Polyethylene glycol modified melamine resin and preparation method thereof

A technology of polyethylene glycol modification and melamine resin, which is applied in the field of polymer materials, can solve the problems of water absorption and heat resistance, and achieve the effects of improving water solubility, improving comprehensive performance, and improving brittle defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

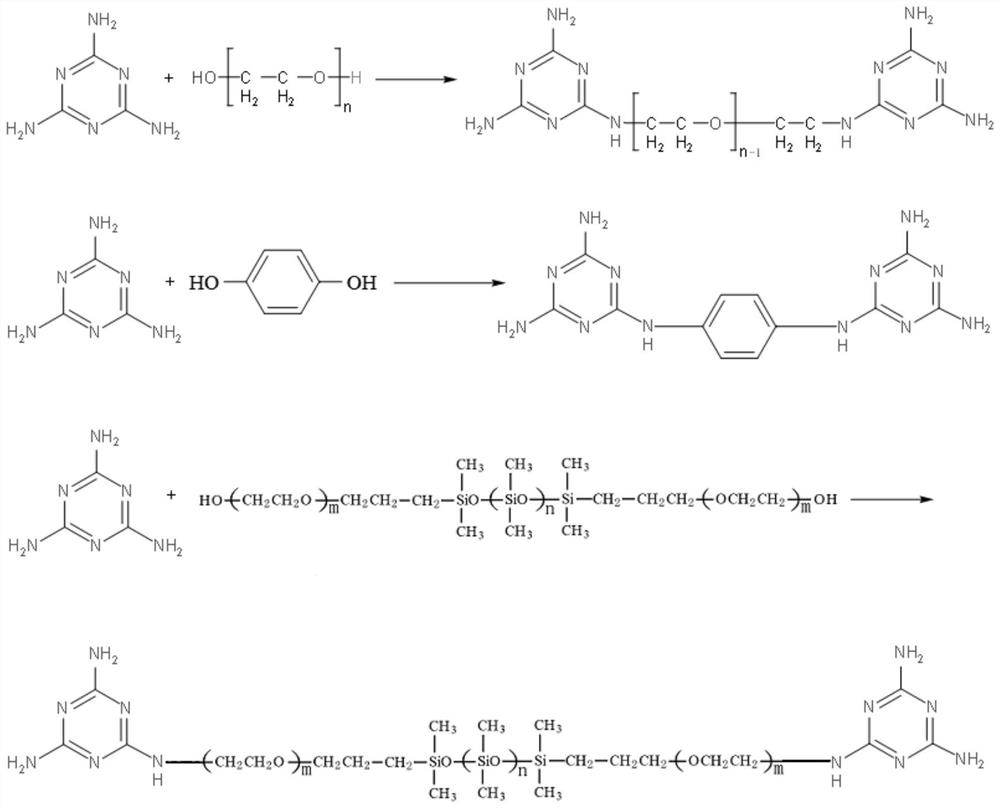

Method used

Image

Examples

Embodiment 1

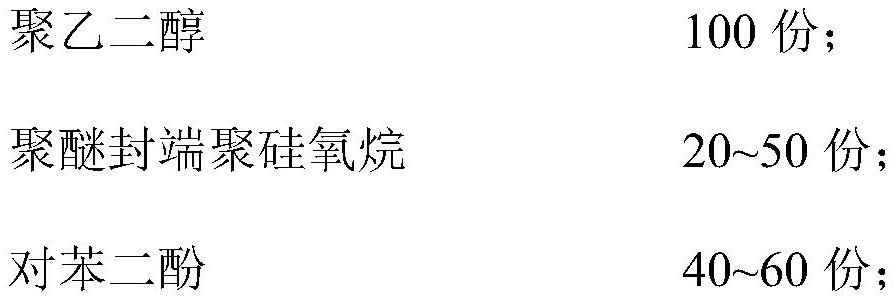

[0043] A kind of preparation method of polyethylene glycol modified melamine resin of the present embodiment, comprises following preparation steps:

[0044] (1) According to the material names and feed amounts (parts by weight) shown in Table 1, add materials 1 to 6 into the reactor and stir and mix evenly, then stir and heat up to about 90°C within 30 minutes and keep the temperature for 1.5 hours. Infrared spectrum Monitor the disappearance of the hydroxyl absorption peak to obtain a prepolymer.

[0045] (2) Add material 7 to the prepolymer in step (1) to adjust the pH to 7.5, then cool down to 60°C, add materials 8-11, heat up to about 95°C for 1 hour and complete the reaction.

[0046] (3) Add materials 12-13 into the reactor and stir to obtain polyethylene glycol-modified melamine resin.

[0047] Table 1. Material code and proportion

[0048]

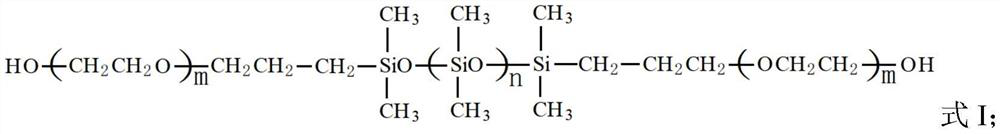

[0049] In this example, the average molecular weight of polyether-terminated polysiloxane is 800, which is prepared by the ...

Embodiment 2

[0052] A kind of preparation method of polyethylene glycol modified melamine resin of the present embodiment, comprises following preparation steps:

[0053] (1) According to the material names and feed amounts (parts by weight) shown in Table 2, add materials 1 to 6 into the reactor, stir and mix evenly, then stir and heat up to about 90°C within 30 minutes and keep the temperature for 2 hours. Monitor by infrared spectrum The hydroxyl absorption peak disappeared, and a prepolymer was obtained.

[0054] (2) Add material 7 to the prepolymer in step (1) to adjust the pH to 7.5, then cool down to 70°C, add materials 8-11, heat up to about 95°C for 1 hour and complete the reaction.

[0055] (3) Add materials 12-13 into the reactor and stir to obtain polyethylene glycol-modified melamine resin.

[0056] Table 2. Material code and proportion

[0057]

[0058] In this example, the average molecular weight of polyether-terminated polysiloxane is 1200, which is prepared by the foll...

Embodiment 3

[0061] A kind of preparation method of polyethylene glycol modified melamine resin of the present embodiment, comprises following preparation steps:

[0062] (1) According to the material names and feed amounts (parts by weight) shown in Table 3, add materials 1 to 6 into the reactor, stir and mix evenly, then stir and heat up to about 90°C within 30 minutes and keep the temperature for 3 hours. Monitor by infrared spectrum The hydroxyl absorption peak disappeared, and a prepolymer was obtained.

[0063] (2) Add material 7 to the prepolymer in step (1) to adjust the pH to 7.5, then cool down to 65°C, add materials 8-11, heat up to about 95°C for 2 hours and complete the reaction.

[0064] (3) Add materials 12-13 into the reactor and stir to obtain polyethylene glycol-modified melamine resin.

[0065] Table 3. Material code and proportion

[0066]

[0067] In this example, the average molecular weight of polyether-terminated polysiloxane is 1600, which is prepared by the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com