acid, 30-40 parts of glass fiber, 5-10 parts of polyurethane prepolymer, and can be added with other components according to practical demand, such as a flame retardant agent, an antioxidant, color masterbatch and the like. The preparation method comprises the following steps: placing polylactic acid into acetone, heating and dissolving at the temperature of 40 to 50 DEG C, then adding glass fiber and polyurethane prepolymer, stirring for 1 to 2 hours, filtering, drying for 3 to 7 hours, obtaining modified glass fiber, mixing the polylactic acid and the modified glass fiber evenly, mixing the materials by an extruder or an internal mixer at the temperature of 170 to 200 DEG C, cutting into granules and obtaining the composite material. The invention overcomes the defects that the existing polylactic acid composite material has large fragility and poor compatibility, and can achieve the requirements of simultaneously strengthening and toughening the polylactic acid.

Owner:溧阳常大技术转移中心有限公司

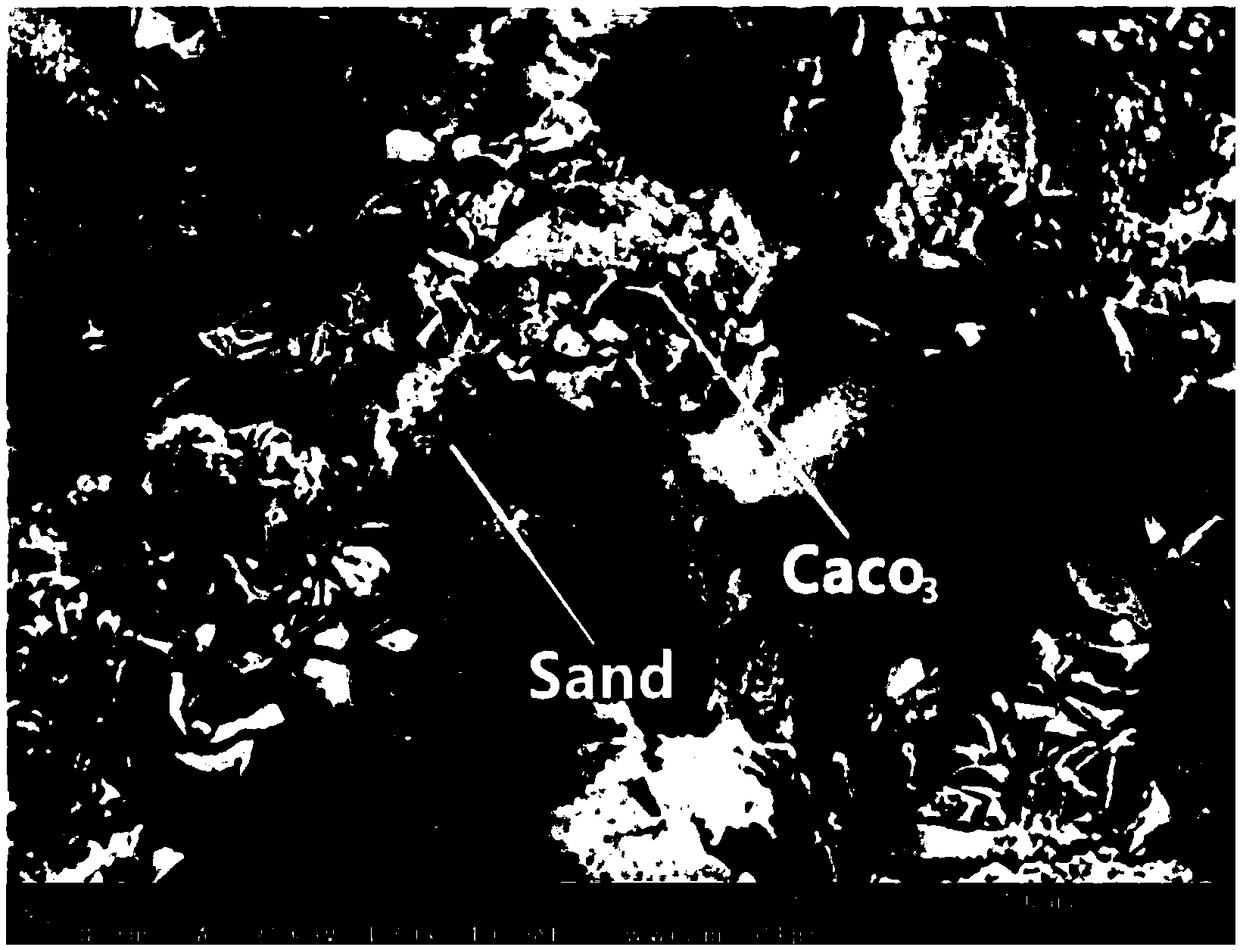

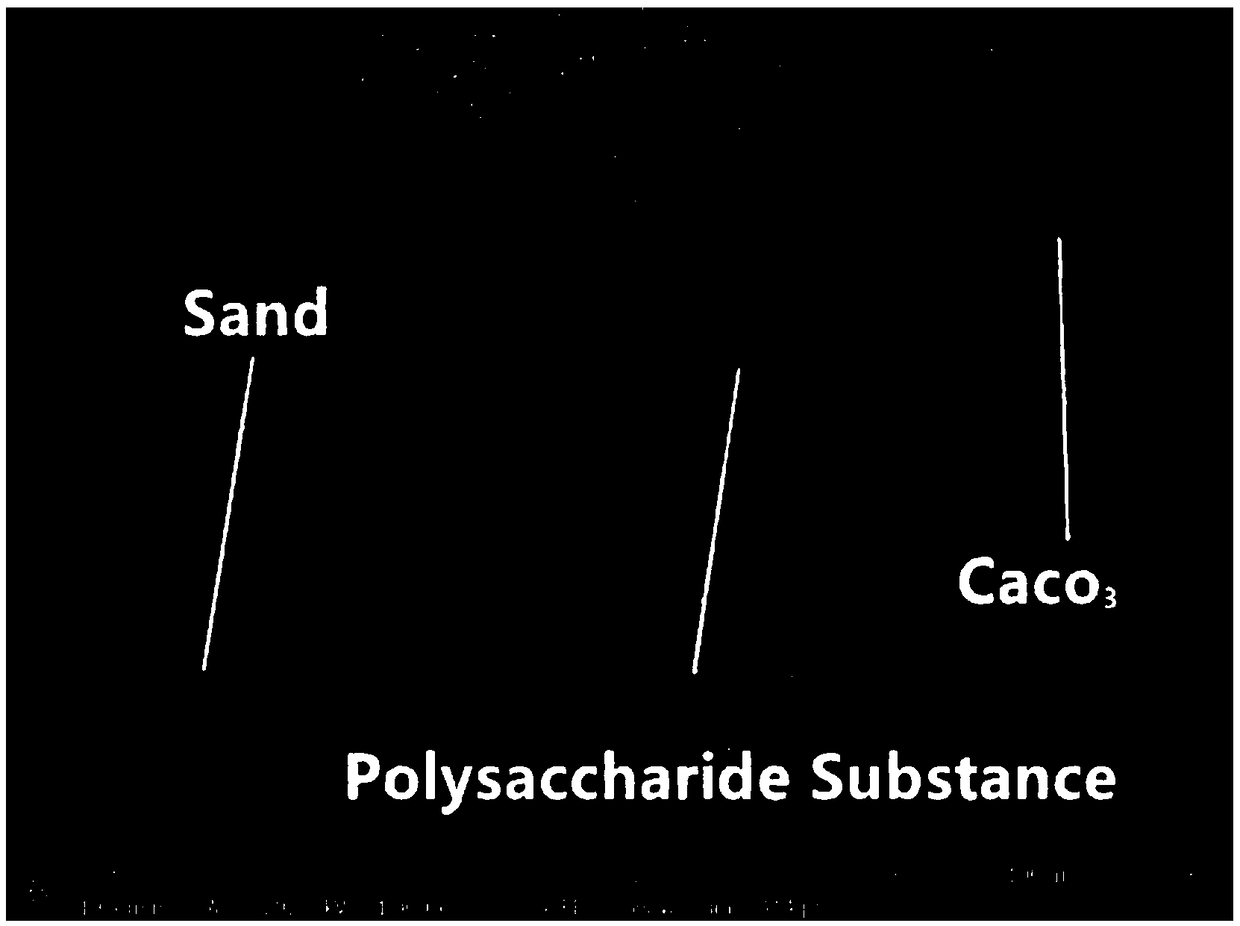

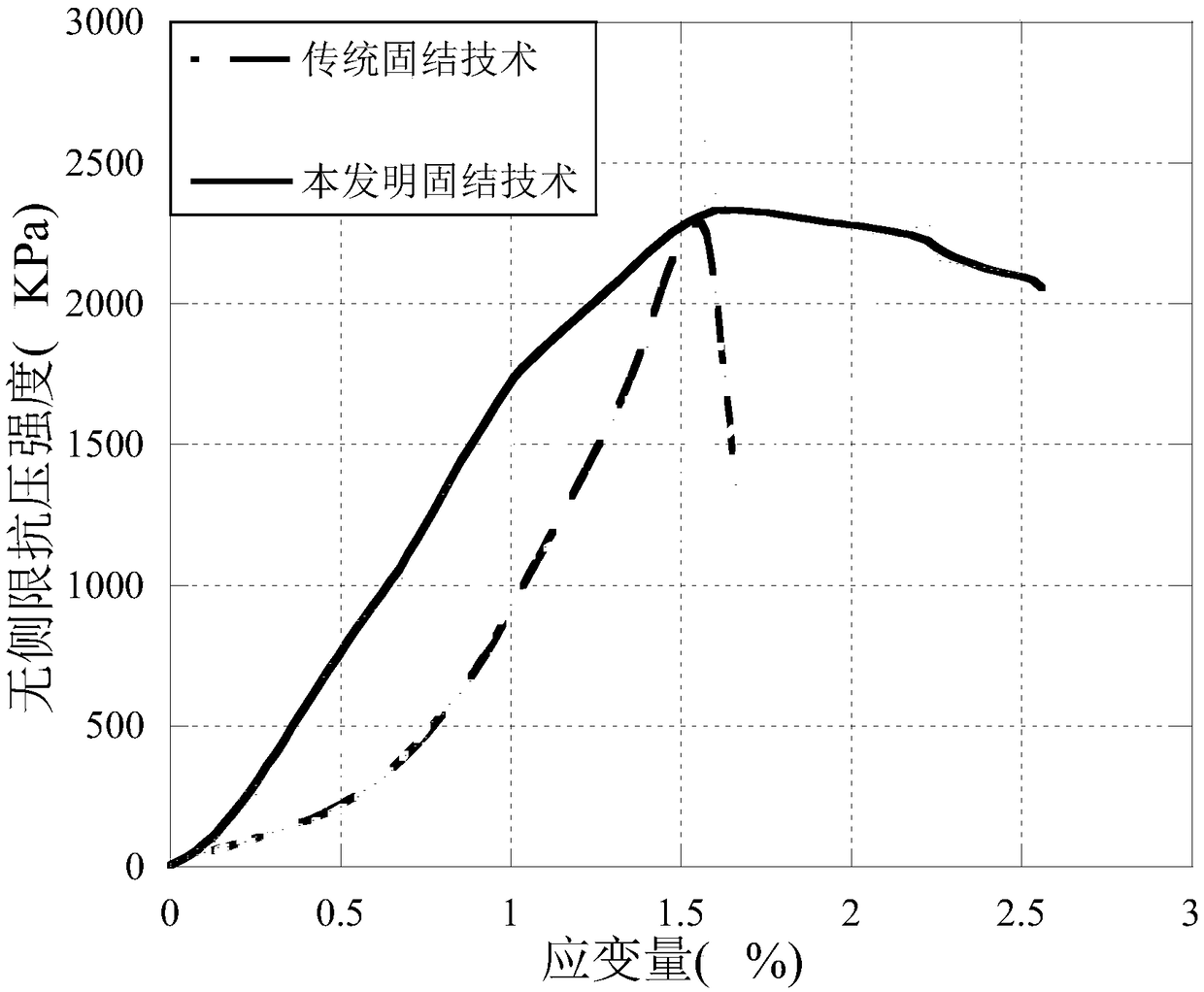

Microorganism calcareous glue, preparation method and application thereof, sandy soil column and preparation method thereof

InactiveCN108823259AIncrease contentLarge internal friction angleBacteriaMicroorganism based processesCalcium in biologyCalcite

The invention discloses environment-friendly microorganism calcareous glue, a preparation method and application thereof, a sandy soil column and a preparation method thereof. The environment-friendlymicroorganism calcareous glue is prepared from a microorganism bacteria solution with mineralization performance, a calcium source nutrient solution and an environment-friendly colloid in a volume ratio of 1 to (10 to 100) to (0.001 to 1). In the preparation of the microorganism bacterial solution, a culture medium is inoculated with 5 percent of sporosarcina pasteurii serving as a strain for performing oscillation and propagation to obtain a bacteria solution; in preparation of the calcium source nutrient solution, the calcium source nutrient solution is prepared according to a formula, andthe preparation of the nutrient solution is finished no less than 3 hours and no more than 6 hours before spraying. The environment-friendly colloid liquid of biomacromolecule liquid with colloidalityis prepared by dissolving exopolysaccharide of cell secretion or purified polysaccharide products. By adopting the environment-friendly microorganism calcareous glue, the defect of large brittlenessof a calcite cementation sand material by only relying on microorganism induction is overcome, and the concretion result of sand is effectively improved.

