Patents

Literature

34results about How to "Realize processing and forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

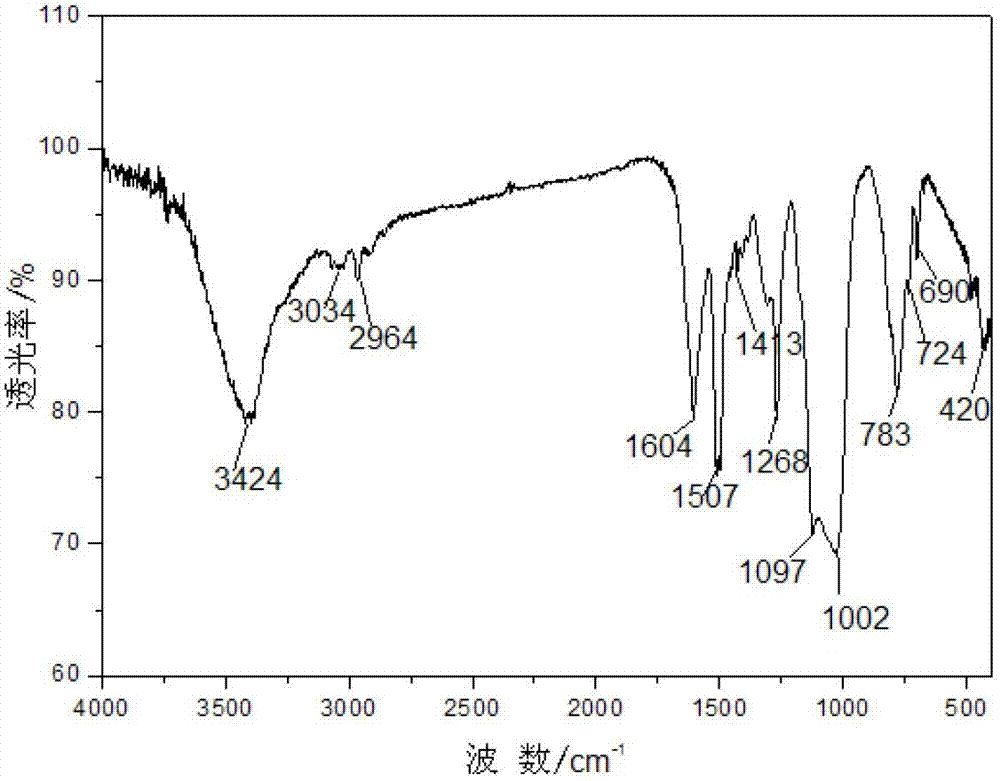

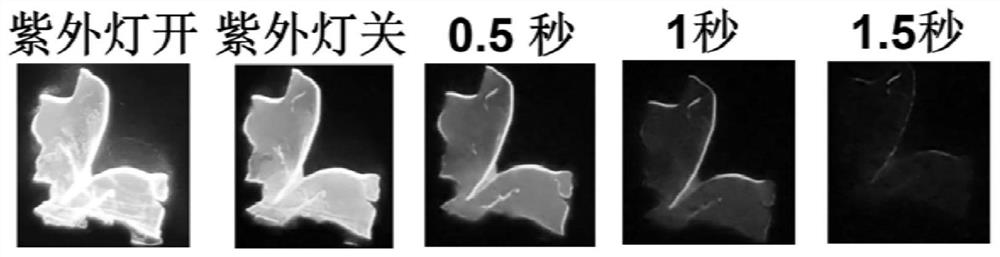

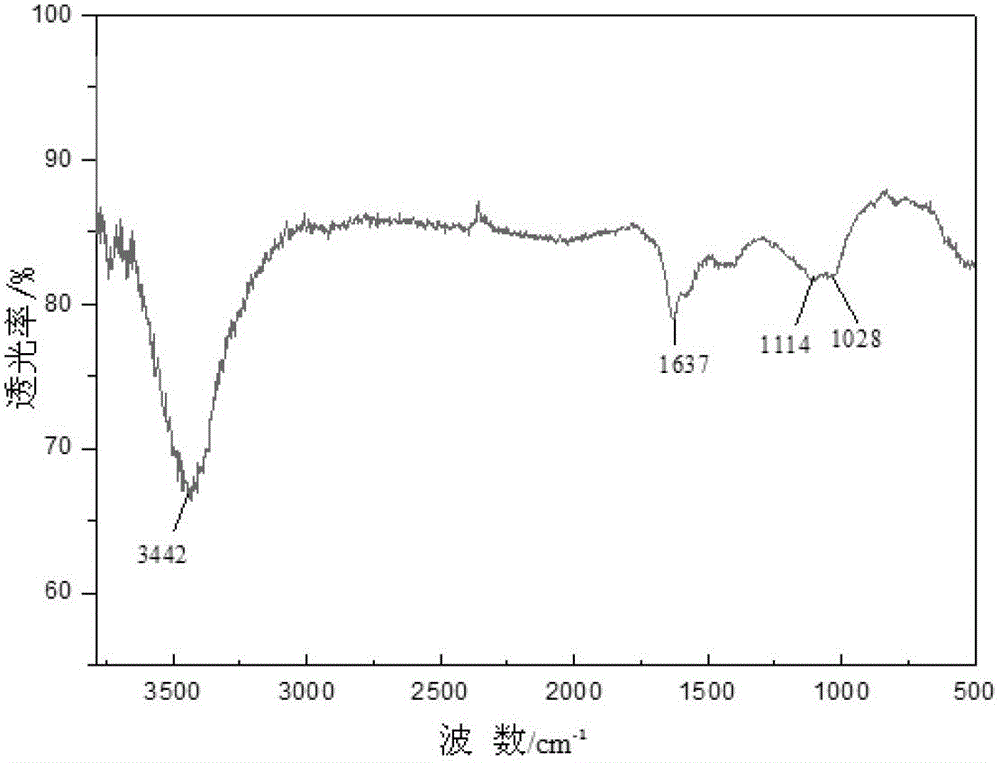

Halogen-free and heavy-atom-free room-temperature phosphorescent material as well as preparation method and application thereof

ActiveCN111363537ARealize processing and formingLow priceLuminescent compositionsAcridineOrganic solvent

