Filling machine

A filling machine and liquid storage tank technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of unstable filling quantity and low degree of automation, and achieve simple structure, high degree of automation and continuous filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

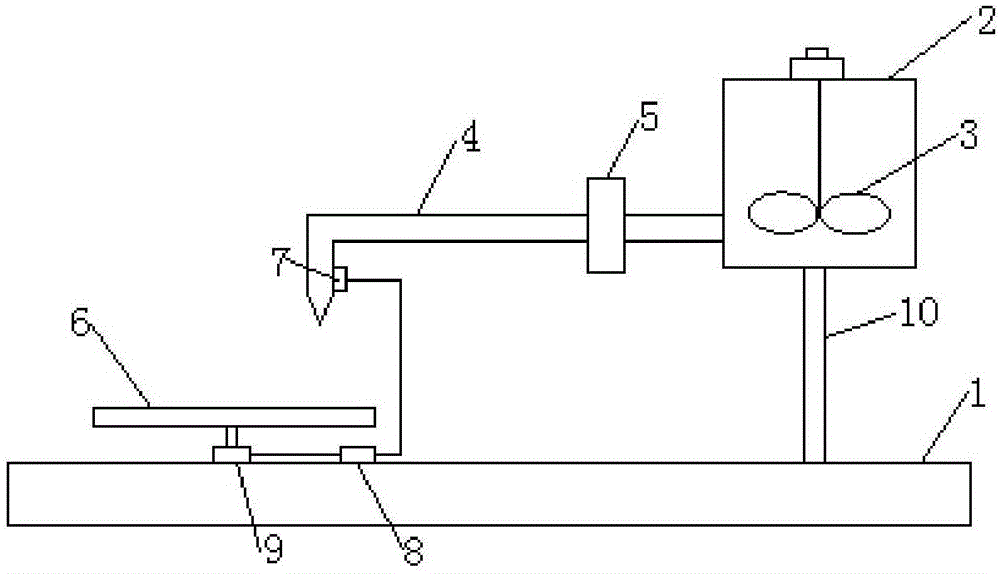

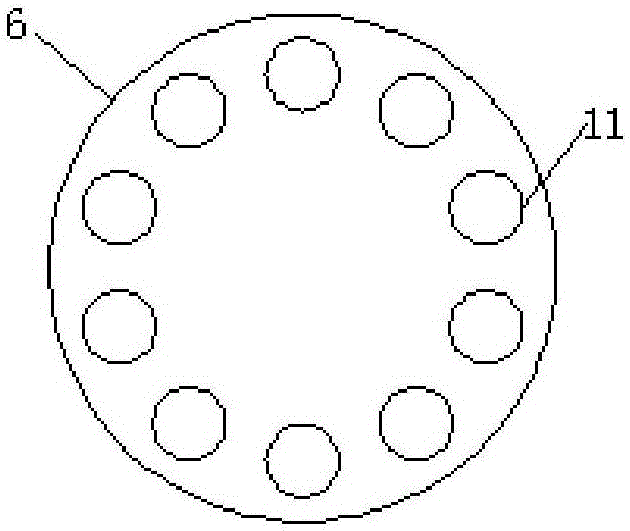

[0017] like figure 1 As shown, a filling machine includes a liquid storage tank 2 and an agitator 3 fixed inside the liquid storage tank 2. The agitator 3 fully stirs the liquid in the liquid storage tank 2 to prevent some substances in the liquid from settling. The bottom of the liquid storage tank 2 is fixed on the base 1 through a lifting rod 10, and the liquid storage tank 2 is set at a suitable height by adjusting the lifting rod 10. The lower left side of the liquid storage tank 2 is connected to a liquid outlet pipe 4, and a flow controller 5 is arranged on the liquid outlet pipe 4. A liquid level sensor 7 is fixed at the end of the liquid outlet pipe 4 away from the liquid stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com