Owner:INNER MONGOLIA UNIV OF TECH

Baking-free brick with waste rubber and coal ash as major raw materials

ActiveCN102976686AImprove brittle defectsLow elastic modulusSolid waste managementWaste rubberFreeze and thaw

The invention discloses a baking-free brick with waste rubber and coal ash as major raw materials. The baking-free brick is composed of the following raw materials in parts by weight: 3-10 parts of waste rubber, 30-45 parts of coal ash, 20-25 parts of yellow sand, 5-10 parts of cement, 10-15 parts of calcium oxide, 3-5 parts of calcium sulfate, 1-2 parts of sodium sulfate, 1.5-2 parts of sodium hydroxide, 0.01-0.05 parts of sodium metaaluminate and 8-15 parts of water. The baking-free brick has the advantages that (1) the major problems that the coal ash baking-free brick is high in water absorption and poor in resistance to freezing and thawing resistance are solved, and the application field and region of the coal-ash baking-free brick are greatly expanded; (2) the production process is simple, the investment is low, the cost is low, the benefit is good, the market competitiveness is strong and the capacity of the market is great; and (3) the solid wastes such as waste tire and coal ash are used for making bricks instead of the traditional clay bricks, so that the baking-free brick is a green novel building material and is an important development project in China.

Owner:河南盖森材料科技有限公司

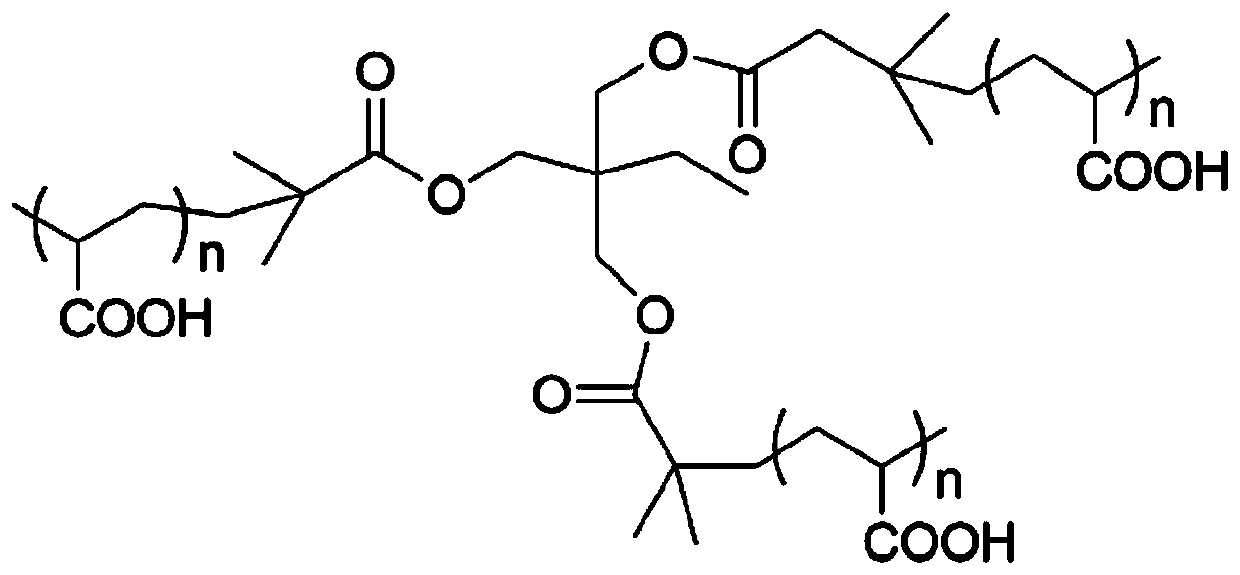

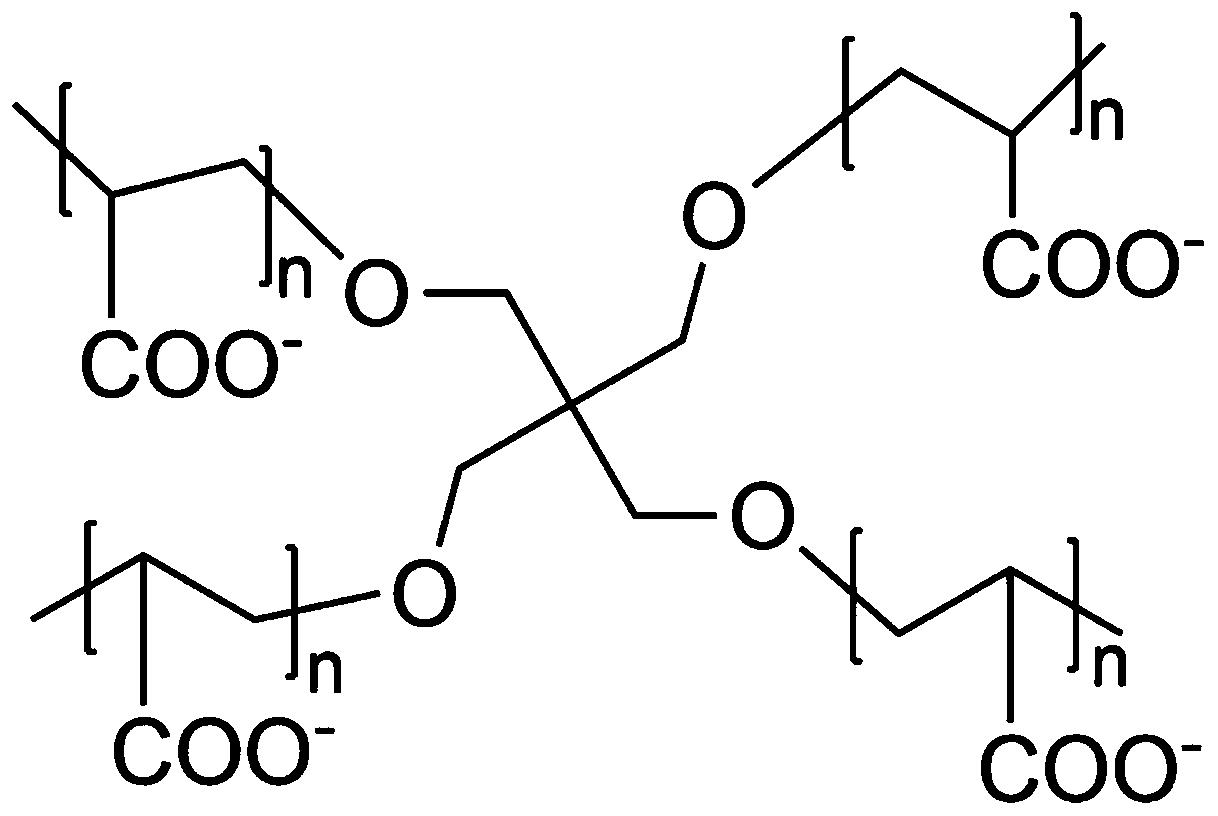

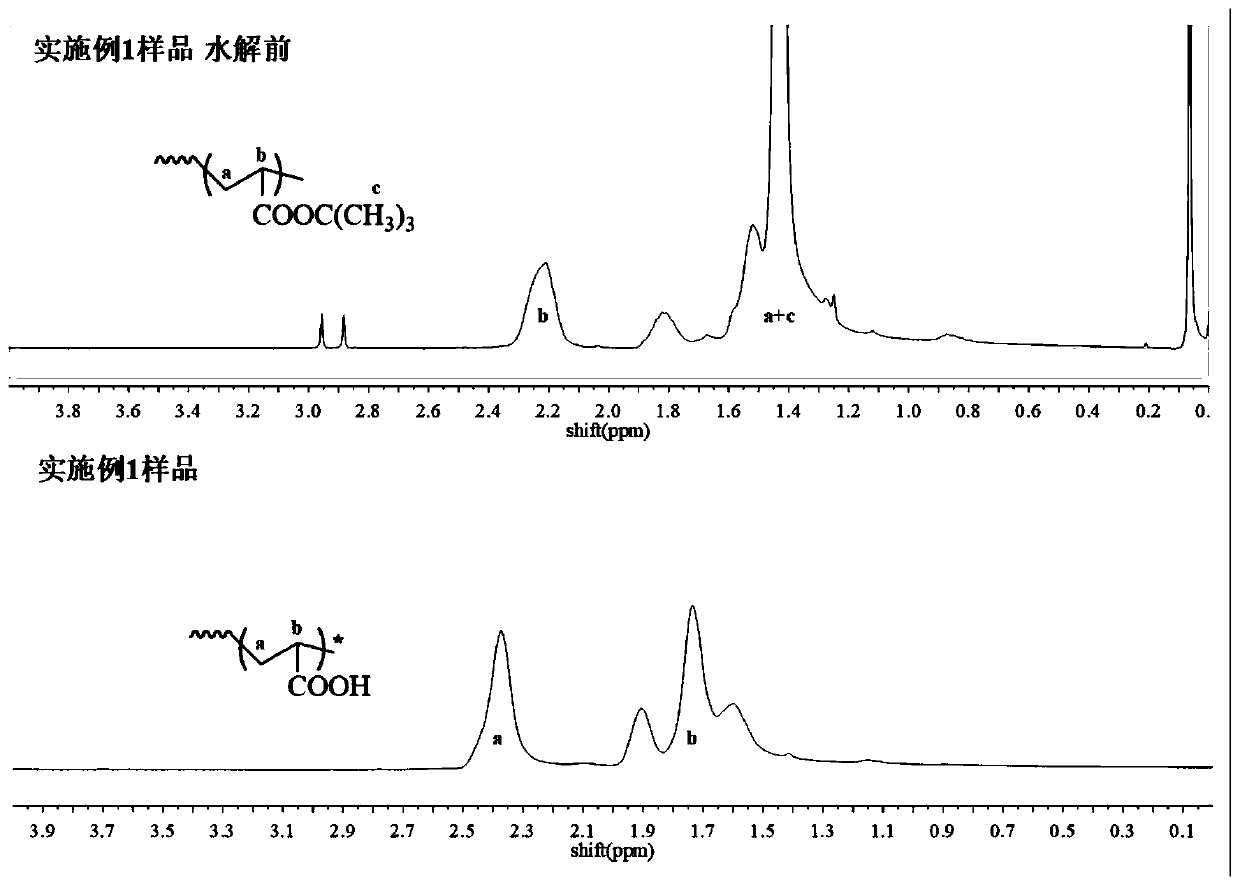

Lithium ion battery binding agent and preparation method and application thereof

ActiveCN109786747AImprove flexibilityEasy to operateCell electrodesSecondary cellsWater solubleSolubility

The invention belongs to the technical field of the lithium ion battery, and especially relates to a lithium ion battery. The lithium ion battery comprises a nonlinear multi-arm homopolymer composed of multi-element small-molecular nuclear parent and polyacrylic acid or polyacrylate branch arm connected to the multi-element small-molecular nuclear parent; the flexibility of the binding agent is increased due to the nonlinear polyacrylic acid or polyacrylate multi-arm structure, and the nonlinear structure has the advantages of multi-dimension efficient binding and water solubility. Relative tothe linear polyacrylic acid type binding agent, the defect that the molecule is fragile is improved to a certain degree. The problem that the cycle performance is bad since the pole plate produces the cracking and peeling and like phenomena due to the own fragility of the binding agent in the battery cycle is effectively solved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