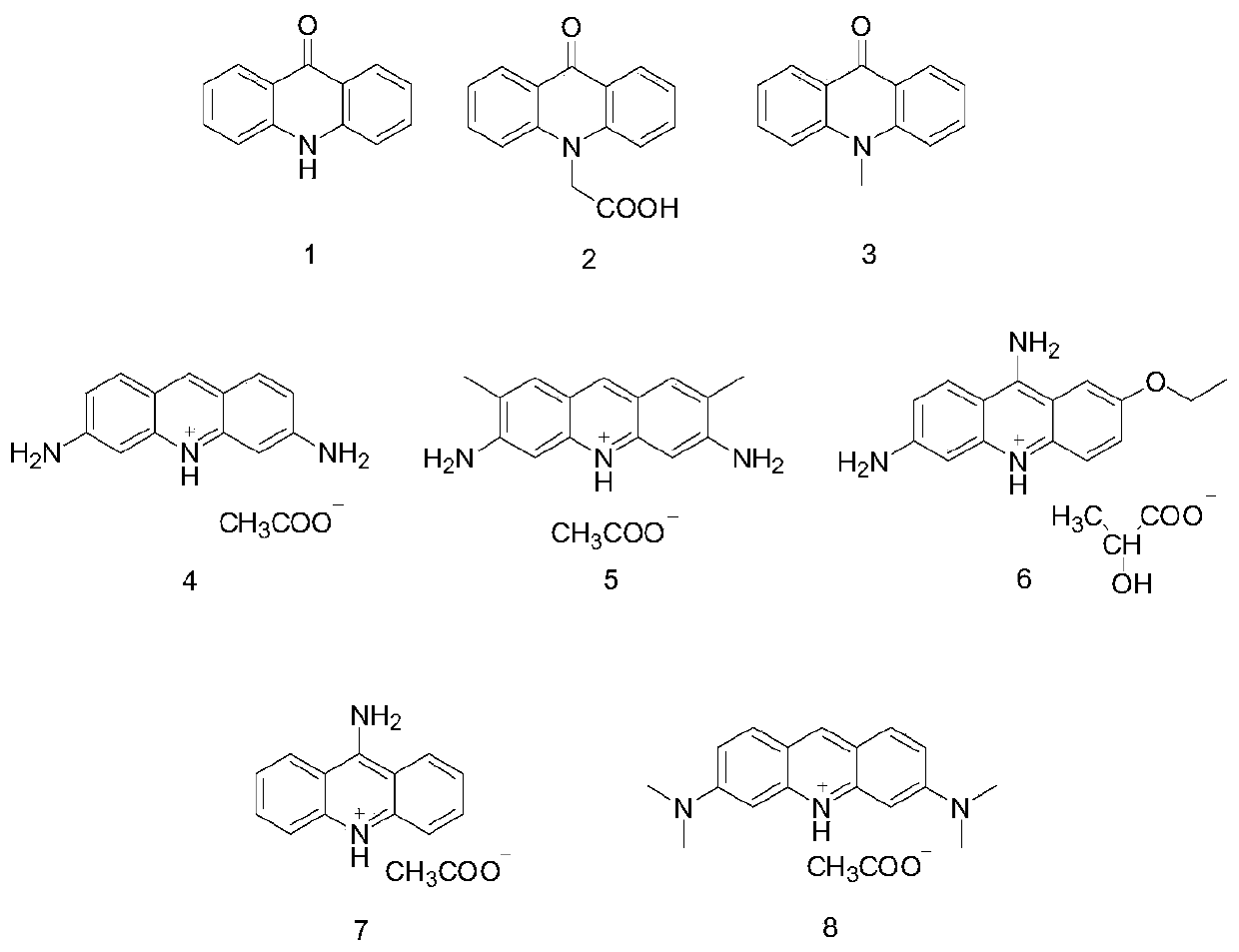

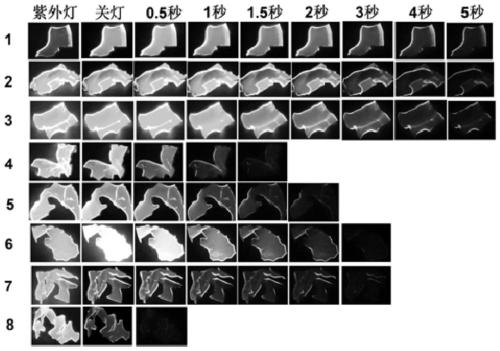

The invention discloses a halogen-free and heavy-atom-free room-temperature phosphorescent material as well as a preparation method and application thereof. A room-temperature phosphorescent reactionmaterial is compounded with a polymer to obtain a pure organic polymer material with a long-life room-temperature phosphorescent light-emitting characteristic; wherein the room-temperature phosphorescent reaction material is selected from one or more of acridine and derivatives thereof, acridinium salt and derivatives thereof, or acridone and derivatives thereof. The halogen-free and heavy-atom-free room-temperature phosphorescent material has a very strong luminescence property, a long luminescence service life and a wide color adjustable range at a room temperature; the raw materials are simple and easily available, and the preparation method is simple, quick, low in cost and suitable for industrial preparation and has a high actual application and popularization value. No metal elementor toxic halogen element exists, only water is used as a solvent in the whole processing process, no organic solvent is used, and the method has obvious advantages in the aspect of environmental protection.

