Biological treatment method, biological treatment system and bioreactor of coal chemical wastewater

A technology for coal chemical wastewater and biological treatment, which is applied in the field of coal chemical wastewater treatment and wastewater treatment containing high concentrations of organic pollutants and ammonia nitrogen. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

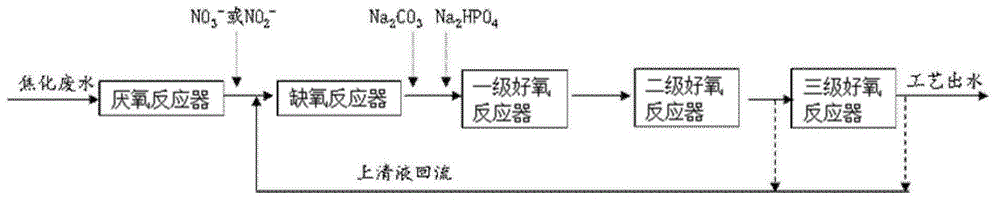

[0083] The pretreated coal chemical wastewater enters the bottom of the anaerobic reactor, and the effluent elevations of the reactors at all levels decrease successively. The anaerobic acidification treatment is carried out in the anaerobic reactor, and the hydraulic retention time of the anaerobic reactor is 7 hours. The effluent from the anaerobic reactor enters the water distribution system at the bottom of the anoxic reactor, and at the same time, the returning nitrification liquid (from the secondary and tertiary aerobic reactors, with a reflux ratio of 6:1) also flows back to the water distribution system, and the dissolved oxygen in the anoxic reactor The concentration is 0.5mg / L, the N / C value is 3, the temperature is 25°C, the pH is 9, and the hydraulic retention time is about 15 hours. The effluent from the anoxic reactor flows into the first-stage aerobic reactor by itself, and at the same time, a certain amount of Na 2 CO 3 and Na 2 HPO 3 . The dissolved oxyg...

Embodiment 2

[0085] The pretreated coal chemical wastewater enters the bottom of the anaerobic reactor, and the effluent elevations of the reactors at all levels decrease successively. The anaerobic acidification treatment is carried out in the anaerobic reactor, and the hydraulic retention time of the anaerobic reactor is 5 hours. The effluent from the anaerobic reactor enters the water distribution system at the bottom of the anoxic reactor, and at the same time, the returning nitrification liquid (from the secondary and tertiary aerobic reactors, with a reflux ratio of 2:1) also flows back to the water distribution system, and the dissolved oxygen in the anoxic reactor The concentration is 0.8mg / L, the N / C value is 2.5, the temperature is 38°C, the pH is 7.7, and the hydraulic retention time is about 40 hours. The effluent from the anoxic reactor flows into the first-stage aerobic reactor by itself, and at the same time, a certain amount of Na 2 CO 3 and Na 2 HPO 3 . The dissolved ...

Embodiment 3

[0087] The pretreated coal chemical wastewater enters the bottom of the anaerobic reactor, and the effluent elevations of the reactors at all levels decrease successively. The anaerobic acidification treatment is carried out in the anaerobic reactor, and the hydraulic retention time of the anaerobic reactor is 15 hours. The effluent from the anaerobic reactor enters the water distribution system at the bottom of the anoxic reactor, and at the same time, the returning nitrification liquid (from the secondary and tertiary aerobic reactors, with a reflux ratio of 8:1) also flows back to the water distribution system, and the dissolved oxygen in the anoxic reactor The concentration is 0.6mg / L, the N / C value is 3.5, the temperature is 20°C, the pH is 9.3, and the hydraulic retention time is about 10 hours. The effluent from the anoxic reactor flows into the first-stage aerobic reactor by itself, and at the same time, a certain amount of Na 2 CO 3 and Na 2 HPO 3. The dissolved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com