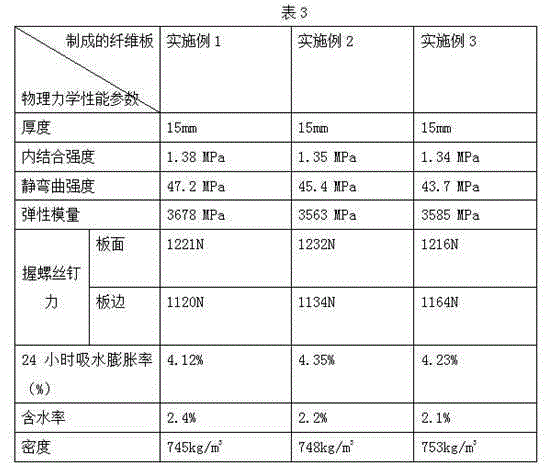

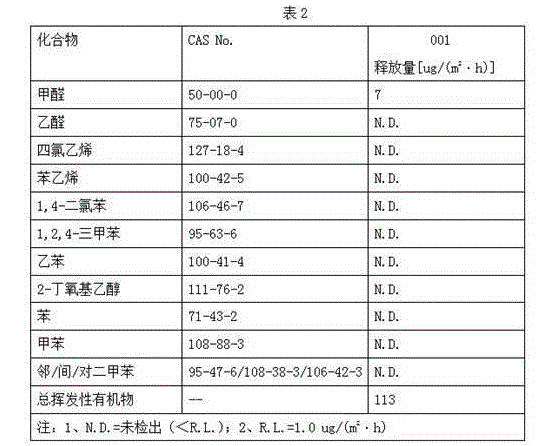

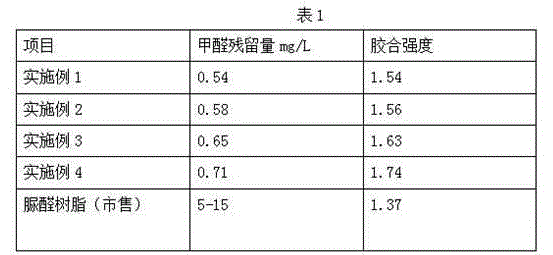

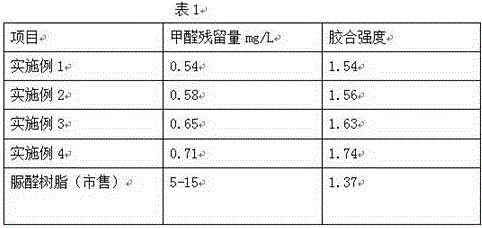

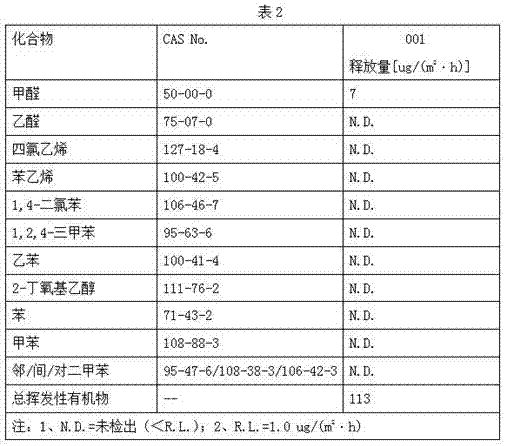

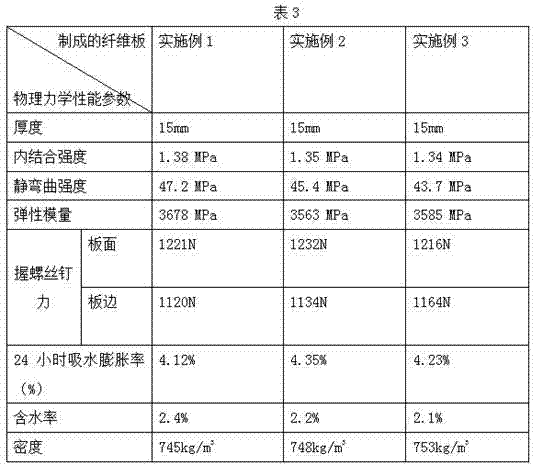

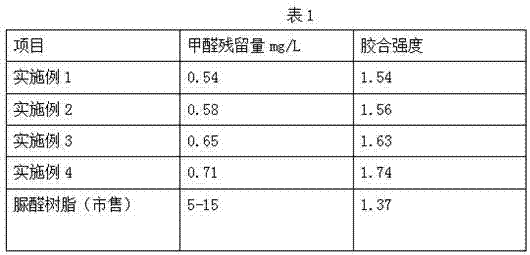

Method for producing fiberboard containing ultramicro amount of residual formaldehyde

ActiveCN105171886AGood adhesivenessHigh bonding strengthDomestic articlesFlat articlesFiberFiberboard

The invention relates to the technical field of manufacturing of artificial fiberboards, in particular to a method for producing a fiberboard containing an ultramicro amount of residual formaldehyde. The method for producing the fiberboard comprises the technological steps of preparation of adhesive, manufacturing of wood fibers, adhesive application, drying, mat formation and pre-pressing, hot pressing and obtaining of a finished product. According to the method, forest logging residues or wood processing residues or bagasse or other materials are used as raw materials for producing the fiberboard, waste materials are changed into valuable things, and full utilization of wood resources is effectively achieved; the adhesive used for producing the fiberboard is adhesive containing only a micro amount of residual formaldehyde, in this way, environmental friendliness and safety are achieved, and the fiberboard has good water resistance and high bonding strength; the fiberboard produced by using the adhesive hardly contains residual formaldehyde and high in binding powder; the content of substances harmful to human bodies is low, the substances harmful to the human bodies hardly exist, and thus harm to the human bodies is reduced; in addition, the internal structure of the board is uniform, the density is proper, the dimensional stability is high, the quality is stable, and the service life is long.

Owner:洪湖市鼎新生物新材料有限公司

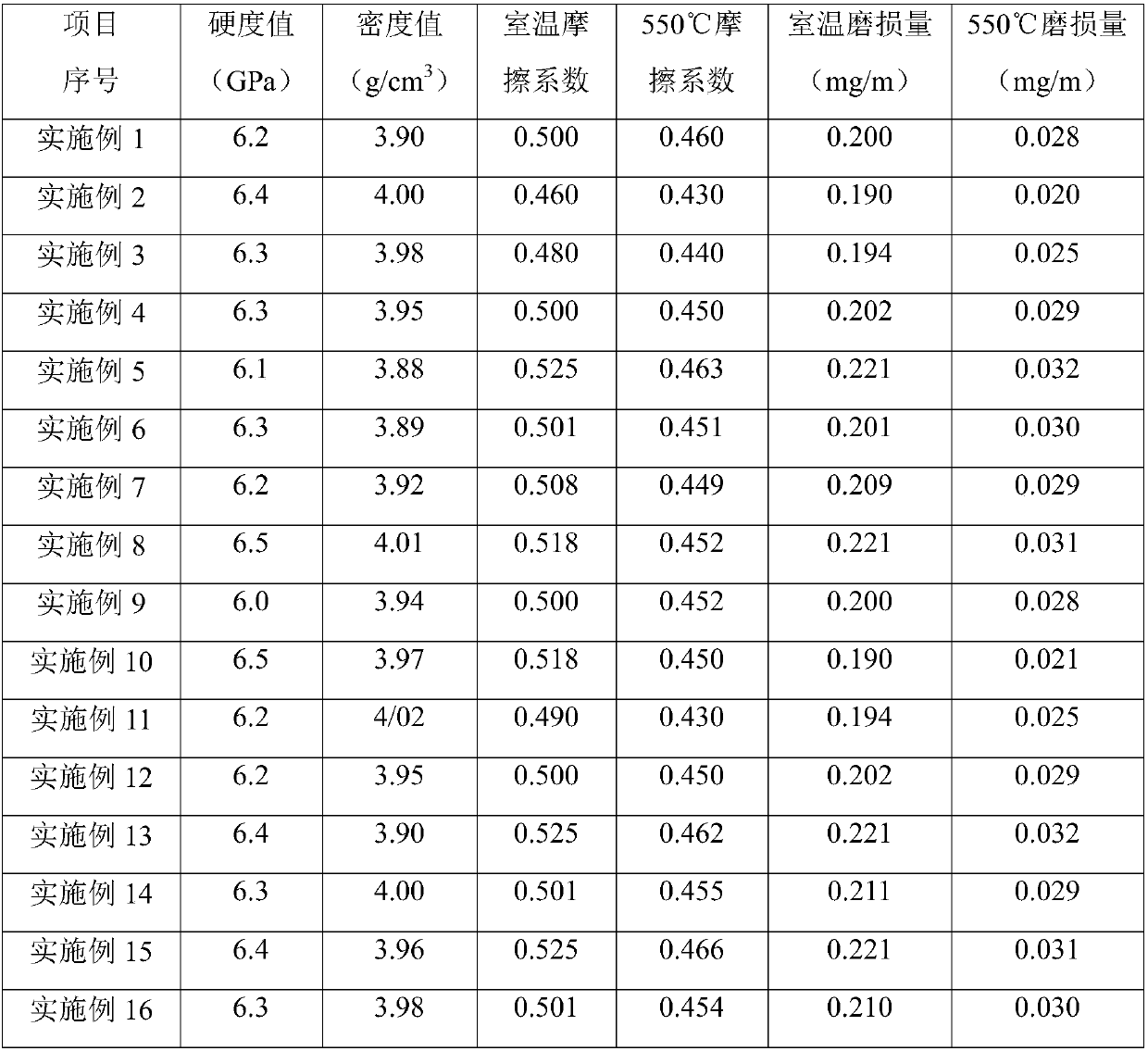

TiAl-based high-temperature-resistant self-lubricating composite and preparation method

ActiveCN107916349AIncrease coefficient of frictionImprove mechanical propertiesCarrying capacityChemical composition

The invention discloses a TiAl-based high-temperature-resistant self-lubricating composite. The composite is prepared from chemical components in percentage by mass as follows: 5%-30% of Ti3SiC2 and the balance of TiAl alloy powder. A preparation method of the TiAl-based high-temperature-resistant self-lubricating composite mainly comprises the steps as follows: the components, namely, Ti3SiC2 andthe TiAl alloy powder are subjected to ball-milling and are evenly mixed, the rotating speed of a ball mill is 300-450 r / min, and the ball-milling time is 2-4 h; the mixed powder is dried and then iscontained in a mold for pre-pressing molding, SPS sintering is performed on the dried pre-pressed powder, the pressure is 20-50 MPa, the vacuum degree is 10-40 Pa, the powder is heated to 800-1,200 DEG C, the temperature is kept for 10-30 min, the heating rate is 50-100 DEG C / min, the powder is subjected to furnace cooling, and a blank is obtained; surface treatment is performed on the blank, andthe TiAl-based high-temperature-resistant self-lubricating composite is obtained. The composite is fatigue-resistant, impact-resistant, high-temperature-resistant and high in carrying capacity, the self-lubricating performance can be realized, the friction coefficient and the abrasion loss can be reduced, and the self-lubricating performance is more excellent under the high-temperature condition.

Owner:YANSHAN UNIV

Special heat dissipation electrostatic spraying coating for LED lamp

InactiveCN106675329AImprove brittle defectsImprove bending strengthPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyModified carbon

The invention discloses a special heat dissipation electrostatic spraying coating for an LED lamp. The heat dissipation electrostatic spraying coating is prepared from the following raw materials: epoxy resin, polyurethane, unsaturated polyester resin, maleic anhydride, methyl tetrahydrophthalic anhydride, m-phthalic anhydride, 2,4,6-tri(dimethylamine methyl) phenol, trimethylolpropane, 2-butyl-2-ethyl-1,3-propylene glycol, magnesium nitride, modified carbon nano tube, graphene, nano calcium carbonate, cerium oxide, silica powder, hexamethyl-disilazane, phenyltrimethoxysilane, phenyl methyl dimethoxysilane, dibutyltin dilaurate, a leveling agent and benzoin, wherein the epoxy resin is a mixture of biscyclopentadiene dioxide epoxy resin and o-cresol formaldehyde epoxy resin. The heat dissipation electrostatic spraying coating is high in heat dissipation property and high in high temperature resistance, and the service life of the LED lamp can be prolonged.

