Preparation method for polysilane azide-multiwalled carbon nanotube composite material

A technology of multi-wall carbon nanotubes and nitriding polysilane is applied in the field of preparation of polysilane-multi-wall carbon nanotube composite materials, which can solve the problems of destroying the integrity of multi-wall carbon nanotubes, complicated preparation process, etc. Destruction, Simplified Reaction Process, Simple Step Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

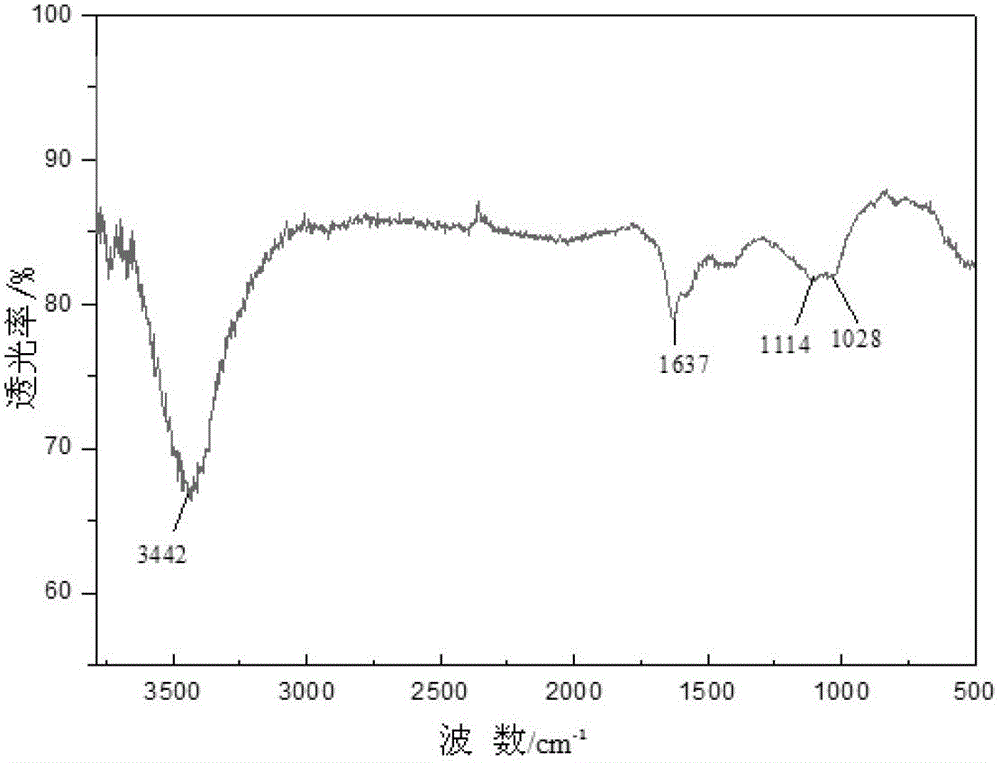

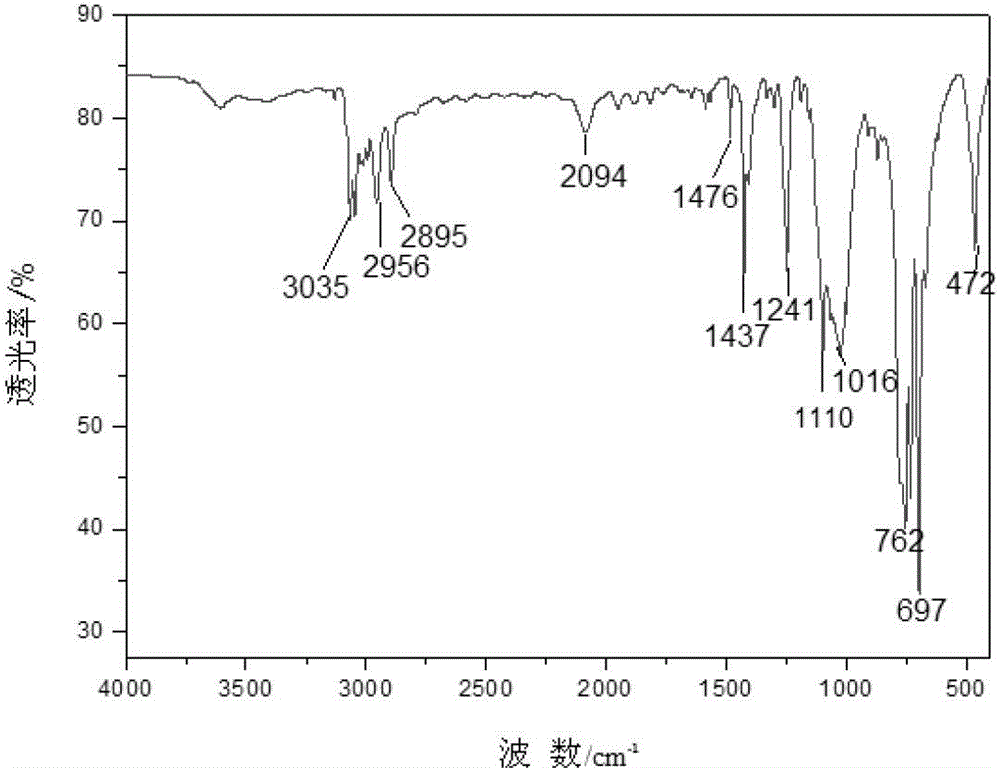

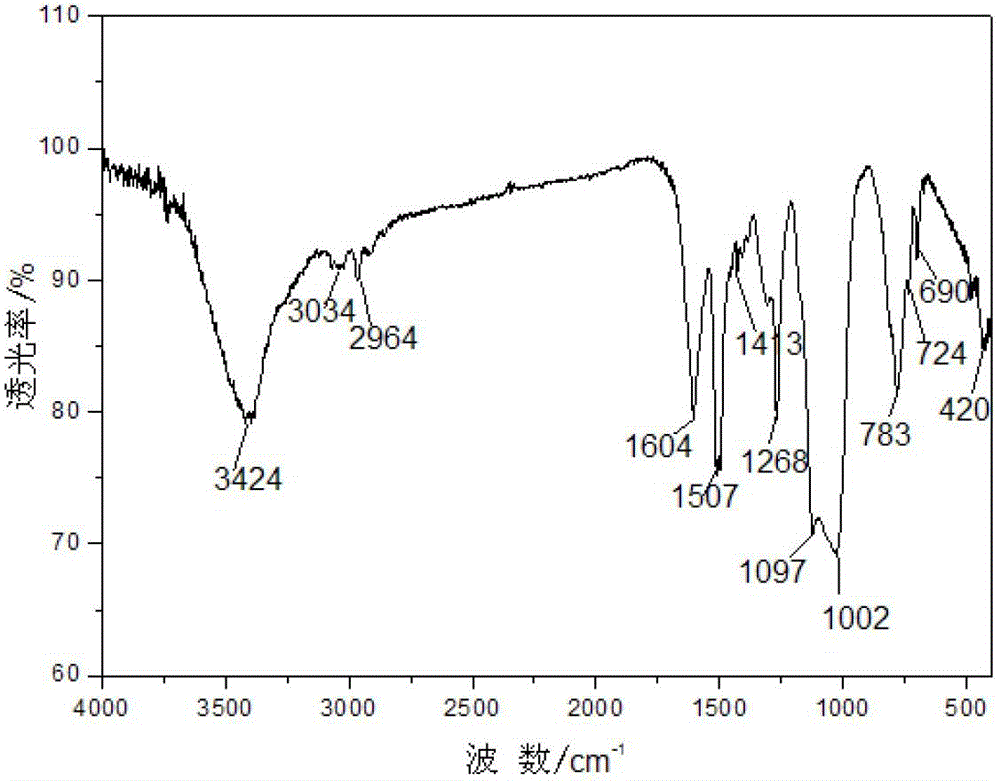

[0017] Specific embodiment 1: This embodiment is a polysilane azide-multi-walled carbon nanotube composite material composed of an acid solution with a concentration of 4mol / L to 6mol / L, an organic solvent, polysilane azide and multi-walled carbon Nanotubes are prepared; the mass of the multi-walled carbon nanotubes and the volume ratio of the acid solution are 1g:(200mL~350mL); the ratio of the mass of the multi-walled carbon nanotubes to the volume of the organic solvent is 1g:( 200mL-350mL); the mass ratio of the multi-walled carbon nanotubes to polysilane azide is 1:(25-120).

[0018] In this embodiment, azide polysilane-multi-wall carbon nanotube composite material is prepared through a [3+2] cycloaddition reaction between azide polysilane and multi-wall carbon nanotubes.

[0019] In this embodiment, the surface of the multi-walled carbon nanotubes is not treated with carboxylation or acyl chloride, which not only simplifies the reaction process of modifying the multi-wal...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the acid solution is hydrochloric acid, nitric acid or sulfuric acid. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the organic solvent is o-dichlorobenzene or monochlorobenzene. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com