Patents

Literature

36results about How to "Realize continuous filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

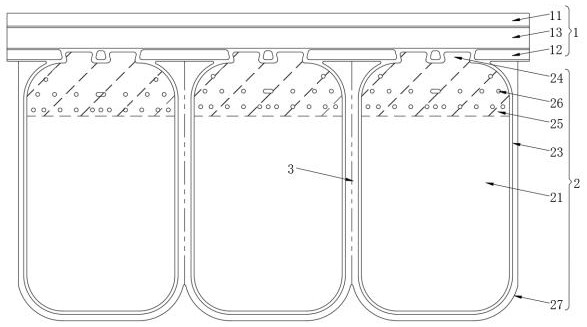

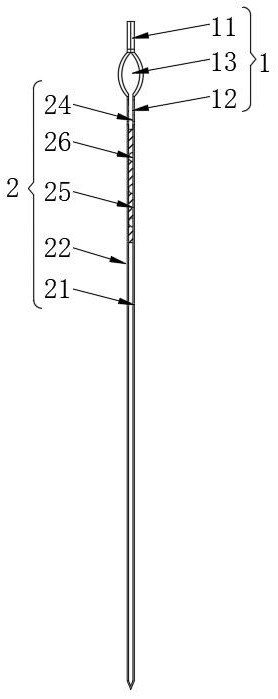

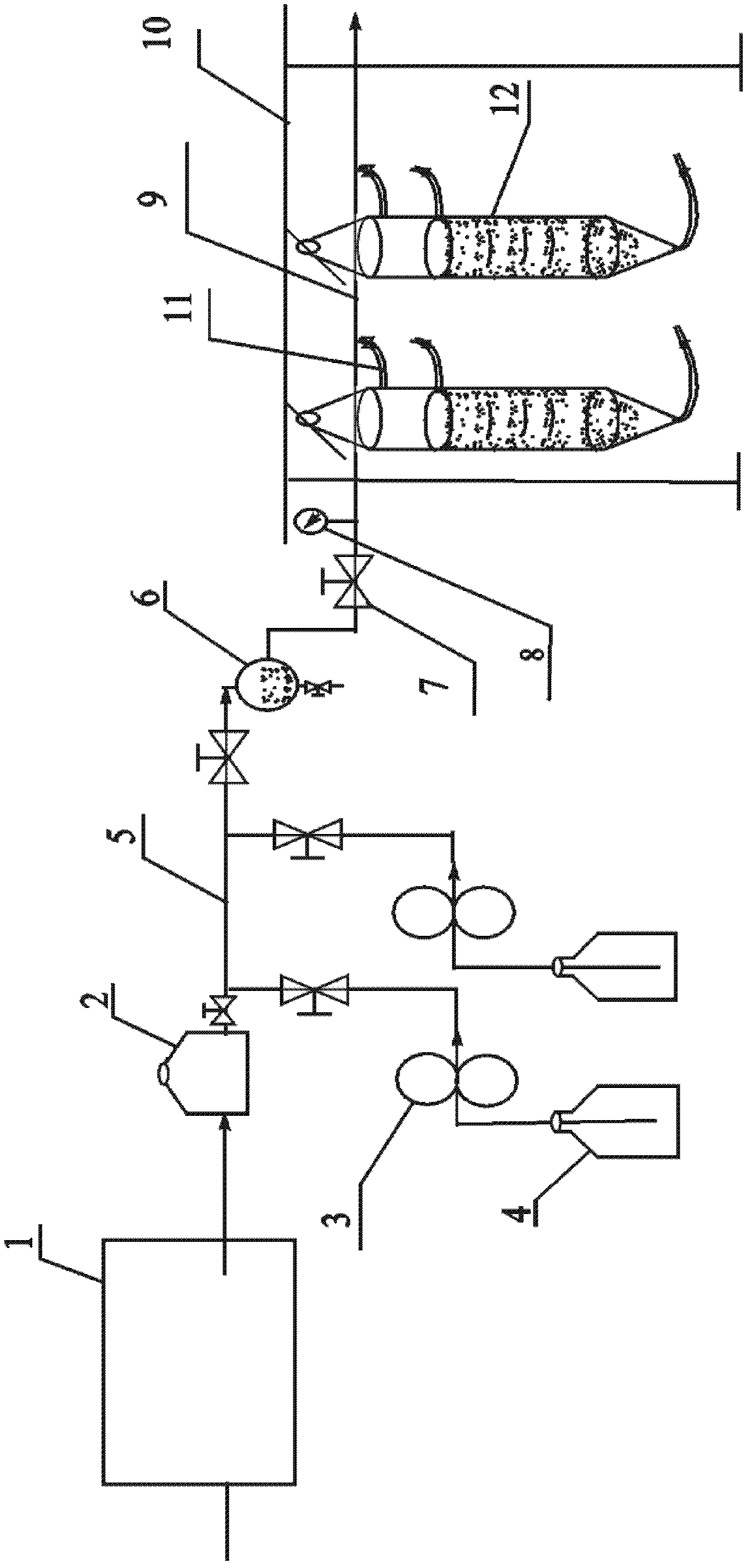

Culture solution continuous filling method and system for chlamydomonas culture

InactiveCN102220242APrevent leakageSystematicBioreactor/fermenter combinationsBiological substance pretreatmentsChlamydomonasPhotobioreactor

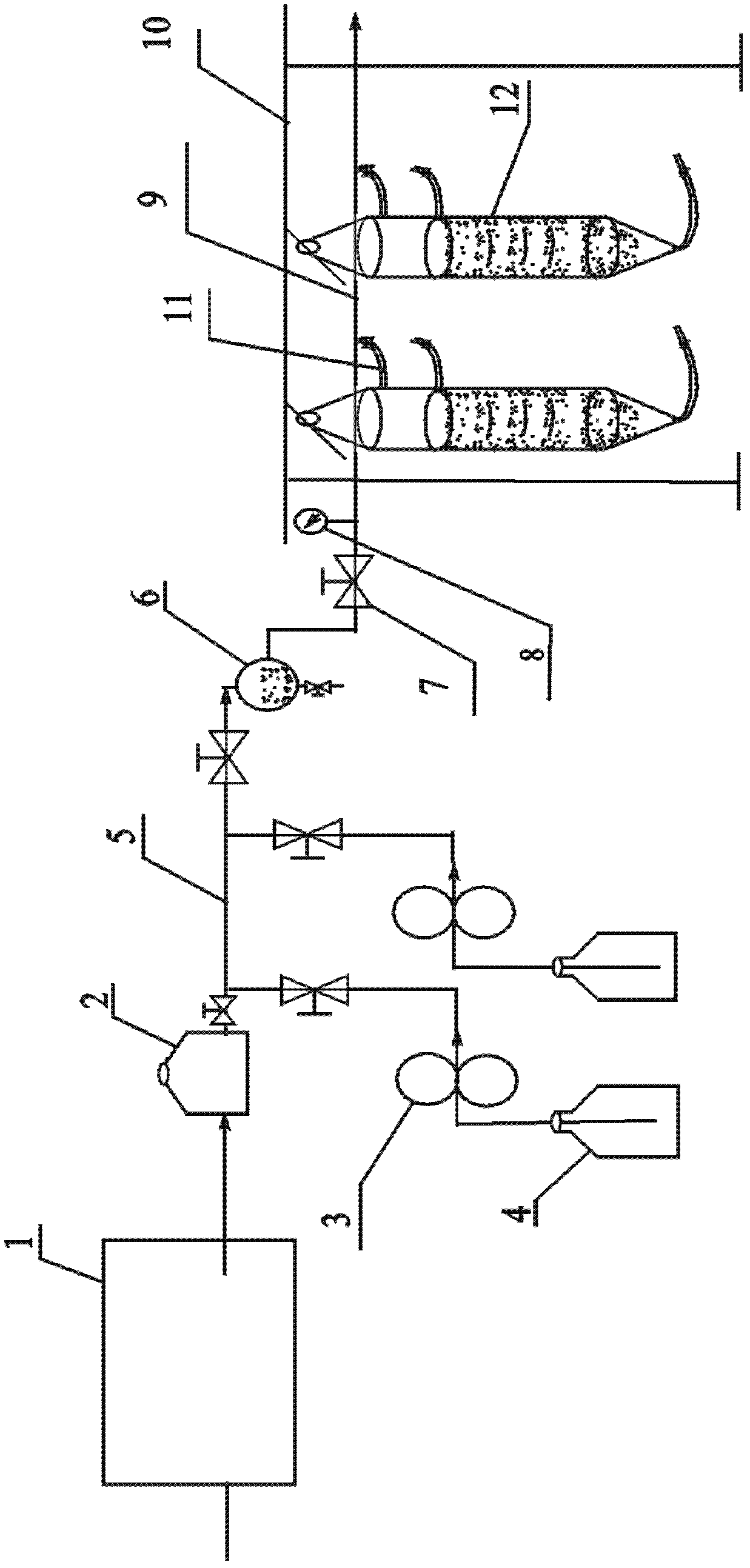

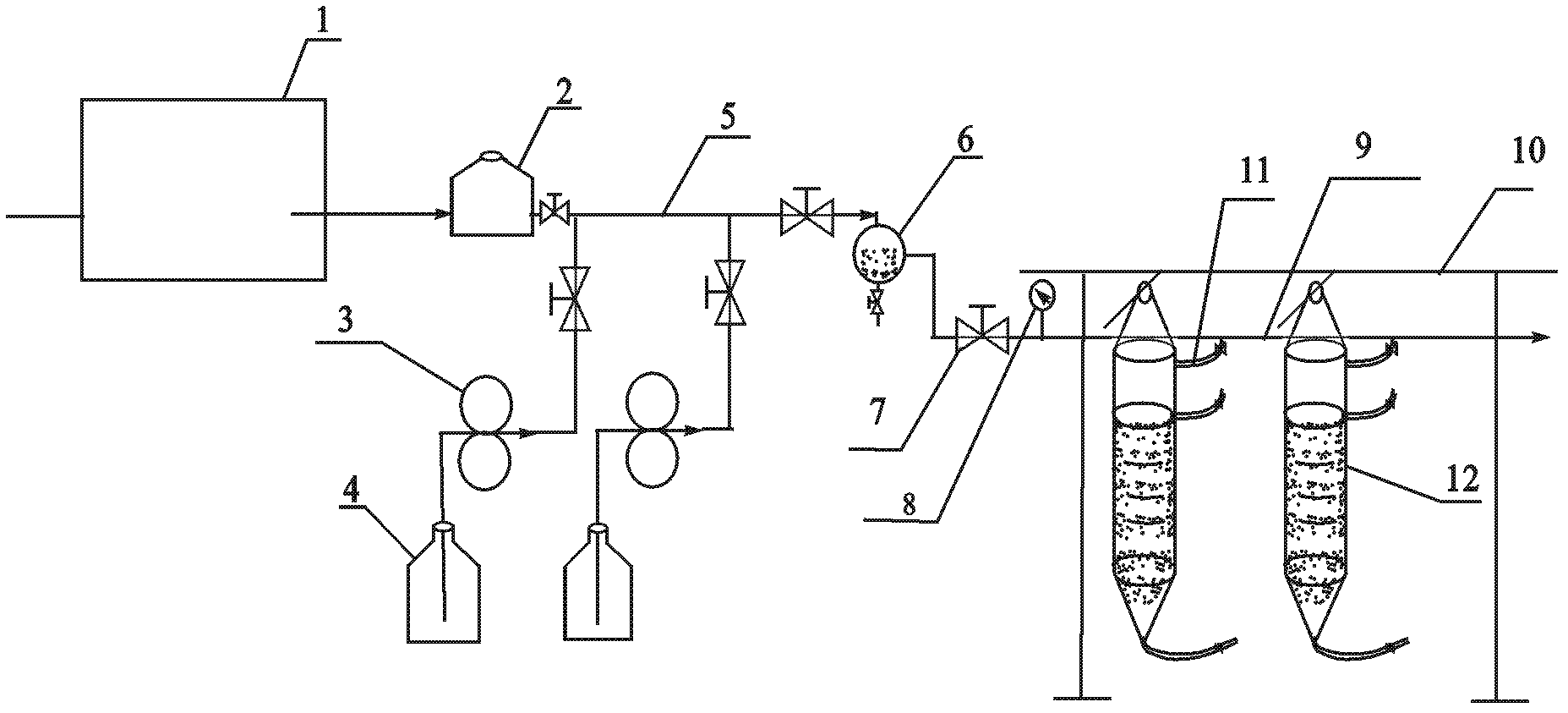

The invention relates to culture solution filling method and system for chlamydomonas culture. The method comprises the following steps: heating, disinfecting and cooling sea water, and then storing the sea water; mixing the sea water and a culture solution with nutritive salt in a various nutritive salt tanks, and filtering through a sand filtering device; and inputting the mixture into a chlamydomonas culture reactor through a pipeline with a quantitative control clamp. The system comprises a constant-pressure storage tank which is provided with a solution transmission pipeline, and is connected with a sea water heating and disinfecting device, and a nutritive salt tank which is used for filling the nutritive solution to the solution transmission pipeline through a pump, wherein the output end of the solution transmission pipeline is connected with the branch of a material liquid transmission pipeline on a culturing bracket through the sand filtering device, and is communicated with a hanging bag type photobioreactor, and the material liquid transmitting pipeline is arranged on a culture support. The method disclosed by the invention can realize the automatic, sterile and unwatched line production of culture solution. The system disclosed by the invention has a closing property, a systematic property, a quantitative property, a cleaning function and a buffering effect.

Owner:OCEAN UNIV OF CHINA

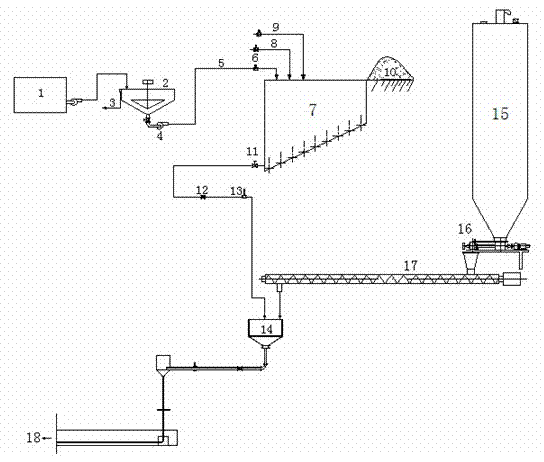

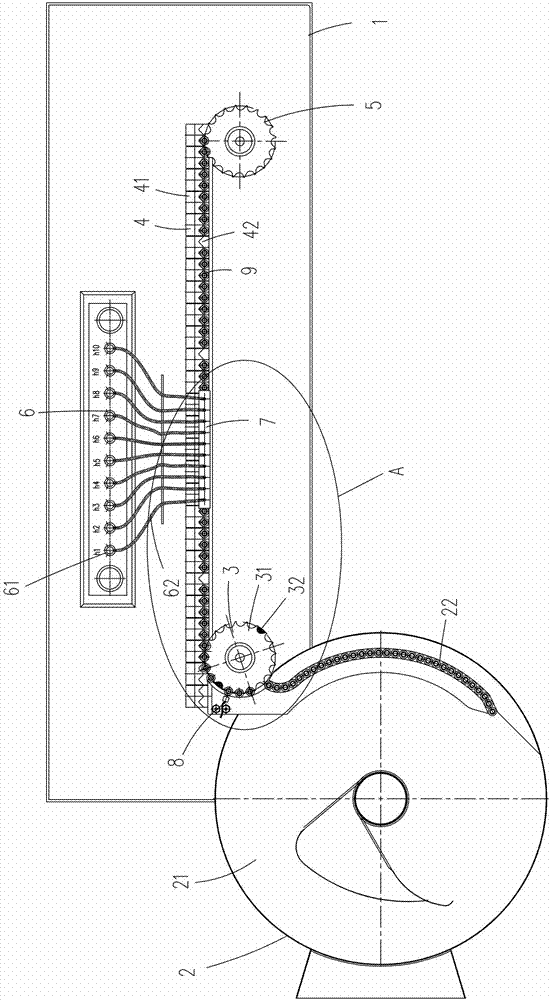

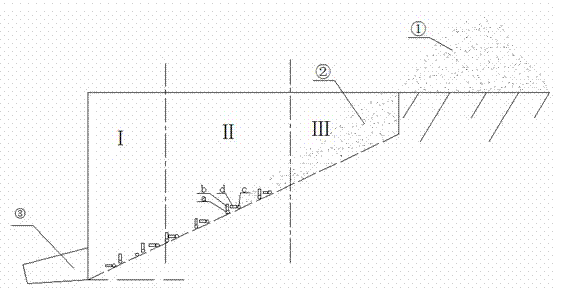

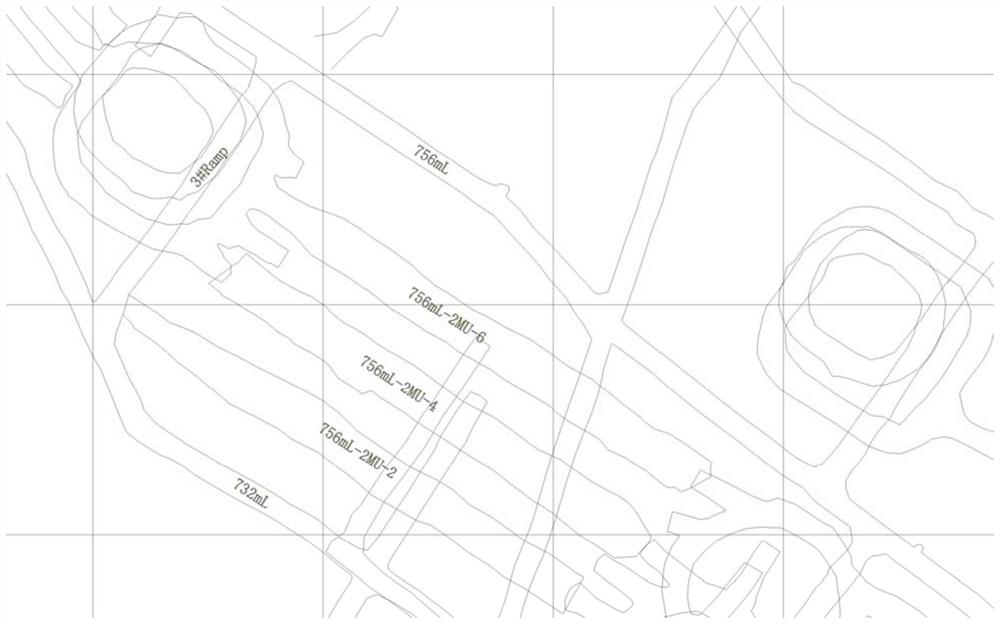

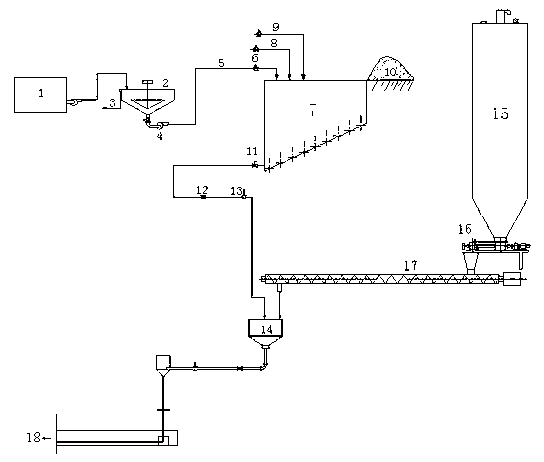

Mortar making system and process suitable for large horizontal sand silo of mine filling station

ActiveCN102367741ATimely supplementSolve the shortcomingsMaterial fill-upTransport systemHigh pressure water

