Method for co-production of various chemical products from natural gas, coal and petroleum

A technology for chemical products and natural gas, applied in the field of co-production of various chemical products, can solve the problems of resource, power waste, unreasonable carbon-hydrogen ratio, and large emission of synthetic relaxation gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

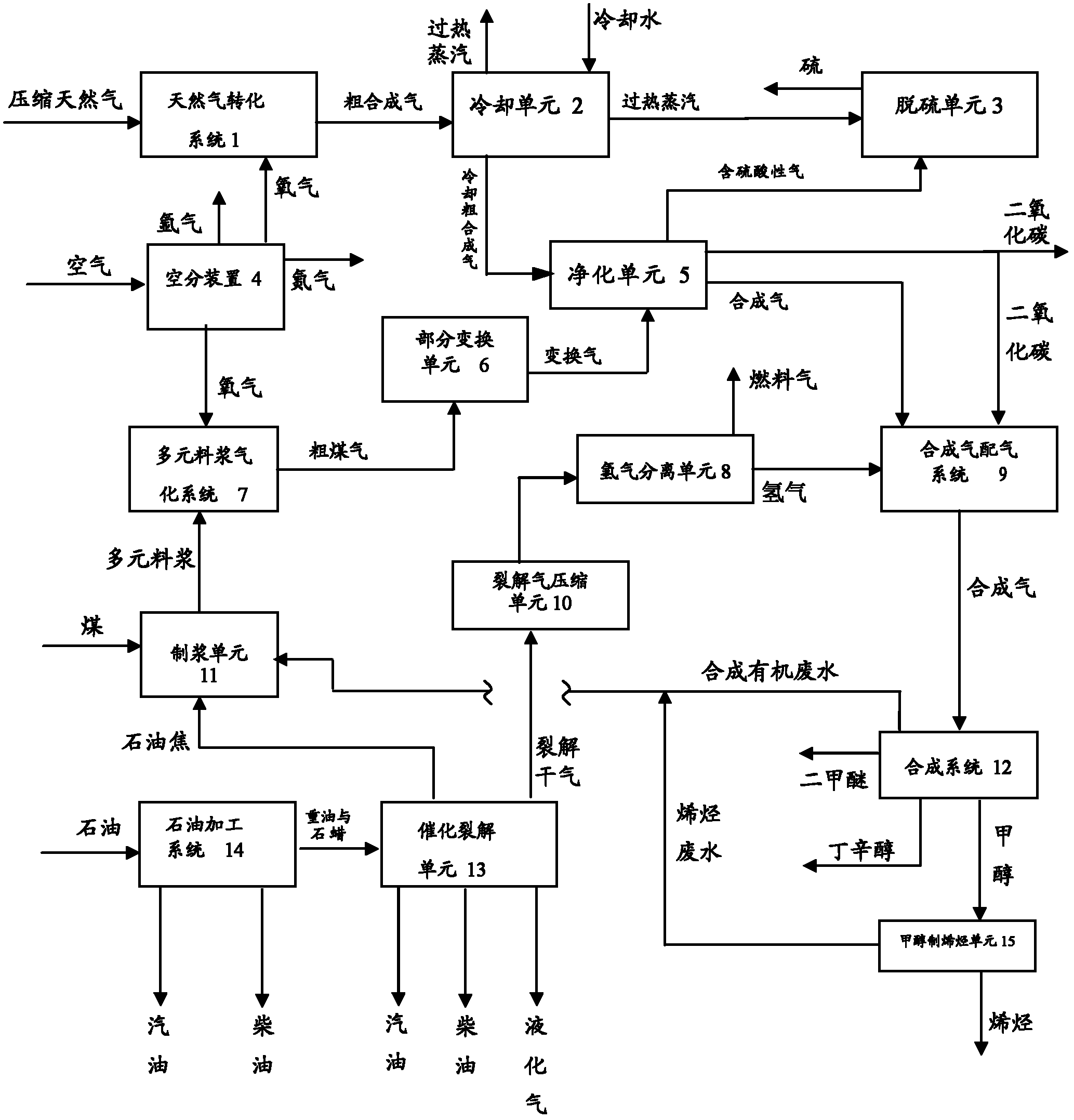

[0090] Example: Use of compressed natural gas as feedstock for part of the synthesis gas source.

[0091] According to this specification, this embodiment figure 1 The described process flow is carried out.

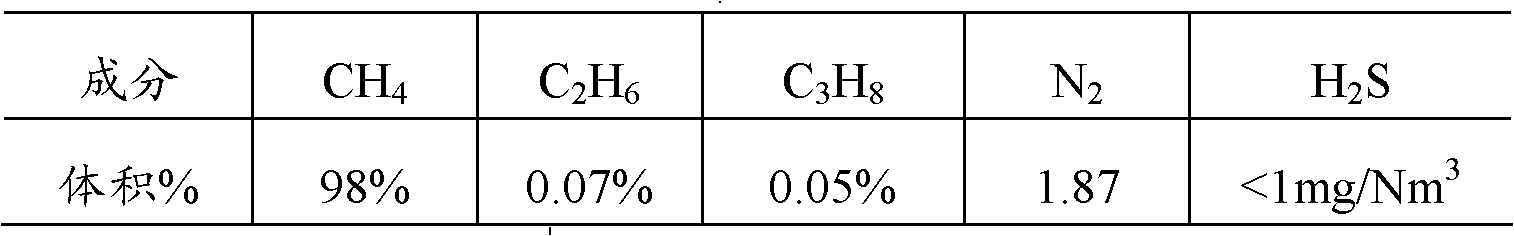

[0092] The composition of the natural gas that this embodiment selects to use (in this natural gas total volume, dry basis) is as follows:

[0093]

[0094] The implementation steps are as follows:

[0095] In the reformer of natural gas reforming system 1, the flow of natural gas entering the reformer is 17540Nm 3 / h, the flow of oxygen (oxygen purity is 99.6%) from the air separation unit 4 is 12278Nm 3 / h, the volume ratio of oxygen to natural gas is 0.7, they react in the natural gas conversion system 1 under the conditions of internal pressure 6.1MPa and temperature 1280℃ to generate a crude synthesis gas with a flow rate of 50000Nm 3 / h, the composition of the crude synthesis gas (based on the total volume of the crude synthesis gas, dry basis) is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com