Large horizontal sand silo suitable for combined filling of mortar in dressing plants and dry tailings in tailings ponds

A technology for tailings ponds and concentrators, which is applied to filling materials, mining equipment, safety devices, etc. It can solve problems such as unbalanced mining and filling in mines, long pulping time, and complicated construction processes, so as to protect the environment and reduce construction and filling costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further describe the present invention, the large-scale horizontal sand bin suitable for joint filling of mineral processing plant mortar and tailings pond dry tailings of the present invention will be further described in detail in conjunction with the accompanying drawings.

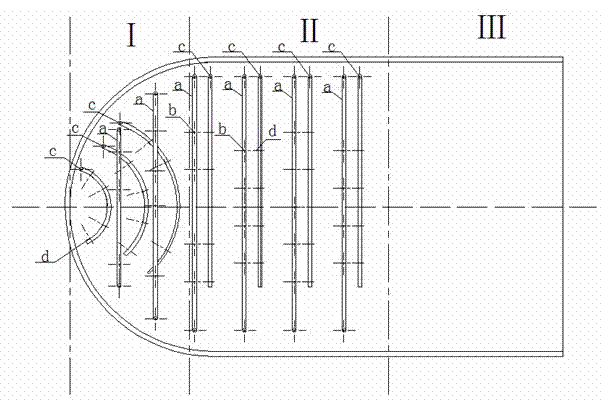

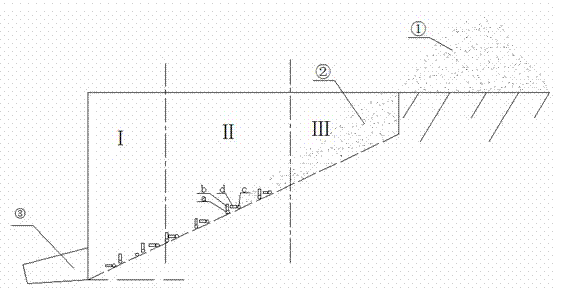

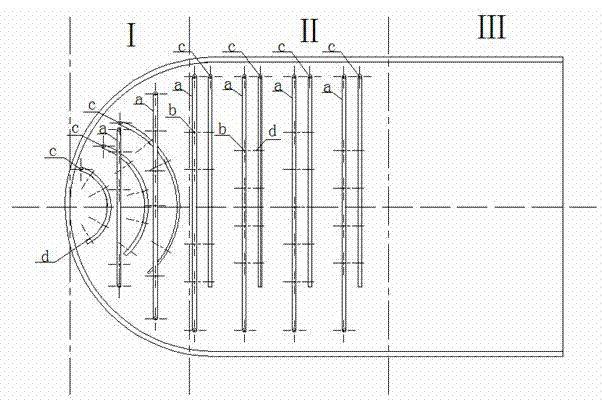

[0025] Depend on figure 1 The present invention shown is suitable for the horizontal projection diagram of the large horizontal sand bin for the combined filling of the mortar of the mineral processing plant and the dry tailings of the tailings silo and combines the figure 2 It can be seen that starting from the sand outlet, along the direction of the horizontal sand silo, it is divided into pulp making area Ⅰ, handling area Ⅱ, and sand storage area Ⅲ; the inclination angle of the bottom plate of the horizontal sand silo is 25 o , the length of the slurry-making area I along the strike of the sand bin is 4m, the length of the transport area II along the strike of the sand bin is 7m, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com