Porous material for purifying high-temperature gas and preparation method thereof

A porous material and high-temperature gas technology, applied in the field of powder metallurgy, can solve problems such as difficult gas purification, difficult welding of porous materials, welding hot cracks, etc., to achieve good weldability, excellent corrosion resistance in high-temperature and complex atmospheres, and reduce burning loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

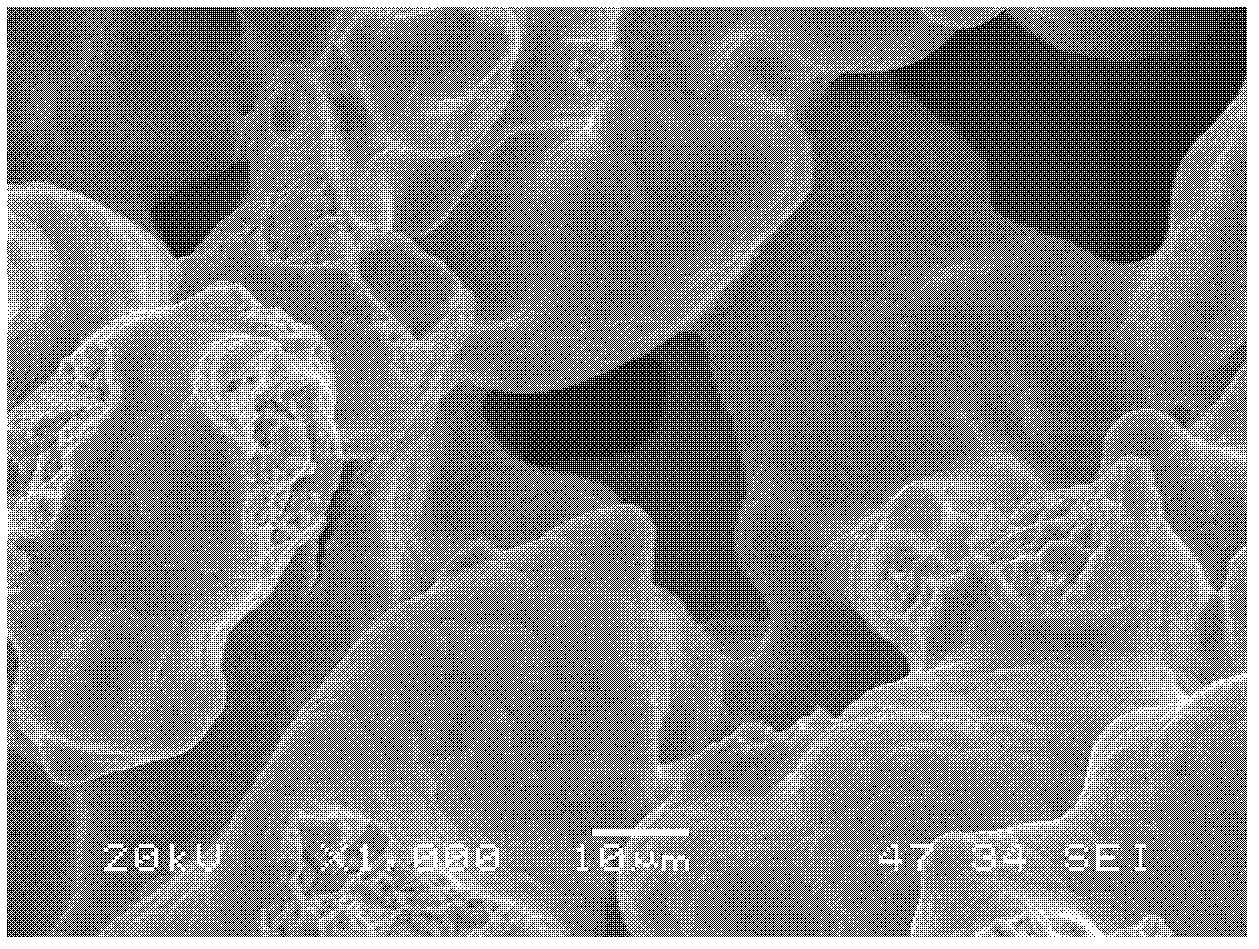

Image

Examples

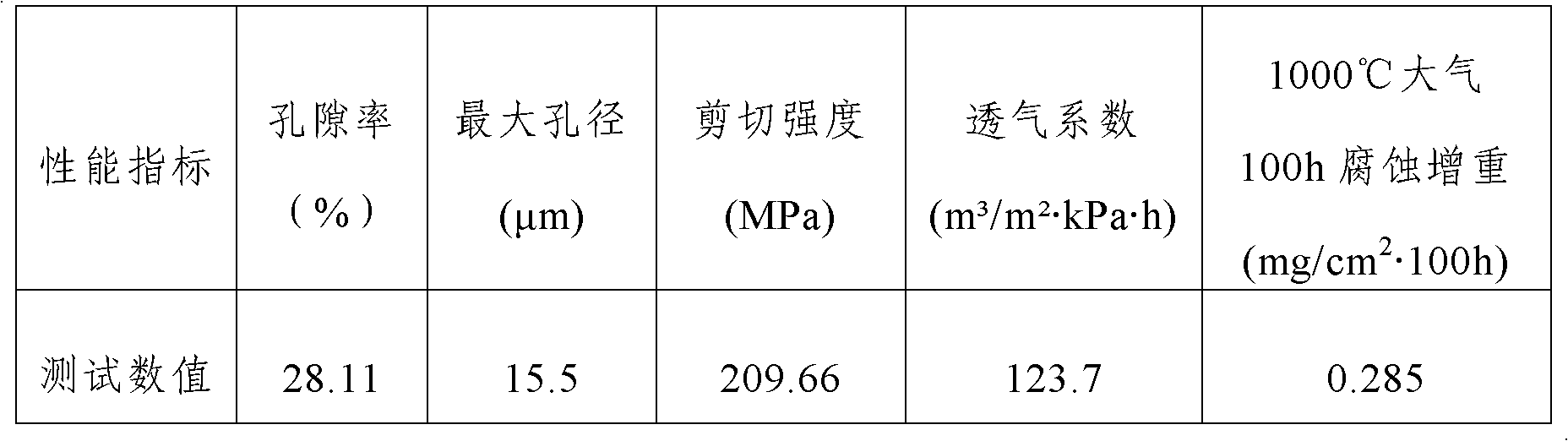

Embodiment 1

[0023] The porous material for purifying high-temperature gas in this embodiment is composed of the following components in mass percentage: Cr 15%, Al 8%, Fe 2%, Y 0.05%, and the balance is Ni and unavoidable impurities.

[0024] The preparation method of the porous material for high-temperature gas purification in this embodiment is as follows:

[0025] Step 1. Put industrially pure Ni, Cr, Al, Fe and Y into a 50kg vacuum induction melting furnace according to the proportioning ratio. -2 pa, smelting 4 times at 1400°C, each time for 10 minutes; then pour the smelted NiCrAl alloy liquid into the intermediate leakage bag preheated to 200°C, using high-pressure water atomization process, at the atomization pressure The alloy powder is made under the condition of 15MPa; the prepared powder is sieved into the following grades with a standard sieve: -60 mesh to +100 mesh, -100 mesh to +150 mesh, -150 mesh to +200 mesh, -200 mesh Mesh ~ +300 mesh and -300 mesh;

[0026] Step 2: P...