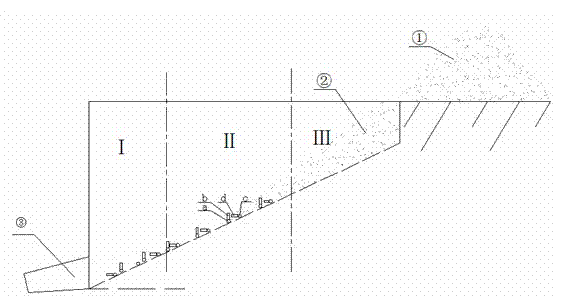

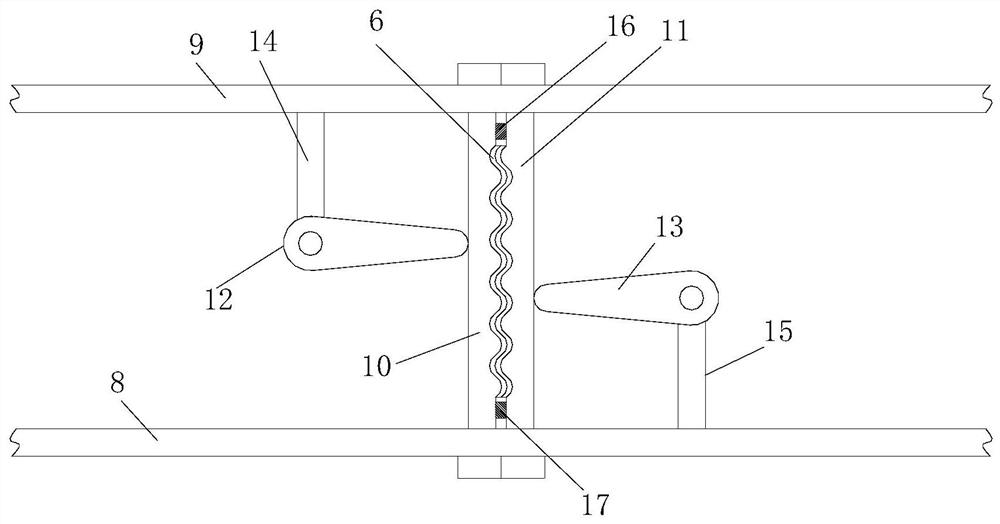

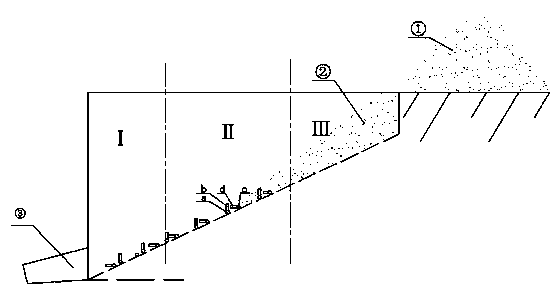

The invention discloses a mortar making system and process suitable for a large horizontal sand silo of a mine filling station. The system comprises a mortar supply and transport system, a high-pressure gas supply pipe (9), a high-pressure water supply pipe (8), a horizontal sand silo (7), an output pipeline of the horizontal sand silo, a cement silo (15), an output system of the cement silo, a stirring device (14) and a filling pipeline, wherein the outlet of the mortar supply and transport system is arranged above the horizontal sand silo (7); the output pipeline of the horizontal sand silo(7), the output system of the cement silo (15) and the stirring device (14) converge; the filling pipeline is connected with a goaf (18); the horizontal sand silo (7) begins from a sand discharge opening; a mortar making area, a transport area and a sand storage area are divided along the trend of the horizontal sand silo (7); annular high-pressure water supply branch pipes and high-pressure gas supply branch pipes are paved in the mortar making area; high-pressure water supply branch pipes and high-pressure gas supply branch pipes are paved in the transport area in parallel; the high-pressure gas supply pipe (9) is connected with the high-pressure gas supply branch pipes in the horizontal sand silo (7); and the high-pressure water supply pipe (8) is connected with the annular high-pressure water supply branch pipes and the high-pressure water supply branch pipes in the horizontal sand silo (7). The system and the process have the following effects: the horizontal sand silo achieves high-capacity continuous filling; the filler quality is ensured; the unsupported roof time of the goaf is reduced; the filling station construction investment is reduced; mining and filling of the mineare balanced; and the system and the process are favorable for the mine to achieve safety production and environmental protection.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

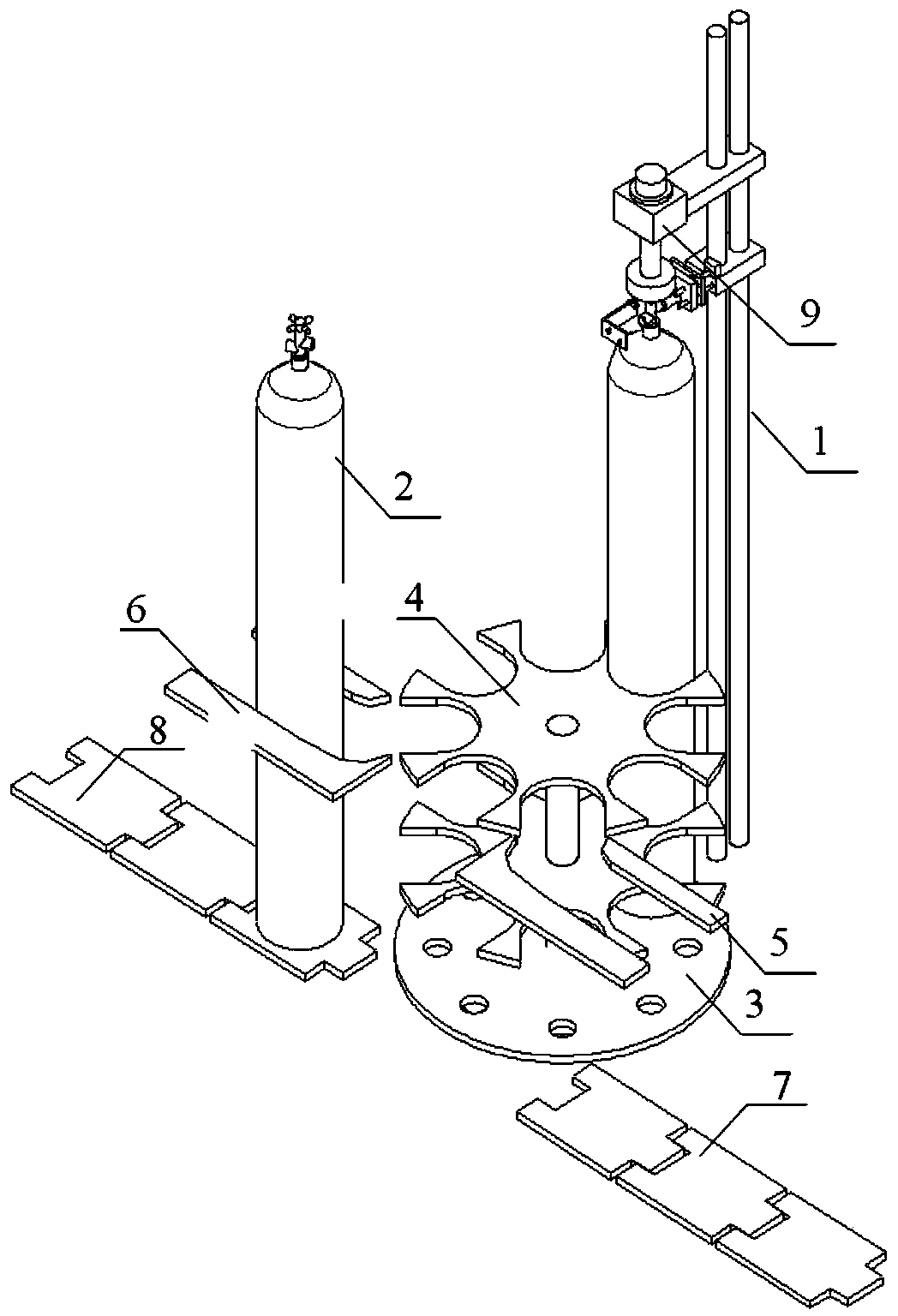

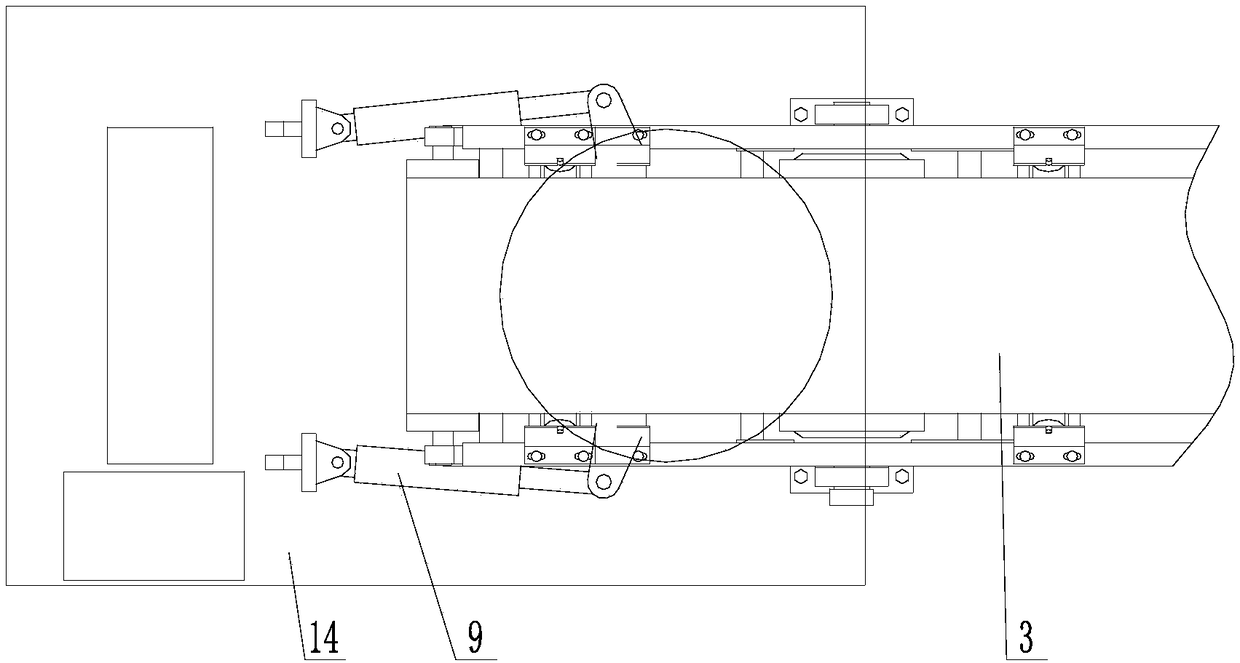

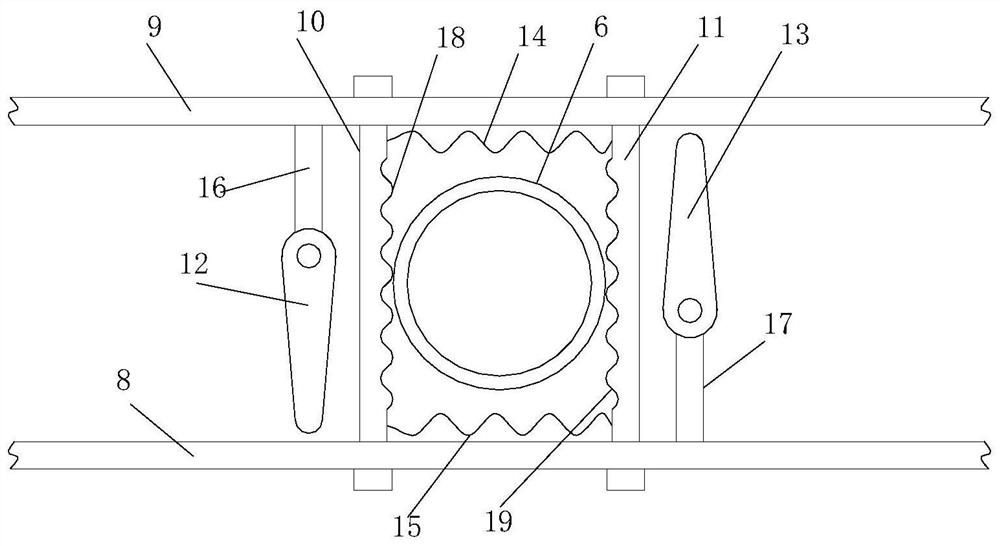

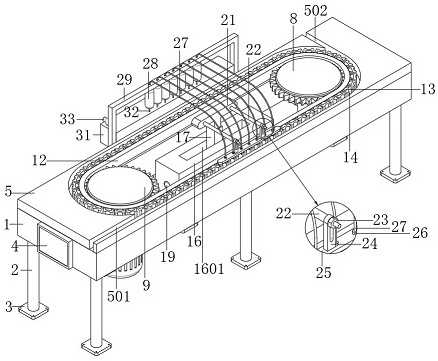

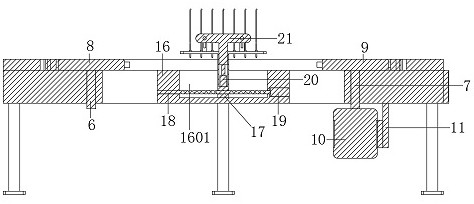

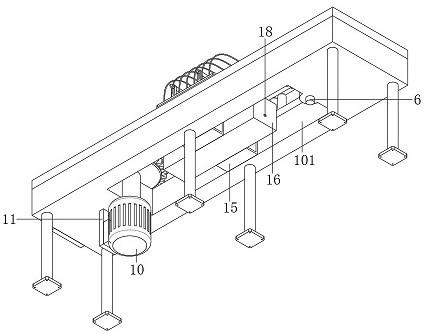

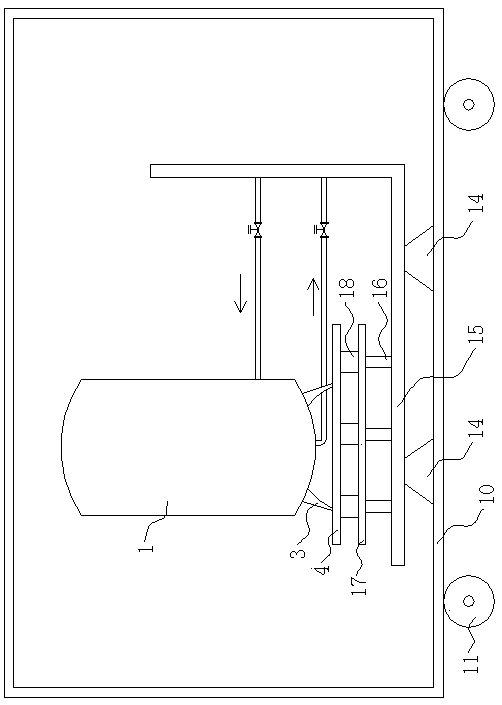

Gas filling system and method of high-pressure gas cylinder

InactiveCN103867886ARealize continuous fillingSimple structureContainer discharging methodsContainer filling under pressureGas cylinderProduct gas

The invention relates to a gas filling system of a high-pressure gas cylinder. The gas filling system comprises a conveying device, a filling turning plate and a gas filling device, wherein the conveying device comprises a gas cylinder input belt for transferring gas cylinders, a gas cylinder output belt for transferring gas cylinders, an output belt side plate, a cylinder feeding guide plate and a cylinder outlet guide plate; the filling turning plate sequentially comprises a steel cylinder tray, a lower indexing star wheel and an upper indexing star wheel, which are coaxially arranged from bottom to top; the gas filling device is arranged on a stand column, the stand column is positioned at one side of the filling turning plate and corresponds to the center of a groove of the indexing star wheel. The gas filling system has a simple structure, can realize continuous filling of the gas cylinders automatically, improves the filling efficiency and saves the labor cost.

Owner:北京正拓气体科技有限公司

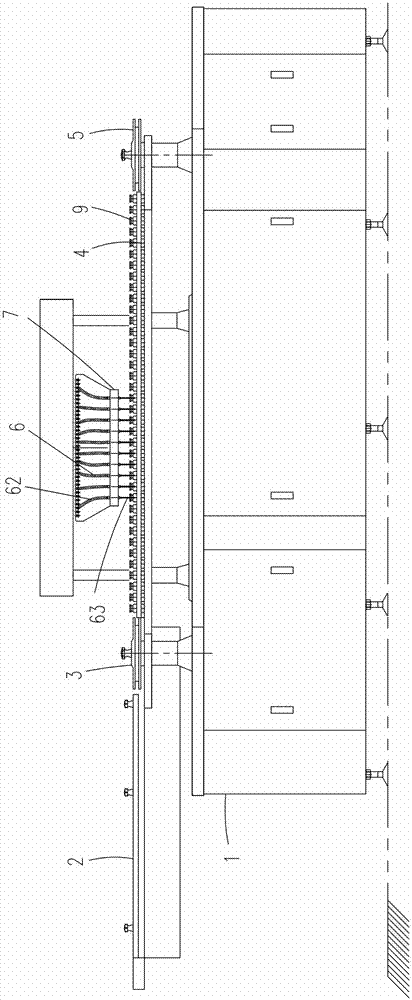

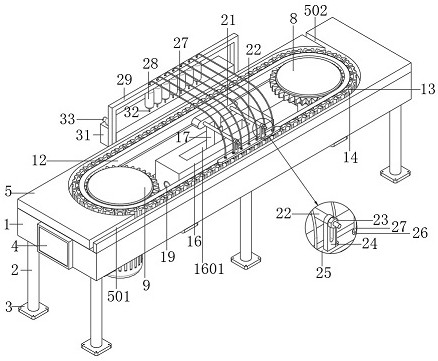

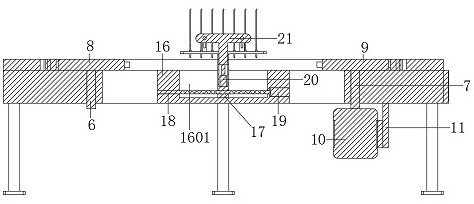

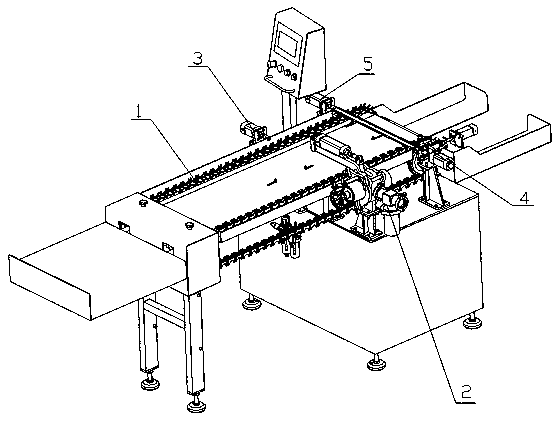

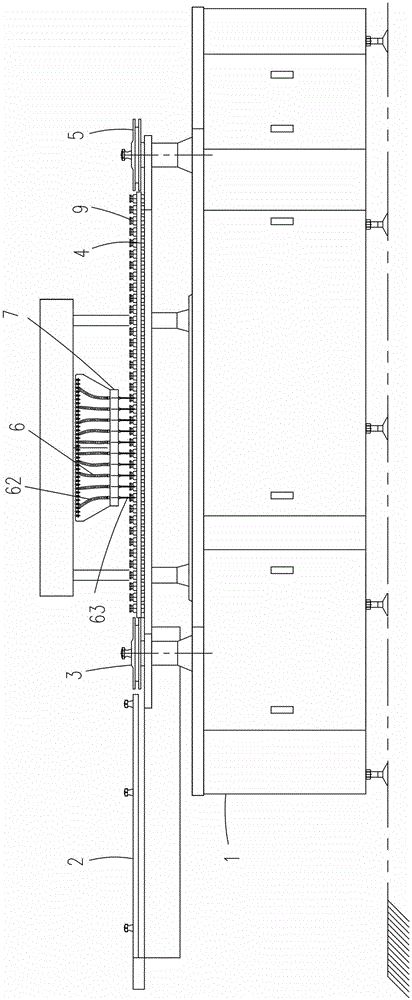

Filling machine

InactiveCN102862691AThere will be no phenomenon of empty bottle outputRealize continuous fillingPackaging automatic controlLiquid materialEngineeringBottle

The invention discloses a filling machine which comprises a filling mechanism, a control mechanism, a bottle inlet dial wheel mechanism and a bottle delivery mechanism. Bottle accommodating portions which are used for being matched with tooth grooves of the bottle inlet dial wheel mechanism to receive bottles are arranged on the bottle delivery mechanism, the filling mechanism comprises a plurality of filling parts which are used for filling bottle bodies in the bottle accommodating portions which are arranged continuously on the bottle delivery mechanism simultaneously, the bottle inlet dial wheel mechanism comprises a bottle inlet dial wheel and a bottle blocking part which is used to be mounted in tooth grooves in the bottle inlet dial wheel to prevent bottles from entering the tooth groove, and the number of the tooth grooves of the bottle inlet dial wheel is integral multiple of that of the filling parts. The filling machine has the advantages of being simple in structure, low in cost, convenient to operate, safe and reliable, high in filling yield and the like.

