Flocculant mixing pipe for sludge treatment equipment

A sludge treatment and flocculant technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, mixers, mixers with rotating stirring devices, etc., can solve the problem of sludge preparation tanks occupying a large area and investment, and the mixing effect Unsatisfactory problems, to achieve fast speed, good mixing effect, continuous mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

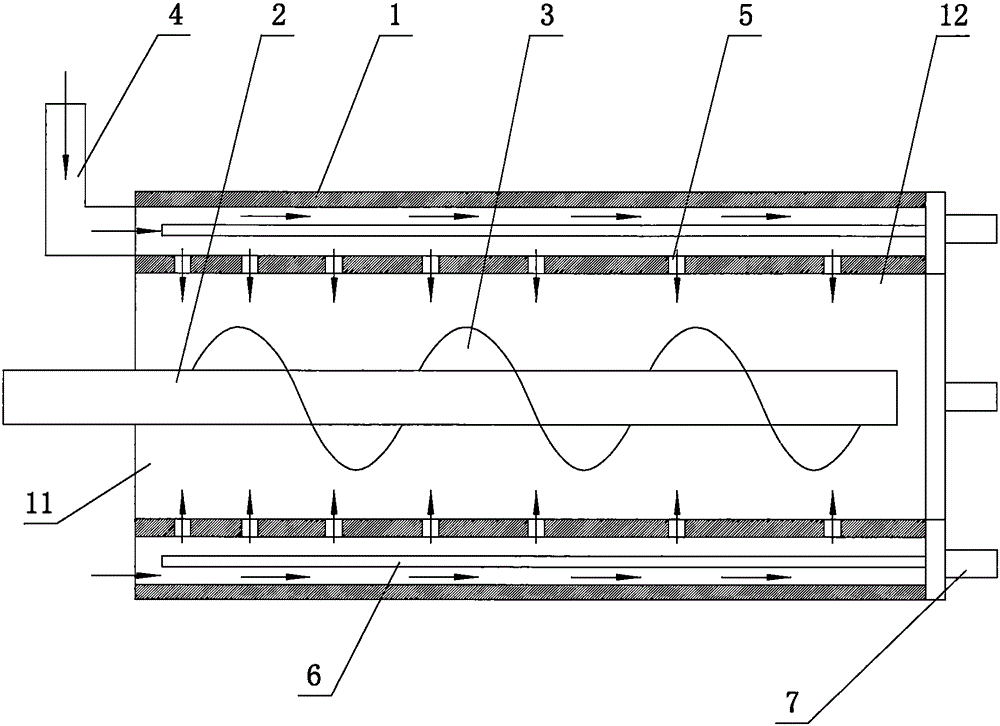

[0011] like figure 1 As shown, the flocculant mixing tube of the sludge treatment equipment of this embodiment includes a fixedly installed pipe sleeve 1 and a stirring shaft 2 movably installed in the pipe sleeve 1. The stirring shaft 2 has a spiral blade 3; the pipe sleeve 1 The pipe wall has a hollow structure, and one end of the pipe wall is installed with a flocculant introduction pipe 4, and the inner wall of the pipe sleeve 1 is provided with through holes 5 communicating with the inner cavity of the pipe wall at intervals, and the distance between adjacent through holes 5 is from the pipe wall. The feed end 11 of the sleeve 1 gradually increases toward the discharge end 12; a plurality of guide rods 6 are arranged in the pipe wall of the sleeve 1, and a guide motor 7 is installed at the end of the guide rod 6, and a plurality of guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com