Flow guide device and spouted bed

A technology of spouted bed and deflector, which is applied in the direction of hearth furnaces, chemical instruments and methods, furnaces, etc., to achieve the effects of reducing collision wear, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

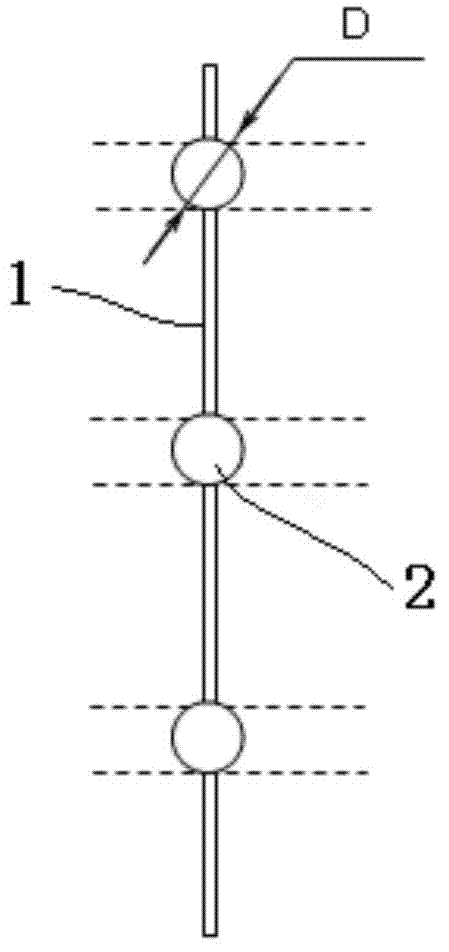

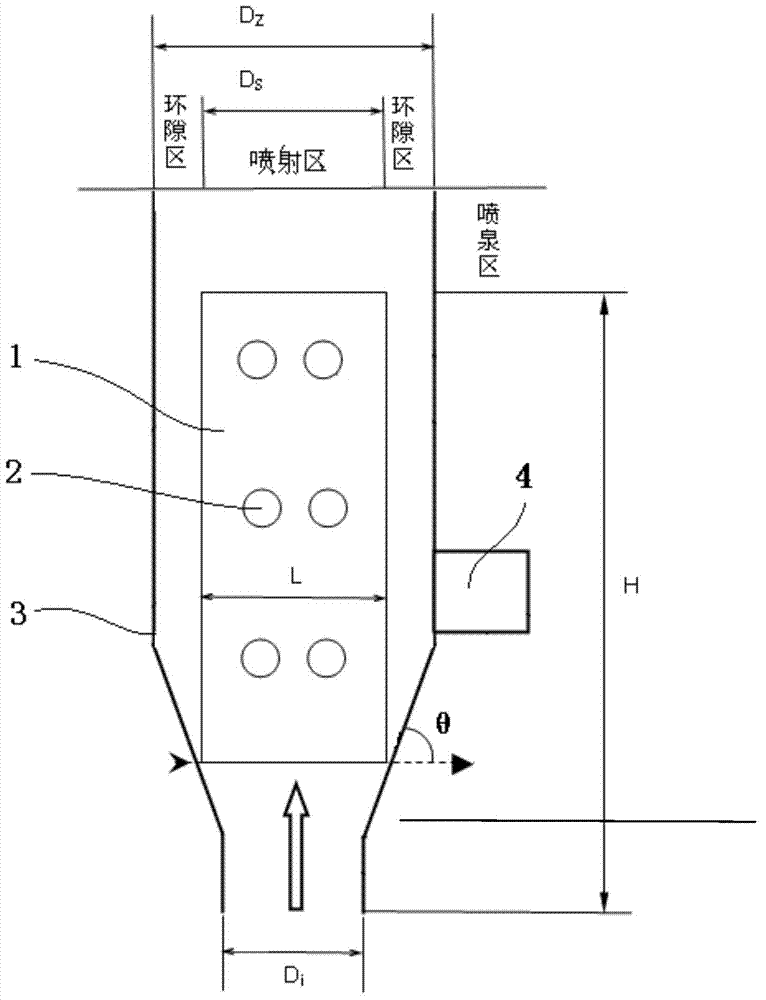

[0039] This embodiment is a specific spouted bed, such as figure 1 In the spouted bed reactor shown, a rotating and controllable deflector 1 is set on the spouted bed bed 3, and the control is realized by the speed-regulating motor 4 on the base of the spouted bed. A series of longitudinal vortex generators distributed in pairs, the diameter D of the longitudinal vortex generator sphere 2 is 4mm, and the diameter of the particles is d p is 0.46mm.

[0040] The sphere is bisected by the deflector, and the horizontal center distance of the pair of longitudinal vortex generators on the deflector is 1.5 times the diameter D of the metal ball, and the longitudinal center distance is 3 times the diameter D of the ball.

[0041] The width of the deflector is L is 20mm, D i 14.3mm, the top of the deflector is located in the area below the spouted bed fountain area to ensure that the structure of the deflector does not affect the overall spouting effect of the spouted bed.

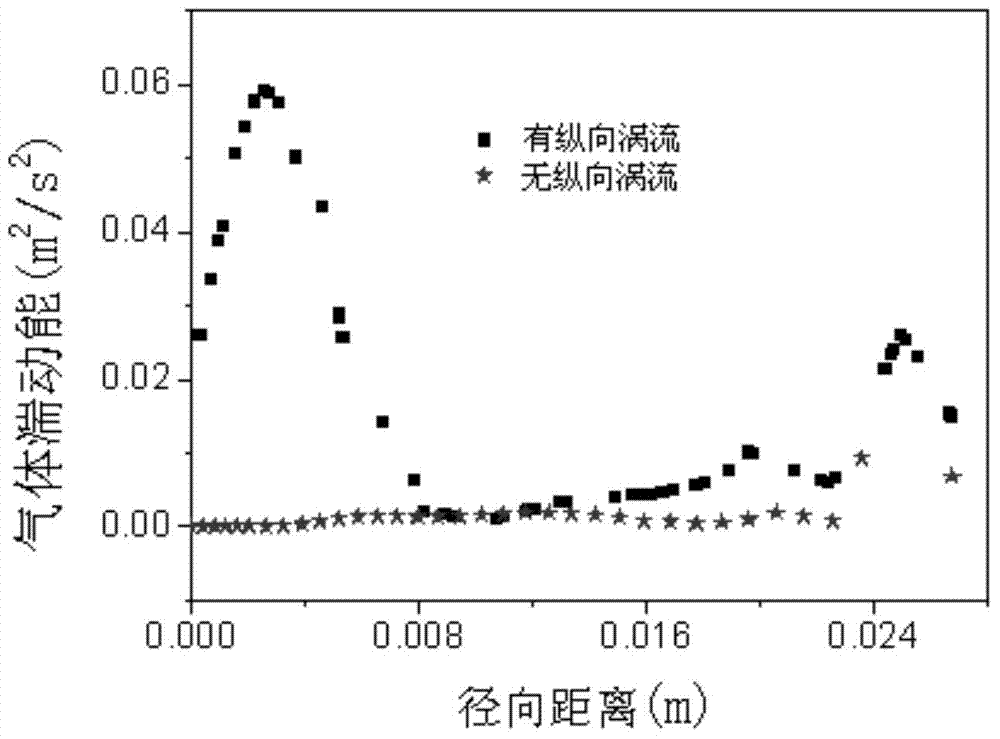

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com