Owner:TRUKING TECH LTD

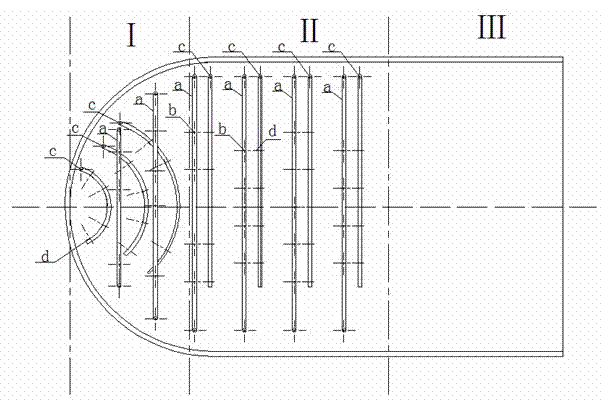

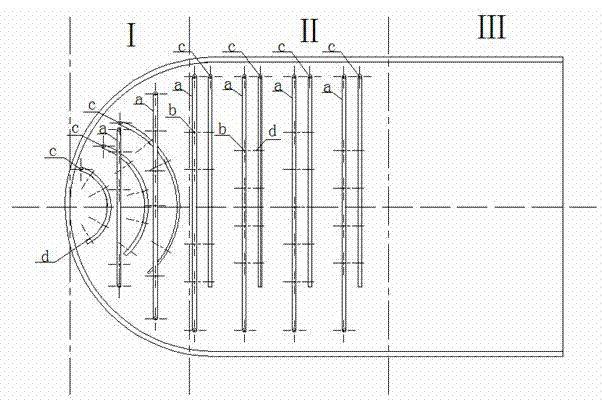

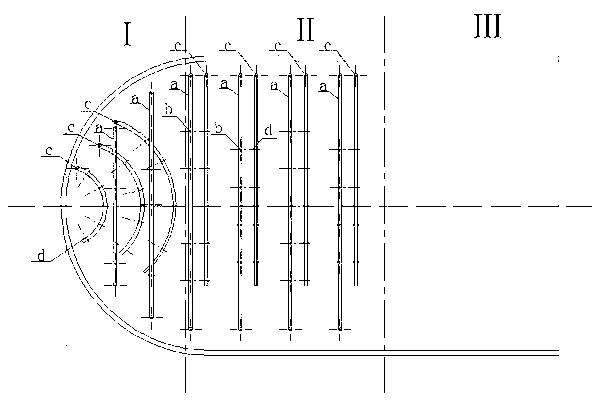

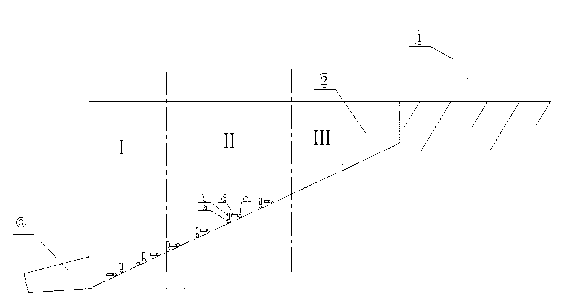

Large horizontal sand silo suitable for combined filling of mortar in dressing plants and dry tailings in tailings ponds

ActiveCN102505961ASolve the shortcomingsAchieve mutual integrationMaterial fill-upSpray nozzleHigh pressure water

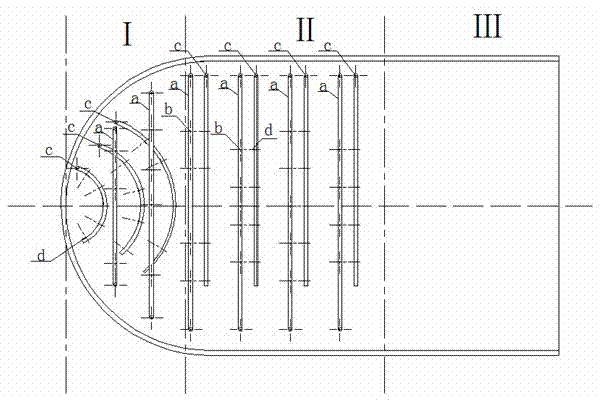

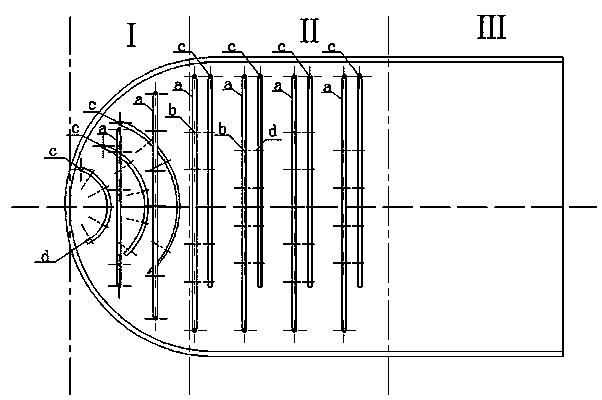

The invention discloses a large horizontal sand silo suitable for combined filling of mortar in dressing plants and dry tailings in tailings ponds. The sand silo is characterized by being divided into a mortar making region (I), a transport region (II) and a tailings storage region (III), wherein ring-shaped high-pressure water supply branch pipes (c) and high-pressure gas supply branch pipes (a) are laid in the mortar making region (I); high-pressure water spray nozzles (d) are horizontally installed on the ring-shaped high-pressure water supply branch pipes (c); high-pressure gas spray nozzles (b) are vertically installed on the high-pressure gas supply branch pipes (a); high-pressure water supply branch pipes (c) and high-pressure gas supply branch pipes (a) are laid in the transport region (II) in parallel; high-pressure water spray nozzles (d) are horizontally installed on the high-pressure water supply branch pipes (c); high-pressure gas spray nozzles (b) are vertically installed on the high-pressure gas supply branch pipes (a); the dip angle of the bottom plate of the horizontal sand silo is 23-26 degrees; the length of the mortar making region (I) along the trend of the sand silo is 3-5 meters; the length of the transport region (II) along the trend of the sand silo is 5-8 meters; and the length of the tailings storage region (III) along the trend of the sand silo is 4-7 meters. The large horizontal sand silo is applied to mortar making, can be used for realizing high-capacity continuous filling, ensuring the quality of the fillers, shortening the unsupported roof time in the goafs, reducing the construction investment of the filling stations and ensuring mine mining and filling to achieve balance and is beneficial to realization of safety production and environmental friendliness of the mines.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Filling machine

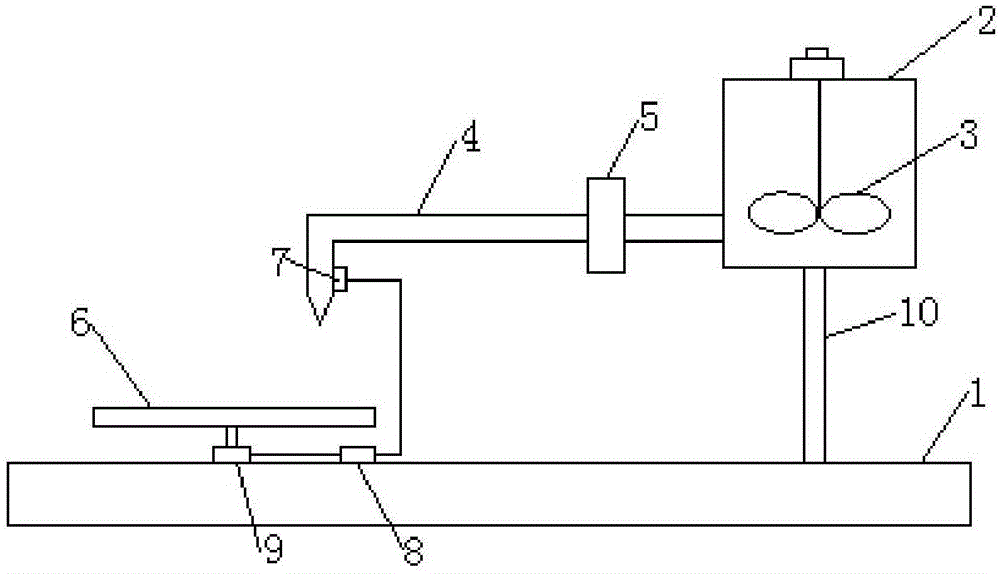

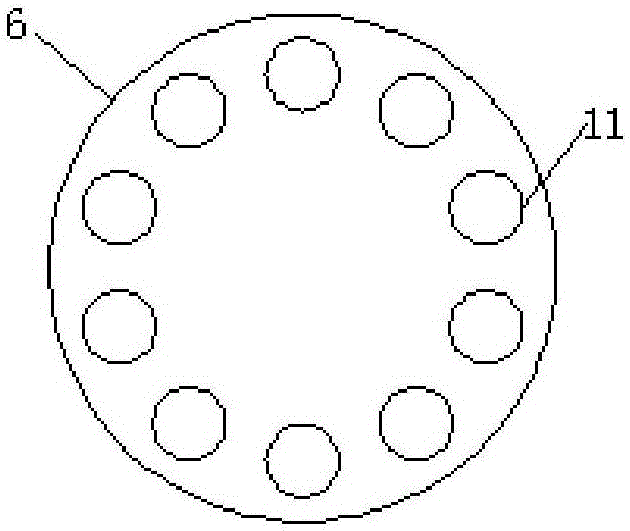

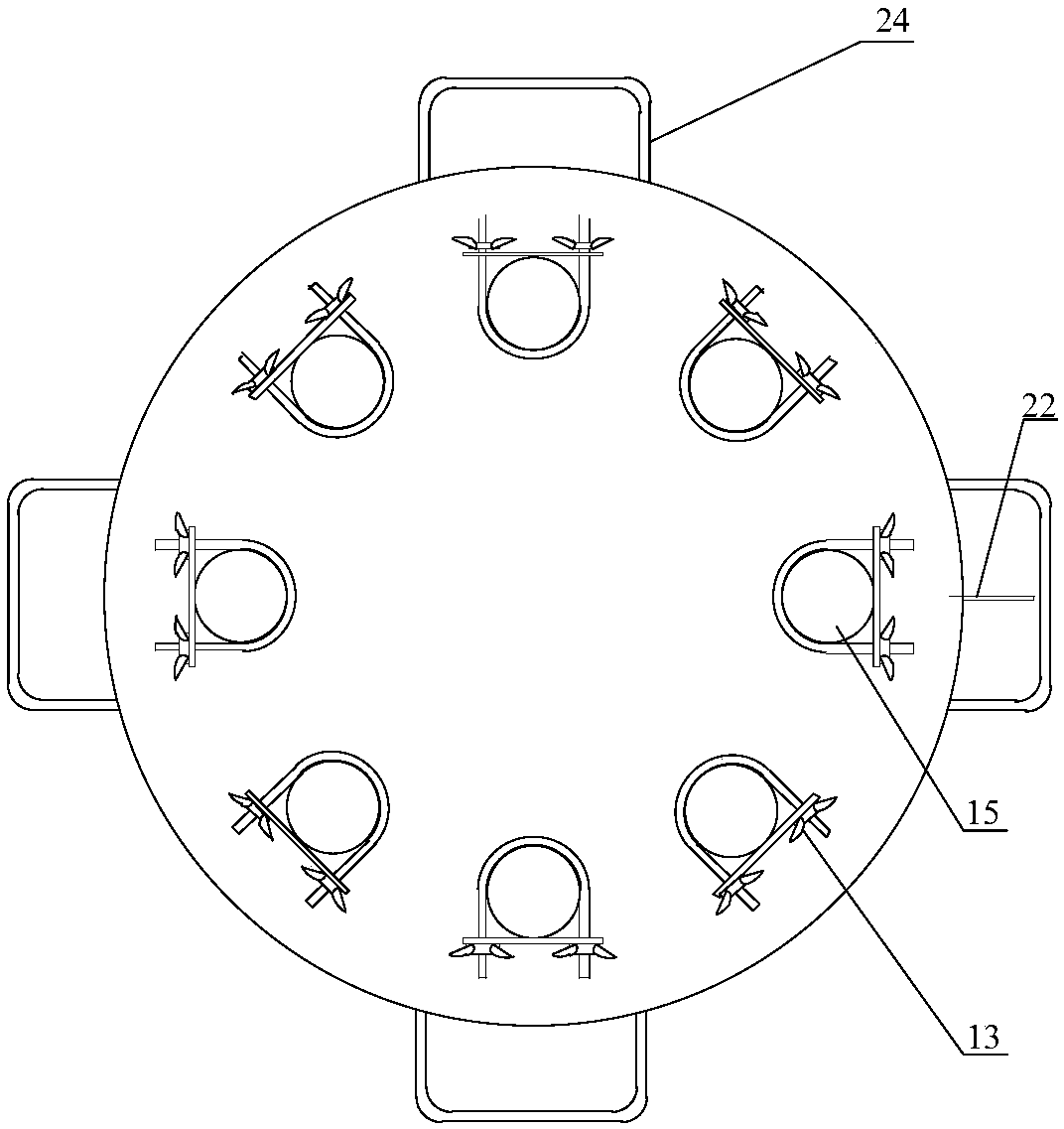

InactiveCN105152113ASimple structureHigh degree of automationLiquid bottlingLiquid storage tankEngineering

The invention provides a filling machine and belongs to the technical field of filling machinery equipment. The filling machine comprises a liquid storage tank and a stirrer, wherein the stirrer is fixed inside the liquid storage tank, the left lower side of the liquid storage tank is connected with a drainpipe, a liquid level sensor is fixed at one end, far away from the liquid storage tank, of the drainpipe, the liquid level sensor is connected with a driving device through a control module, a rotary table is mounted at the upper part of the driving device, and the rotary table rotates for 36 degrees at certain time intervals. 10 sunk circular cup grooves are evenly formed in the rotary table, and the circular cup grooves are arrayed annularly. The filling machine provided by the invention has a simple structure, is convenient to operate, is high in filling efficiency, can achieve continuous filling without need of a great deal of manpower resource, is accurate in filing quantity, and can be in large scale population and application.

Owner:JINYAN TIANJIN BIOTECH CO LTD

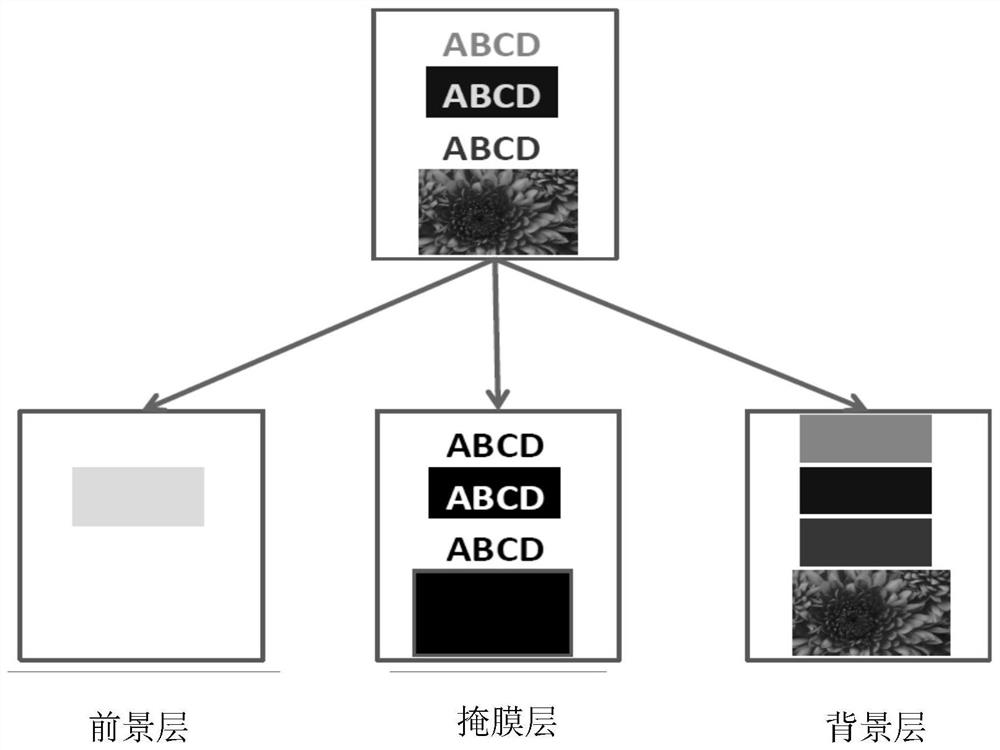

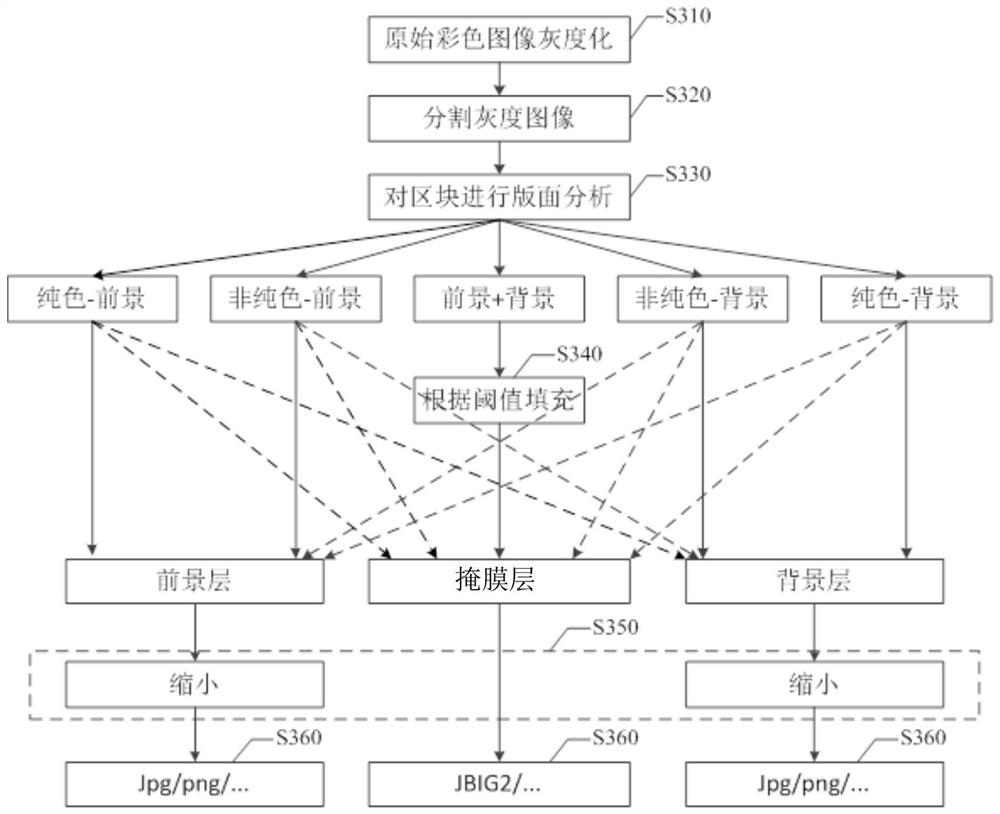

Image processing method and device, electronic equipment and memory medium

ActiveCN108924557AIncrease the compression ratioImprove transmission efficiencyDigital video signal modificationImaging processingImage compression

