Treatment method of coating with anti-corrosion function on iron-based surface

A technology of coating treatment and anti-corrosion coating, which is applied in anti-corrosion coatings, coatings, metal material coating processes, etc., can solve the problems of not being able to meet high strength, corrosion resistance and wear resistance at the same time, achieve high hardness, improve properties, effects of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

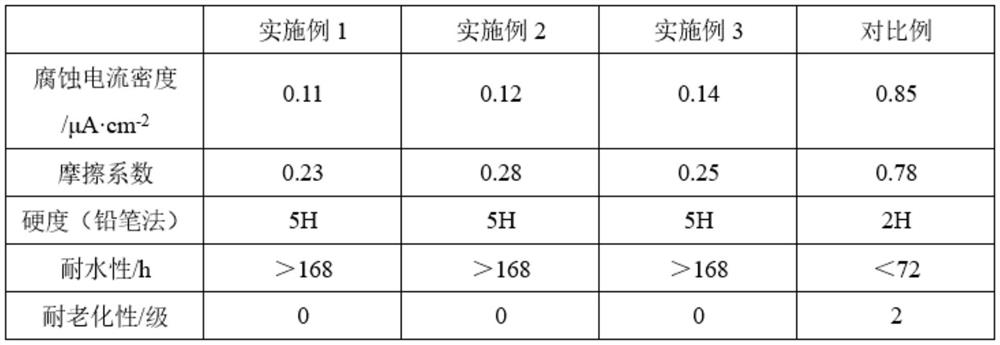

Examples

Embodiment 1

[0047] A coating treatment method with an anti-corrosion function on an iron-based surface, comprising the following steps:

[0048] (1) grinding the iron-based alloy;

[0049] (2) sandblasting the polished iron-based alloy;

[0050] (3) After cleaning the surface of the iron-based alloy after sand blasting, place it in an oven at 60-100°C for 0.2-0.5h, and spray the first anti-corrosion coating on the surface of the iron-based alloy while it is hot;

[0051] (4) After the first anti-corrosion coating is completely dry, place the iron-based alloy coated with the first anti-corrosion coating in an oven at 60-100°C for another 0.2-0.5h, and then heat the first anti-corrosion coating while it is hot. The surface of the coating is coated with a second anti-corrosion coating by supersonic flame spraying.

[0052] The sandblasting is dry sandblasting, the abrasive used in the sandblasting is 20# white corundum sand, the pressure of the sandblasting is 0.65MPa, and the speed of the...

Embodiment 2

[0083] A coating treatment method with an anti-corrosion function on an iron-based surface, comprising the following steps:

[0084] (1) grinding the iron-based alloy;

[0085] (2) sandblasting the polished iron-based alloy;

[0086] (3) After cleaning the surface of the iron-based alloy after sand blasting, place it in an oven at 60-100°C for 0.2-0.5h, and spray the first anti-corrosion coating on the surface of the iron-based alloy while it is hot;

[0087] (4) After the first anti-corrosion coating is completely dry, place the iron-based alloy coated with the first anti-corrosion coating in an oven at 60-100°C for another 0.2-0.5h, and then heat the first anti-corrosion coating while it is hot. The surface of the coating is coated with a second anti-corrosion coating by supersonic flame spraying.

[0088] The sand blasting treatment is dry sand blasting treatment, the abrasive used in the sand blasting treatment is 20# white corundum sand, the pressure of the sand blastin...

Embodiment 3

[0119] A coating treatment method with an anti-corrosion function on an iron-based surface, comprising the following steps:

[0120] (1) grinding the iron-based alloy;

[0121] (2) sandblasting the polished iron-based alloy;

[0122] (3) After cleaning the surface of the iron-based alloy after sand blasting, place it in an oven at 60-100°C for 0.2-0.5h, and spray the first anti-corrosion coating on the surface of the iron-based alloy while it is hot;

[0123] (4) After the first anti-corrosion coating is completely dry, place the iron-based alloy coated with the first anti-corrosion coating in an oven at 60-100°C for another 0.2-0.5h, and then heat the first anti-corrosion coating while it is hot. The surface of the coating is coated with a second anti-corrosion coating by supersonic flame spraying.

[0124] The sandblasting is dry sandblasting, the abrasive used in the sandblasting is 20# white corundum sand, the pressure of the sandblasting is 0.65MPa, and the speed of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com