Owner:TIANCHANG JINLING ELECTRONICS

Low-noise high-temperature-resistant brake pad

InactiveCN106117956AGood heat resistanceGood processabilityFriction liningActuatorsPerliteCarbon nanotube

The present invention discloses a low-noise high-temperature-resistant brake pad, comprising a steel plate, a heat-insulating layer and a friction block; the friction block is made from phenolic resin, bismaleimide resin, carboxylic butadiene-styrene latex, epoxy resin, o-cresol formaldehyde epoxy resin, polybenzimidazole resin, high silica fiber, quartz fiber, barium sulfate, titanium carbide, nano aluminum oxide, mica, molybdenum disulfide, expanded perlite, ZrW2O8 powder, multi-walled carbon nanotubes, nano aluminum nitride, hexagonal boron nitride, epoxidized soybean oil, tung oil, polycarbosilane and brown fused alumina. The low-noise high-temperature-resistant brake pad provided herein has excellent resistance to high temperature and wear, excellent thermal stability, low noise in use and long service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

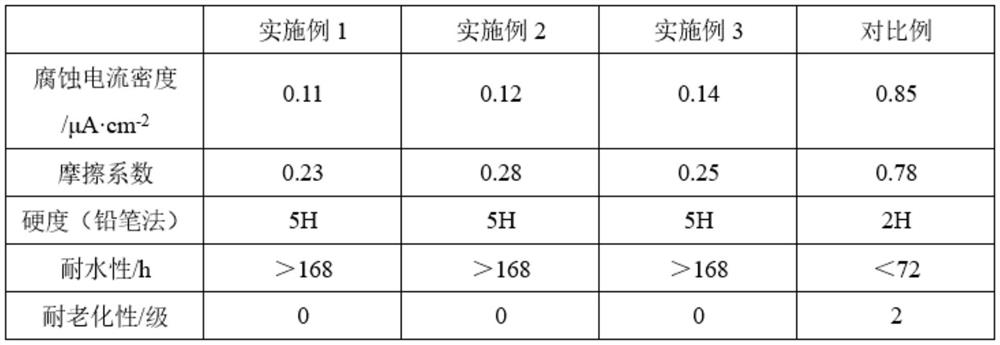

Treatment method of coating with anti-corrosion function on iron-based surface

InactiveCN111704845AHigh hardnessImprove corrosion resistanceMolten spray coatingAnti-corrosive paintsSand blastingHigh velocity

The invention relates to the field of anticorrosive coatings, in particular to a treatment method of a coating with an anticorrosive function on an iron-based surface, which comprises the following steps: (1) polishing an iron-based alloy; (2) performing sand blasting treatment on the polished iron-based alloy; (3) cleaning the surface of the iron-based alloy subjected to sand blasting treatment,putting the iron-based alloy into a drying oven of 60-100 DEG C to be treated for 0.2-0.5 h, and spraying a first anti-corrosion coating on the surface of the iron-based alloy by using high velocity oxy-fuel while the iron-based alloy is hot; and (4) after the first anti-corrosion coating is completely dried, placing the iron-based alloy coated with the first anti-corrosion coating in a drying oven at the temperature of 60-100 DEG C to be treated again for 0.2-0.5 h, and then spraying a second anti-corrosion coating on the surface of the first anti-corrosion coating through hypersonic flame while the iron-based alloy is hot. The method solves the problem that an existing treatment method for spraying a single coating usually cannot meet the requirements for high strength, corrosion resistance, abrasion resistance and the like at the same time.

Owner:宁波计氏金属新材料有限公司

Heatproof anti-corrosion high-flame-retardant epoxy resin powder paint

InactiveCN105315846AImprove brittle defectsImprove adhesionFireproof paintsAnti-corrosive paintsGlycolurilAcrylic resin

The invention discloses heatproof anti-corrosion high-flame-retardant epoxy resin powder paint. The powder paint is prepared from bisphenol A epoxy resin, acrylic resin, modified polytetrafluoroethylene, organic silicon resin, phenolic resin, tetramethoxy methyl glycoluril, tetramethyl thiourea, toluene diisocynate, 2-methylimidazole, 2-butyl-2-ethyl-1,3-propylene glycol, nano-zinc oxide, expansible graphite, attapulgite, talcum powder, ferric oxide, zinc borate, polyethylene wax, glycerine, pentaerythritol, an acrylate flatting agent, hydroxyethyl cellulose and organic silicon defoamer. The heatproof anti-corrosion high-flame-retardant epoxy resin powder paint is good in heat resistance, excellent in ageing resistance, high in flame retardant property, good in decorativeness and long in service life.

Owner:安徽圣德建材科技有限公司

Human body canal cast filler and preparation method thereof

InactiveCN102391617AEasy to prepareSimple and fast operationDead animal preservationEducational modelsHuman bodyPolymer science

The invention provides a human body canal cast filler and a preparation method of the human body canal cast filler; and the human body canal cast filler is good in physicochemical performance, strong in acid-base resistance, good in flexibility and stronger in support force. The human body canal cast filler is prepared by the components according to the volume ratio: 100ml of cyclodextrin (CYD)-128 type epoxy resin, 20-24ml of liquid-state nitrile rubber, 35-40ml of polypropylene glycol diglycidyl ether, 15ml of 2, 4, 6-tri-(dimethylamino methyl) phenol (DMP-30), 45ml of modified polyether amine epoxy resin curing agent ZY-1784 and 40-45ml of high-performance epoxy resin toughening modifier (RF-400). The human body canal cast filler is easy in preparation as well as simple and convenient in operation, can be completed by once injection without after-teeming, and can be immediately prepared when injection is not sufficient. The invention has the characteristics of being good in fluidity, low in injection resistance, full in molding, fin and attractive, low in contractibility rate, environment-friendly and the like.

Owner:黄海龙

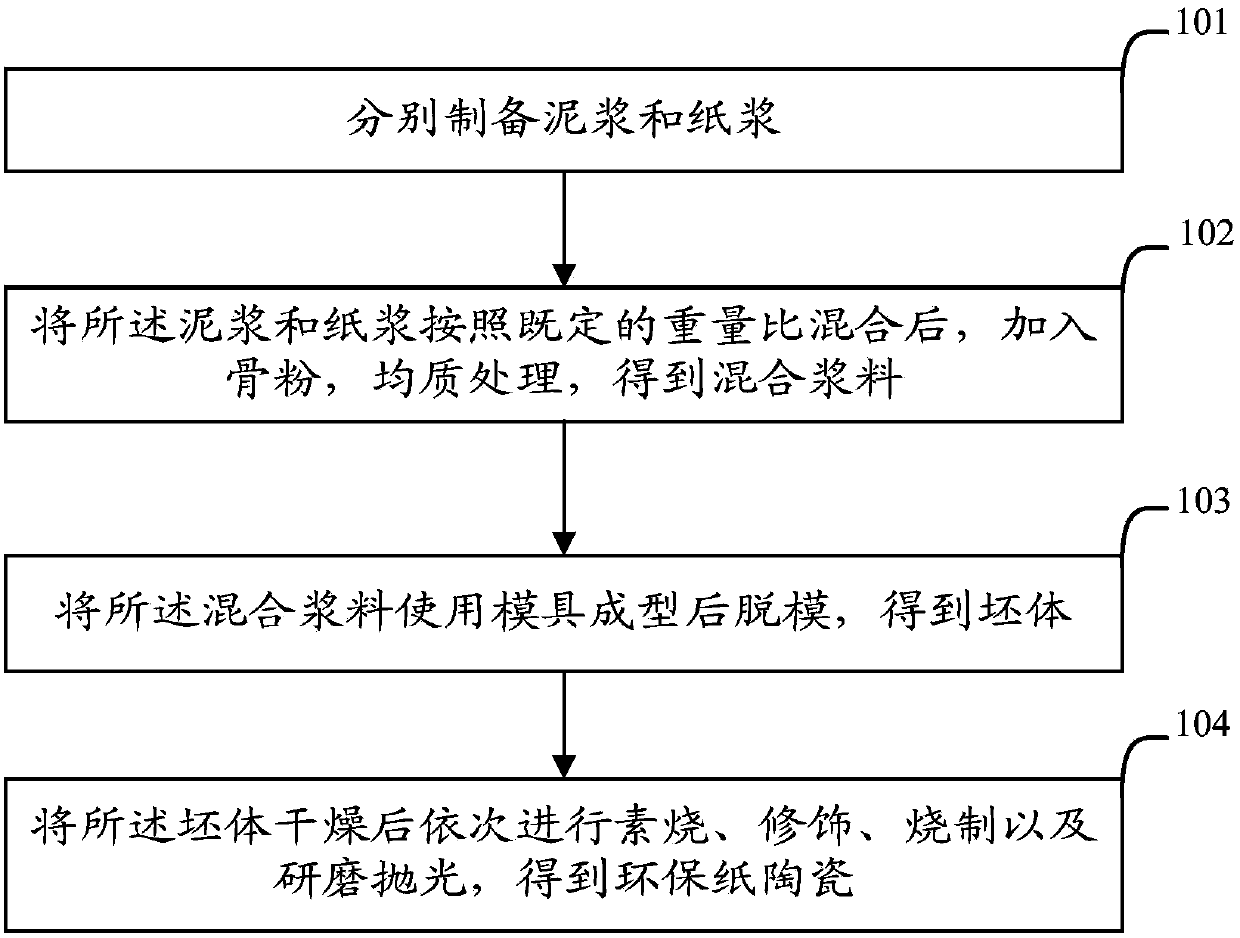

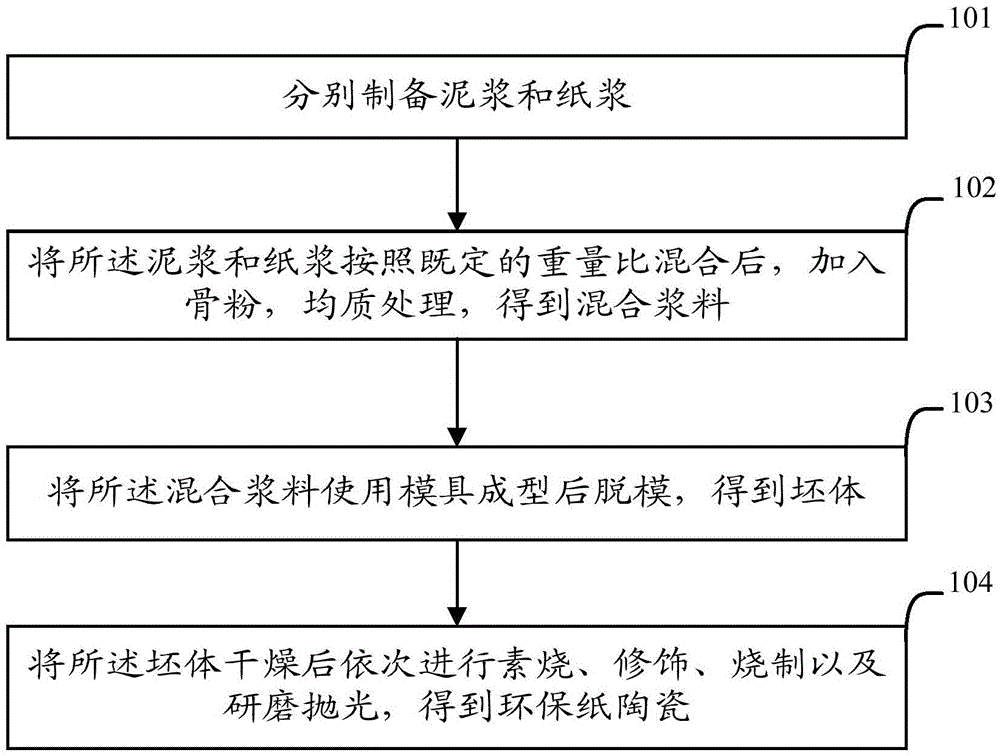

Environment-friendly paper ceramic and preparation method thereof

The invention relates to the filed of production of ceramic and in particular relates to environment-friendly paper ceramic and a preparation method thereof. The environment-friendly paper ceramic is prepared from the following raw material components in parts by weight: 450-500 parts of mud, 20-25 parts of paper pulp and 90-100 parts of bone meal, wherein a weight ratio of paper scrap to water in the paper pulp is 1:2. The environment-friendly paper ceramic provided by the invention has the advantages that the paper pulp is added in the raw materials used for preparation of ceramic, so that flexibility of the whole slurry is improved, the slurry can coat a mould in a thin layer in a die moulding process, and further a ceramic product with the thickness of 1mm can be prepared; in a drying process of the environment-friendly paper ceramic, after massive moisture is removed, cracking phenomenon can not be caused or is hardly caused, further ceramic making success rate is effectively increased, and the defect that manpower and material resources are wasted as a muddy green body cracks easily in the prior art is effectively overcome.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

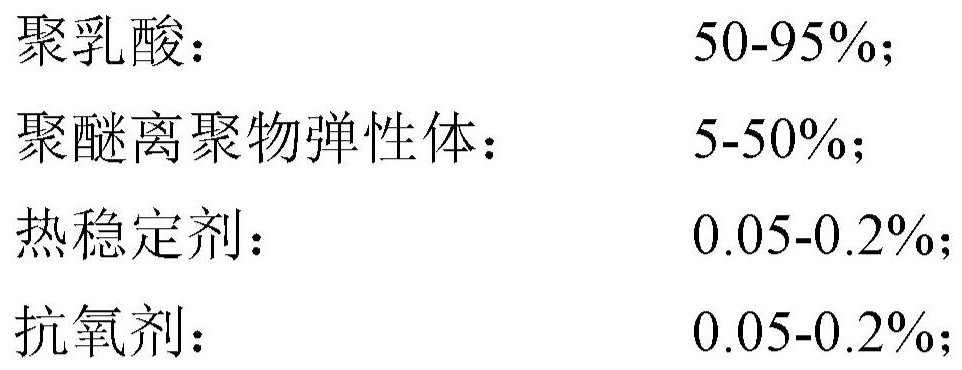

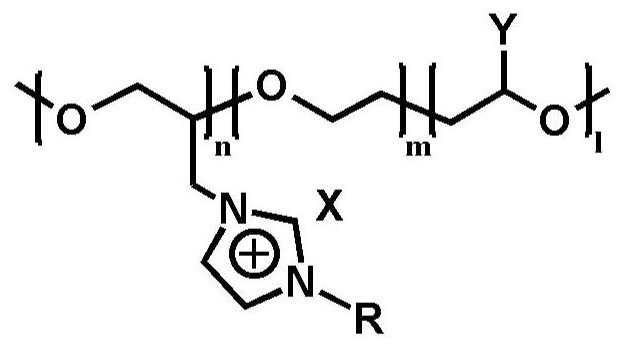

High-transparency toughness polylactic acid-based material and preparation method thereof

ActiveCN111748182AImprove impact strength and elongation at breakImprove brittle defectsBio-packagingHalogenAnoxomer

The invention discloses a high-transparency toughness polylactic acid-based material and a preparation method thereof. The polylactic acid-based material is composed of polylactic acid, a halogenatedpolyether elastomer, an ionomer elastomer synthesized from imidazole-containing monomers, a heat stabilizer and an antioxidant. The halogenated polyether elastomer adopted by the invention is obtainedby quaternization reaction of an elastomer with a polyether chain as a main chain and a halogen group in a side chain and a compound with an imidazole group in an end group, wherein the molar contentof an ionomer group of the obtained halogenated polyether elastomer is 20-30%. The polylactic acid is premixed with the obtained elastomer ionomer, a heat stabilizer and an antioxidant, and then meltprocessing is conducted by using an internal mixer or a screw extruder. According to the method disclosed by the invention, the tough polylactic acid base material with high transparency is preparedby selecting a proper elastomer to be compounded with polylactic acid, adjusting the proportion, combining a processing technology and changing the anion type in the ionomer, so that the defect of serious brittleness of polylactic acid is improved, and the application field of the material is expanded.

