Synthetic adhesive using papermaking black liquor as raw material and its production method

A papermaking black liquor and adhesive technology, which is applied in the field of wood board adhesives to achieve the effects of reducing costs, protecting the environment and reducing waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

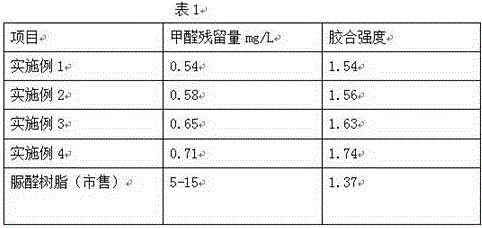

Examples

Embodiment 1

[0032] The adhesive is synthesized by using papermaking black liquor as a raw material, and consists of the following raw materials in parts by weight:

[0033] 50 parts of papermaking black liquor;

[0034] 100 parts of phenolic resin;

[0035] 1 part of coupling agent;

[0036] 1 part of auxiliary agent;

[0037] 1 part of treatment agent.

[0038] The papermaking black liquor is bagasse papermaking black liquor; the solid weight content of the papermaking black liquor is 25%.

[0039] The preparation method of the phenolic resin is as follows: according to the molar ratio of formaldehyde and phenol as 1.1:1, under the condition of NaOH basic catalyst, the phenolic resin prepolymer with a molecular weight of 1400 can be generated through heating and polymerization.

[0040] The coupling agent is γ-mercaptopropyltriethoxysilane.

[0041] The auxiliary agent is a leveling agent polyether modified polydimethylsiloxane.

[0042] The treatment agent is ozone.

[0043] Pape...

Embodiment 2

[0048] The adhesive is synthesized by using papermaking black liquor as a raw material, and consists of the following raw materials in parts by weight:

[0049] 150 parts of papermaking black liquor;

[0050] 150 parts of phenolic resin;

[0051] 4 parts of coupling agent;

[0052] 5 parts of auxiliary agent;

[0053] 3 parts of treatment agent.

[0054] The papermaking black liquor is a mixture of concentrated lignin separated from bagasse papermaking black liquor by acid precipitation and acid precipitation solution according to the patent application (CN 104153232A) of Guangxi Xingdao Technology Development Co., Ltd.; The solid weight content of the papermaking black liquor is 30%.

[0055] The preparation method of the phenolic resin is as follows: according to the molar ratio of formaldehyde and phenol as 3:1, under the condition of NaOH basic catalyst, the phenolic resin prepolymer with a molecular weight of 1600 can be generated by heating and polymerizing.

[0056...

Embodiment 3

[0064] The adhesive is synthesized by using papermaking black liquor as a raw material, and consists of the following raw materials in parts by weight:

[0065] 300 parts of papermaking black liquor;

[0066] 250 parts of phenolic resin;

[0067] 7 parts of coupling agent;

[0068] 8 parts of auxiliary agent;

[0069] Treatment agent 4 parts.

[0070] The papermaking black liquor is bagasse papermaking black liquor; the solid weight content of the papermaking black liquor is 35%.

[0071] The preparation method of the phenolic resin is as follows: according to the molar ratio of formaldehyde and phenol as 4:1, under the condition of NaOH basic catalyst, the phenolic resin prepolymer with a molecular weight of 1800 can be produced by heating and polymerizing.

[0072] The coupling agent is γ-mercaptopropyltriethoxysilane.

[0073] The auxiliary agent is N-methylpyrrolidone solution of anti-settling agent modified polyurea.

[0074] The treatment agent is sulfonated cobalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com