Owner:SUN YAT SEN UNIV

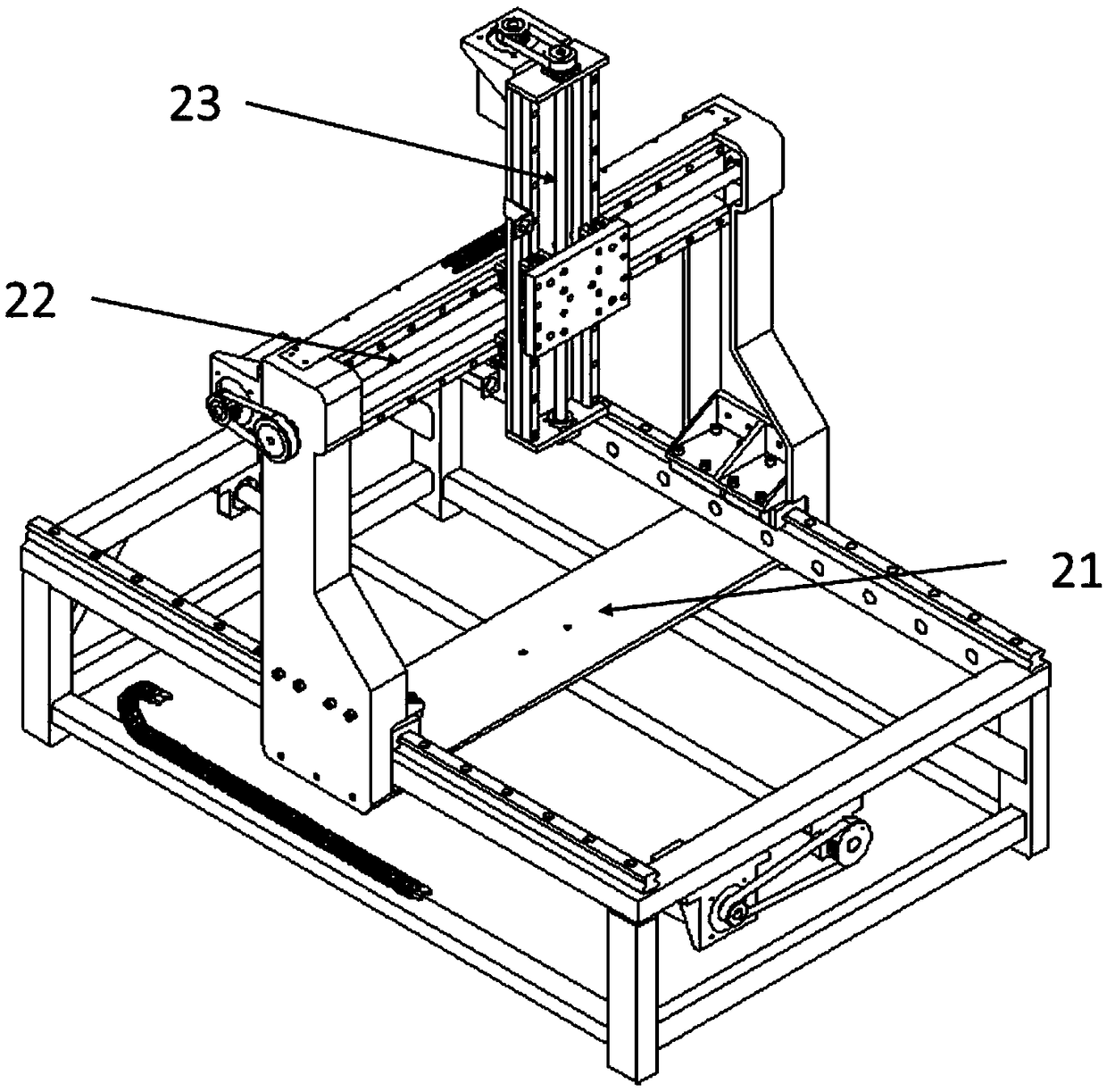

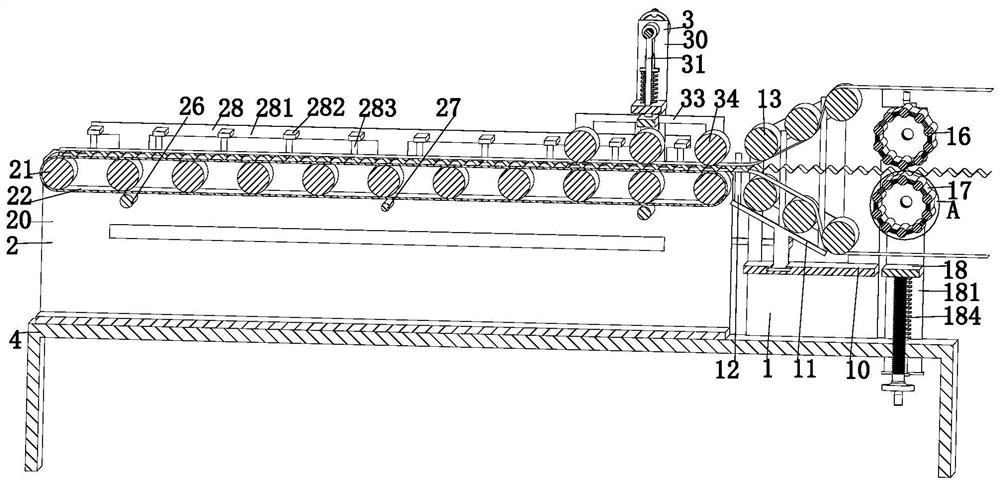

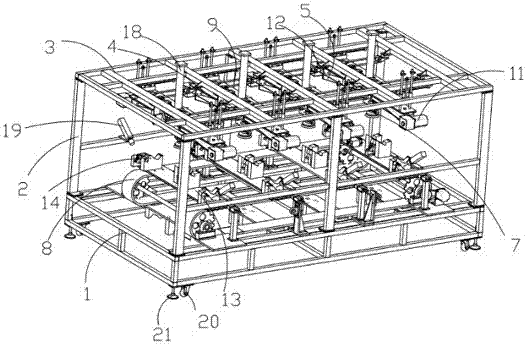