Owner:TIANJIN UNIV

Synthetic adhesive using papermaking black liquor as raw material and its production method

InactiveCN105018011BGood adhesivenessHigh bonding strengthNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesBlack liquorAdhesive

The invention discloses an adhesive synthesized by using papermaking black liquor as a raw material and a production method thereof. The adhesive is composed of the following raw materials in parts by weight: 50-500 parts of papermaking black liquor, 100-300 parts of phenolic resin, 1-10 parts of a coupling agent, 1-10 parts of an assistant and 1-5 parts of a processing agent. The production method includes the following steps: (1) putting the papermaking black liquor into a reaction still, adding a chlorhydric acid or sulphuric acid aqueous solution while stirring to adjust the pH of the solution to be 4-8, then heating, and when the temperature becomes stable at 60-90 DEG C, reacting for 10 minute to 2 hours; (2) after the step (1) is ended, adding phenolic resin, the coupling agent and the assistant, and then adding a NaOH aqueous solution until phenolic resin, the coupling agent and the assistant are dissolved, adjusting the pH value of the solution to be 11-14, and carrying out a polymerization reaction at 90-110 DEG C for 20 minutes to 3 hours; (3) after the step (2) is ended, adding the processing agent, stirring and reacting for 10-20 minutes. According to the invention, the papermaking black liquor is used as the main raw material to react with phenolic resin, and is combined with the coupling agent and the assistant, so that the gluing property of the adhesive is remarkably improved, and the papermaking black liquor is turned into treasure from waste.

Owner:广西星岛科技发展有限公司

High-heat-resistance epoxy resin electrostatic-spraying powder paint

InactiveCN106752206AImprove heat resistanceImprove impact resistanceFireproof paintsPowdery paintsSilanesCarbon nanotube

The invention discloses a high-heat-resistance epoxy resin electrostatic-spraying powder paint which is prepared from a bisphenol A epoxy resin, dicyclopentadiene dioxide, a polyaryl thioether resin, an organic silicon resin, dicyandiamide, maleic anhydride, 2-thiobenzimidazole, 2-methylimidazole, 2-butyl-2-ethyl-1,3-propanediol, talcum powder, fumed silica, precipitation-process barium sulfate, carbon nanotubes, nano silicon dioxide, N-phenyl-3-aminopropyltrimethoxy silane, a leveling agent, a sensitizer and a defoaming agent. The high-heat-resistance epoxy resin electrostatic-spraying powder paint has the advantages of favorable heat resistance, excellent impact resistance and long service life.

Owner:TIANCHANG JINLING ELECTRONICS

Preparation method of environment-friendly blue brick

InactiveCN106747334AHigh strengthLow costCeramic materials productionClaywaresEnvironmental resistanceBrick

The invention relates to a preparation method of an environment-friendly blue brick and belongs to the field of building wall materials. The preparation method comprises the following steps: (1) raw material pretreatment; (2) batching and stirring: weighing shale, clay, sludge, waste ceramics, vermiculite, volcanic ash, bean curd swilling, pine barks, bamboo residues and carbon according to the proportion occupied by all the raw materials, adding a proper amount of water, stirring the raw materials and uniformly mixing to obtain a mixture; (3) digesting; (4) pressing and molding: pressing and molding the digested mixture to obtain a brick blank, and naturally airing the brick blank till the moisture content is 16-20 percent to obtain the air-dried brick blank; (5) brick blank sintering: enabling the air-dried brick blank to enter a kiln for firing and sintering for 8-10 hours at a temperature of 1050-1250 DEG C; (6) sealing the kiln and cooling. According to the preparation method of the environment-friendly blue brick, the cost can be reduced, and safety and environmental protection are realized.

Owner:柳州市圣垒贸易有限公司

Potassium feldspar tailing environmentally-friendly brick and preparation method thereof

InactiveCN108840709AReduce processing timeReduced processing performanceCeramic materials productionCeramicwareBrickSludge

The invention discloses a potassium feldspar tailing environmentally-friendly brick and a preparation method thereof, and relates to the technical field of preparation of an environmentally-friendly brick. The preparation method comprises the following steps: (1) taking the following components in parts by weight: potassium feldspar tailing, oyster shells, sludge, ceramic powder, vermiculite powder, cinerite, bean curd swill, pine bark scraps, bamboo scraps, carbon powder, modified coal ash, quick lime, an anti-cracking agent and a foaming agent; (2) pulverizing the potassium feldspar tailing,the oyster shells, the ceramic and the vermiculite into powder; (3) mixing the feldspar tailing powder and the oyster shell powder, adding water and grinding to obtain a first mixed material; (4) adding water into all the raw materials and stirring to obtain a second mixed material; (5) digesting; (6) pressing and forming; (7) sintering a green brick; and (8) sealing a kiln and cooling. Accordingto the potassium feldspar tailing environmentally-friendly brick and the preparation method thereof, waste serves as the raw material, so that the production cost is reduced while environmental pollution is reduced.

