Built-in maintenance-free cadmium nickel alkalescent accumulator

A maintenance-free, built-in technology, applied in the direction of alkaline batteries, alkaline battery electrodes, nickel batteries, etc., can solve the problems of unfavorable hydrogen and oxygen catalytic combination, no compensation for losses, and short battery maintenance-free period , to achieve long maintenance-free period, reduce water loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

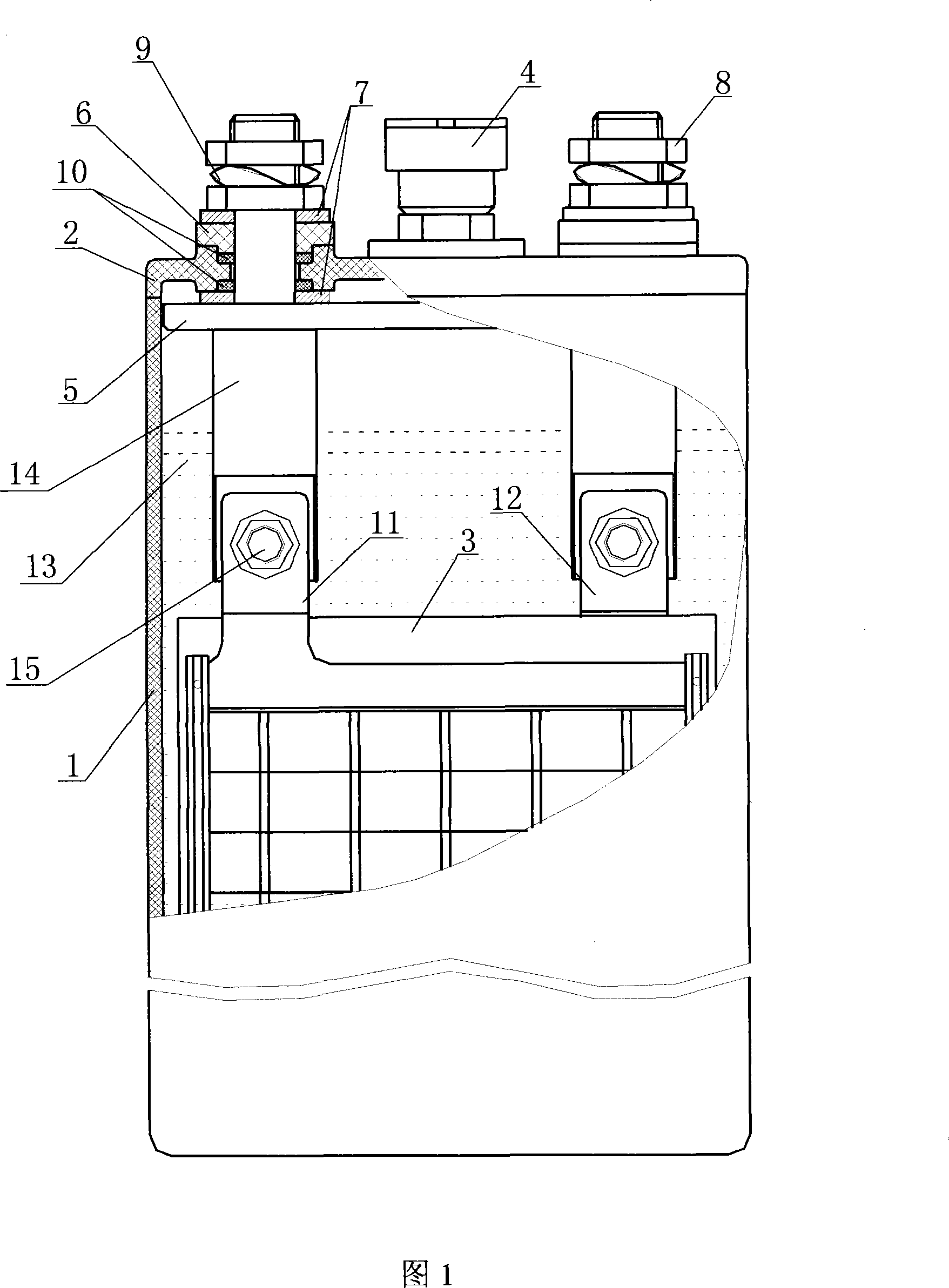

[0027] Embodiment 1: see accompanying drawing.

