Internal circulation biological desulphurization reactor and method thereof

A biological desulfurization and cyclic reaction technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of insufficient contact reaction between sulfide and oxygen, decreased conversion rate of sulfide, and increased floor space. Achieve the effect of improving the return effect, compact device structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific drawings and specific embodiments. If there is no special description or conflict between the various preferred embodiments, any combination can be made.

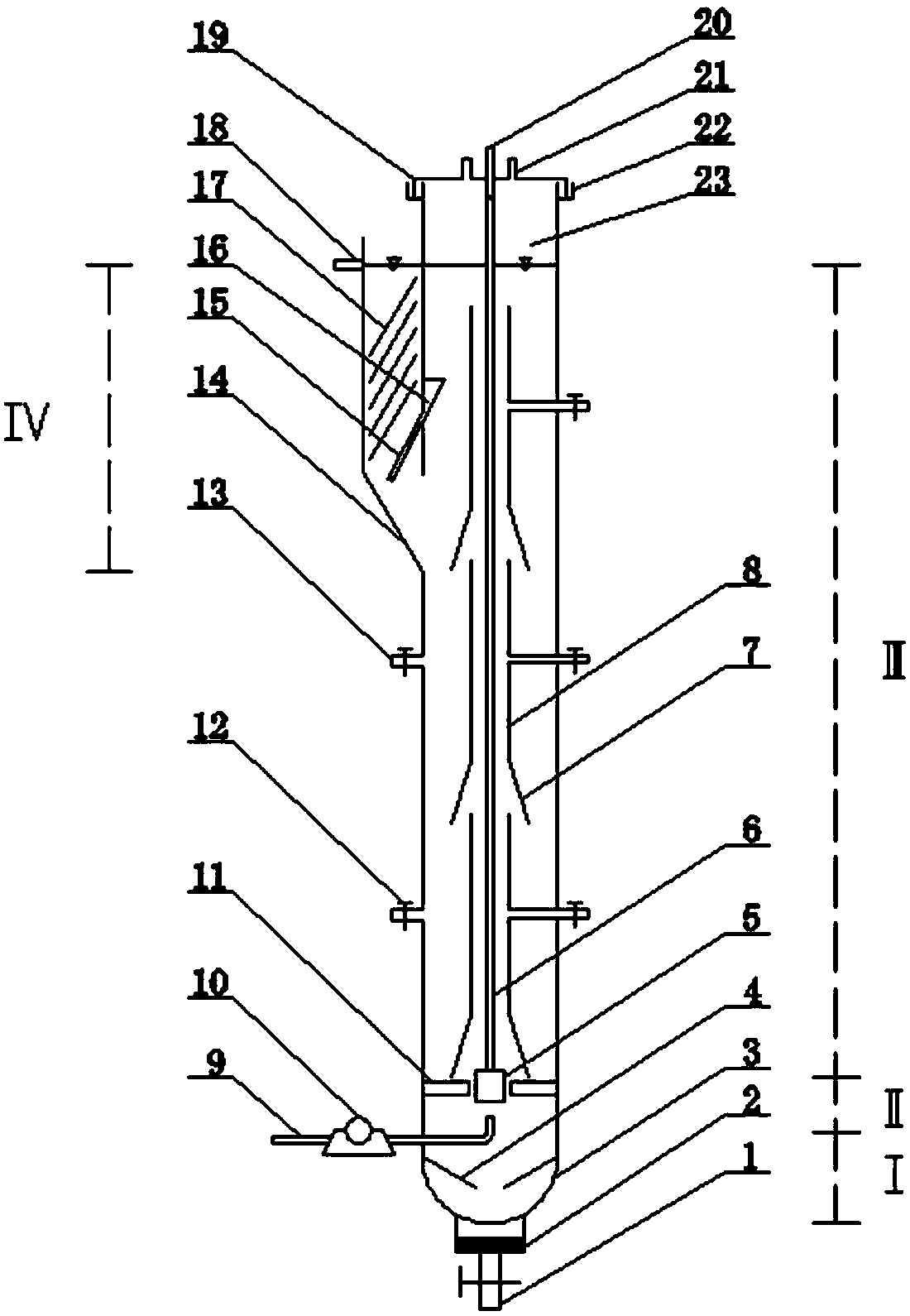

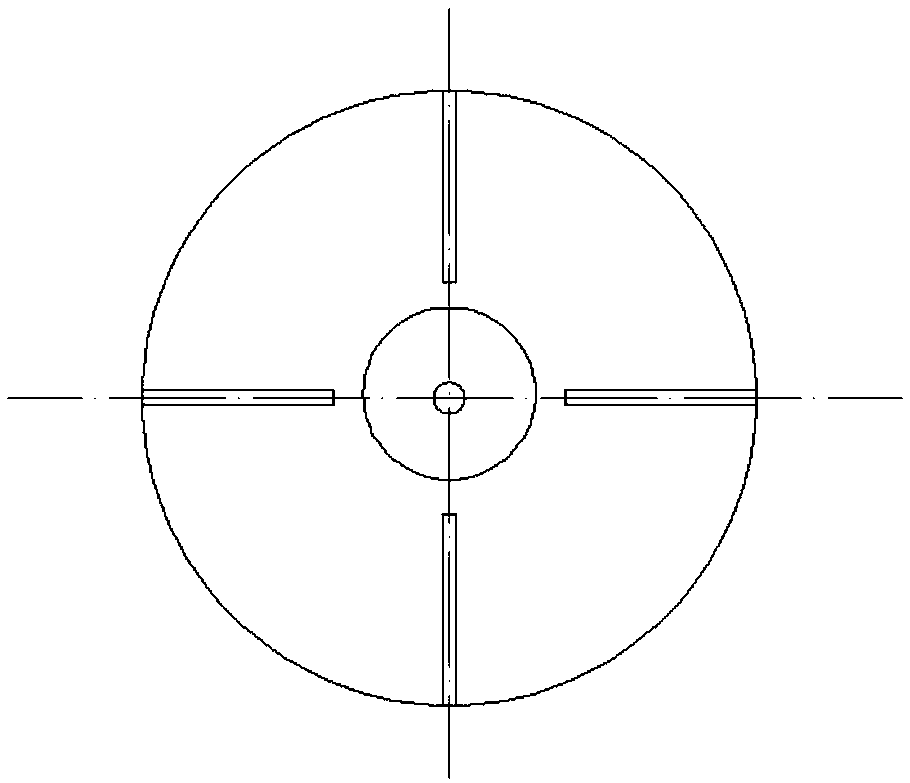

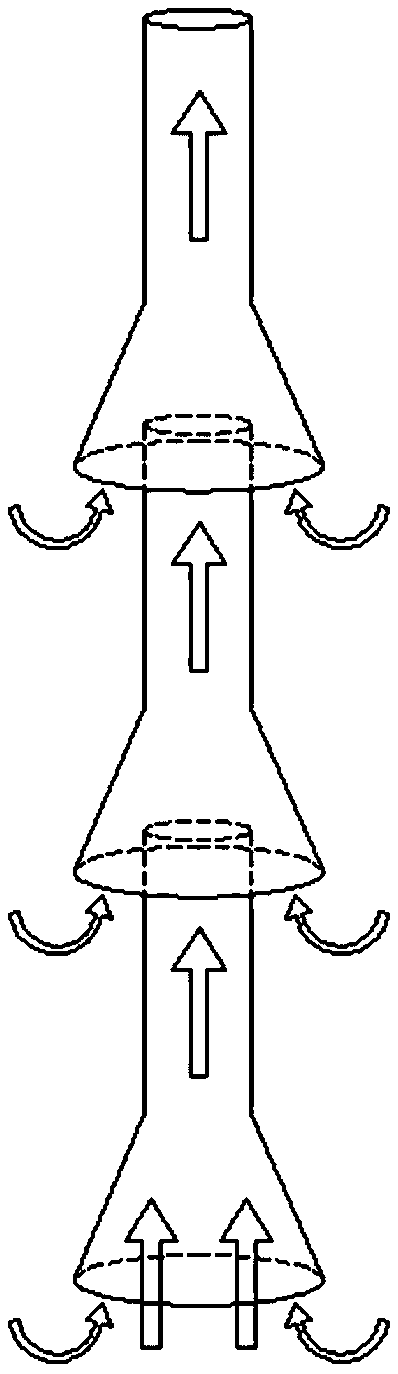

[0028] Such as Figure 1~5 As shown, an internal circulation biological desulfurization reactor, the main body of the reactor is a cylindrical outer wall, which is divided into sulfur collection area I, water inlet area II, circulation reaction area III, and precipitation area IV from bottom to top. It is arranged on the upper periphery of the cylindrical outer wall.

[0029] In the sulfur collection area I, the sulfur discharge pipe 1, the screw port 2 and the mud collection tank 3 are arranged in sequence from bottom to top, and the annular sloping plate 4 is arranged on the inner top of the mud collection tank 3 and slopes downward toward the center to realize the Separation and discharge of sludge; the sulfur discharge pipe 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com