Owner:贺州市骏鑫矿产品有限责任公司

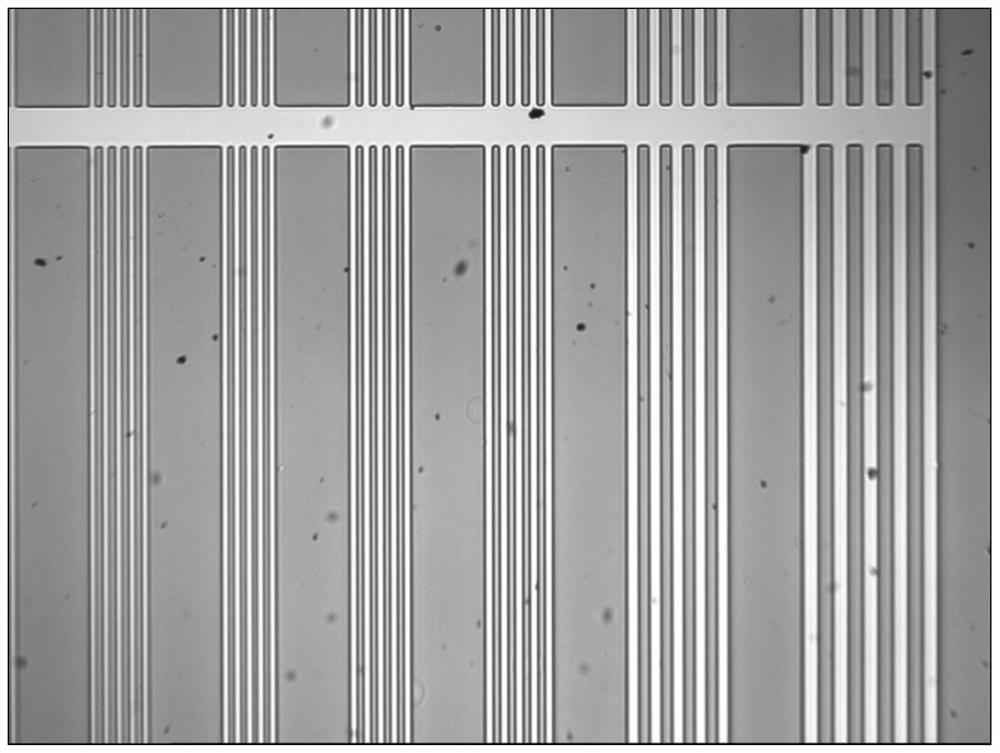

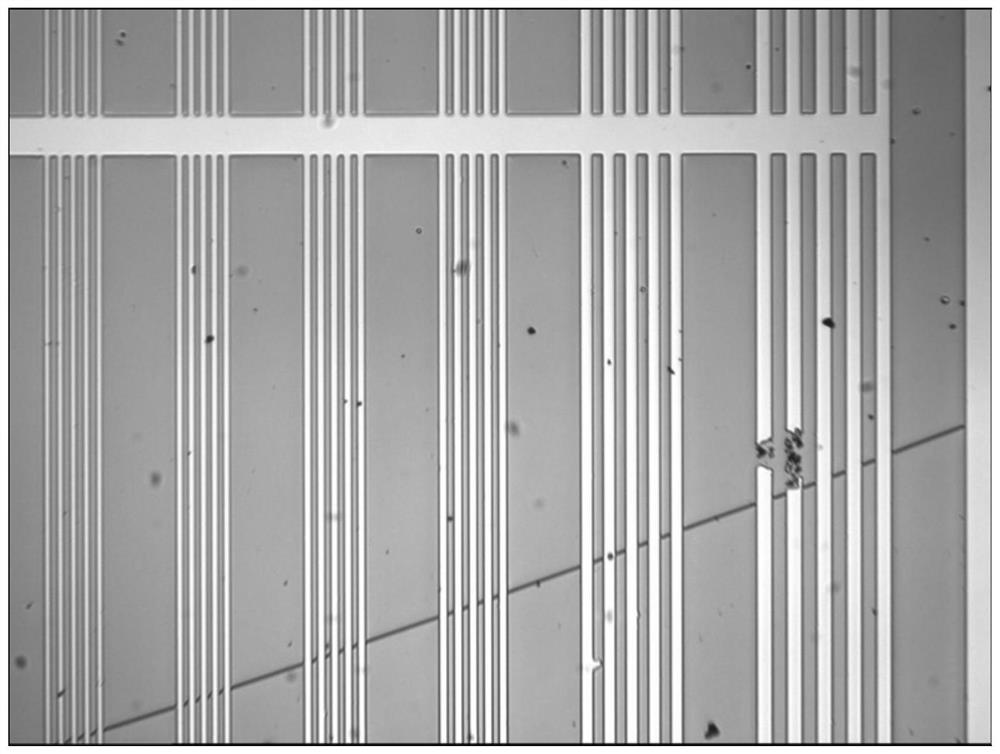

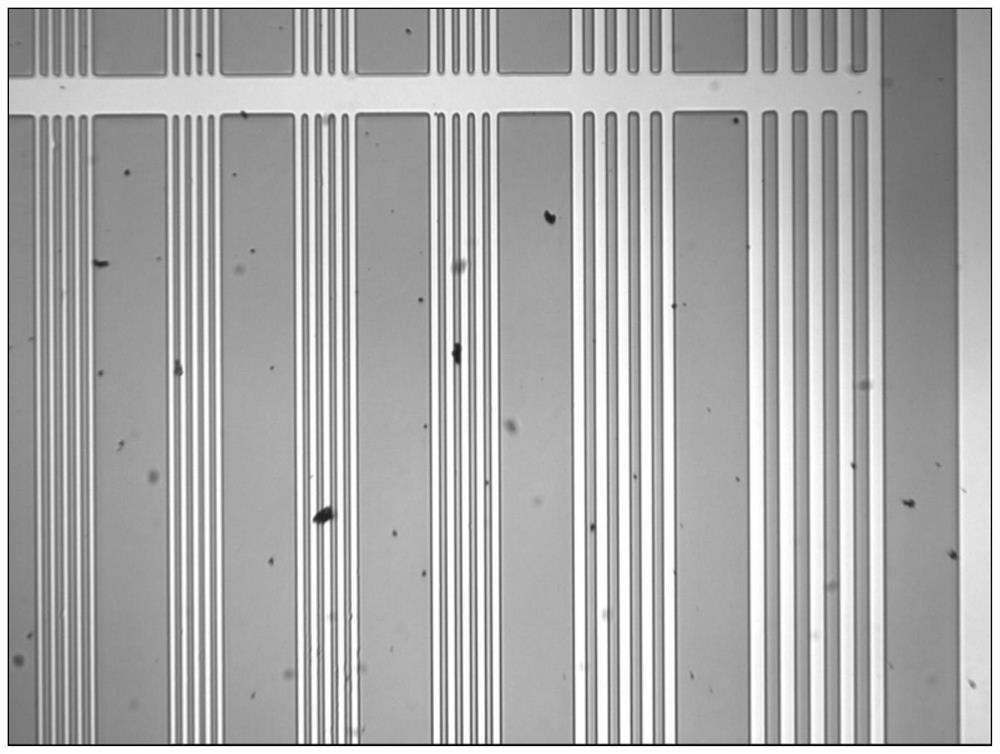

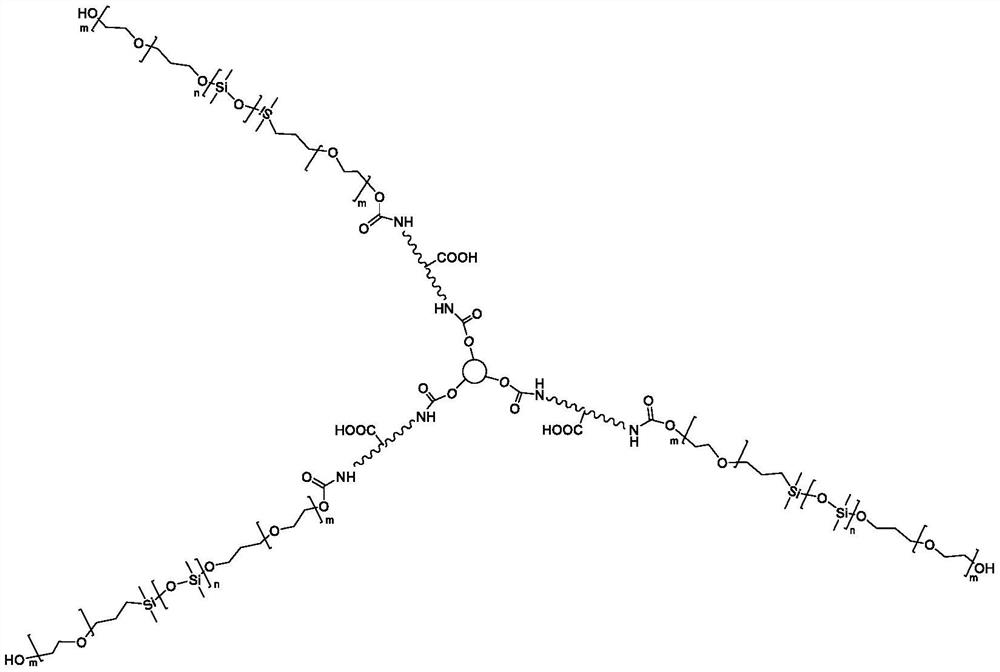

Chemically amplified positive ultraviolet photoresist, and preparation method and using method thereof

PendingCN113671793AImprove brittle defectsSolve crackingPhotomechanical exposure apparatusPhotosensitive material processingPolymer resinUltraviolet

The invention relates to a chemically amplified positive ultraviolet photoresist, and a preparation method and a using method thereof. The photoresist comprises, by mass, 25-45% of poly-p-hydroxystyrene polymer resin; 0.5-1.5% of a photoinduced acid generator; 0.1-0.2% of an acid quencher; 2-4% of a cross-linking agent; 0.1-0.5% of a flatting agent; and 48.8-72.3% of a solvent. The preparation method comprises the following step: mixing the components of the chemical amplification type positive ultraviolet photoresist. The using method comprises the following steps: coating a silicon wafer with the chemical amplification type positive ultraviolet photoresist, and sequentially carrying out pre-baking, exposure, post-baking and development. The chemically amplified positive ultraviolet photoresist solves the problem of photoresist cracking, especially the problem of cracking of positive thick film (10-30 microns) photoresist, is suitable for a passivation layer or a high-energy injection process at the rear section of an integrated circuit, and expands the application range.

Owner:江苏汉拓光学材料有限公司

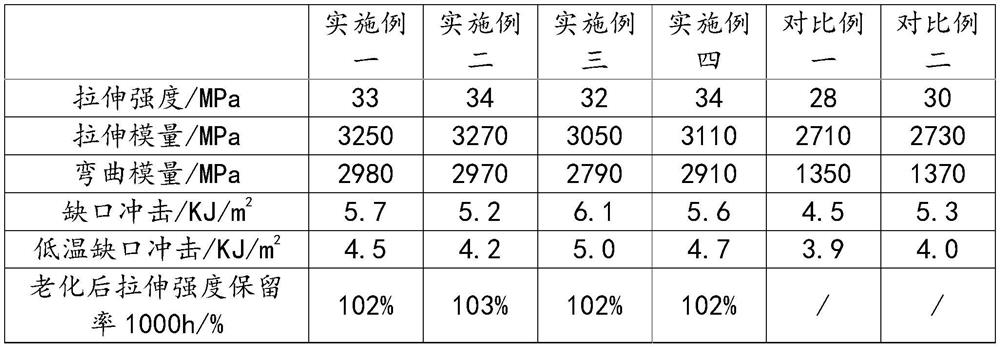

Mineral modified polypropylene composite material for vehicles and preparation method of mineral modified polypropylene composite material

The invention discloses a mineral modified polypropylene composite material for vehicles and a preparation method thereof, and provides the following technical scheme aiming at the problems of the existing PP modified material: the mineral modified polypropylene composite material is prepared from the following raw materials in parts by weight: 50-90 parts of polypropylene (PP), 10-40 parts of talc master batch, 3-10 parts of flexibilizer, 0.1-0.5 part of stabilizer, 0.1-0.5 part of lubricant and 0.2-1 part of other auxiliaries. The preparation method comprises the following steps: material preparation, material premixing and mixing. The mineral modified polypropylene composite material for vehicles provided by the invention has good mechanical properties and excellent aging resistance, and also has good processability and product appearance, and the preparation method of the material provided by the invention is simple and has high comprehensive benefits.

Owner:SUZHOU SUNWAY POLYMER

Modified-2-methylimidazole-containing electrostatic-spraying powder paint

InactiveCN106752703AImprove impact resistanceImprove heat resistanceFireproof paintsPowdery paintsCarbon nanotubeFumed silica

The invention discloses a modified-2-methylimidazole-containing electrostatic-spraying powder paint which is prepared from a hydrogenated bisphenol A epoxy resin, a novolac epoxy resin, uranium dioxide dicyclopentadiene, a polyaryl thioether resin, nylon, dicyandiamide, phthalic anhydride, modified 2-methylimidazole, aluminum hydroxide, fumed silica, precipitation-process barium sulfate, carbon nanotubes, nano silicon dioxide, magnesium hydroxide, nano cerium oxide, micro wax powder, N-phenyl-3-aminopropyltrimethoxy silane, a leveling agent and a defoaming agent. The modified-2-methylimidazole-containing electrostatic-spraying powder paint has the advantages of favorable heat resistance, excellent impact resistance, low curing temperature and long service life.

Owner:TIANCHANG JINLING ELECTRONICS

Composite material of wood flour-modified polylactic acid and preparation method of composite material

The invention discloses a composite material of wood flour-modified polylactic acid and a preparation method of the composite material. The composite material is prepared from the following components in parts by weight: 11-26 parts of poplar wood flour, 8-19 parts of willow wood flour, 7-17 parts of locust wood flour, 5-17 parts of maleic anhydride, 5-12 parts of ethylene glycol, 3-12 parts of an L-lactide monomer, 4-11 parts of a silane coupling agent, 8-10 parts of a carbon nano tube and 23-50 parts of polylactic acid. The composite material of the wood flour-modified polylactic acid has the advantages that (1) the composite material is an environment-friendly material and has a wide application prospect; (2) the defect of large brittleness of the polylactic acid is improved and the performance is improved; and (3) the problem of poor compatibility of the wood flour and the polylactic acid is solved.

Owner:苏州奥宇包装科技有限公司

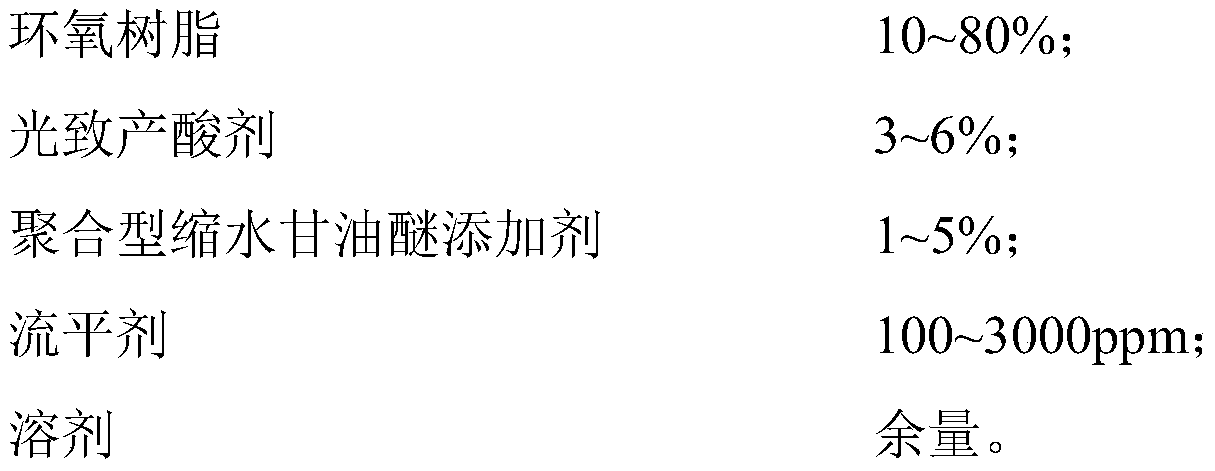

Epoxy-type negative thick film photoresist as well as preparation method and use method thereof

ActiveCN111007696AImprove brittle defectsHigh impact strengthPhotosensitive materials for photomechanical apparatusEpoxy resin coatingsPolymer sciencePhotoacid generator

The invention relates to an epoxy-type negative thick film photoresist, which comprises the following components in percentage by mass: 10-80% of epoxy resin; 3-6% of a photoacid generator; 1-5% of apolymeric glycidyl ether additive; a leveling agent with a concentration being 100 to 3000 ppm; and the balance of a solvent. The invention also relates to a preparation method and a use method of theepoxy-type negative thick film photoresist. According to the invention, the adhesive film cracking defect of the thick film photoresist is significantly improved, and the application range is expanded. The thickness of a photoresist coating film is about 10-200 microns, and the photoresist coating film is suitable for preparing a circuit or a device with a microstructure with a high depth-to-width ratio.

