Combustion optimization system and adjustment method for preventing high temperature corrosion of water wall

A technology of combustion optimization and adjustment method, applied in the combustion method, combustion chamber, control combustion and other directions, can solve the problems of uneven heating, affect the burning of pulverized coal, increase the swirl intensity, etc., and achieve the flue gas temperature field and smoke. The airflow field is evenly distributed, the swirl intensity is effectively matched, and the effect of strengthening the lateral mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

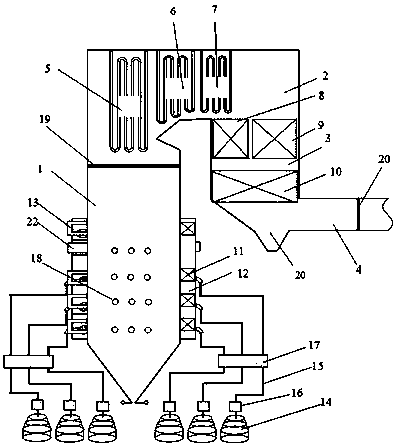

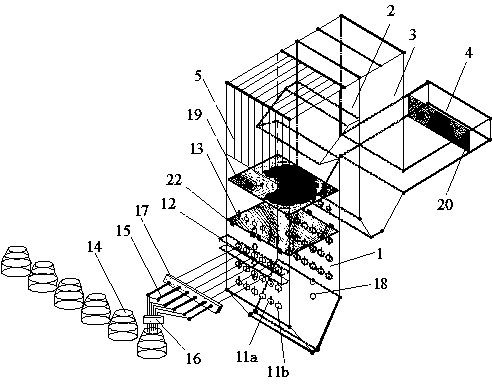

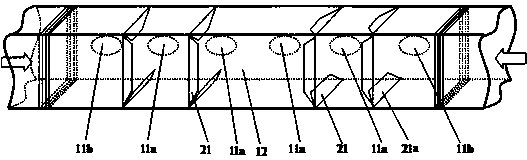

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] Such as figure 1 , figure 2 As shown, the object of combustion optimization in this embodiment is a 660MW ultra-supercritical counter-swirl combustion boiler, which includes a furnace 1, a burner 11, a panel superheater 5, a high-temperature superheater 6, a high-temperature Reheater 7, low-temperature superheater 8, low-temperature reheater 9, economizer 10, secondary air wind box 12, overfire air nozzle 13, coal mill 14, primary air pulverized coal pipeline 15. The furnace 1 is composed of the front wall, the rear wall and the water-cooled walls on both sides. The upper, middle and lower layers of burners are respectively arranged on the front and rear walls. Each layer has 6 burners, a total of 36 burners. Each layer burns Devices 11 are co-located in a secondary air wind box 12. The boiler is equipped with 6 coal mills 14, and each coal mill supplies p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com