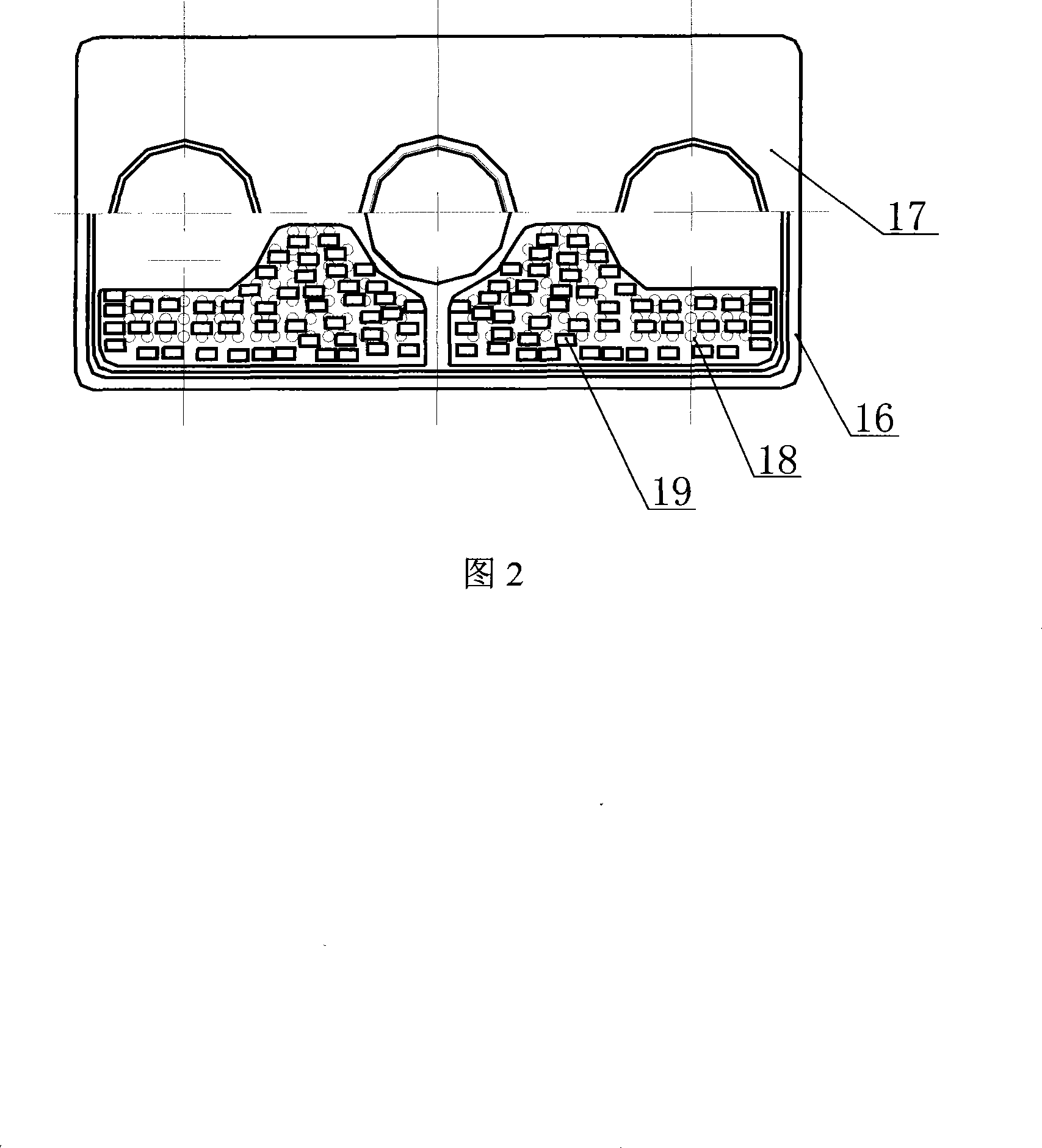

[0028] A built-in maintenance-free cadmium-nickel alkaline storage battery, mainly composed of a positive plate 11, a negative plate 12, a separator 3, a battery container (consisting of a single case 1 and a single cover 2 that is sealed and connected with the single case 1, and the same prior art), valve-controlled assembly air plug 4 and auxiliary components, electrolyte 13, and an absorption box 5 with hydrogen elimination catalyst 19 and holes 18 arranged in the electrolyte 13 above the battery container Composition; Its connection mode can be with prior art, wherein:

[0029] Described absorption box 5 is made of the absorption box body 16 that has hole 18, the absorption box cover 17 that is connected with absorption box body 16, the dehydrogenation catalyst 19 that places in the absorption box body 16; There are various dehydrogenation catalysts, such as the LH series dehydrogenation catalysts produced by the Lanzhou Ch...

Embodiment 2

[0037] Embodiment 2: see accompanying drawing.

[0038]A built-in maintenance-free cadmium-nickel alkaline battery, mainly composed of a bag-type positive plate 11, a dry negative plate 12, a spacer 3, a battery container (by a single case 1 and a single cover sealed with the single case 1 2 constitute, with the prior art), valve-controlled assembly gas plug 4 and auxiliary components, electrolyte 13, and a hydrogen elimination catalyst 19, hole 18 is housed in the electrolytic solution 13 top that is arranged in the described battery container The absorption box 5 is formed; Its connection mode can be with prior art, wherein:

[0039] Described absorption box 5 is made of the absorption box body 16 that has hole 18, the absorption box cover 17 that is connected with absorption box body 16, the dehydrogenation catalyst 19 that is placed in the absorption box body 16 (particle size is 2mm~3mm spherical shape can use 50~60 grains of hydrogen-oxygen combination hydrogen eliminat...

Embodiment 3

[0048] Embodiment 3: see accompanying drawing.

[0049] A built-in maintenance-free cadmium-nickel alkaline storage battery, mainly composed of a bag-type positive plate 11, an electrodeposited negative plate 12, a separator 3, a battery container (by a single case 1 and a single cover sealed with the single case 1 2 constitute, with the prior art), valve-controlled assembly gas plug 4 and auxiliary components, electrolyte 13, and a hydrogen elimination catalyst 19, hole 18 is housed in the electrolytic solution 13 top that is arranged in the described battery container The absorption box 5 is formed; Its connection mode can be with prior art, wherein:

[0050] (1) The absorption box 5 is composed of an absorption box body 16 with holes 18, an absorption box cover 17 connected with the absorption box body 16, a hydrogen elimination catalyst 19 placed in the absorption box body 16 (the particle size is 2 mm to 3 mm spherical 50~60 grains of dehydrogenation catalysts that can c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com