Owner:江苏汉拓光学材料有限公司

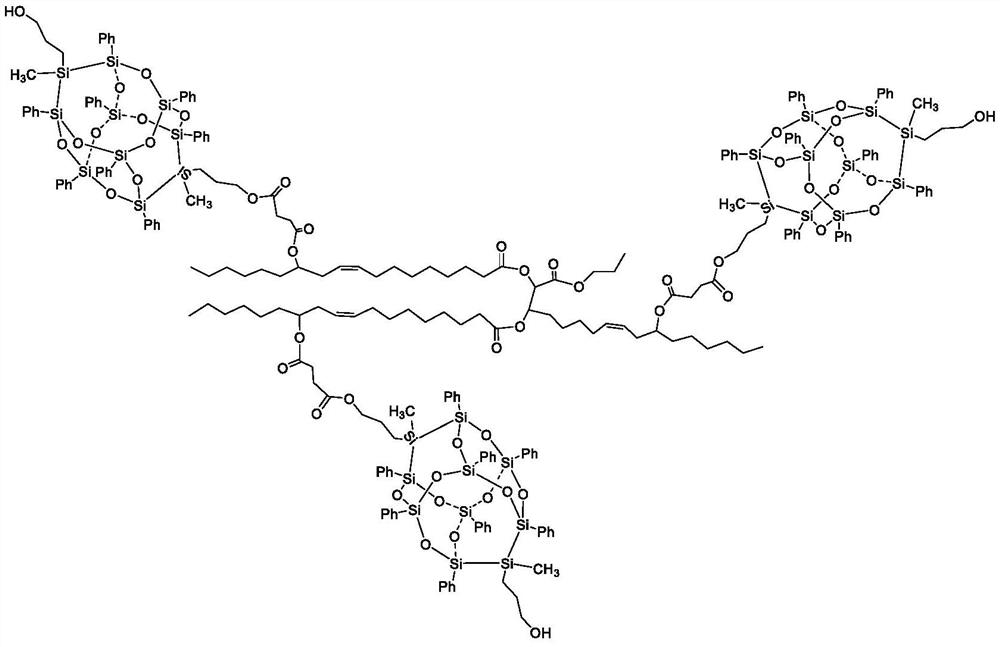

Waste plastic regeneration process

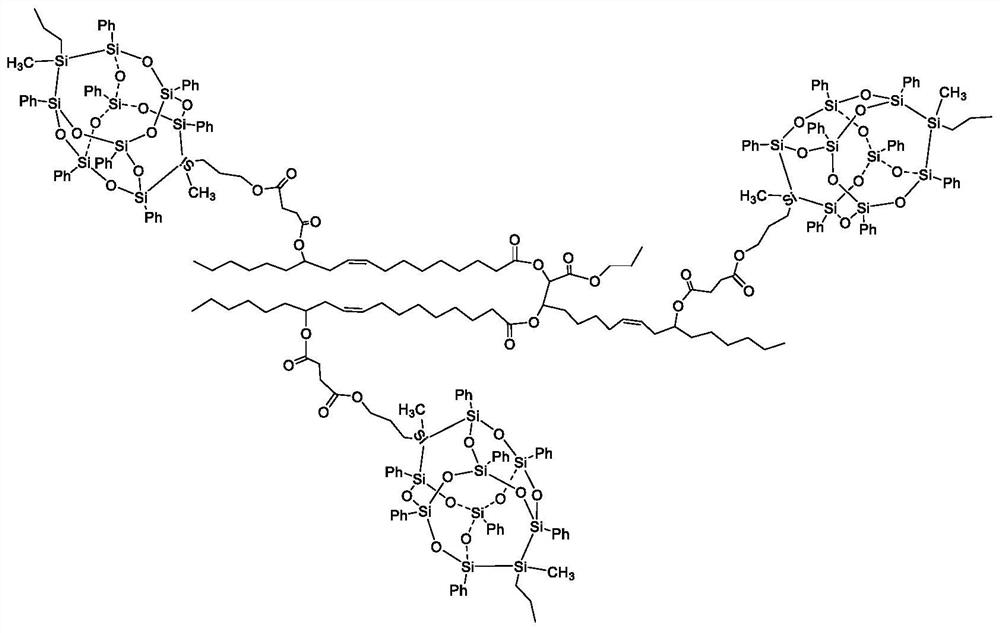

InactiveCN113698688AGood toughnessGood compatibilityPlastic recyclingMechanical material recoveryChemistryCarboxylic group

The invention discloses a waste plastic regeneration process, which belongs to the technical field of waste plastic regeneration. The technology comprises the following steps that 1, waste plastic is smashed, sieved, soaked in alkali liquor, cleaned and dried, and waste plastic particles are obtained; and 2, the waste plastic particles and an auxiliary agent are uniformly stirred and mixed at 110-120 DEG C, and extrusion granulation is conducted to obtain the waste plastic regenerated plastic. The auxiliary agent is added in the waste plastic regeneration process, so that the technical problems of brittleness, poor toughness and poor wear resistance of the waste plastic regenerated material are solved, and the auxiliary agent is obtained through gradual reaction of modified castor oil, dihydroxyl POSS, carboxyl-containing binary isocyanate and hydroxyl-terminated polyether modified polydimethoxy siloxane, so that molecules contain a POSS structure, a straight-chain siloxane chain and a polyether chain, the auxiliary agent has excellent compatibility with waste plastics, and the toughness, strength and wear resistance of waste plastic particles are improved by adding the auxiliary agent.

Owner:界首市云锋再生资源有限公司

Normal-temperature impregnating resin for fiber reinforced plastic grids

The invention discloses normal-temperature impregnating resin for fiber reinforced plastic grids. The normal-temperature impregnating resin for the fiber reinforced plastic grids is composed of, by weight, 90-100 parts of epoxy resin, 30-40 parts of epoxy resin modifying agent, 80-90 parts of normal-temperature curing agent, 5-10 parts of pigment and 1-5 parts of release agent. The normal-temperature impregnating resin for the fiber reinforced plastic grids has the advantages of being needless of heating, easy to process, low in toxicity, high in solidifying speed, resistant to corrosion and high temperatures, capable of achieving demolding easily, high in reliability, low in cost and the like.

Owner:DE RUISEN NANTONG COMPOSITE MATERIAL CO LTD

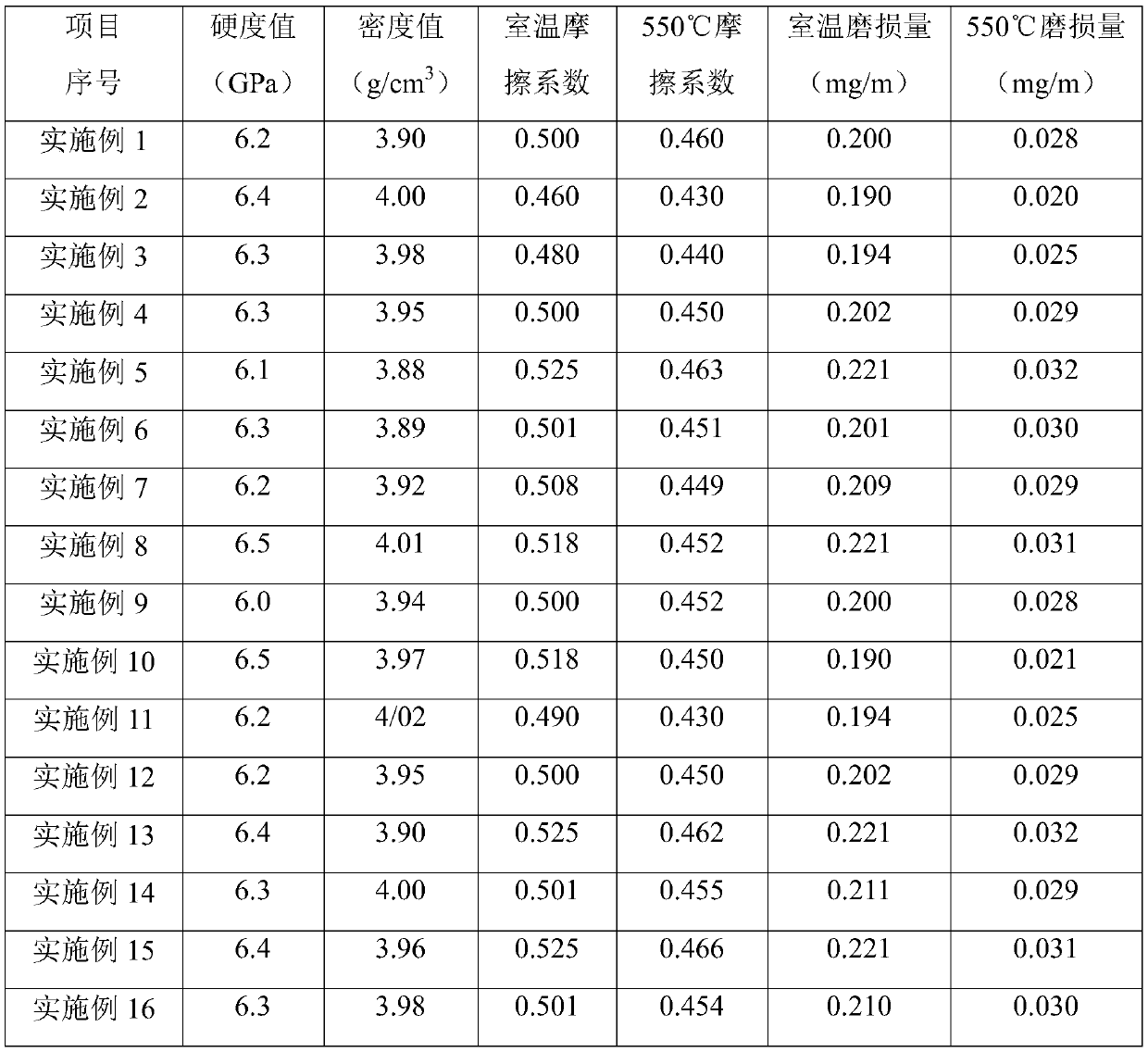

A kind of tial-based high temperature resistant self-lubricating composite material and its preparation method

ActiveCN107916349BIncrease coefficient of frictionImprove mechanical propertiesCarrying capacityChemical composition

The invention discloses a TiAl-based high-temperature-resistant self-lubricating composite. The composite is prepared from chemical components in percentage by mass as follows: 5%-30% of Ti3SiC2 and the balance of TiAl alloy powder. A preparation method of the TiAl-based high-temperature-resistant self-lubricating composite mainly comprises the steps as follows: the components, namely, Ti3SiC2 andthe TiAl alloy powder are subjected to ball-milling and are evenly mixed, the rotating speed of a ball mill is 300-450 r / min, and the ball-milling time is 2-4 h; the mixed powder is dried and then iscontained in a mold for pre-pressing molding, SPS sintering is performed on the dried pre-pressed powder, the pressure is 20-50 MPa, the vacuum degree is 10-40 Pa, the powder is heated to 800-1,200 DEG C, the temperature is kept for 10-30 min, the heating rate is 50-100 DEG C / min, the powder is subjected to furnace cooling, and a blank is obtained; surface treatment is performed on the blank, andthe TiAl-based high-temperature-resistant self-lubricating composite is obtained. The composite is fatigue-resistant, impact-resistant, high-temperature-resistant and high in carrying capacity, the self-lubricating performance can be realized, the friction coefficient and the abrasion loss can be reduced, and the self-lubricating performance is more excellent under the high-temperature condition.

Owner:YANSHAN UNIV

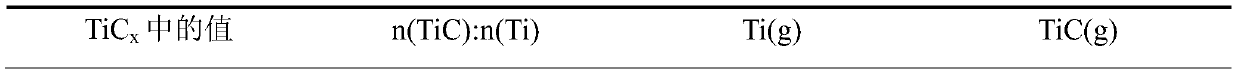

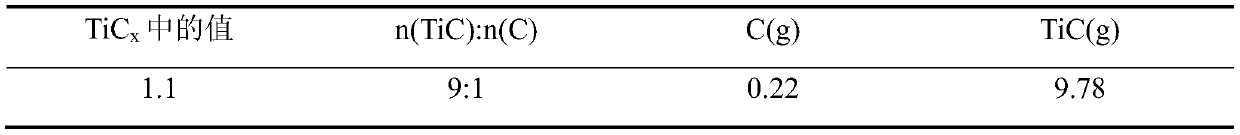

TiAl-based high-temperature resistant self-lubricating composite material and preparation method thereof

InactiveCN110629093AImprove brittle defectsImprove self-lubricating performanceTemperature resistanceRaw material

The invention provides a TiAl-based high-temperature resistant self-lubricating composite material and a preparation method thereof, and belongs to the field of composite materials. The composite material is prepared by mixing and sintering raw materials, and comprises the following raw materials of, in percentage by mass, 5-50% of TiCx, 5-50% of Ti3AlC2 or Ti3SiC2, and the balance of TiAl mixed powder; the TiAl mixed powder comprises the following components of, in percentage by mass, 5-40% of Al, 1-5% of Cr, and the balance Ti; and x in TiCx is greater than or equal to 0.4 but smaller than or equal to 0.9 or x is equal to 1.1. The composite material not only has high bearing performance, high strength and high temperature resistance, but also has a self-lubricating property at high temperature, and is beneficial to manufacturing friction materials under severe working conditions such as high temperature.

