Process of preparing synthetic natural gas by using yellow phosphorus tail gas

A yellow phosphorus tail gas and process technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems that the yellow phosphorus tail gas purification method has not been proposed and cannot meet the second-level natural gas standard, and achieve high reliability, stable operation, The effect of high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

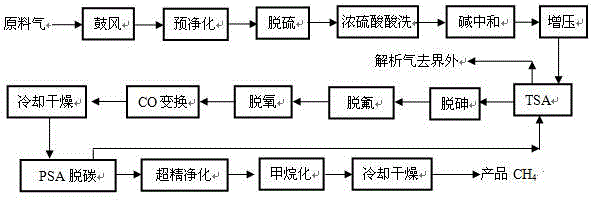

Method used

Image

Examples

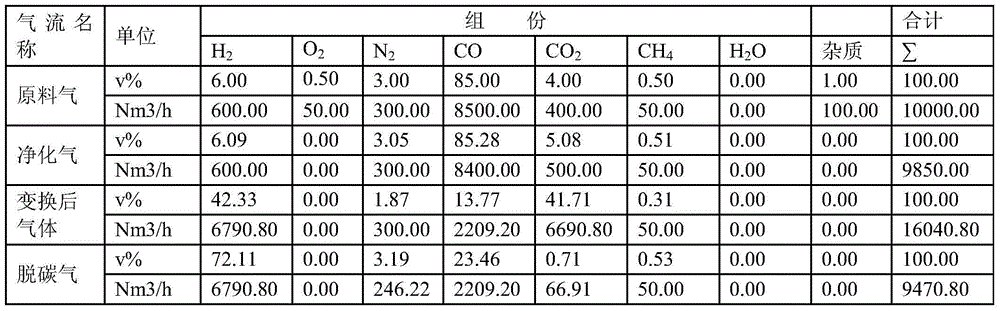

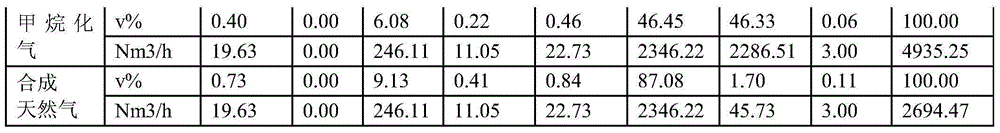

Embodiment 1

[0047] Table 1 Yellow phosphorus tail gas components

[0048] Element Volume fraction / % Element Mass concentration / mg·m -3 O 2 0.5 PH3 2550 CO 85 h 2 S 10050 H 2 5.0 HF 610 N 2 4.0 SO 2 29 CO 2 4.0 CS 2 18 CH 4 0.5 COS 315

[0049] Gas flow 10000Nm 3 / h

[0050] The yellow phosphorus tail gas from the yellow phosphorus plant is pressurized to 50kPa by the blower and then enters the pre-purification system composed of two towers to remove viscous impurities such as tar in the yellow phosphorus tail gas.

[0051] The pre-purified yellow phosphorus tail gas enters the bottom of two series-connected desulfurization towers in turn, and the desulfurization solution enters from the upper part of the tower, sprays the yellow phosphorus tail gas from top to bottom, absorbs hydrogen sulfide in the yellow phosphorus tail gas, and removes the yellow phosphorus from hydrogen sulfide The tail gas enters the co...

Embodiment 2

[0070] Table 3 Yellow phosphorus tail gas components

[0071] Element Volume fraction / % Element Mass concentration / mg·m 3 O 2 0.2 pH 3 1550 CO 95 h 2 S 8050 H 2 2.0 HF 1010 N 2 1.0 SO 2 56 CO 2 1.0 CS 2 120 CH 4 0.8 COS 115

[0072] Gas flow 20000Nm 3 / h

[0073] The yellow phosphorus tail gas from the yellow phosphorus plant is pressurized to 70kPa by the blower and then enters the pre-purification system composed of two towers to remove viscous impurities such as tar in the yellow phosphorus tail gas.

[0074] The pre-purified yellow phosphorus tail gas enters the bottom of two series-connected desulfurization towers in turn, and the desulfurization solution enters from the upper part of the tower, sprays the yellow phosphorus tail gas from top to bottom, absorbs hydrogen sulfide in the yellow phosphorus tail gas, and removes the yellow phosphorus from hydrogen sulfide The tail gas enters the ...

Embodiment 3

[0093] Table 5 Yellow phosphorus tail gas components

[0094] Element Volume fraction / % Element Mass concentration / mg·m 3 O 2 0.8 pH 3 340 CO 90 h 2 S 12120 H 2 3.5 HF 460 N 2 3.0 SO 2 25 CO 2 2.5 CS 2 310 CH 4 0.2 COS 78

[0095] Gas flow 50000Nm 3 / h

[0096] The yellow phosphorus tail gas from the yellow phosphorus plant is pressurized to 60kPa by the blower and then enters the pre-purification system consisting of two towers to remove viscous impurities such as tar in the yellow phosphorus tail gas.

[0097] The pre-purified yellow phosphorus tail gas enters the bottom of two series-connected desulfurization towers in turn, and the desulfurization solution enters from the upper part of the tower, sprays the yellow phosphorus tail gas from top to bottom, absorbs hydrogen sulfide in the yellow phosphorus tail gas, and removes the yellow phosphorus from hydrogen sulfide The tail gas enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com