Biodegradation expanded plastic and method for manufacturing same

A technology of foamed plastics and biodegradation, applied in the field of biodegradable foamed plastics and its manufacturing, can solve the problems of non-degradable foamed plastics, white pollution, etc., and achieve the effects of low water absorption, good dimensional stability, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

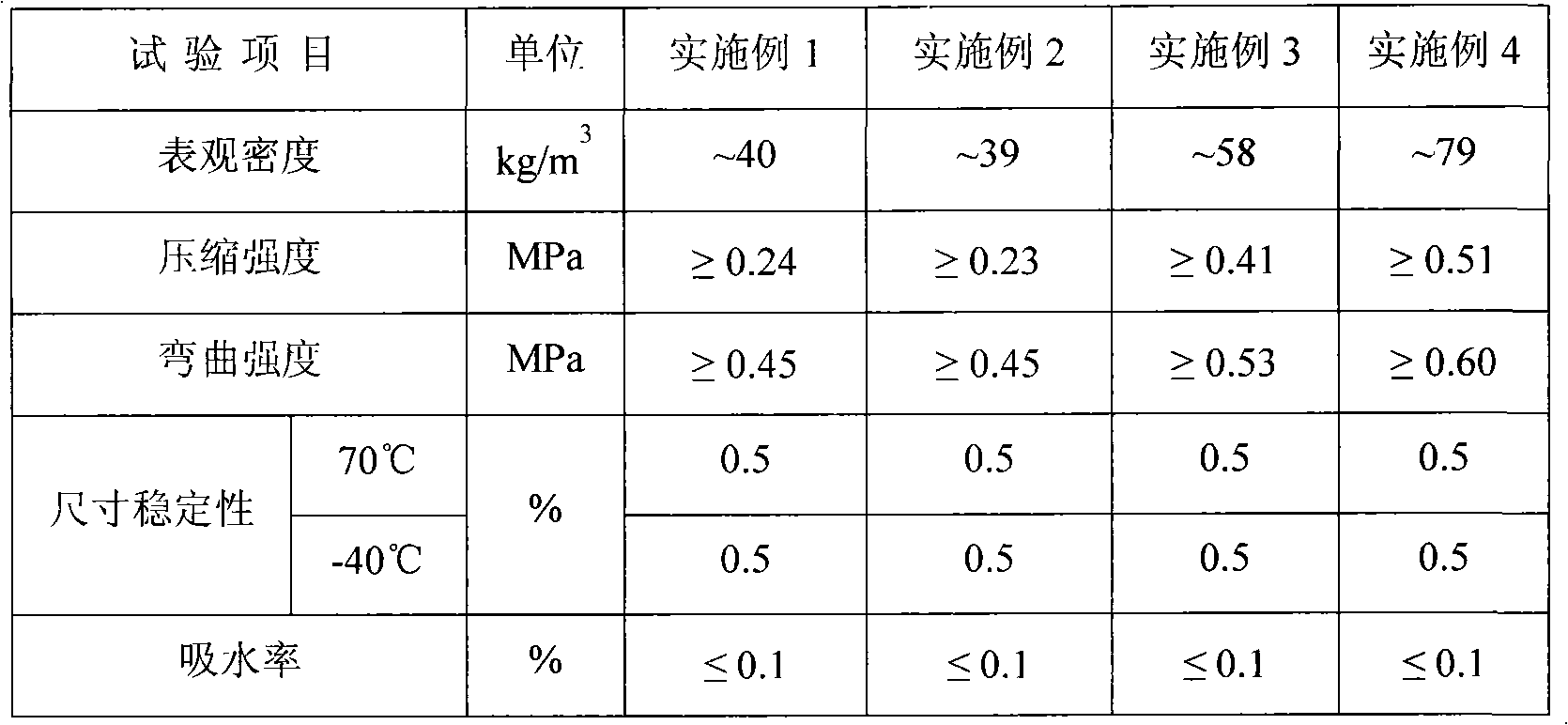

Examples

Embodiment 1

[0045]Get 100 parts by weight of polylactic acid resin, polylactic acid plasticizer adopts 10 parts by weight of oligomer polylactic acid (OLA), and polyhydroxyalkanoate copolymer adopts 3-hydroxybutyl ester-3-hydroxypentyl ester copolymer (PHBV) 20 parts by weight, 20 parts by weight of corn starch, 17 parts by weight of foaming agent azodicarbonamide (AC); 4 parts by weight of zinc oxide (ZnO) as a blowing agent; 1.0 parts by weight of lubricant adopts the following mixture: 0.50 parts by weight of stearamide, 0.30 parts by weight of zinc stearate, 0.20 parts by weight of polyethylene wax; 0.6 parts by weight of antiaging agent adopts the following mixture: tetrakis [3-(3,5-di-tert-butyl-4-hydroxybenzene base) propionic acid] 0.3 parts by weight of pentaerythritol, 0.15 parts by weight of tris (2,4-di-tert-butylphenyl) phosphite, 0.10 parts by weight of 2-hydroxyl-4-n-octyloxybenzophenone, 2- (2'-hydroxyl-3', 5'-di-tert-butylphenyl)-5-chlorobenzotriazole 0.05 parts by weight...

Embodiment 2

[0051] Get 100 parts by weight of polylactic acid resin, polylactic acid plasticizer adopts 10 parts by weight of polyethylene glycol (PEG), polyhydroxyalkanoate copolymer adopts 3-hydroxybutyl ester-3-hydroxypentyl ester copolymer (PHBV) 30 Parts by weight, 20 parts by weight of cornstarch, 17 parts by weight of foaming agent azodicarbonamide (AC); 4 parts by weight of zinc oxide (ZnO) as a foaming agent; 0.8 parts by weight of lubricant adopts the following mixture: ethylene double oil 0.40 parts by weight of acid amide, 0.20 parts by weight of calcium stearate, 0.20 parts by weight of polyethylene wax; 0.45 parts by weight of anti-aging agent adopts the following mixture: ) 0.20 parts by weight of octadecyl propionate, 0.10 parts by weight of tris (2,4-di-tert-butylphenyl) phosphite, 0.10 parts by weight of 2-hydroxyl-4-n-octyloxybenzophenone, 2- (2'-hydroxyl-3', 5'-di-tert-butylphenyl)-5-chlorobenzotriazole 0.05 parts by weight;

[0052] First make polylactic acid (PLA) c...

Embodiment 3

[0057] Get 100 parts by weight of polylactic acid resin, polylactic acid plasticizer adopts 20 parts by weight of polylactic acid-ethylene glycol copolymer (PLA-PEG), polyhydroxyalkanoate copolymer adopts 3-hydroxybutyrate-4-hydroxybutyrate Ester copolymer (P-3HB-co-4HB) 10 parts by weight, corn starch 40 parts by weight, foaming agent azodicarbonamide (AC) 12 parts by weight; foaming agent zinc oxide (ZnO) 3 parts by weight 1.2 parts by weight of lubricant adopt the following mixture: 0.50 parts by weight of ethylene bisoleic acid amide, 0.40 parts by weight of calcium stearate, 0.30 parts by weight of polyethylene wax; 0.70 parts by weight of anti-aging agent adopt the following mixture: four [3-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] 0.30 parts by weight of pentaerythritol, 0.15 parts by weight of tris(2,4-di-tert-butylphenyl) phosphite, dilauryl thiodipropionate 0.10 parts by weight of esters, 0.10 parts by weight of 2-hydroxyl-4-n-octyloxybenzophenone, 2-(2'-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com