Biomass briquette fuel production system with automatic moisture proportioning function

A technology of biomass molding machine and molding fuel, which is applied in the direction of fuel, solid fuel, petroleum industry, etc. It can solve the problems of troublesome process, water addition, and inability to directly shape and process, and achieve the effect of reducing costs and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

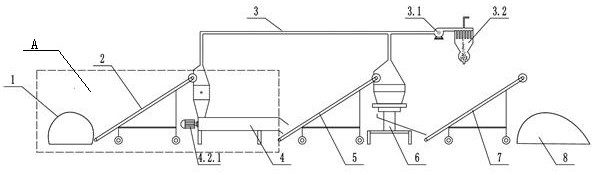

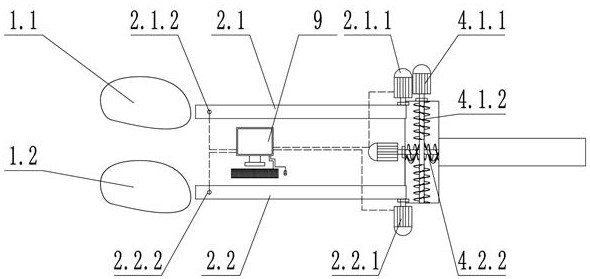

[0028] Example 1: as figure 1 and 2 As shown, a biomass briquetting fuel production system with automatic moisture proportioning function includes a conveying unit, a continuous mixing unit, a forming unit and a dust removal unit.

[0029] The conveying unit includes a conveying device 2 for conveying the crushed biomass raw material 1, and the conveying device 2 includes a dry biomass raw material conveyor belt 2.1 for conveying dry biomass raw material 1.1 and a wet biomass raw material for conveying wet biomass raw material 1.2 Conveyor belt 2.2. In this embodiment, the dry biomass raw material 1.1 is pulverized wood chips, peanut shells, etc., and the wet biomass raw material 1.2 is pulverized strawberry seedlings, pepper stalks, eggplant stalks, wet corn stalks, and the like.

[0030] Dry biomass raw material moisture sensor 2.1.2 is installed on dry biomass raw material conveyor belt 2.1, wet biomass raw material moisture sensor 2.2.2 is installed on wet biomass raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com