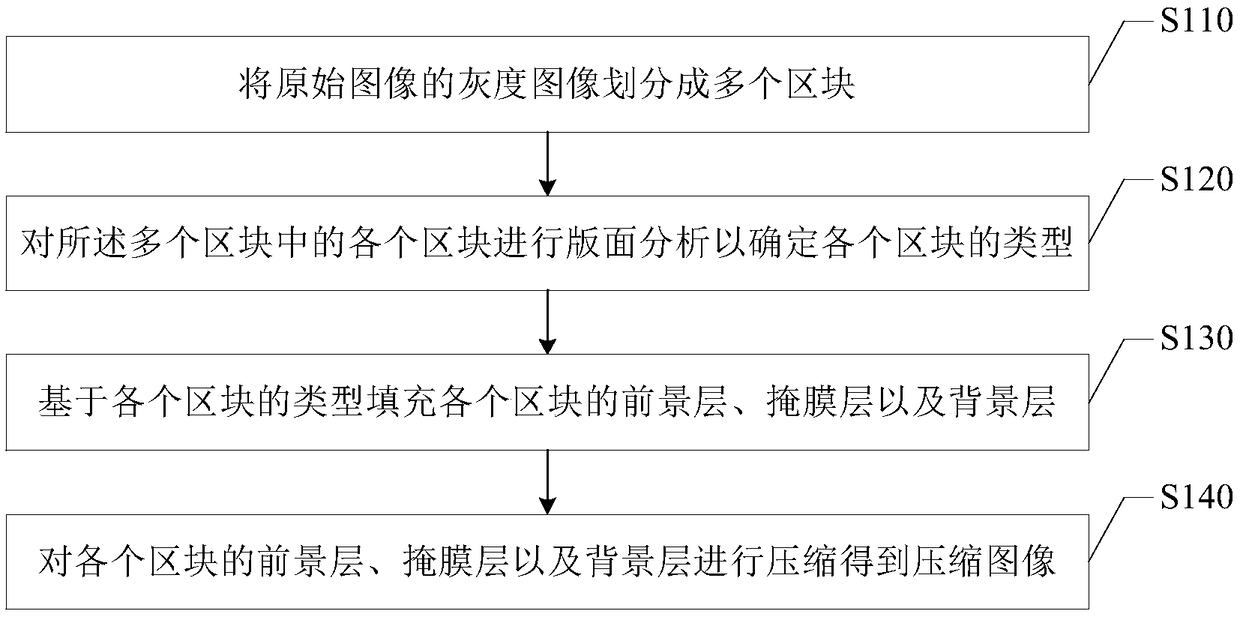

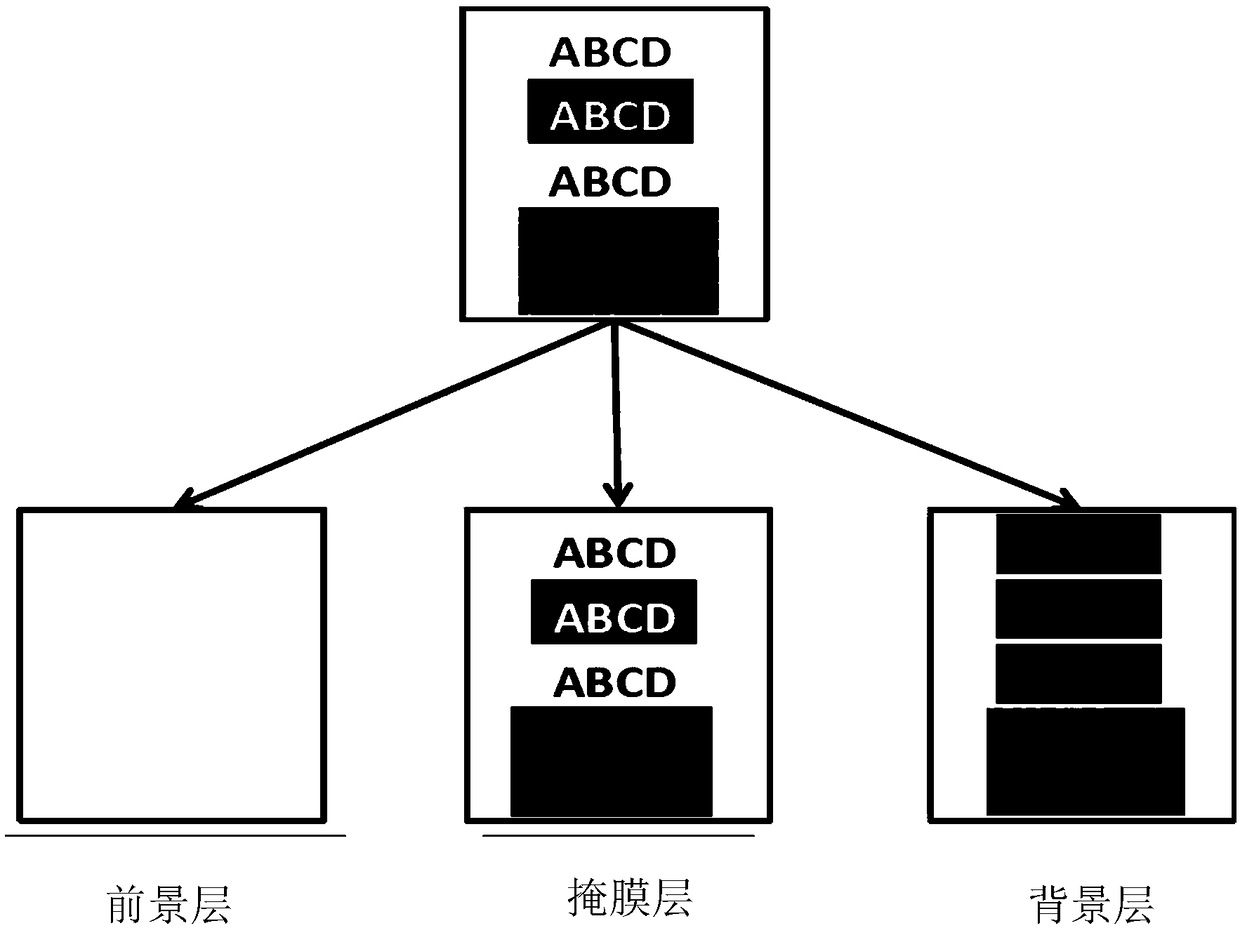

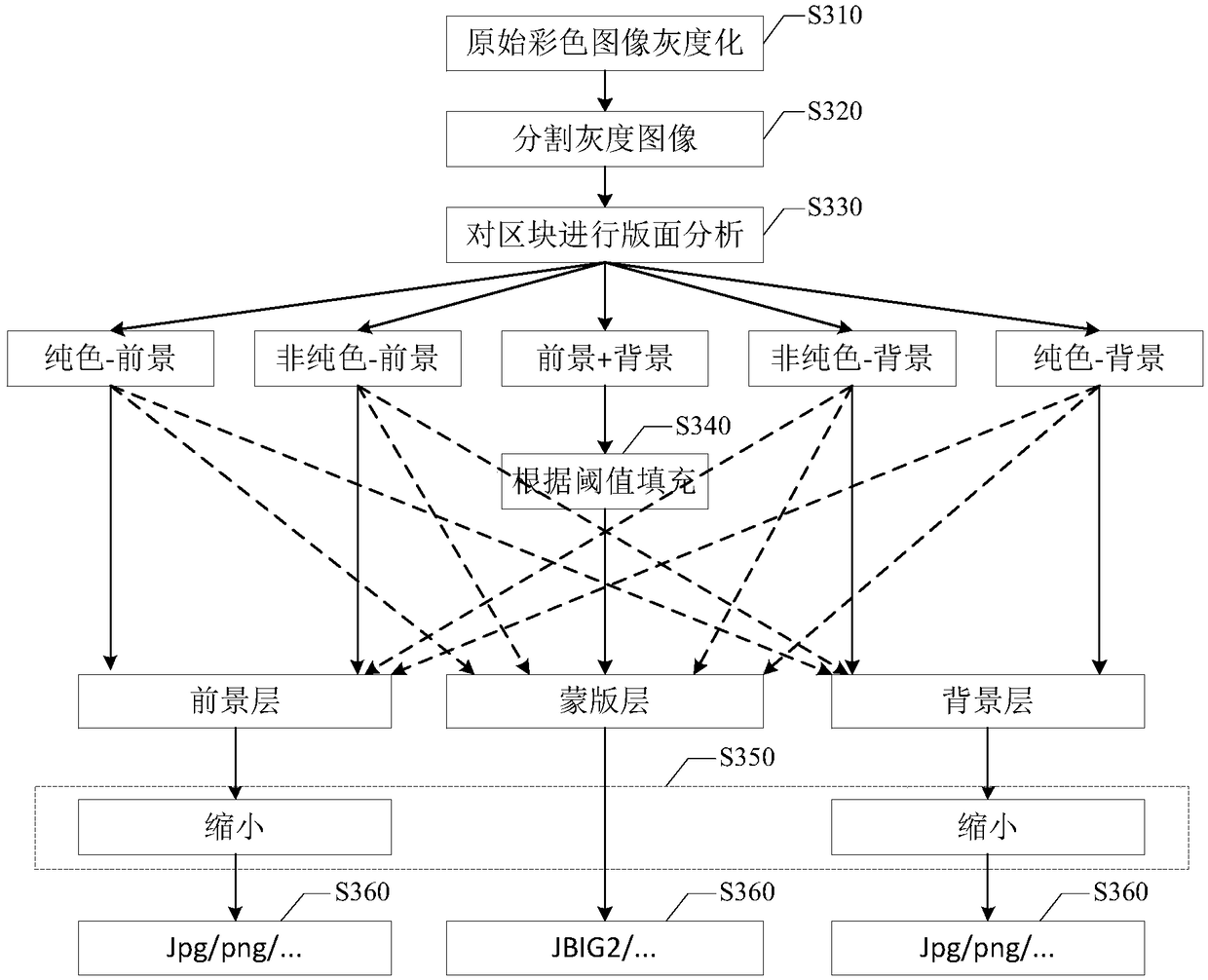

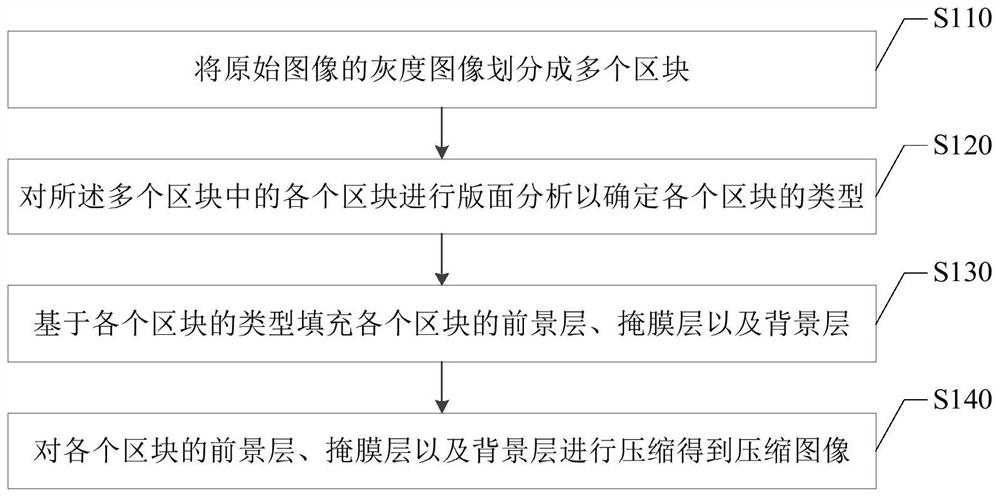

The embodiment of the invention provides an image processing method and device, electronic equipment and a memory medium and relates to the technical field of image processing. The method comprises the steps of dividing a gray image of an original image into a plurality of blocks; carrying out layout analysis on each block in the plurality of blocks, thereby determining a type of each block; filling in a foreground layer, a mask layer and a background layer of each block according to the type of each block; and compressing the foreground layer, the mask layer and the background layer of each block, thereby obtaining a compressed image. According to the technical scheme provided by the embodiment of the invention, image pixel values can be filled in contiguously, fidelity is realized, and an image compression ratio is further improved.

