Energetic material kneading device and method

A kneading device and material feeding technology, which is applied to chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of large mixing amount, large batch quality difference, and inability to charge continuously, so as to reduce the amount of drug, The effect of ensuring stable quality and improving intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

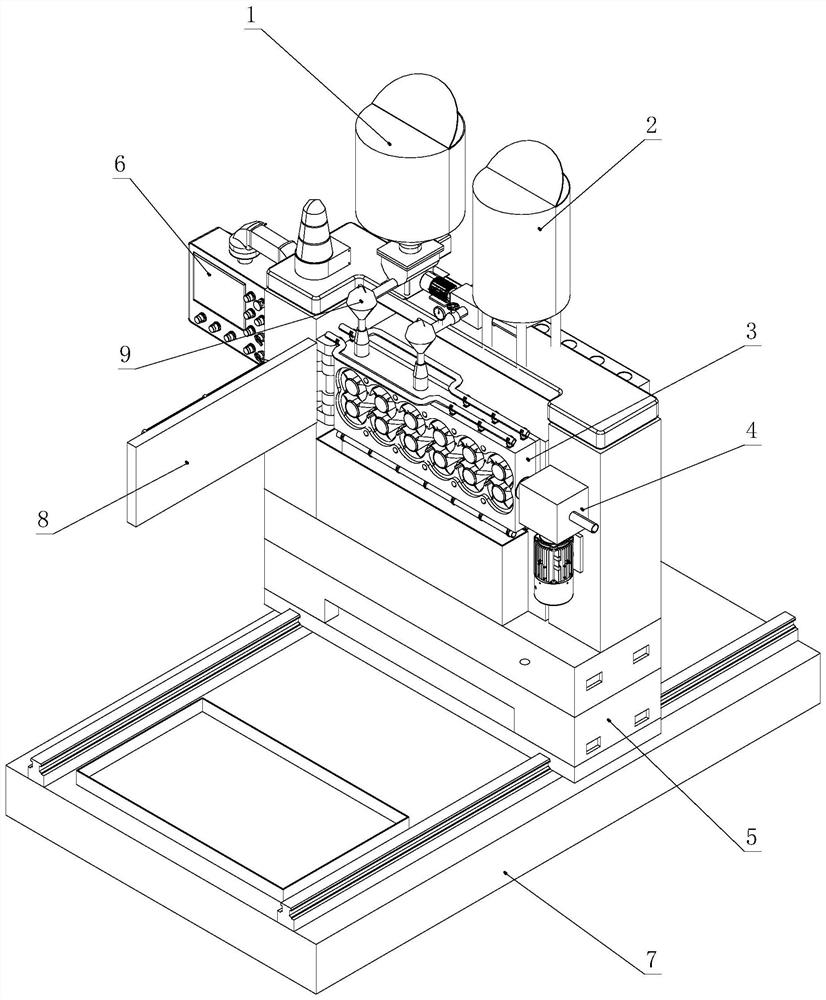

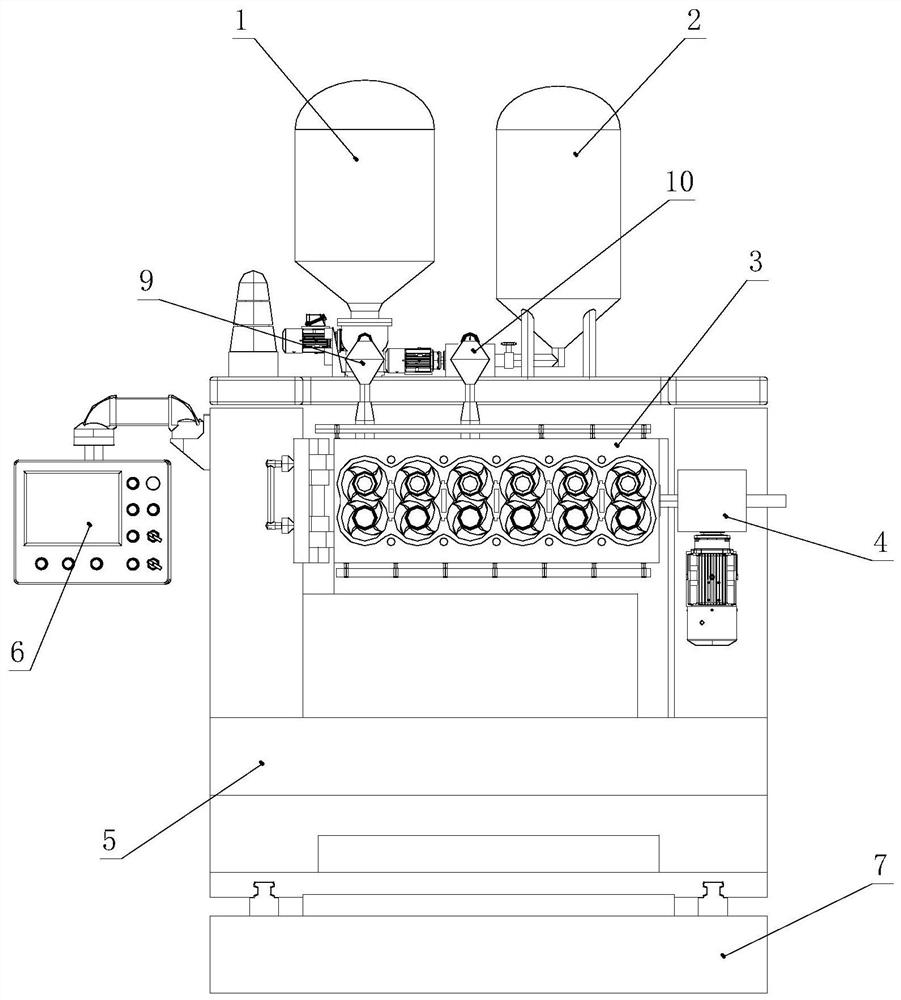

[0032] A kneading device for energetic materials, comprising: a multi-chamber kneading assembly 3, the multi-chamber kneading assembly 3 is provided with at least four sequentially connected kneading units, the kneading units include a kneading chamber, and a pair of kneading chambers are arranged in the kneading chamber Mixing paddles to sequentially realize the feeding, premixing, final mixing and discharging of the energetic material; the first feeding assembly 1, the first feeding assembly 1 is used to input the first energy-containing material to the multi-chamber kneading assembly 3 Solid phase component; the second feeding component 2, the second feeding component 2 is used to input the second solid phase component of the energetic material to the multi-chamber kneading component 3.

[0033] Further, one side of the kneading chamber is provided with an openable observation window 8, the observation window 8 is made of explosion-proof glass, on the one hand, it is conveni...

Embodiment 2

[0043] A method for kneading energetic materials based on embodiment 1, comprising the following steps:

[0044] The solid-phase component of the energetic material is batched according to the set ratio, and sent into the left kneading chamber of the multi-chamber kneading assembly 3 through the first feeding assembly 1 and the second feeding assembly 2;

[0045] Through the mixing paddles in the kneading chambers of the multi-chamber kneading assembly 3, the energetic materials are sequentially fed, pre-mixed, final-mixed and discharged;

[0046] The energetic material sent out from the discharge end of the multi-chamber kneading assembly 3 is sent to the charging station through the feeding assembly 4 .

[0047] For the kneading of the energetic material that needs to add the liquid phase component, the liquid phase component of the energetic material is fed into the multi-chamber kneading assembly 3 through the third feeding assembly 9 and / or the fourth feeding assembly 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com