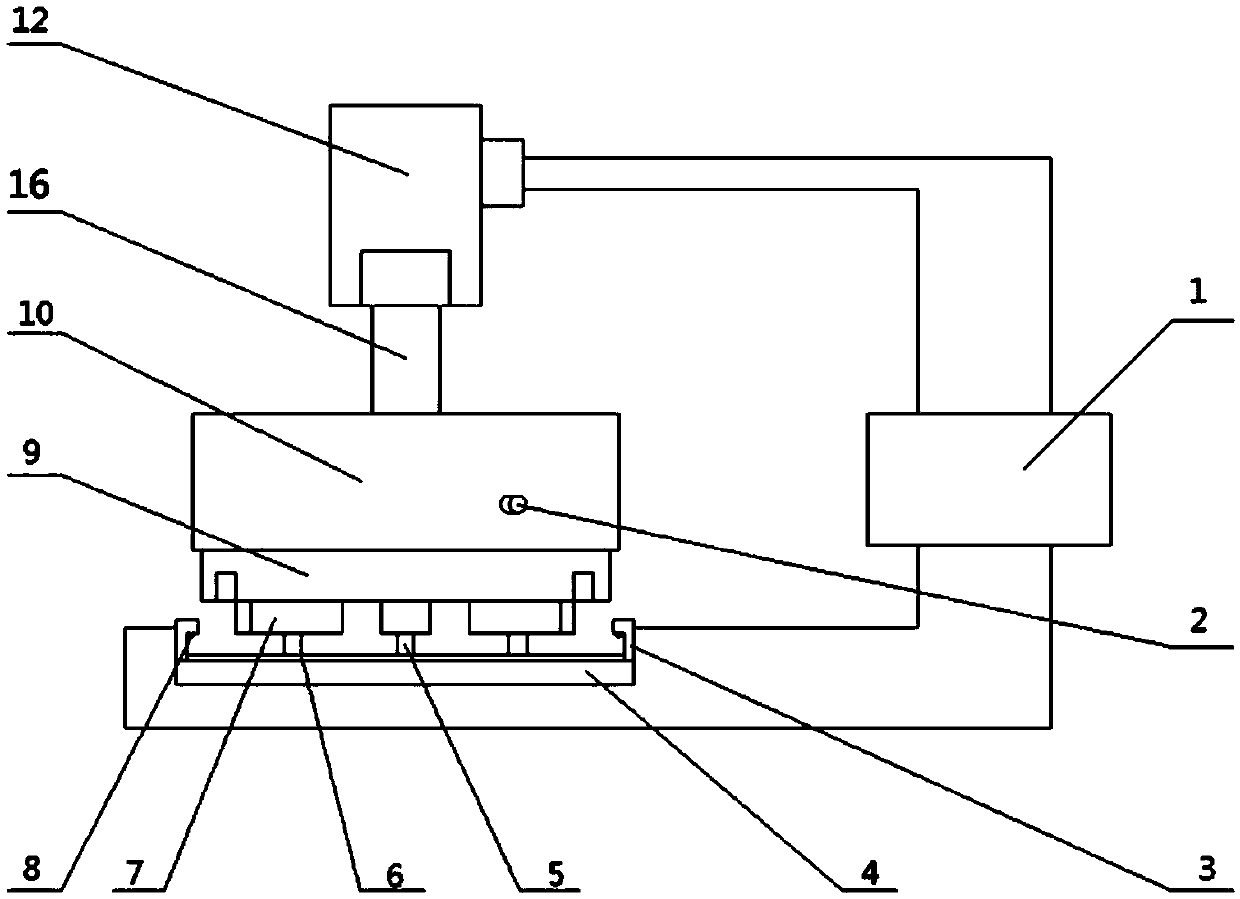

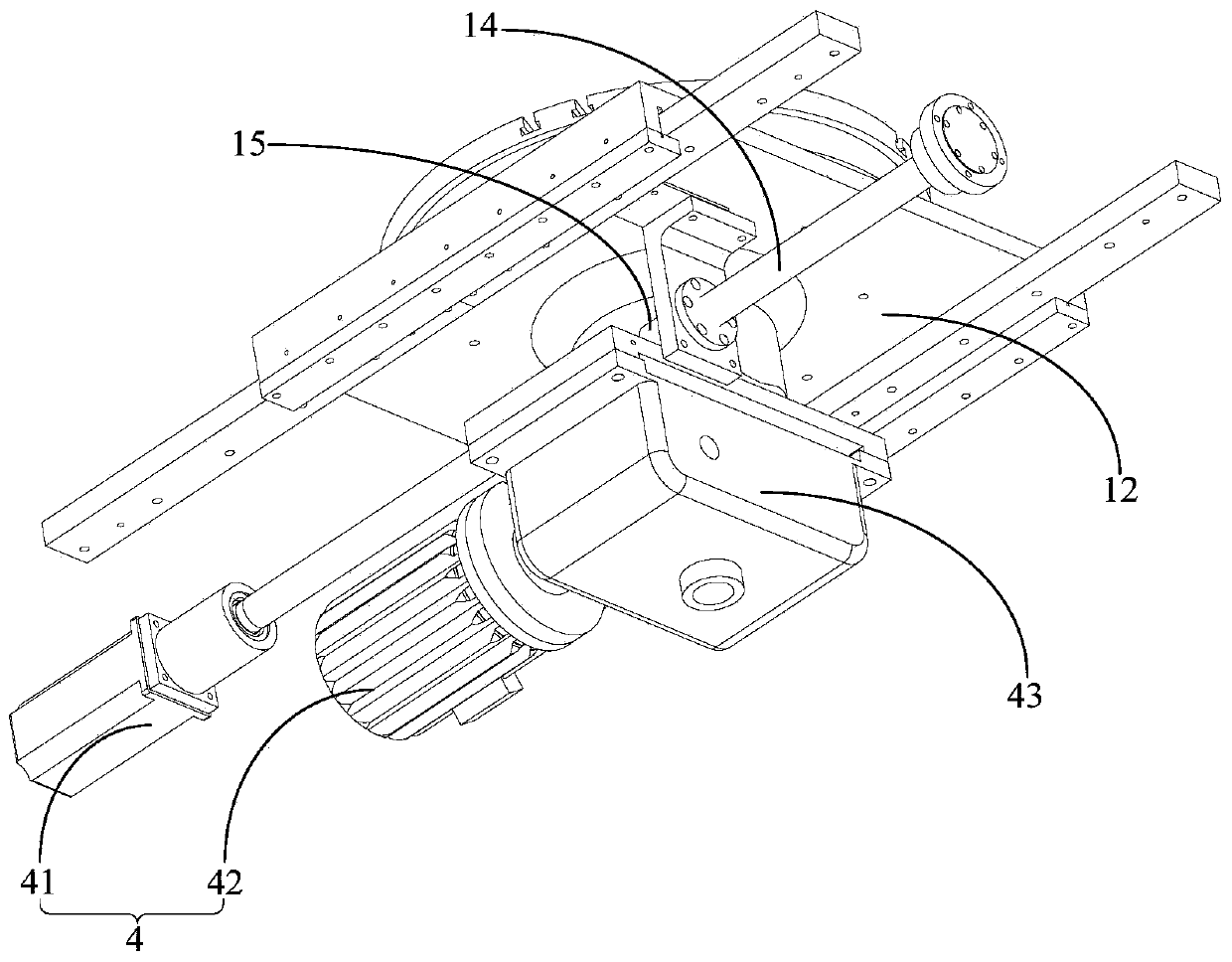

Desktop type cement-based material 3D printer

InactiveCN109500977AAchieve high-precision printingMove preciselyAdditive manufacturing apparatusFeeding arrangmentsControl systemRectangular coordinates