Owner:YANSHAN UNIV

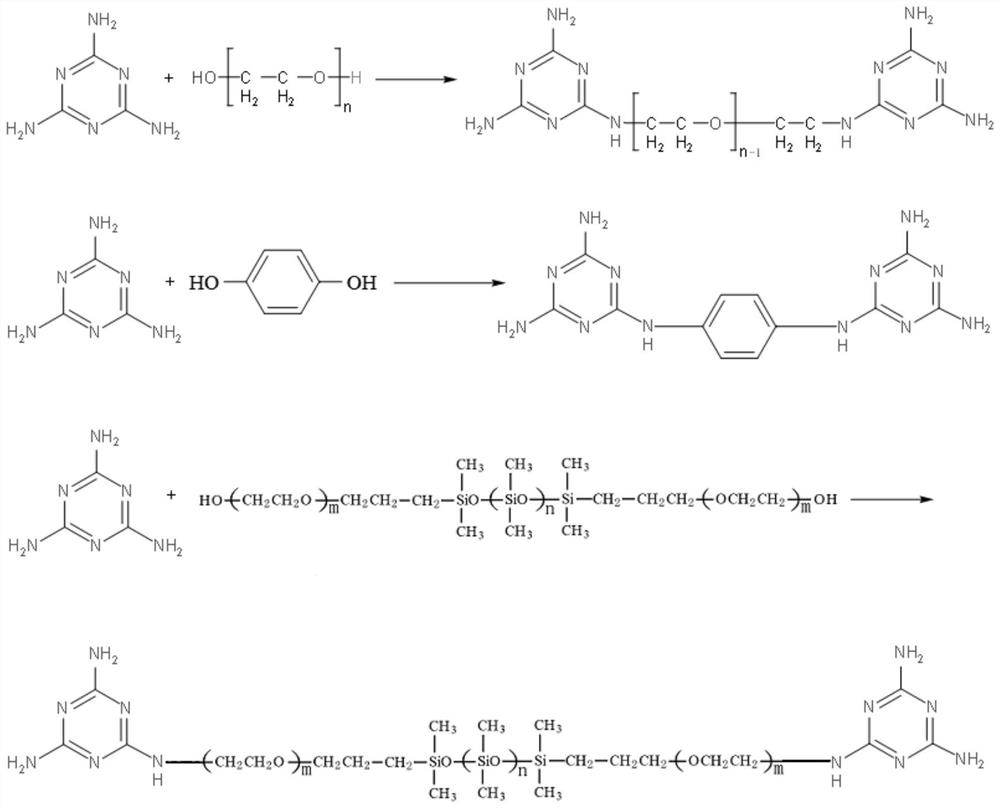

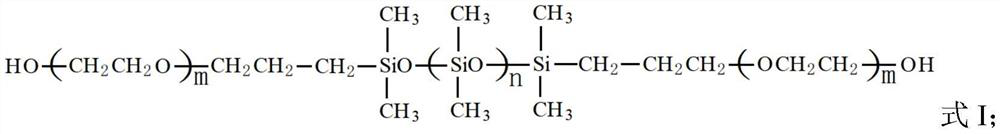

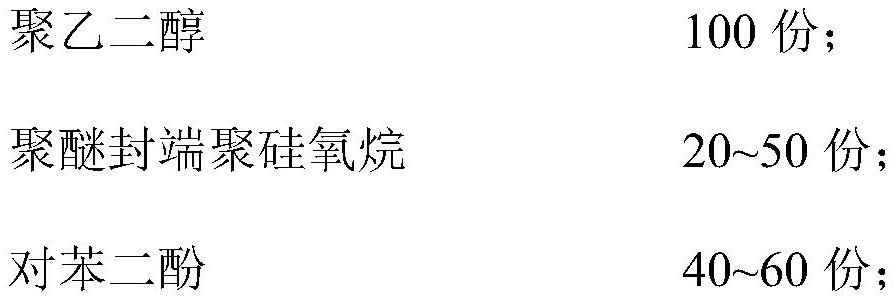

Polyethylene glycol modified melamine resin and preparation method thereof

The invention belongs to the technical field of polymer materials, and discloses polyethylene glycol modified melamine resin and a preparation method thereof. The preparation method comprises the following steps: adding polyethylene glycol, polyether-terminated polysiloxane, hydroquinone, melamine, water and an acidic catalyst into a reactor, uniformly stirring and mixing, then heating to 85-95 DEG C, and carrying out heat preservation reaction to obtain a prepolymer; adding a pH regulator to regulate the pH value to 7-9, cooling to 80 DEG C or below, adding hydroquinone, melamine, formaldehyde and a basic catalyst, heating to 90-100 DEG C, and carrying out heat preservation reaction; and after the reaction is completed, adding water and methanol for dilution to obtain the polyethylene glycol modified melamine resin. According to the preparation method disclosed by the invention, the molecular flexibility is improved and the moisture absorption rate is reduced by introducing long-chain polyethylene glycol and polysiloxane structures, the heat resistance of a system is improved by introducing a benzene ring structure, and the finally obtained melamine resin simultaneously has the comprehensive properties of high strength, high heat resistance and low moisture absorption rate.

Owner:江门建滔电子发展有限公司

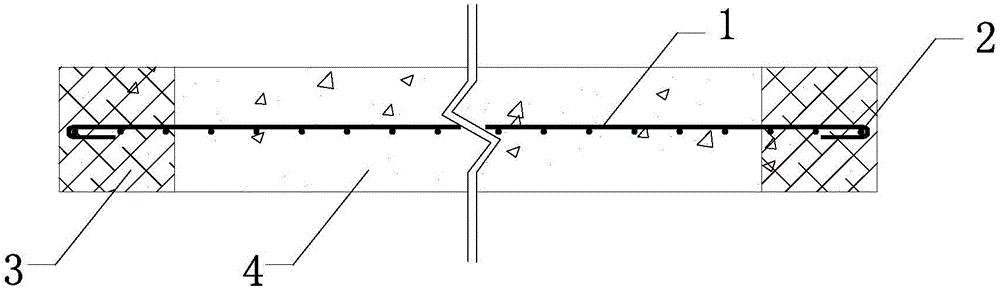

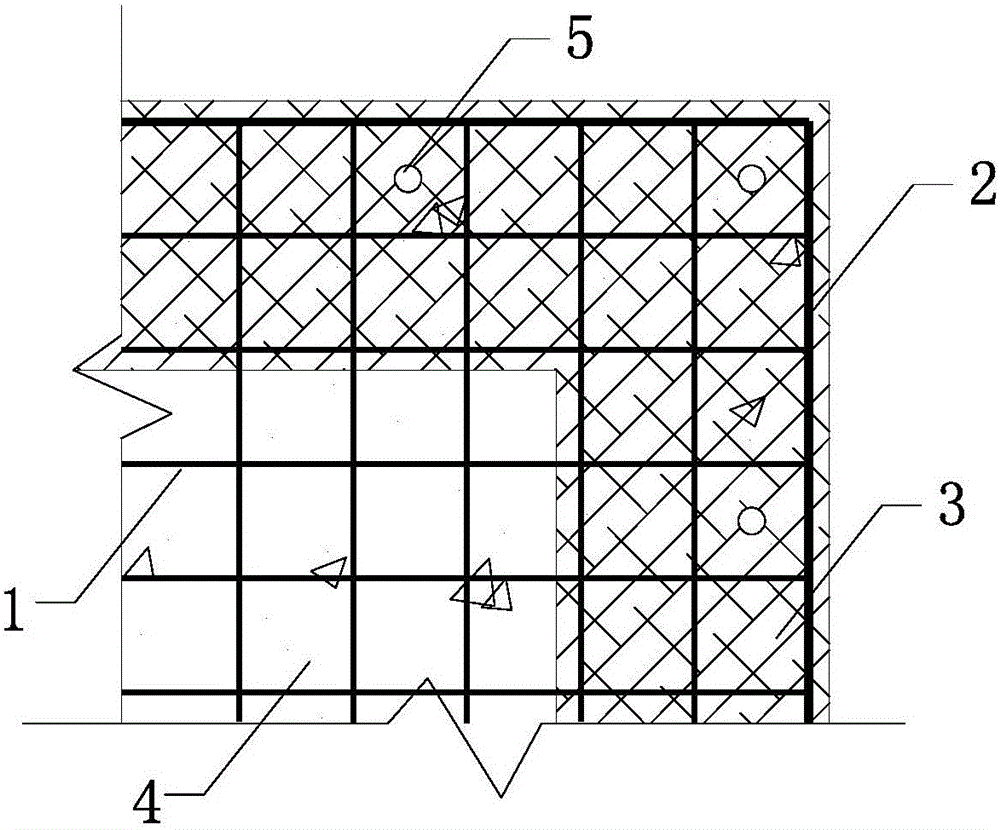

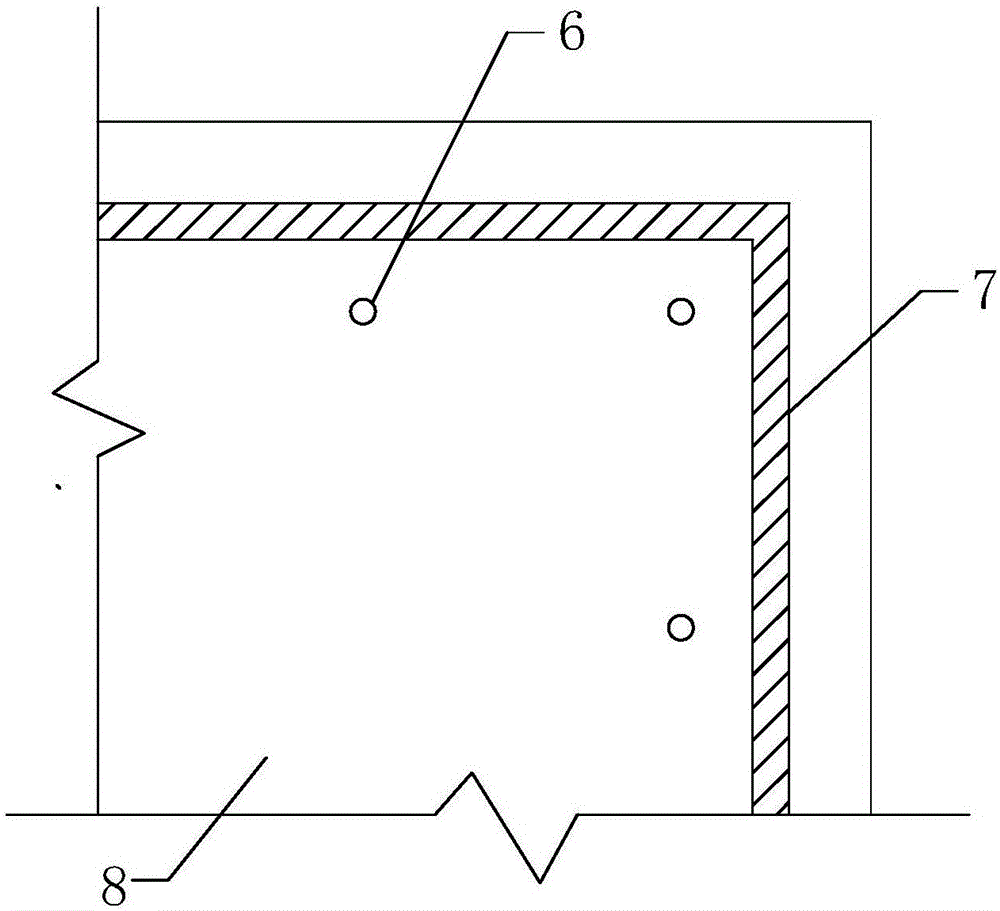

Single-row reinforcement sheet with fiber concrete on frames and common concrete in middle and manufacturing method

InactiveCN105863152AImprove brittle defectsHigh tensile strengthConstruction materialFiberCrack resistance

The invention provides a single-row reinforcement sheet with fiber concrete on frames and common concrete in the middle and a manufacturing method, and belongs to the field of manufacturing of concrete slabs in building structure engineering. Fibers meeting different structure requirements are adopted by the fiber concrete according to design requirements, the common concrete is adopted except the frames of the sheet, the strength and diameter of reinforcement meshes arranged on the frames are greater than those of steel bars of an orthogonal steel wire mesh in the middle, and therefore the sheet with the fiber concrete on the frames and the common concrete in the middle is formed. The steel bars are arranged in hooks formed by bending steel wires extending from the four sides of the steel wire mesh, and a complete reinforced mesh is precast. The fiber concrete is poured on the periphery of the sheet, and the common concrete is poured in the sheet. The initial cracking resistance of the concrete sheet is improved, shrinkage plastic cracks at the early stage of the concrete are reduced, and the single-row reinforcement sheet has great significance to solution of the prevalent problems that current concrete sheets are low in sheet frame strength, prone to collision loss and high in manufacturing cost. The sheet is easy to construct, the using number of formworks and supports in construction can be greatly reduced, operation intensity of workers is lowered, and the amount of labor used in engineering is reduced.

Owner:BEIJING UNIV OF TECH

A kind of production method of ultrafine formaldehyde residue fiberboard

Owner:洪湖市鼎新生物新材料有限公司

A kind of environment-friendly paper ceramics and preparation method thereof

The invention relates to the filed of production of ceramic and in particular relates to environment-friendly paper ceramic and a preparation method thereof. The environment-friendly paper ceramic is prepared from the following raw material components in parts by weight: 450-500 parts of mud, 20-25 parts of paper pulp and 90-100 parts of bone meal, wherein a weight ratio of paper scrap to water in the paper pulp is 1:2. The environment-friendly paper ceramic provided by the invention has the advantages that the paper pulp is added in the raw materials used for preparation of ceramic, so that flexibility of the whole slurry is improved, the slurry can coat a mould in a thin layer in a die moulding process, and further a ceramic product with the thickness of 1mm can be prepared; in a drying process of the environment-friendly paper ceramic, after massive moisture is removed, cracking phenomenon can not be caused or is hardly caused, further ceramic making success rate is effectively increased, and the defect that manpower and material resources are wasted as a muddy green body cracks easily in the prior art is effectively overcome.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com