Internal circulation upflow anaerobic sludge blanket reactor

An up-flow anaerobic and sludge bed technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of increased operating costs, high suspended solids in effluent, and excessively large three-phase separators, and achieve high work efficiency. , low cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

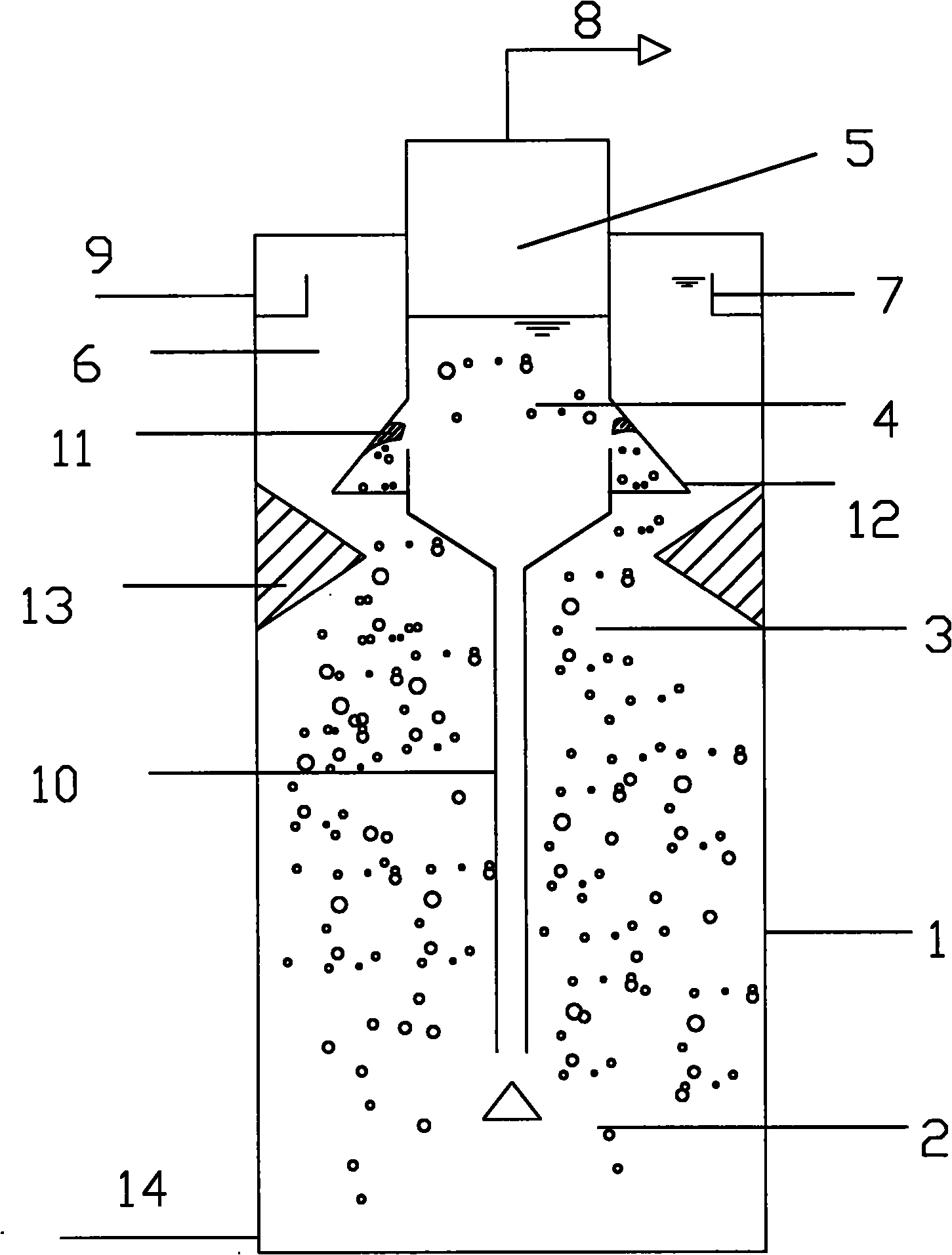

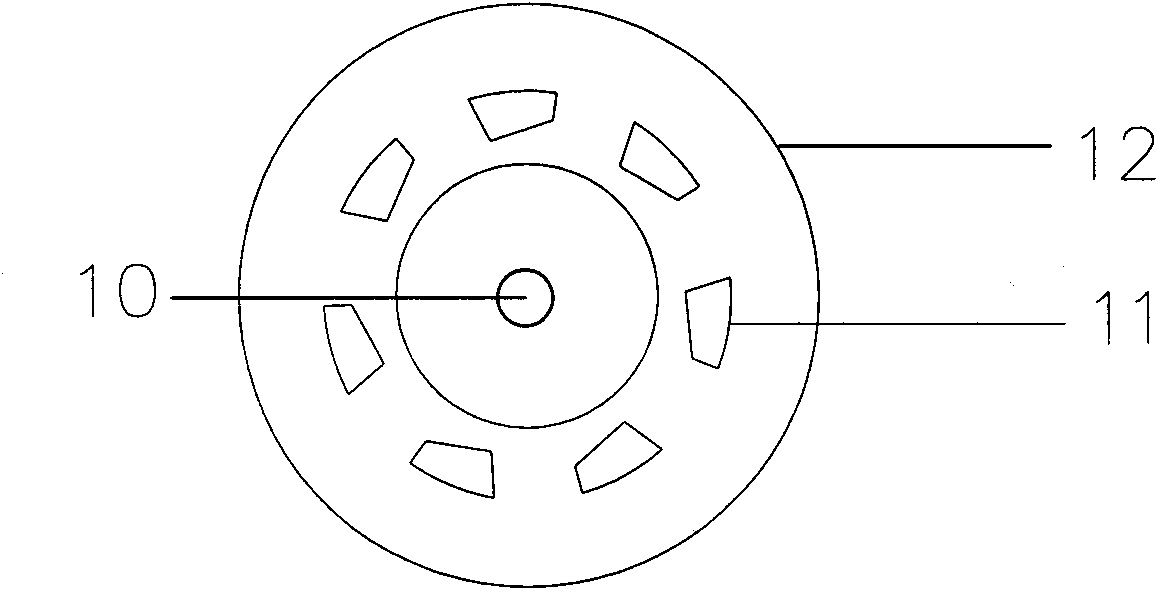

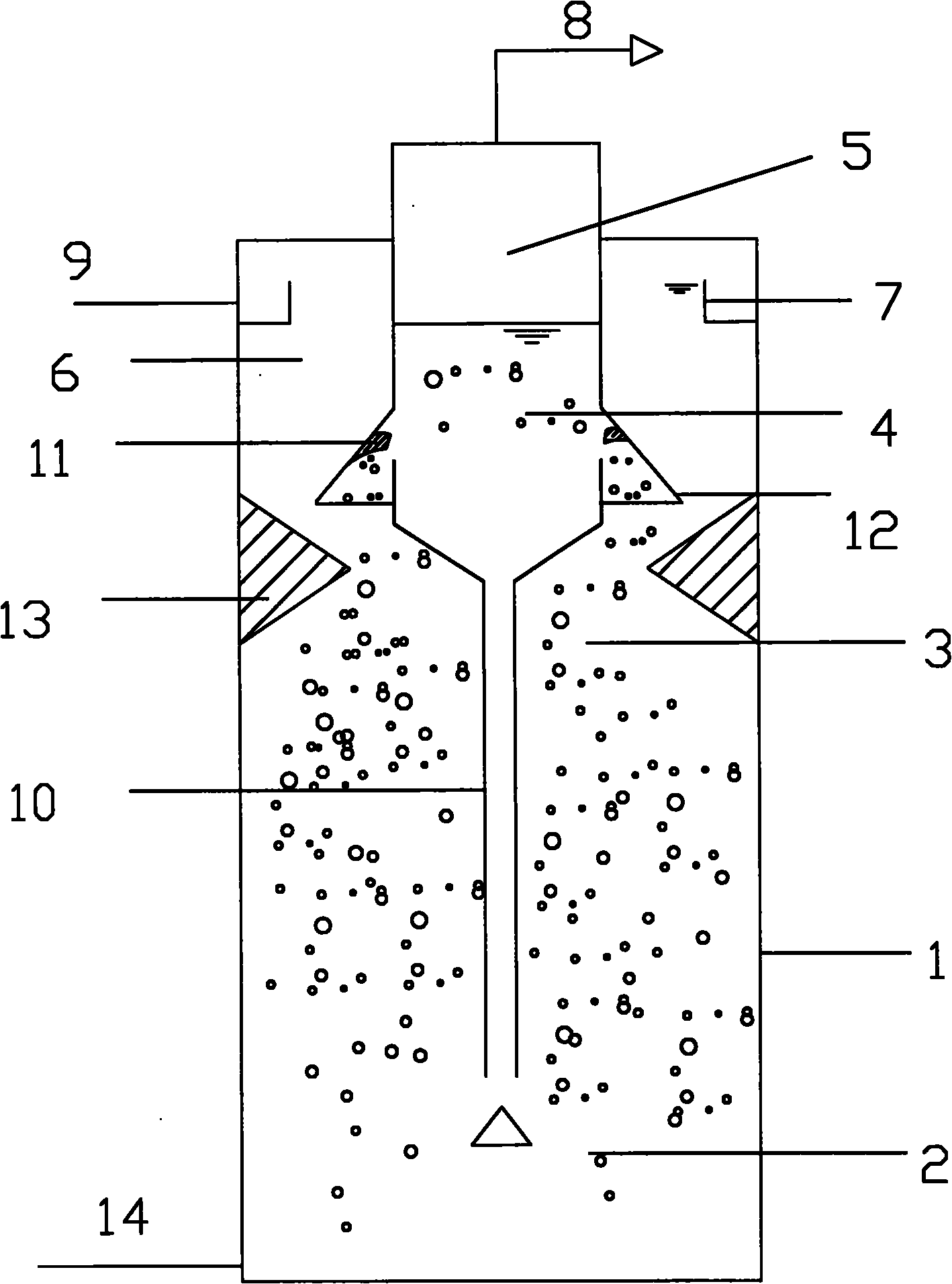

[0010] Depend on figure 1 , 2 As shown, the present invention includes a body and a three-phase separator. The lower part of the body 1 is a sludge bed area 2, and the upper part of the sludge bed area 2 is a suspension area 3, and the center of the suspension area 3 is equipped with an upper protruding body. The three-phase separator 12, the three-phase separator 12 inner gas collection chamber 5 below is a three-phase separation zone 4, the three-phase separator above the suspension zone 3 and the inner wall of the vessel form a precipitation zone 6, the three-phase separator 12 The return pipe 10 in the center of the lower part passes through the suspension area 3 and extends into the sludge bed area 2. There is a gas outlet pipe 8 on the upper part of the gas collection chamber 5. There is a waste water inlet pipe 14 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com