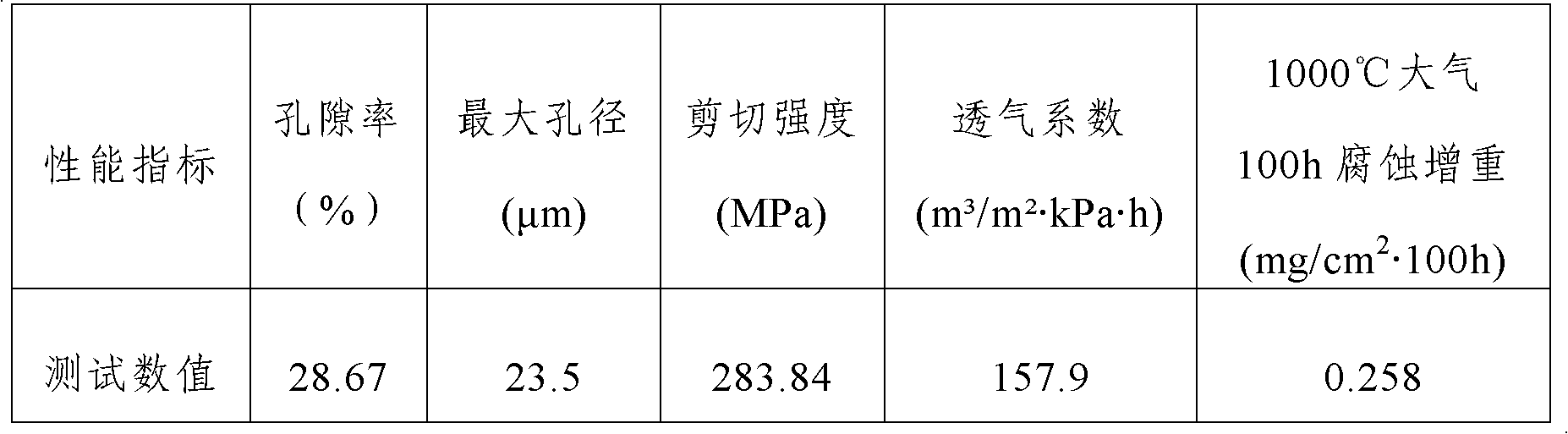

Embodiment 2

[0034] The porous material for purifying high-temperature gas in this embodiment is composed of the following components by mass percentage: Cr 20%, Al 12%, Fe 3%, Y 0.1%, and the balance is Ni and unavoidable impurities.

[0035] The preparation method of the porous material for high-temperature gas purification in this embodiment is as follows:

[0036] Step 1. Put industrially pure Ni, Cr, Al, Fe and Y into a 50kg vacuum induction melting furnace according to the proportioning ratio. -2 pa, smelting at 1700°C for 3 times, each time for 3 minutes; then pour the smelted NiCrAl alloy liquid into the intermediate leakage bag preheated to 200°C, using high-pressure water atomization process, at the atomization pressure The alloy powder is made under the condition of 25MPa; the prepared powder is sieved into the following grades with a standard sieve: -60 mesh to +100 mesh, -100 mesh to +150 mesh, -150 mesh to +200 mesh, -200 mesh Mesh ~ +300 mesh and -300 mesh;

[0037] Step 2: ...

Embodiment 3

[0044] The porous material for purifying high-temperature gas in this embodiment is composed of the following components in mass percentage: Cr 10%, Al 5%, Fe 1%, and the balance is Ni and unavoidable impurities.

[0045] The preparation method of the porous material for high-temperature gas purification in this embodiment is as follows:

[0046] Step 1. Put commercially pure Ni, Cr, Al and Fe into a 50kg vacuum induction melting furnace according to the proportioning ratio, and put the industrially pure Ni, Cr, Al and Fe into a 50kg vacuum induction smelting furnace under a vacuum degree of not more than 10 -2 pa, smelting 4 times at 1600°C, each time for 5 minutes; then pour the smelted NiCrAl alloy liquid into the intermediate leakage bag preheated to 400°C, using high-pressure water atomization process, at the atomization pressure The alloy powder is made under the condition of 10MPa; the prepared powder is sieved into the following grades with a standard sieve: -60 mesh t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com