Waste plastic regeneration process

A technology of waste plastics and craftsmanship, applied in the field of waste plastics regeneration, can solve the problems of poor toughness, poor wear resistance, brittle waste plastic recycled materials, etc., and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Modified castor oil is made through the following steps:

[0045] After mixing 0.1mol castor oil, 100mL tetrahydrofuran and 0.34mol succinic anhydride, add castor oil and 0.5% p-toluenesulfonic acid by mass, reflux reaction at 85°C for 12h under stirring, rotary evaporation under reduced pressure, and vacuum drying at 45°C , to obtain modified castor oil.

Embodiment 2

[0047] Modified castor oil is made through the following steps:

[0048] After mixing 0.1mol castor oil, 100mL tetrahydrofuran and 36mol succinic anhydride, add castor oil and 1.2% p-toluenesulfonic acid by mass, reflux reaction at 85°C for 12h under stirring, rotary evaporation under reduced pressure, and vacuum drying at 45°C. Modified castor oil was obtained.

Embodiment 3

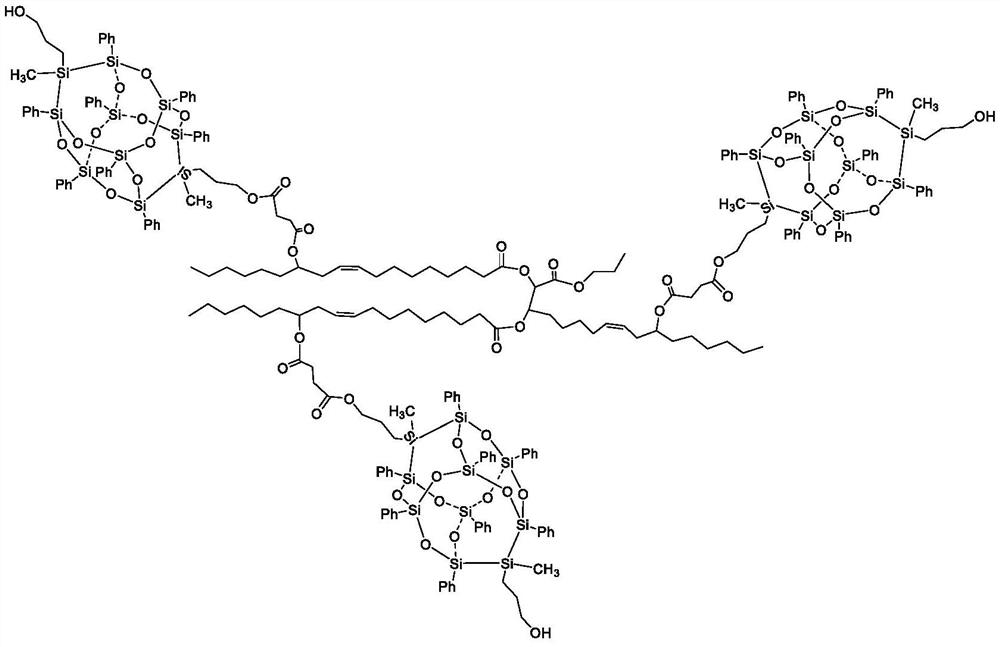

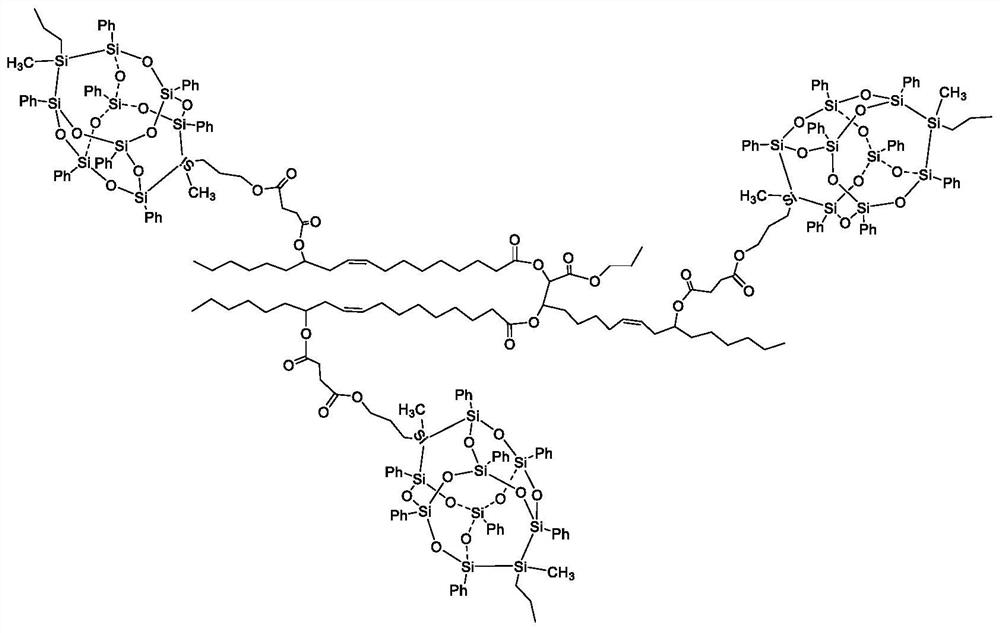

[0050]Dihydroxy POSS is made by the following steps:

[0051] Add 120mL of isopropanol into a flask equipped with a condenser and a magnetic stirrer, add 0.14mol of phenyltrimethoxysilane, 4mg of deionized water and 0.1mol of flake sodium hydroxide in turn under stirring, stir well, and use an oil bath to Heat the reaction system to 72°C in a pot, reflux under nitrogen atmosphere for 6 hours, then stir and react for 18 hours at room temperature, remove the isopropanol from the mixed solution by rotary evaporation, and dry it in vacuum at 65°C for 12 hours to obtain octaphenyl POSS sodium salt ;Put 0.1mol octaphenyl POSS sodium salt into a three-necked flask, under nitrogen protection, add 150mL anhydrous tetrahydrofuran, stir well, add 0.2mol triethylamine, react in ice bath at 0°C for 1h, slowly add dropwise with a constant pressure funnel 0.23mol tetrahydrofuran solution of methyldichlorosilane, the dropping rate is 2 drops / second, react for 4h, then raise the temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com