Owner:VIDAA(荷兰)国际控股有限公司

Lunar soil concrete and preparation method thereof

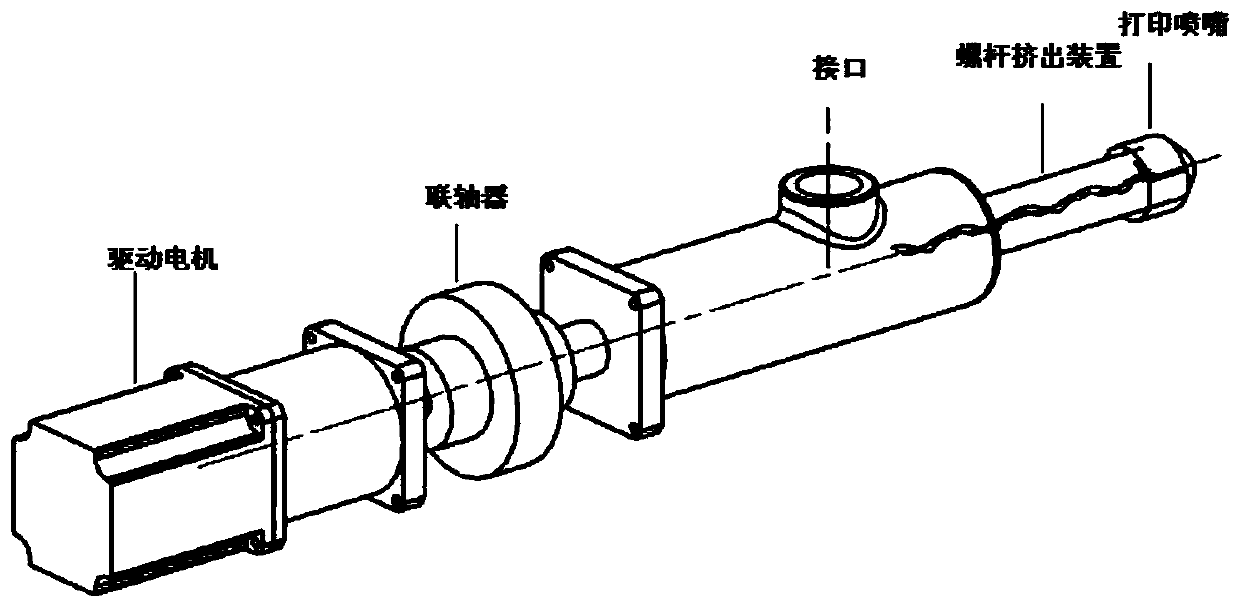

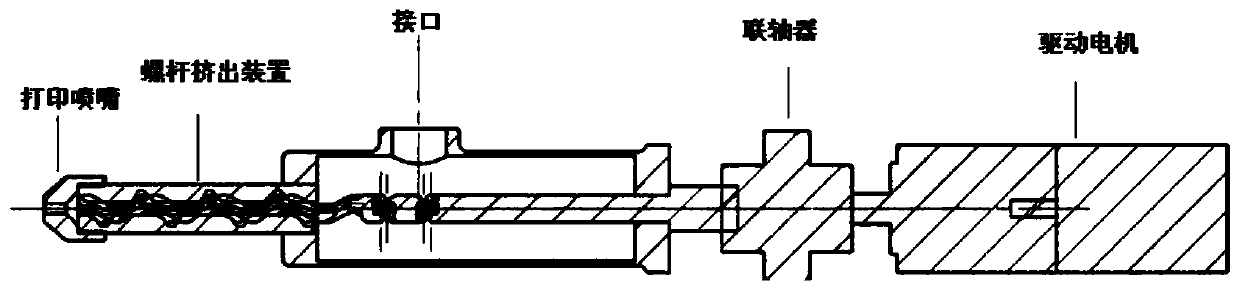

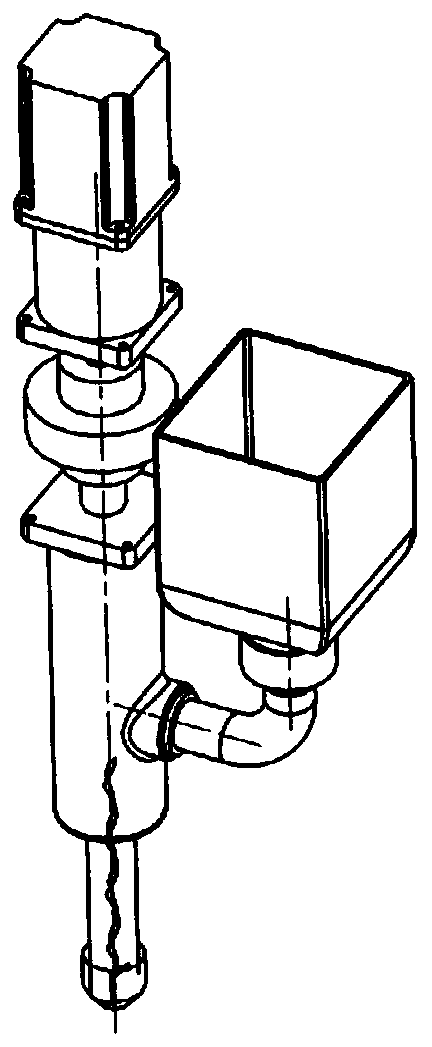

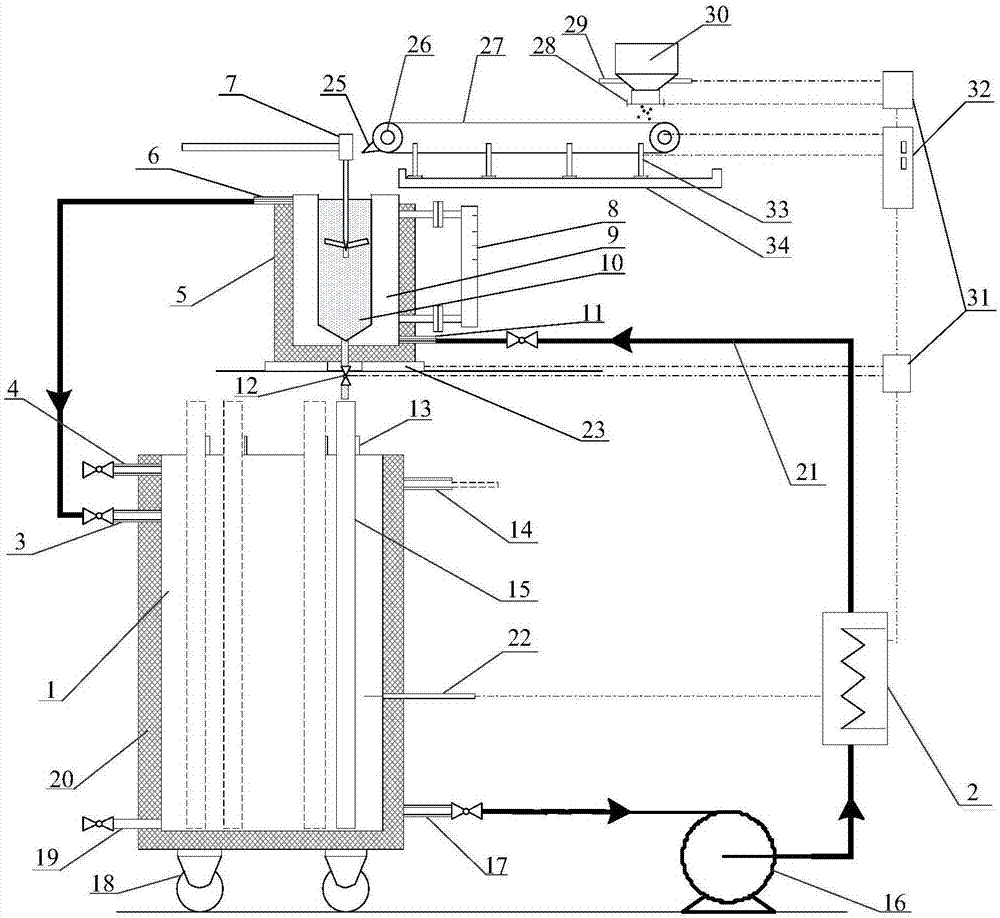

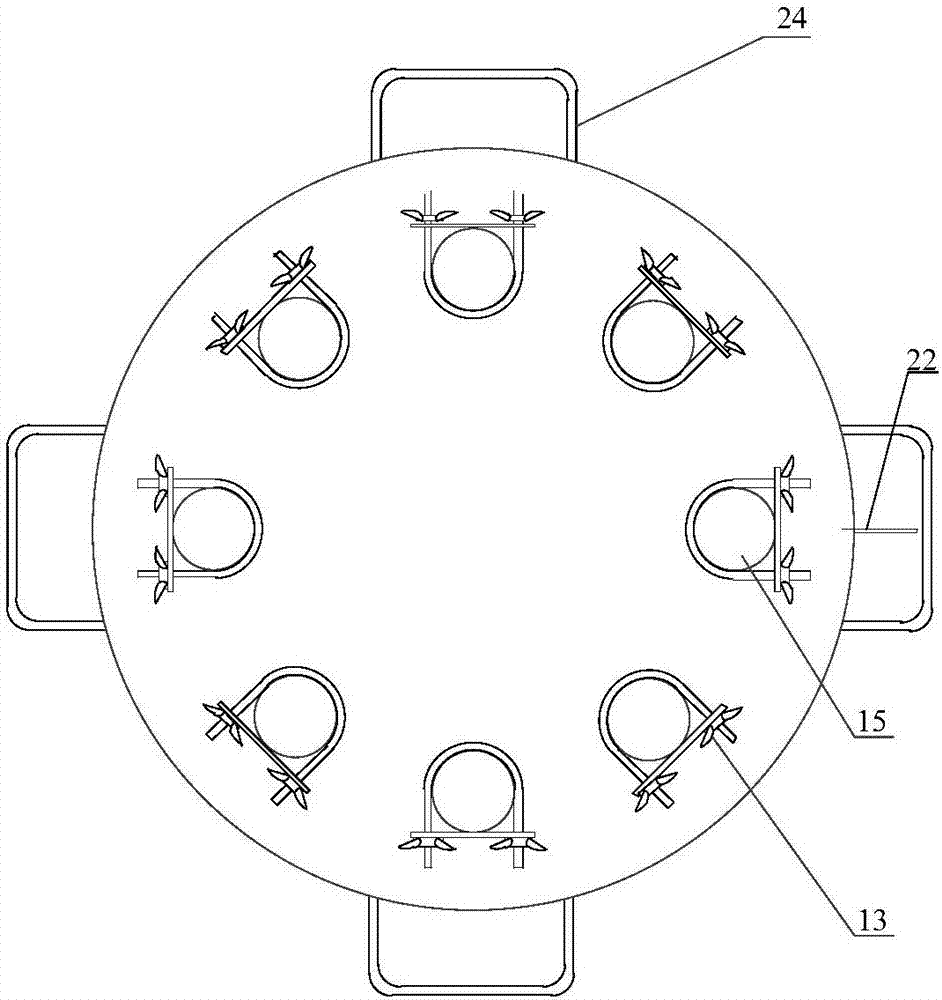

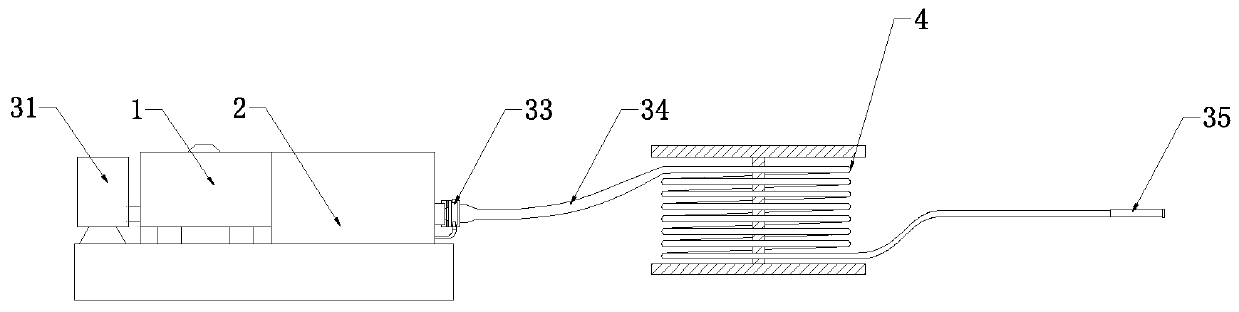

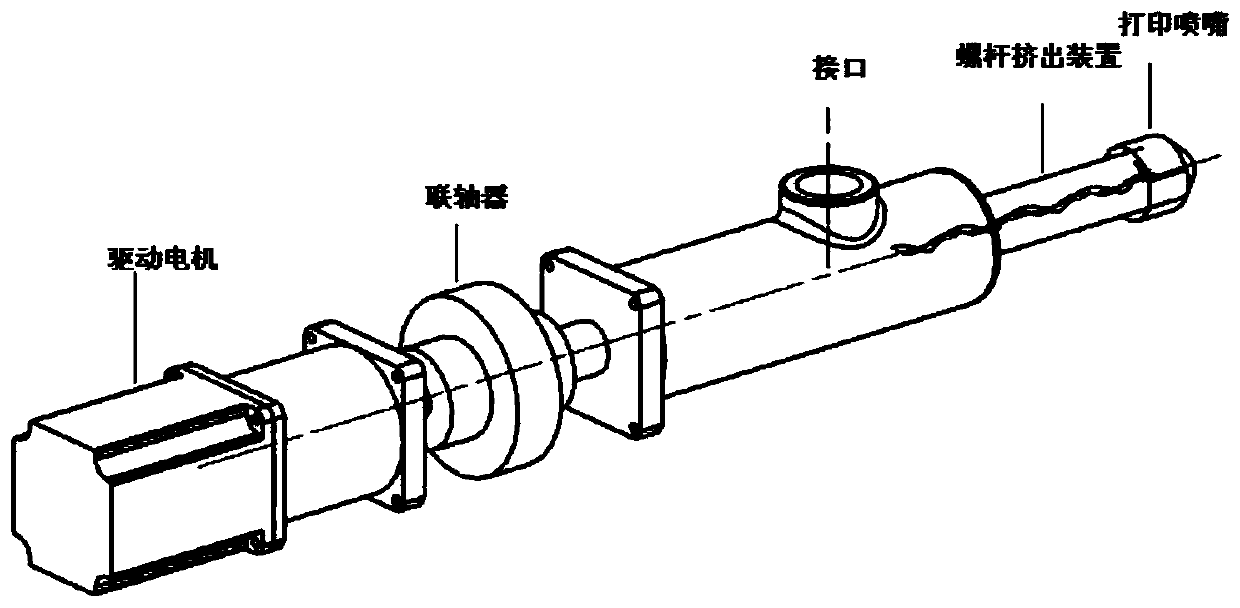

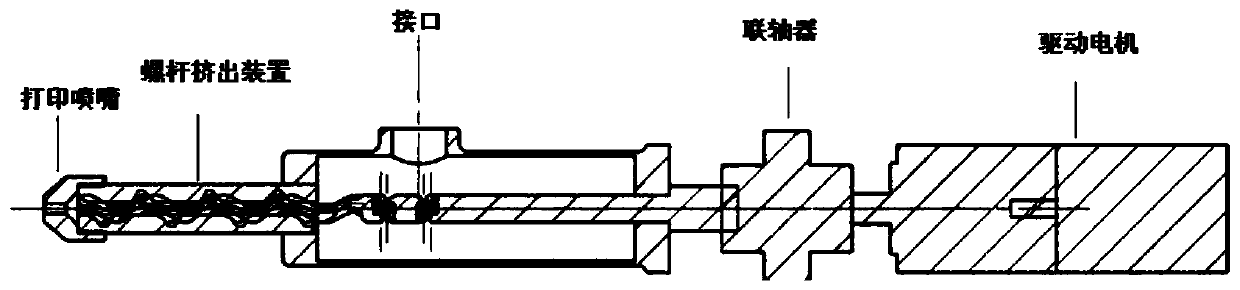

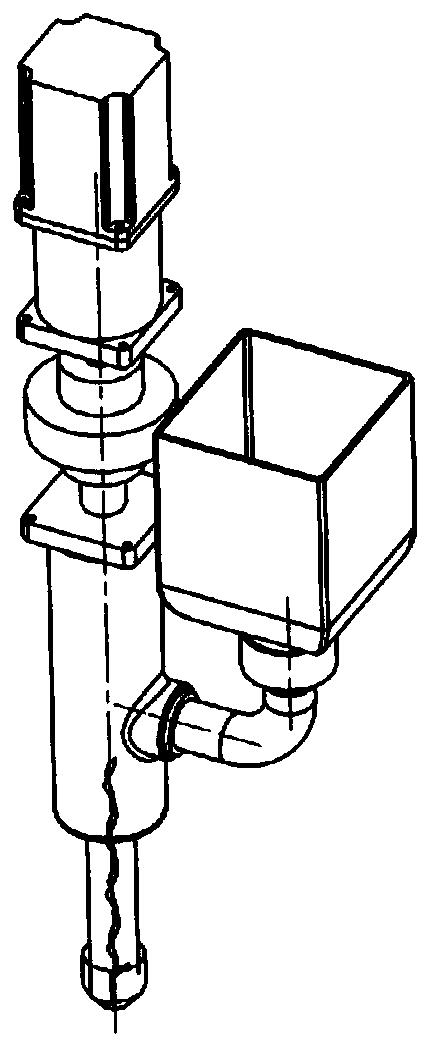

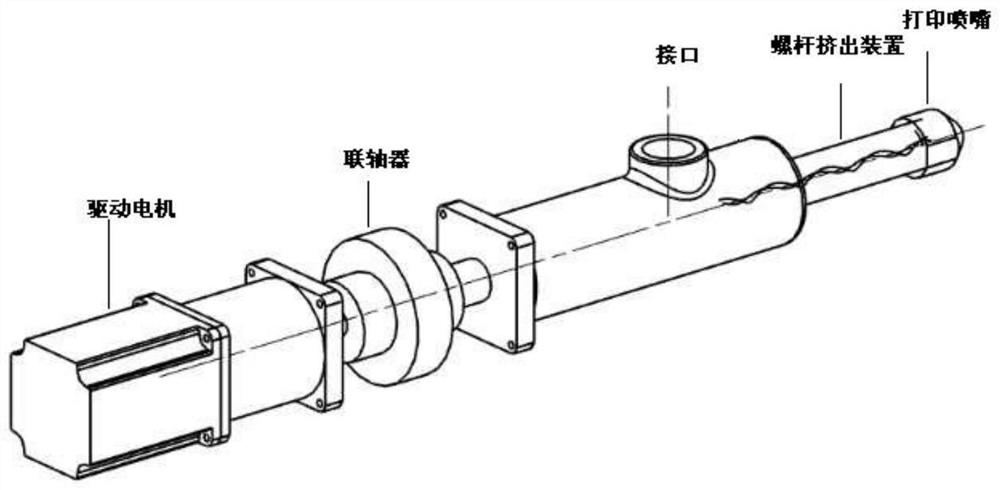

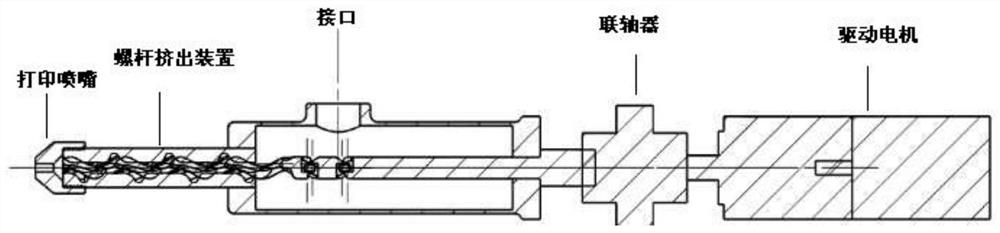

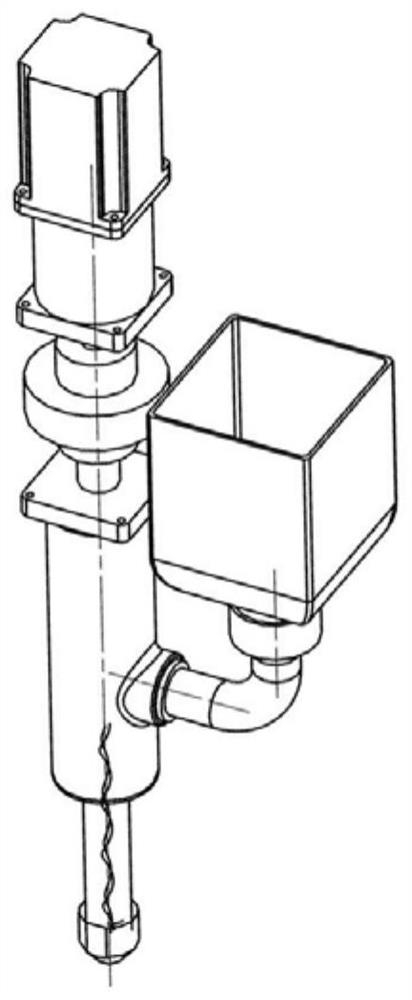

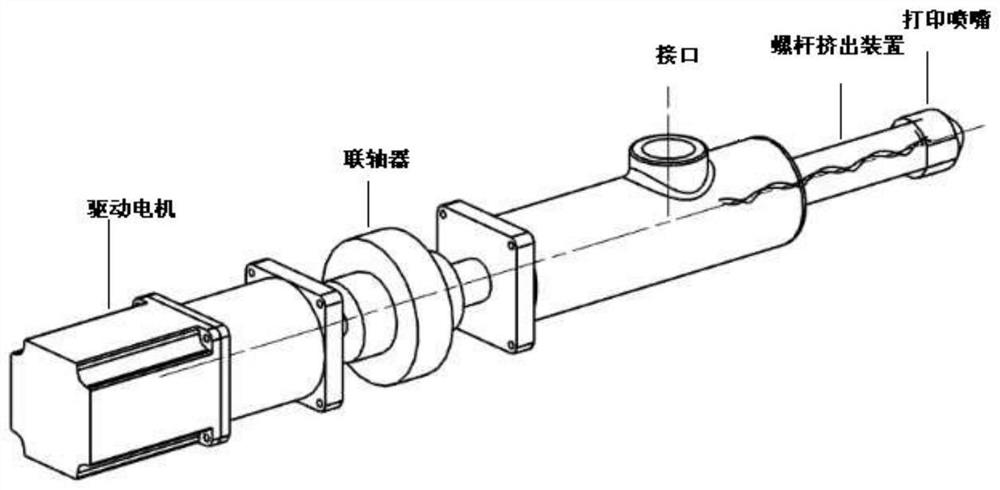

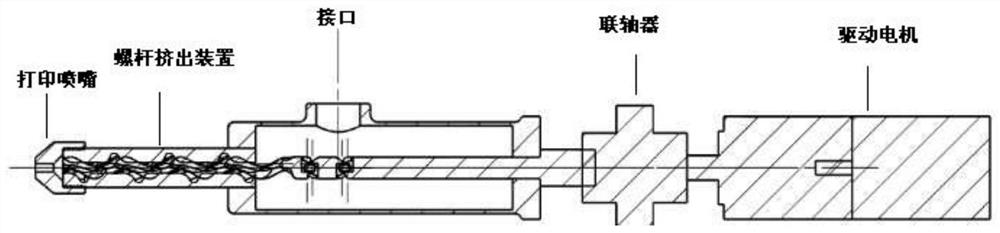

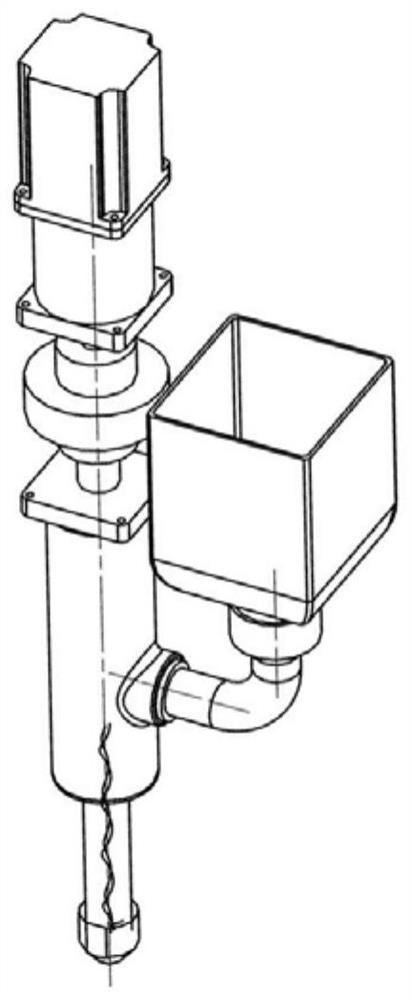

ActiveCN110256039ARealize instant refillAvoid cloggingAdditive manufacturing apparatusAviationCoupling

The invention relates to a lunar soil "concrete" and a preparation method thereof, and the lunar soil "concrete" is mainly used for aerospace, aviation, architectural paint and other technical fields. Lunar soil "concrete" hybrid 3D printing technology is an important key technology for follow-up lunar surface base construction of the moon in the future. A lunar soil simulant hybrid 3D printing device can realize continuous and controllable extrusion molding of lunar soil "concrete" by designing a lunar soil simulant hybrid 3D printing head. The hybrid 3D printing head is a key component of the lunar soil hybrid printing device, and can be employed to realize the continuous and controllable extrusion of lunar soil "concrete". The hybrid 3D printing head is a functional component integrating a drive motor, a coupling, a screw pump, an interface, a screw extrusion apparatus, a printing nozzle and other parts, and can realize the continuous and controllable extrusion molding of lunar soil "concrete" material.

