Gas distribution device

A gas distribution device and gas chamber technology, applied in the direction of granular/powdered fuel gasification, combined combustion relief, etc., can solve the problems of difficult ash discharge, lower gasification efficiency, etc., and achieve the effect of prolonging residence time and strengthening horizontal mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

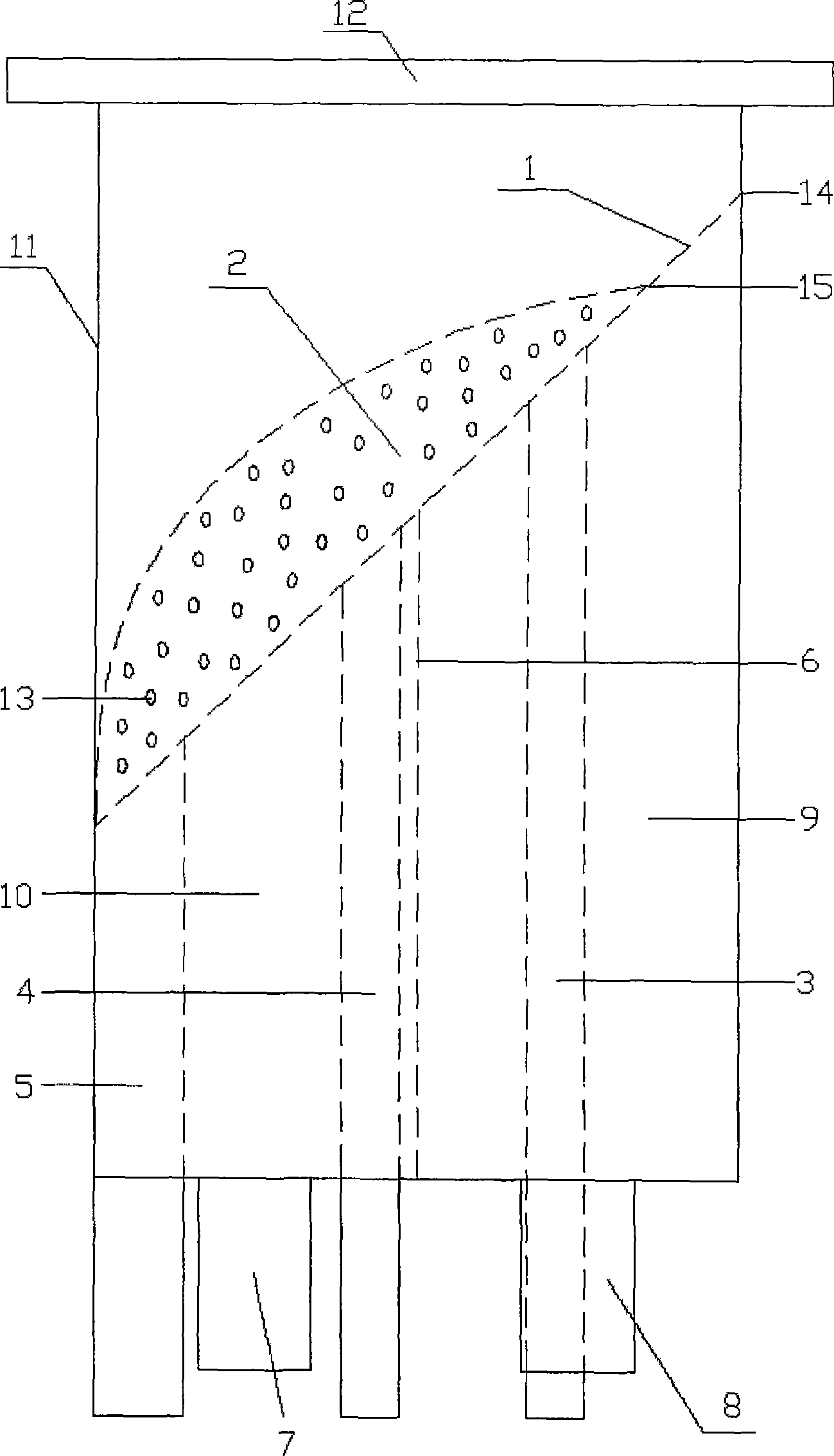

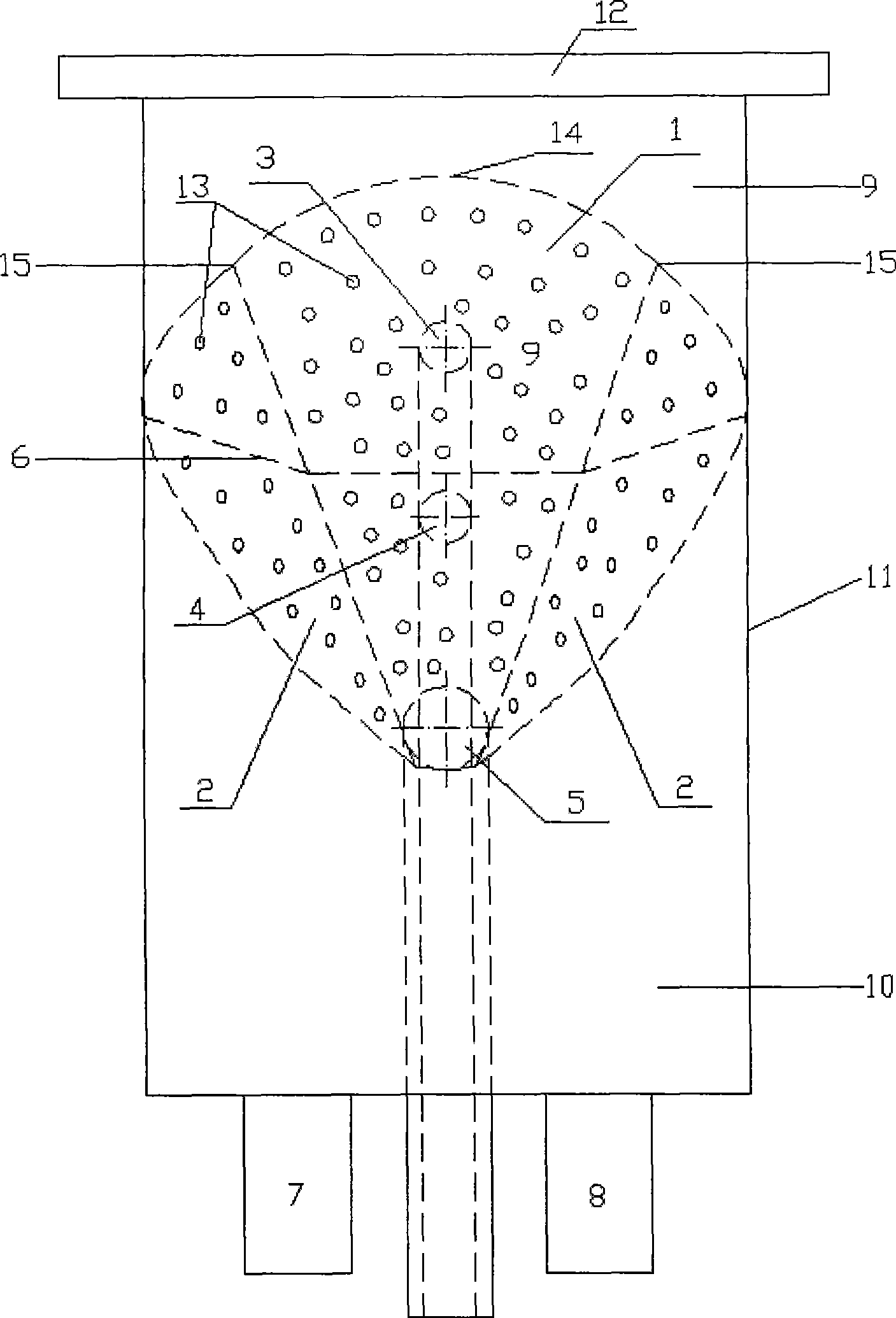

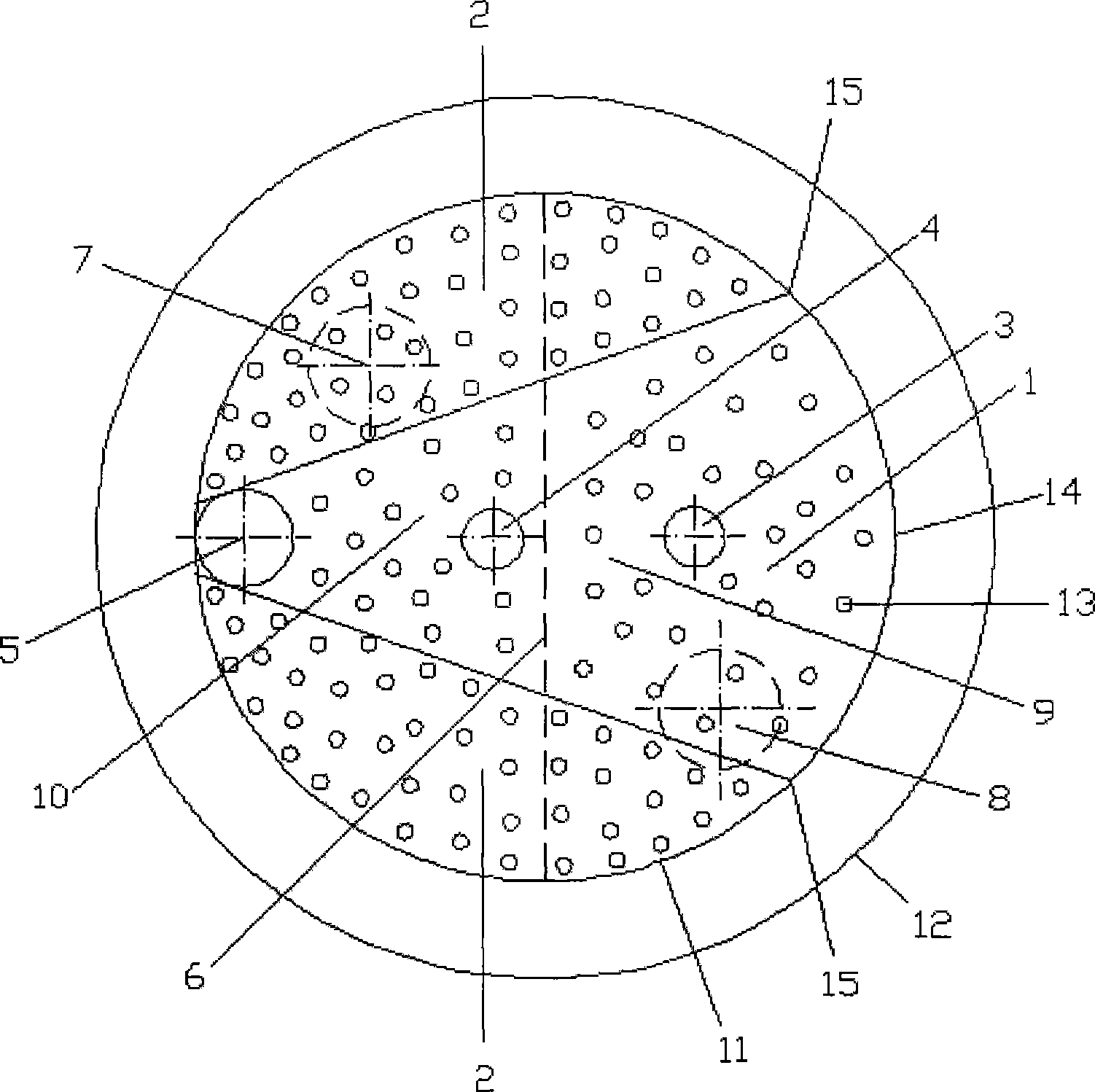

Embodiment 1

[0016] The main board 1 and the side wings 2 form a gas distribution plate. The side wings 2 are located on both sides of the main board 1, symmetrical along the center line of the main board 1, and form an angle of 20° with the plane where the main board 1 is located. The main