Owner:BEIJING SATELLITE MFG FACTORY

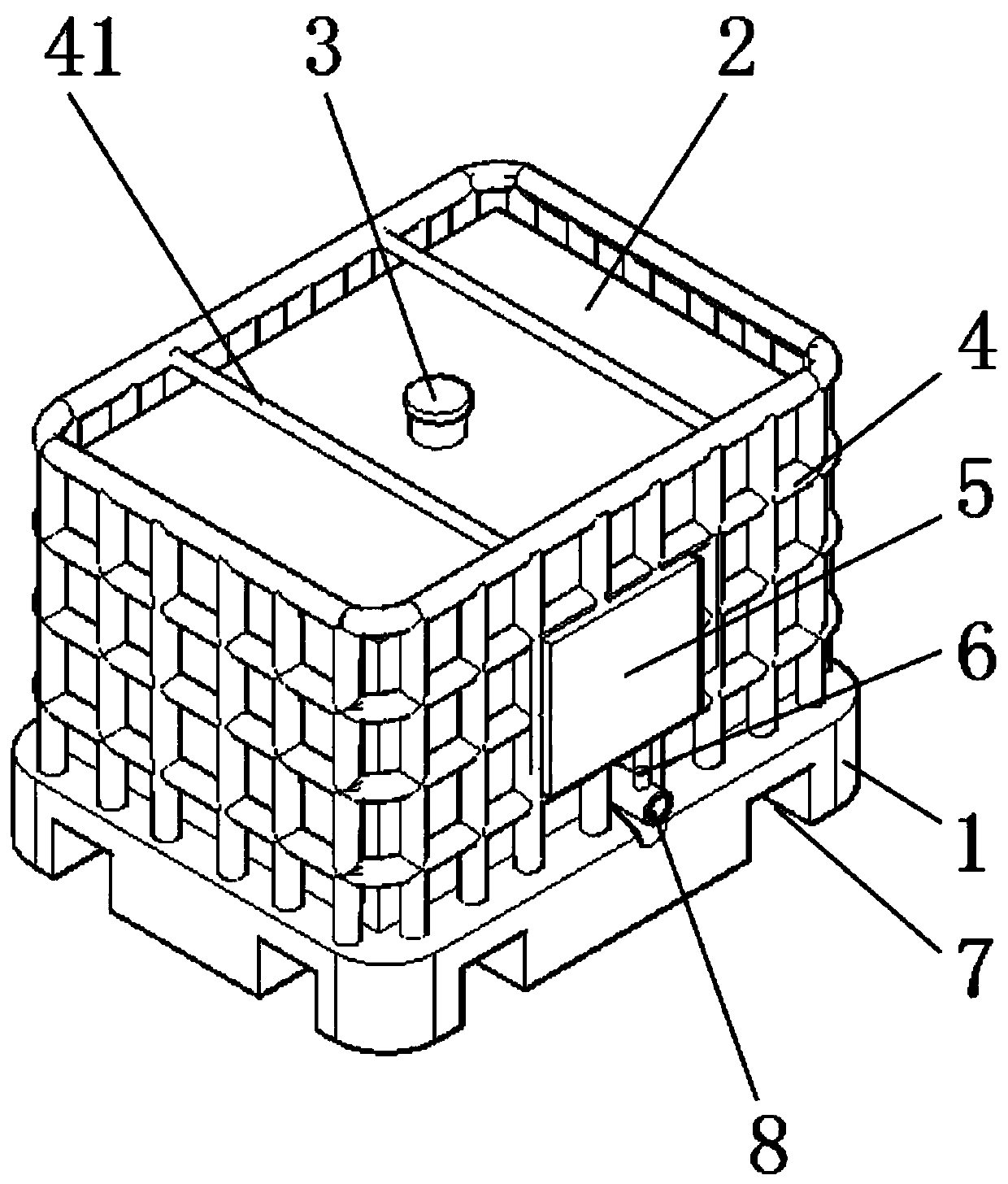

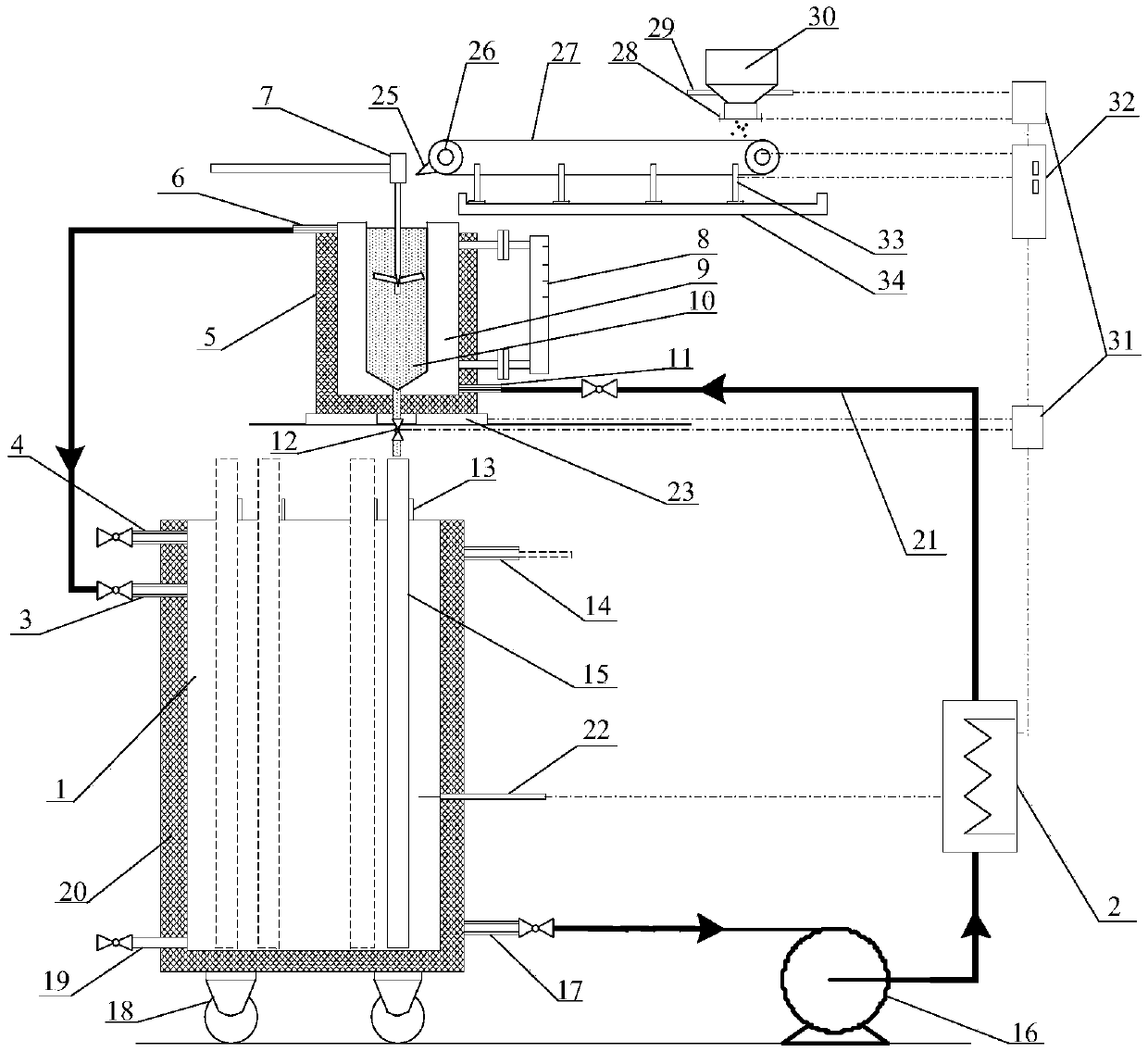

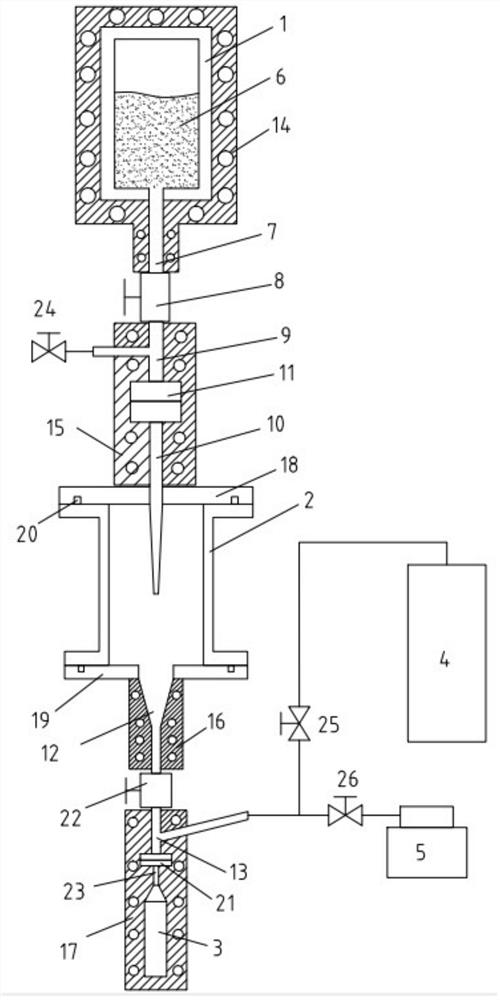

Automatically controlled hybrid phase change material melting and filling device

ActiveCN107042898AUniform endothermic meltingAvoid cloggingLiquid materialAutomatic controlHeating furnace

The invention discloses an automatically controlled hybrid phase change material melting and filling device which contains a temperature controllable heating constant-temperature cycle working medium case and an automatic filling, immersion and heating furnace. The heating constant-temperature cycle working medium case is composed of an electric heater and a case body. The bottom of the heating constant-temperature cycle working medium case is provided with two pairs of universal wheels, a heating working medium compensation port, an overflow port and a dirt discharge port. A heating working medium outlet and a heating working medium inlet are formed in the side face of the case body. A plurality of holes are dispersed in a cover plate on the top of the case body, and unit tubes to be filled are inserted in the holes. The outer layer of the automatic filling, immersion and heating furnace is a heating cycle working medium channel which is provided with a heating working medium inlet, a heating working medium outlet and a liquid level meter. The inner layer of the automatic filling, immersion and heating furnace is filled with a phase change material to be molten. The bottom of the automatic filling, immersion and heating furnace is connected with an unloading pipe and an electric adjusting valve. A lifting stirrer is arranged in the hollow portion of the automatic filling, immersion and heating furnace. Since a loading device adopts a belt with the discharging amount controlled by weighing to conduct conveying, multi-batch quantitative automatic filling is achieved. The case body and an outer cavity of a melting furnace form a cycle heating working medium loop with the whole process being constant in temperature. The automatically controlled hybrid phase change material melting and filling device is reasonable in structure, reliable in performance, easy and convenient to operate and high in filling speed.

Owner:NANJING UNIV OF TECH

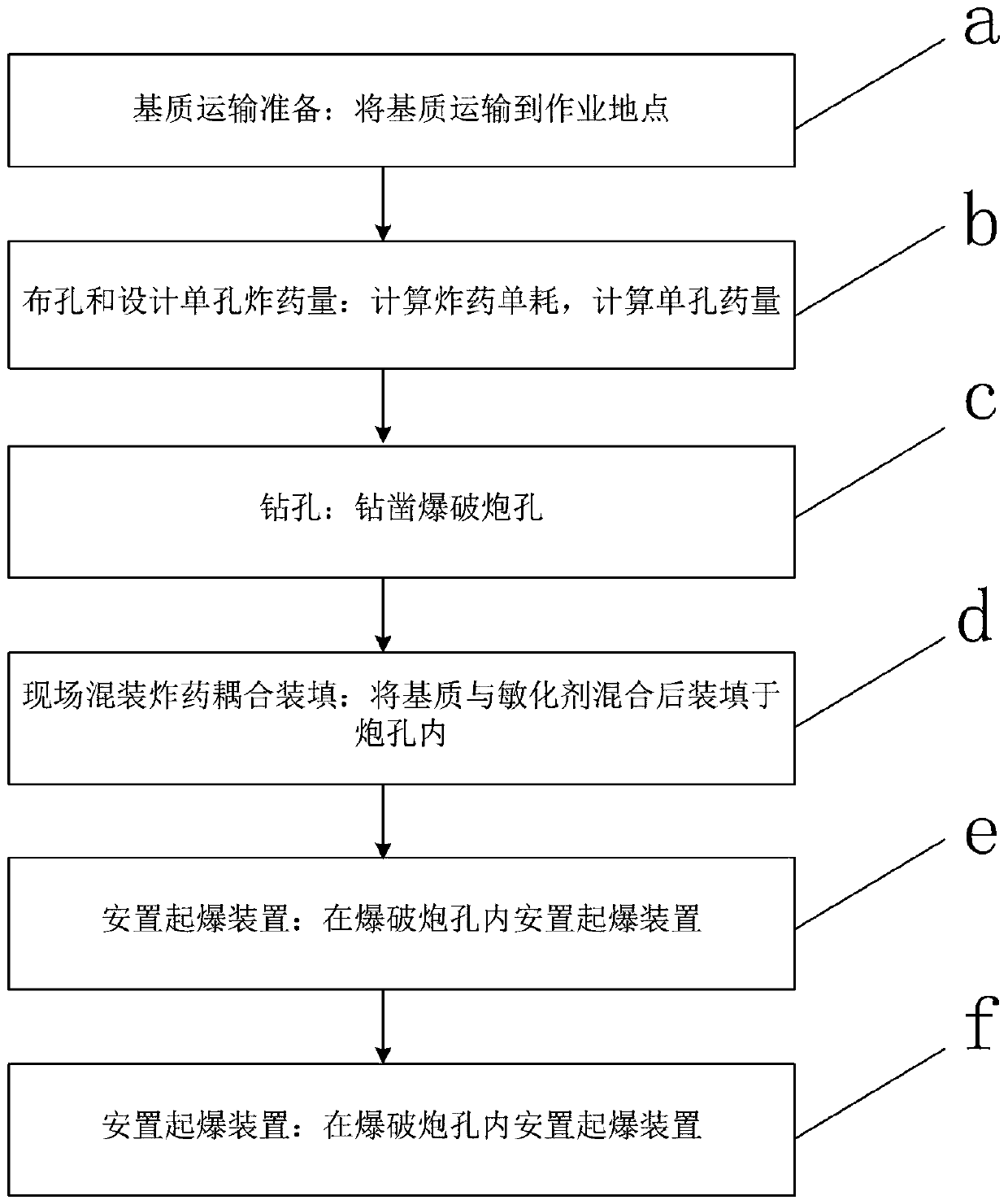

Underground explosive blasting construction method

The invention discloses an underground explosive blasting construction method. The underground explosive blasting construction method includes following steps: preparing matrix transportation: transporting a matrix to an operation site; arranging holes and designing explosive charge of each single hole; drilling the holes; completing coupling filling for mixed explosives on the operation site; placing an initiation device; and igniting the initiation device. The underground explosive blasting construction method can add the emulsion matrix which is mixed on an earth station into a site explosive loader, adds an sensitizing agent and performs explosive loading operation on the site, completely improves safety control level, adopts a novel explosive packing and transportation mode to achievecontinuity of mechanization operation, and thereby achieves continuous filling of a large quantity of the explosives, and achieves loading mechanization. Additionally, the interior of a whole transportation pipeline does not have concave-convex portions due to internal treatment performed on connection portions of the transportation pipeline, diameters of the transportation pipeline reach consistency, transportation resistance in the transportation pipeline is reduced, loading radius is greatly enlarged, and simultaneously the mixed explosive filling operation can be achieved for places wherevehicles cannot reach, the number of employees is reduced from a hundred or more in traditional work to ten or more, and essential safety is comprehensively improved.

Owner:四川省南部永生化工有限责任公司

Lunar regolith concrete suitable for being extruded and preparation method thereof

ActiveCN110405903ARealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationDrive motor

The invention relates to lunar regolith concrete suitable for being extruded and a preparation method thereof, and the lunar regolith concrete suitable for being extruded and the preparation method thereof are mainly used in the technical fields of aerospace, aviation, building coatings and the like. A lunar regolith 'concrete' hybrid 3D printing technology is an important key technology in the future lunar follow-up lunar surface base construction. A lunar regolith simulant hybrid 3D printing device can realize continuous and controllable lunar regolith 'concrete' extrusion molding by designing a lunar regolith simulant hybrid 3D printing head. The hybrid 3D printing head is the key component of the lunar regolith hybrid printing device and is used for realizing continuous and controllable extrusion of lunar regolith 'concrete'. The device is a functional assembly integrating parts such as a driving motor, a coupler, a screw pump, a connector, a screw extrusion device and a printing nozzle into a whole, so that the continuous and controllable extrusion molding of the lunar regolith 'concrete' material is realized.

Owner:BEIJING SATELLITE MFG FACTORY

One-way water inlet film ice bag capable of achieving continuous filling and filling equipment

PendingCN114852503AImprove filling efficiencyFast filling speedDomestic cooling apparatusLighting and heating apparatusThin membraneEngineering

Owner:东莞市薪源环保科技有限公司

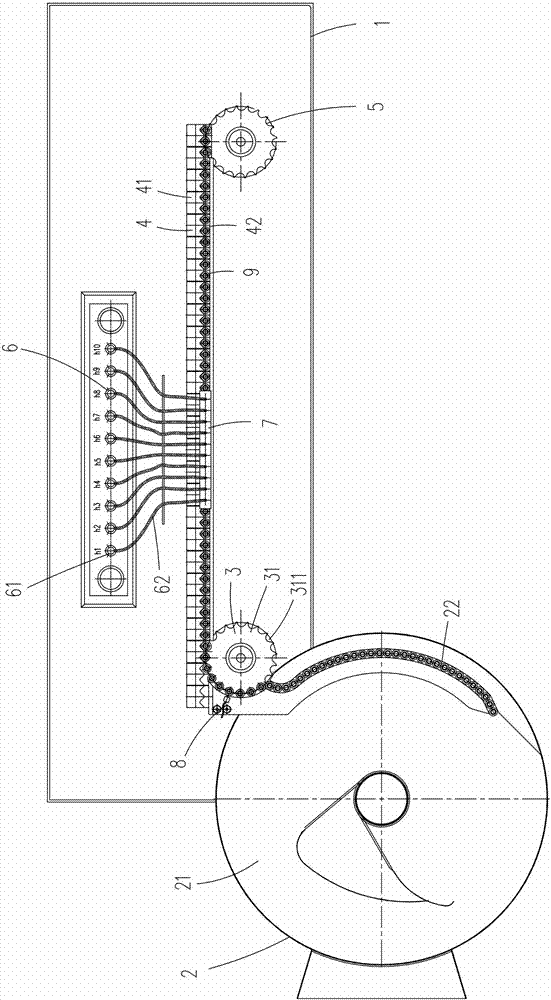

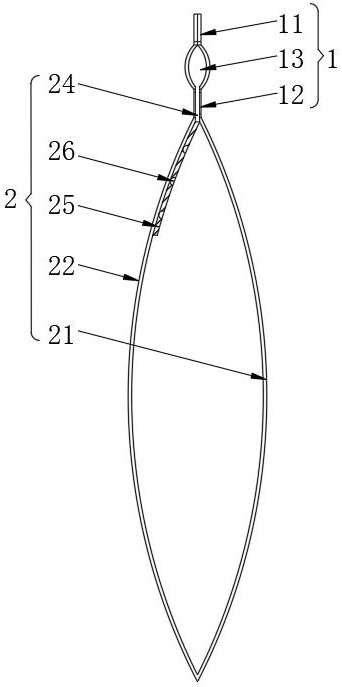

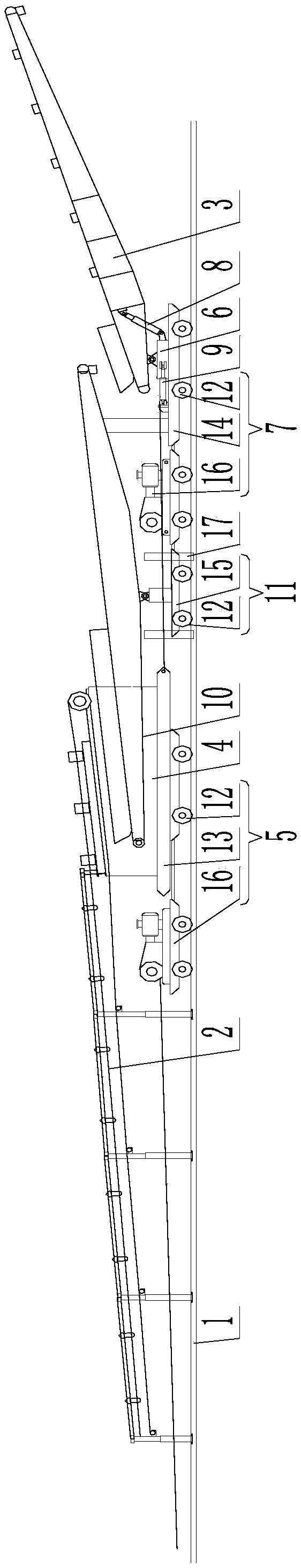

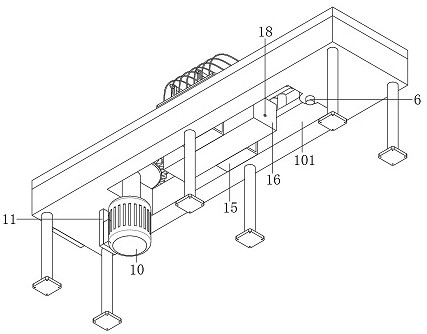

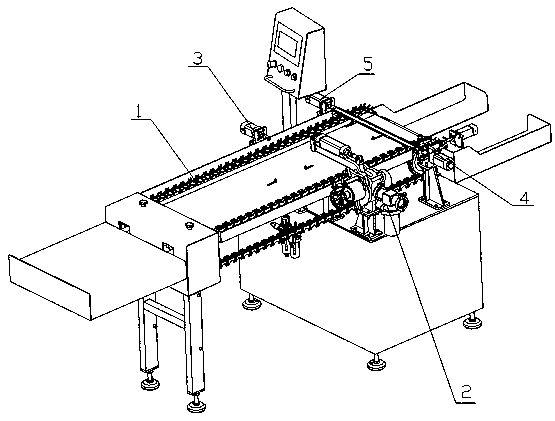

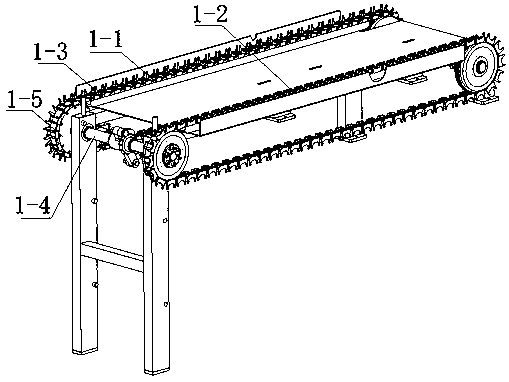

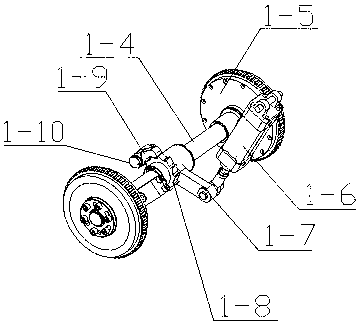

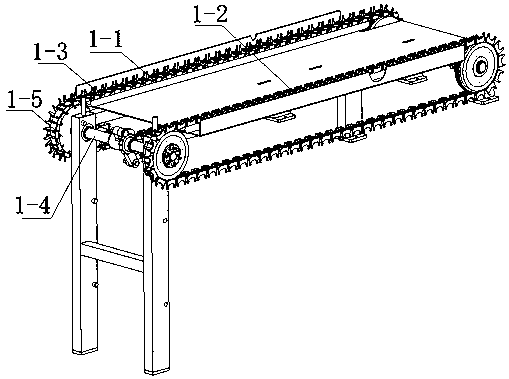

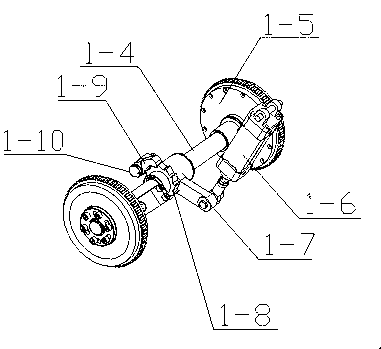

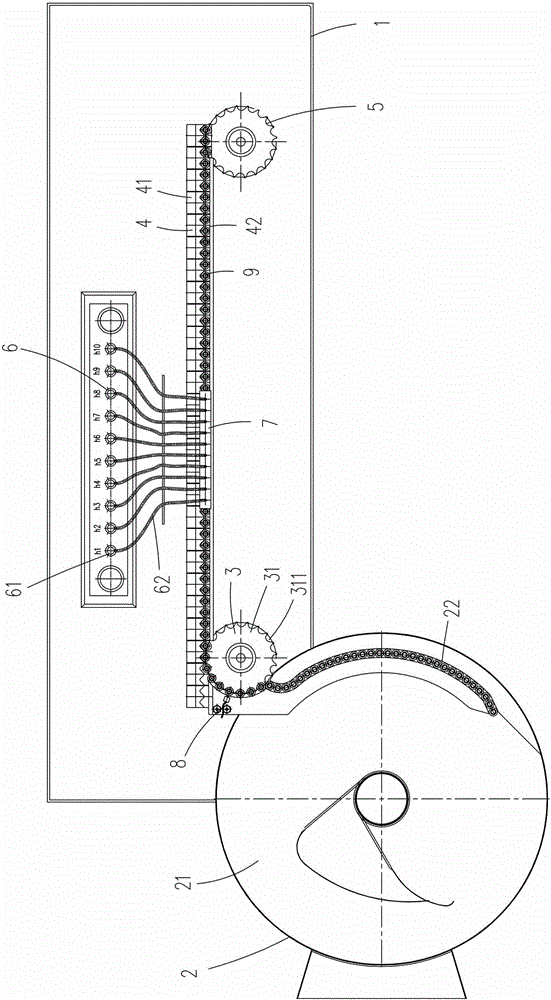

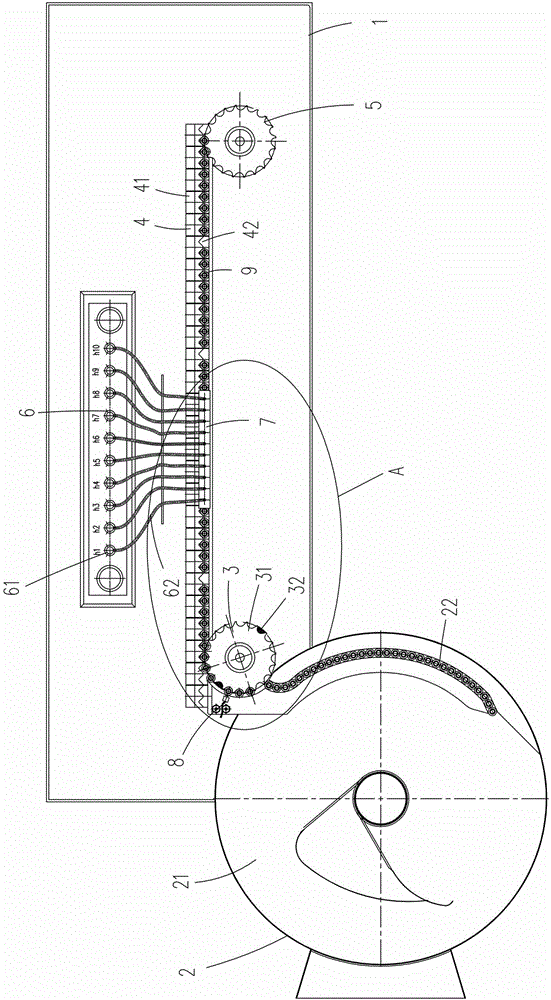

Continuous backfilling gangue projection system

PendingCN108643965ARealize continuous fillingHighly consistentMaterial fill-upFilling rateEngineering

The invention relates to a continuous backfilling gangue projection system and belongs to the technical field of mine extracting equipment. The continuous backfilling gangue projection system is arranged on an inner track of a roadway. The projection system comprises a feeding belt conveyer and a projection belt conveyor, wherein the projection belt conveyor is connected with the discharge end ofthe feeding belt conveyor, and a mounting seat is arranged on the tail portion of the feeding belt conveyer. The mounting seat is connected with a first walking mechanism and is an open hollow cylinder body. The projection belt conveyer is arranged on A second walking mechanism by a rotating table, the rotating table is connected with the feeding end of the projection belt conveyer in a hinged mode. A first extension unit is hinged between the projection belt conveyor and the rotating table, and second extension units are hinged between the two sides of the rotating table and the second walking mechanism respectively. According to the continuous backfilling gangue protection system, the highest projection position can be maintained to achieve continuous movement and continuous filling, theheights of the backfilling bodies are the same, continuous filling of the roadway can be realized during operation, and the filling density and filling rate are increased.

Owner:JIZHONG ENERGY MACHINERY EQUIP XINGTAI MACHINERY FACTORY

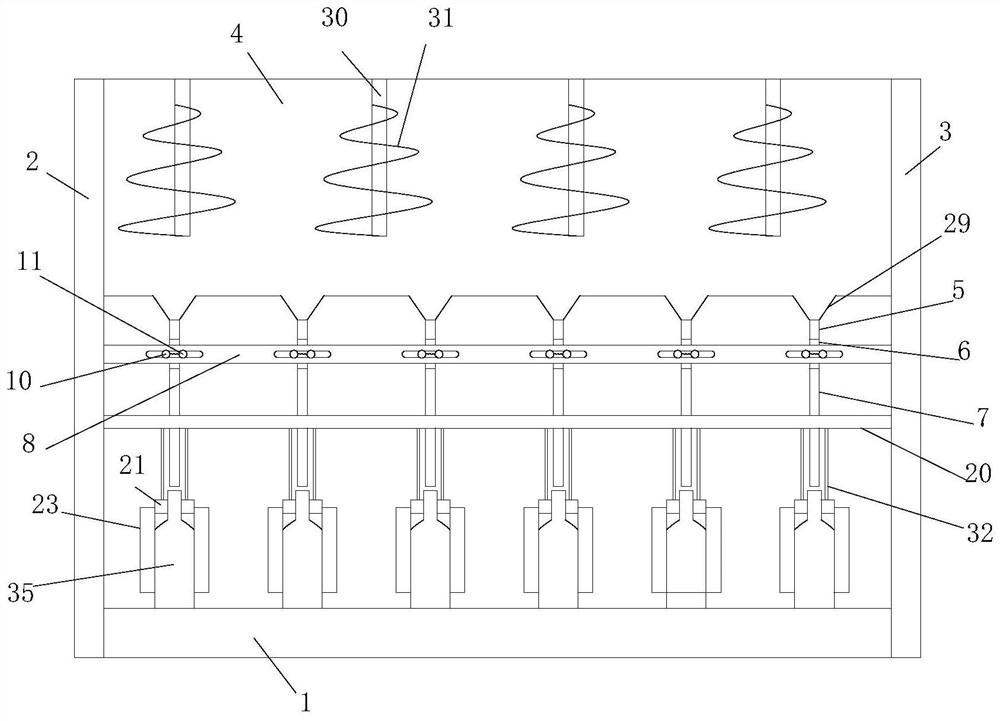

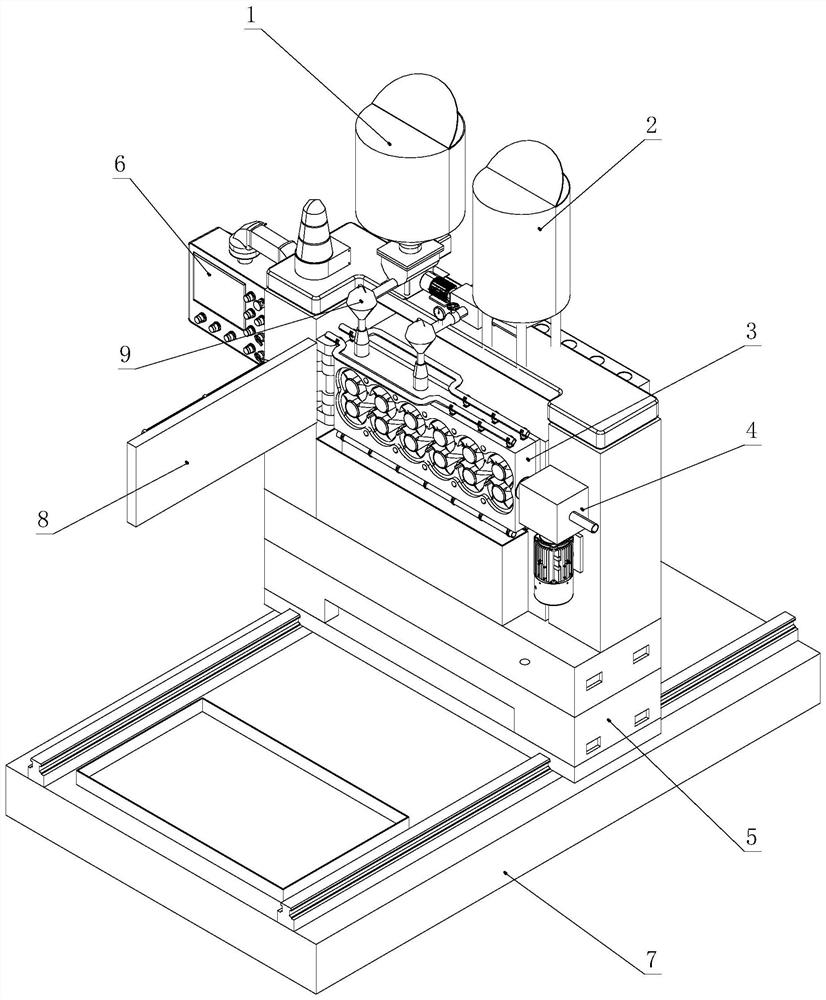

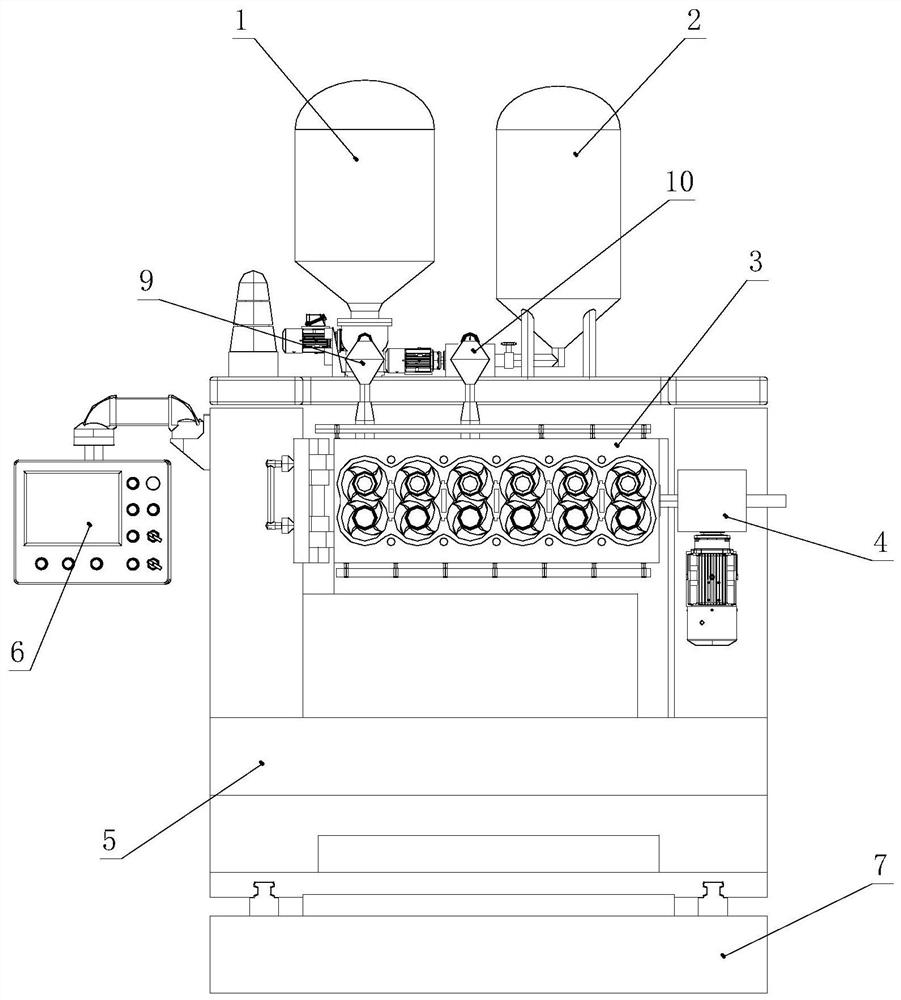

Filling machine applied to compound amino acid injection production

ActiveCN112193457ARealize continuous fillingImprove work efficiencyLiquid materialGear wheelElectric machinery

The invention relates to the field of injection production related equipment, in particular to a filling machine applied to compound amino acid injection production. The machine comprises a base, a motor bracket, C-shaped steel, a locking screw cap and a locking bolt, a plurality of groups of support legs are uniformly arranged at the front and rear parts of the bottom end of the base, and the bottom ends of the support legs are fixedly connected with fixed seats; a touch screen controller is arranged in the middle of the left end of the base, a limiting stop block is arranged at the top end of the base, an input sliding groove and an output sliding groove are formed at the front end of the left side and the rear end of the right side of the limiting stop block correspondingly, and a rectangular mounting hole is formed in the middle of the base; and a driving rotating shaft and a driven rotating shaft are rotatably connected to the positions, located at the left end and the right end of the rectangular mounting hole, of the base correspondingly, a driving gear and a driven gear are fixedly connected to the top ends of the driving rotating shaft and the driven rotating shaft correspondingly, and a driving motor output end is fixedly connected to the bottom end of the driving rotating shaft. The filling machine capable of improving the filling efficiency of the compound amino acid injection is provided.

Owner:安徽富邦药业有限公司

Culture solution continuous filling method and system for chlamydomonas culture

InactiveCN102220242BPrevent leakageContinuous raiseBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidNutrition

Owner:OCEAN UNIV OF CHINA

Filling machine for seasonings prepared from yellow serofluid of bean curd production line

InactiveCN112110404APrevent dumpingRealize continuous fillingSafety device in filling machineryBiotechnologyEngineering

The invention provides a filling machine for seasonings prepared from yellow serofluid of a bean curd production line. The filling machine for the seasonings prepared from the yellow serofluid of thebean curd production line comprises a filling positioning table and a filling mechanism, wherein the filling positioning table is provided with a conveying face; multiple positioning pieces which aredistributed linearly and used for positioning filling bottles are arranged on the conveying face; the filling mechanism comprises a filling storage tank and an adjusting mechanism; the filling storagetank is located above the filling positioning table; the two ends of the filling storage tank are connected with a first vertical frame and a second vertical frame correspondingly; multiple filling pipes communicating with the filling storage tank are arranged at the bottom of the filling storage tank, and are used for filling the filling bottles positioned by the multiple positioning pieces correspondingly; the filling pipes comprise connecting pipes, adjusting hoses and direct filling pipes which are connected in sequence; the connecting pipes are connected with the filling storage tank; and the adjusting mechanism is used for controlling opening or closing of channels in the adjusting hoses of the multiple filling pipes. According to the filling machine for the seasonings prepared fromthe yellow serofluid of the bean curd production line provided by the invention, through cooperation of a first conveying mechanism, the filling positioning table, the filling mechanism and a secondconveying mechanism, continuous filling can be achieved, and the working efficiency is effectively improved.