board 1 is placed on the cylinder at an angle of 25° to the horizontal direction. The inside of 11 is connected to the wall of cylinder 11. There are vertically upward small holes 13 on the main board 1 and side wings 2. The opening rate is 0.5%, and the aperture is 0.5 mm. The ash discharge pipe 5 and the ash discharge port on the main board 1 Connected, the ash discharge port is elliptical, the connection line between the main board 1 and the side wing 2 passes through the tangent of the ellipse of the ash discharge port, the upper end point 15 of the connection line is located between the apex 14 on the main board 1 and the baffle plate 6, and the cylinder 11 has Two jet tubes 3, 4, the centers of whi...

Embodiment 2

[0019] The side wing 2 forms an angle of 30° with the plane where the main board 1 is located, and the main board 1 is placed obliquely at an angle of 40° to the horizontal direction in the cylinder 11 and connected to the wall of the cylinder 11. The main board 1 and the side wing 2 are provided with vertically upward small Hole 13, the opening ratio is 2%, and the aperture is 2 millimeters, and other is the same as embodiment 1.

Embodiment 3

[0021] The side wing 2 forms an angle of 40° with the plane where the main board 1 is located, and the main board 1 is placed obliquely at an angle of 50° to the horizontal direction in the cylinder 11 and connected to the wall of the cylinder 11. The main board 1 and the side wing 2 are provided with vertically upward small Hole 13, the opening rate is 5%, and the aperture is 3 millimeters, and other is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com