Owner:安徽省旌一农业旅游发展有限公司

A kind of lunar soil concrete and preparation method thereof

ActiveCN110256039BRealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationSoil science

The invention relates to a lunar soil "concrete" and a preparation method thereof, which are mainly used in technical fields such as aerospace, aviation, and architectural coatings. The lunar soil "concrete" hybrid 3D printing technology is an important key technology for the construction of the future lunar base. The lunar soil simulant hybrid 3D printing device can realize continuous and controllable printing by designing the lunar soil simulant hybrid 3D printing head. Extrusion of lunar soil "concrete". The hybrid 3D printing head is a key component of the lunar soil hybrid printing device, which is used to realize the continuous and controllable extrusion of lunar soil "concrete". It is a functional component that integrates drive motors, couplings, screw pumps, interfaces, screw extrusion devices, printing nozzles and other components to realize the continuous and controllable extrusion of lunar soil "concrete" materials.

Owner:BEIJING SATELLITE MFG FACTORY

Hard pipe material filling production line

InactiveCN110626531ASimple designHigh positioning accuracySolid materialLiquid materialProduction lineEngineering

The invention provides a hard pipe material filling production line. The line comprises a hard pipe conveying device, a hard pipe material filling connecting quantitative device and a hard pipe end cover automatic capping device. The hard pipe conveying device comprises a support. Two oppositely parallel conveying belts are arranged on the support. A plurality of hard pipe brackets are arranged onthe surfaces of the synchronous belts at intervals. Grooves are formed in the surfaces of the hard pipe brackets correspondingly so that hard pipes can be accommodated. The hard pipe material fillingcontinuous quantitative device comprises an end cover jacking cylinder and a material filling continuous quantitative unit which are arranged oppositely. The hard pipe end cover automatic capping device comprises an end cover jacking cylinder and an end cover mechanism which are arranged oppositely. According to the hard pipe material filling production line provided by the invention, manual intervention is greatly reduced during using, the production efficiency is greatly improved, the labor intensity of workers is relieved, and the product quality is improved.

Owner:HEBEI XIAOJIN MACHINERY MFG

An Automatically Controlled Mixed Phase Change Material Melting and Filling Device

ActiveCN107042898BUniform endothermic meltingAvoid cloggingLiquid materialElectricityAutomatic control

The invention discloses an automatically controlled hybrid phase change material melting and filling device which contains a temperature controllable heating constant-temperature cycle working medium case and an automatic filling, immersion and heating furnace. The heating constant-temperature cycle working medium case is composed of an electric heater and a case body. The bottom of the heating constant-temperature cycle working medium case is provided with two pairs of universal wheels, a heating working medium compensation port, an overflow port and a dirt discharge port. A heating working medium outlet and a heating working medium inlet are formed in the side face of the case body. A plurality of holes are dispersed in a cover plate on the top of the case body, and unit tubes to be filled are inserted in the holes. The outer layer of the automatic filling, immersion and heating furnace is a heating cycle working medium channel which is provided with a heating working medium inlet, a heating working medium outlet and a liquid level meter. The inner layer of the automatic filling, immersion and heating furnace is filled with a phase change material to be molten. The bottom of the automatic filling, immersion and heating furnace is connected with an unloading pipe and an electric adjusting valve. A lifting stirrer is arranged in the hollow portion of the automatic filling, immersion and heating furnace. Since a loading device adopts a belt with the discharging amount controlled by weighing to conduct conveying, multi-batch quantitative automatic filling is achieved. The case body and an outer cavity of a melting furnace form a cycle heating working medium loop with the whole process being constant in temperature. The automatically controlled hybrid phase change material melting and filling device is reasonable in structure, reliable in performance, easy and convenient to operate and high in filling speed.

Owner:NANJING TECH UNIV

Large horizontal sand silo suitable for combined filling of mortar in dressing plants and dry tailings in tailings ponds

ActiveCN102505961BSolve the shortcomingsAchieve mutual integrationMaterial fill-upSpray nozzleHigh pressure water

The invention discloses a large horizontal sand silo suitable for combined filling of mortar in dressing plants and dry tailings in tailings ponds. The sand silo is characterized by being divided into a mortar making region (I), a transport region (II) and a tailings storage region (III), wherein ring-shaped high-pressure water supply branch pipes (c) and high-pressure gas supply branch pipes (a) are laid in the mortar making region (I); high-pressure water spray nozzles (d) are horizontally installed on the ring-shaped high-pressure water supply branch pipes (c); high-pressure gas spray nozzles (b) are vertically installed on the high-pressure gas supply branch pipes (a); high-pressure water supply branch pipes (c) and high-pressure gas supply branch pipes (a) are laid in the transport region (II) in parallel; high-pressure water spray nozzles (d) are horizontally installed on the high-pressure water supply branch pipes (c); high-pressure gas spray nozzles (b) are vertically installed on the high-pressure gas supply branch pipes (a); the dip angle of the bottom plate of the horizontal sand silo is 23-26 degrees; the length of the mortar making region (I) along the trend of the sand silo is 3-5 meters; the length of the transport region (II) along the trend of the sand silo is 5-8 meters; and the length of the tailings storage region (III) along the trend of the sand silo is 4-7 meters. The large horizontal sand silo is applied to mortar making, can be used for realizing high-capacity continuous filling, ensuring the quality of the fillers, shortening the unsupported roof time in the goafs, reducing the construction investment of the filling stations and ensuring mine mining and filling to achieve balance and is beneficial to realization of safety production and environmental friendliness of the mines.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Image processing method, device, electronic device and storage medium

ActiveCN108924557BIncrease the compression ratioImprove transmission efficiencyDigital video signal modificationPattern recognitionImaging processing

Embodiments of the present invention provide an image processing method, device, electronic equipment, and storage medium, and relate to the technical field of image processing. The method includes: dividing the grayscale image of the original image into a plurality of blocks; performing layout analysis on each block in the plurality of blocks to determine the type of each block; filling the space of each block based on the type of each block A foreground layer, a mask layer, and a background layer; compressing the foreground layer, the mask layer, and the background layer of each block to obtain a compressed image. The technical solution of the embodiment of the present invention can realize continuous filling of image pixel values, and further improve image compression rate while maintaining fidelity.

Owner:VIDAA(荷兰)国际控股有限公司

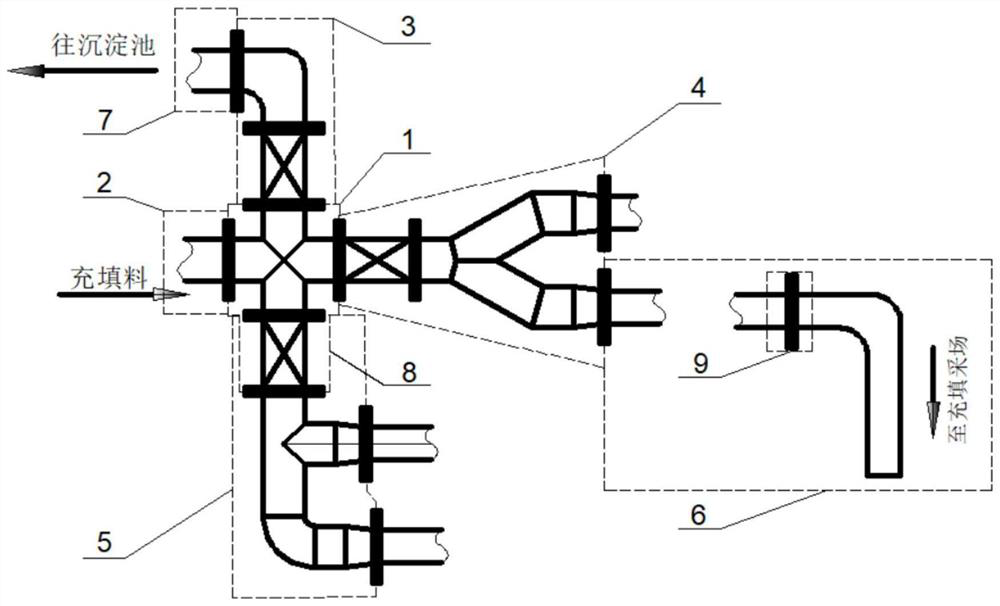

Multi stope fast switching continuous filling device and its application method

The invention provides a multi-stop fast-switching continuous filling device and a use method thereof, which belong to the technical field of mine filling. The device includes a four-way pipe, a filling incoming pipe, a sedimentation tank module, a filling module, a stope connection module, a sedimentation tank connecting pipe, a valve and a flange. The entrance of the four-way pipe is connected to the filling incoming pipe through a flange. The three outlets of the pipe are respectively connected to the sedimentation tank module, filling module A, and filling module B through flanges, and valve switches are used to control the flow direction. The sedimentation tank module is connected to the sedimentation tank connecting pipe through flanges, and the filling module is connected to the stope connection module Through flange connection, the stope connection module is connected with the filling stope. The device has simple processing, low manufacturing cost, simple operation, and high practicability. It not only improves the single filling efficiency, but also eliminates the pipe moistening and washing processes when switching filling in multiple stopes, and has high practical value.

Owner:UNIV OF SCI & TECH BEIJING

A kind of lunar soil concrete suitable for extrusion and its preparation method

ActiveCN110405903BRealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationLunar soil

Owner:BEIJING SATELLITE MFG FACTORY

Mortar making system and process suitable for large horizontal sand silo of mine filling station

ActiveCN102367741BSolve the shortcomingsAchieve mutual integrationMaterial fill-upStructural engineeringPipe

The invention discloses a mortar making system and process suitable for a large horizontal sand silo of a mine filling station. The system comprises a mortar supply and transport system, a high-pressure gas supply pipe (9), a high-pressure water supply pipe (8), a horizontal sand silo (7), an output pipeline of the horizontal sand silo, a cement silo (15), an output system of the cement silo, a stirring device (14) and a filling pipeline, wherein the outlet of the mortar supply and transport system is arranged above the horizontal sand silo (7); the output pipeline of the horizontal sand silo (7), the output system of the cement silo (15) and the stirring device (14) converge; the filling pipeline is connected with a goaf (18); the horizontal sand silo (7) begins from a sand discharge opening; a mortar making area, a transport area and a sand storage area are divided along the trend of the horizontal sand silo (7); annular high-pressure water supply branch pipes and high-pressure gas supply branch pipes are paved in the mortar making area; high-pressure water supply branch pipes and high-pressure gas supply branch pipes are paved in the transport area in parallel; the high-pressure gas supply pipe (9) is connected with the high-pressure gas supply branch pipes in the horizontal sand silo (7); and the high-pressure water supply pipe (8) is connected with the annular high-pressure water supply branch pipes and the high-pressure water supply branch pipes in the horizontal sand silo (7). The system and the process have the following effects: the horizontal sand silo achieves high-capacity continuous filling; the filler quality is ensured; the unsupported roof time of the goaf is reduced; the filling station construction investment is reduced; mining and filling of the mine are balanced; and the system and the process are favorable for the mine to achieve safety production and environmental protection.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

A high-temperature heat pipe working medium charging device and method

ActiveCN110411253BReduce the risk of contaminationAvoid human contactIndirect heat exchangersThermodynamicsConical tube

The invention discloses a high-temperature heat pipe working medium filling device and method. The device comprises a working medium container, a conical pipe, a quartz container, a packaging pipe anda high-temperature heat pipe which are arranged sequentially from top to bottom, the bottom of the working medium container is in communication with the first end of a first communicating pipeline, the second end of the first communicating pipeline is connected with the first end of the conical pipe, the second end of the conical pipe is arranged in a cavity of the quartz container, the bottom ofthe quartz container is in communication with the first end of a second connecting pipeline, the second end of a second communicating pipeline is in communication with the packaging pipe, the packaging pipe is communicated with the high-temperature heat pipe, the first end of the first communicating pipeline is connected with the second end of the first communicating pipeline through a first valve, and the first end of the second communicating pipeline is connected with the second end of the second communicating pipeline through a second valve. According to the device and method, human contact is avoided, and the risk that the working medium is polluted in the filling process is reduced; the device can realize continuous filling and is suitable for continuous production; and the device issimple in structure and convenient to operate.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Hard tube material filling process and hard tube material filling production line

ActiveCN111422390AIncrease productivitySimple designSolid materialLiquid materialProcess engineeringManufacturing line

The invention provides a hard tube material filling process and a hard tube material filling production line. The hard tube material filling process comprises the following steps of (1) arranging a hard tube; (2) arranging a filling pump; (3) arranging a filling port in the end part of the hard pipe to correspond to a discharging port in the filling pump; (4) starting the filling pump to fill thehard pipe with materials; and (5) performing cover pressing sealing on the filling port after hard tube filling. The hard tube material filling production line involves a hard tube conveying device, hard tube material filling continuous quantifying devices and automatic hard tube end cover pressing devices. According to the hard tube material filling production line and the hard tube material filling process, the manual intervention is greatly reduced in the using process, so that the production efficiency is greatly improved, the labor intensity of workers is reduced, and the product qualityis improved.

Owner:HEBEI XIAOJIN MACHINERY MFG

Energetic material kneading device and method

InactiveCN112266310AEnables continuous mixingReduce doseTransportation and packagingMixer accessoriesContinuous mixingMechanical engineering

The invention relates to the technical field of energetic device production, in particular to an energetic material kneading device. According to the technical scheme, the energetic material kneadingdevice comprises a multi-cavity kneading assembly, a first feeding assembly and a second feeding assembly. The multi-cavity kneading assembly is provided with at least four kneading units which are sequentially communicated, each kneading unit comprises a kneading cavity, and a pair of mixing blades are arranged in each kneading cavity so as to sequentially achieve feeding, premixing, final mixingand discharging of energetic materials; the first feeding assembly is used for inputting a first solid-phase component of an energetic material into the multi-cavity kneading assembly; and the secondfeeding assembly is used for inputting a second solid-phase component of the energetic material into the multi-cavity kneading assembly. According to the invention, continuous mixing of energetic materials can be realized, the online dosage of kneading and mixing of the energetic materials can be reduced, continuous filling of the energetic materials can be realized, the intrinsic safety of the production process is improved, and the stable quality of the product can be ensured.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

A filling machine applied to the production of compound amino acid injection

ActiveCN112193457BRealize continuous fillingImprove work efficiencyLiquid materialDrive shaftGear wheel

The invention relates to the field of equipment related to injection production, in particular to a filling machine applied to the production of compound amino acid injection, comprising a base, a motor bracket, a C-shaped steel, a locking nut and a locking bolt. A number of sets of legs are evenly arranged, the bottom ends of the legs are fixedly connected with a fixed seat, the middle of the left end of the base is provided with a touch screen controller, the top of the base is provided with a limit stop, and the left side of the limit stop The front end and the right rear end are respectively provided with an input chute and an output chute, a rectangular mounting hole is opened in the middle of the base, and the left and right ends of the base are respectively connected with a driving shaft and a driven shaft in rotation. The top ends of the driving shaft and the driven shaft are respectively fixedly connected with a driving gear and a driven gear, and the bottom end of the driving shaft is fixedly connected with an output end of a driving motor. The present invention provides a filling method capable of improving the filling efficiency of compound amino acid injection. machine.

Owner:安徽富邦药业有限公司

Filling machine

InactiveCN102862691BThere will be no phenomenon of empty bottle outputRealize continuous fillingPackaging automatic controlLiquid materialEngineeringMechanical engineering

The invention discloses a filling machine which comprises a filling mechanism, a control mechanism, a bottle inlet dial wheel mechanism and a bottle delivery mechanism. Bottle accommodating portions which are used for being matched with tooth grooves of the bottle inlet dial wheel mechanism to receive bottles are arranged on the bottle delivery mechanism, the filling mechanism comprises a plurality of filling parts which are used for filling bottle bodies in the bottle accommodating portions which are arranged continuously on the bottle delivery mechanism simultaneously, the bottle inlet dial wheel mechanism comprises a bottle inlet dial wheel and a bottle blocking part which is used to be mounted in tooth grooves in the bottle inlet dial wheel to prevent bottles from entering the tooth groove, and the number of the tooth grooves of the bottle inlet dial wheel is integral multiple of that of the filling parts. The filling machine has the advantages of being simple in structure, low in cost, convenient to operate, safe and reliable, high in filling yield and the like.

Owner:TRUKING TECH LTD

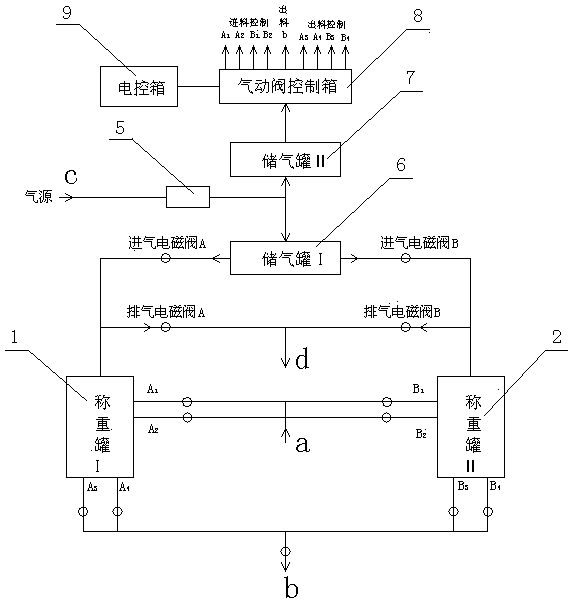

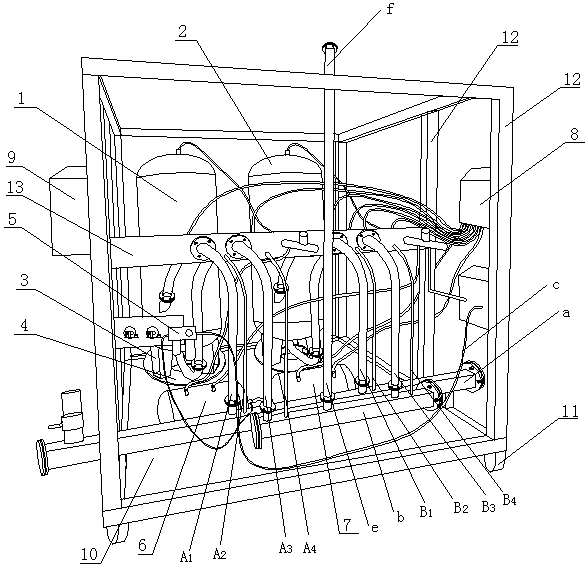

Pre-weighed reciprocating fluid weight output filling device

The invention relates to a pre-weighed reciprocating fluid weight output filling device and belongs to a filling machine for a weighing method. A weighing tank I and a weighing tank II are arranged inparallel, and sensors are separately fixed to the bottoms of the weighing tank I and the weighing tank II; a large flow liquid inlet pipe A1 and a small flow liquid inlet pipe A2 connected to a feeding pipe a are connected to the weighing tank I through pipelines; a large flow liquid inlet pipe B1 and a small flow liquid inlet pipe B2 connected to the feeding pipe a are connected to the weighingtank II through pipelines; the bottom of the weighing tank I is connected to a large flow liquid outlet pipe A3 and a small flow liquid outlet pipe A4; the bottom of the weighing tank II is connectedto a large flow liquid outlet pipe B3 and a small flow liquid outlet pipe B4; and the large flow liquid outlet pipe A3, the small flow liquid outlet pipe A4, the large flow liquid outlet pipe B3 and the small flow liquid outlet pipe B4 are connected to a discharge pipe b. According to the pre-weighed reciprocating fluid weight output filling device, the two weighing tanks work alternately, so thatthe device can fill liquids continuously. By monitoring the weight of the fluids in the tanks by the weight sensors, the fluid weight is output precisely, and meanwhile, the pre-weighed reciprocatingfluid weight output filling device fills the liquids on a transport cart directly, so that the problem that it is labor- and time-wasting to fill the liquids in the prior art that the liquids are filled first and are loaded then is solved.

Owner:朱福鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com