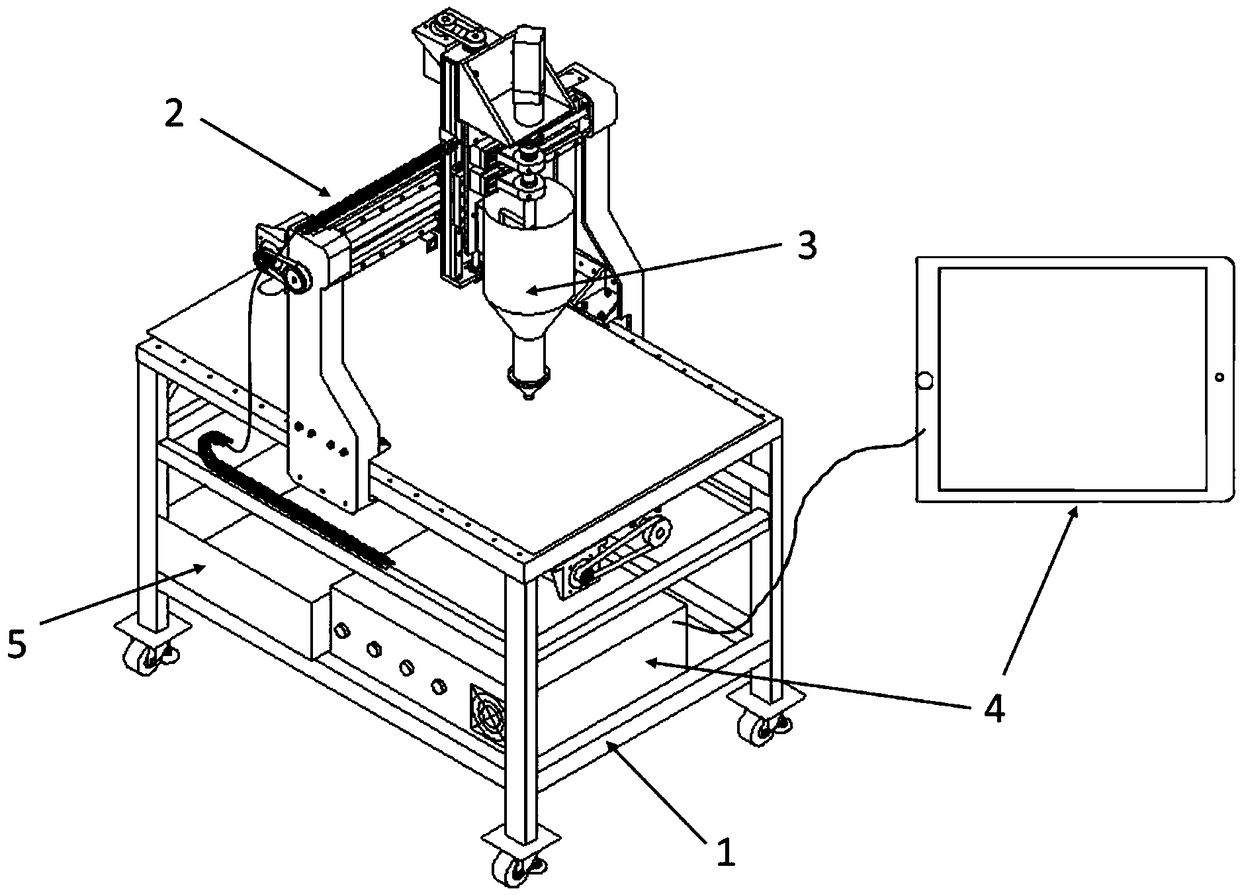

The invention discloses a desktop type cement-based material 3D printer which comprises a main framework, a moving system, an extrusion system and a control system. The moving system comprises an x-axis moving mechanism, a y-axis moving mechanism and a z-axis moving mechanism, the x-axis moving mechanism is installed on the main framework, the y-axis moving mechanism is installed on the x-axis moving mechanism, the z-axis moving mechanism is installed on the y-axis moving mechanism, the extrusion system is installed on the z-axis moving mechanism, and the control system is installed on the main framework. According to the printer, based on the Cartesian spatial rectangular coordinate system principle, a single printing spray head is adopted and cooperated with the x-axis moving mechanism,the y-axis moving mechanism and the z-axis moving mechanism, precise and stable space movement of the printing spray head can be achieved, high-precision printing and rapid printing of a printing model are achieved, and the printer has the good application prospect in the aspects of cement-based material performance research, accessorial building model manufacturing and the like.

Owner:HEBEI UNIV OF TECH

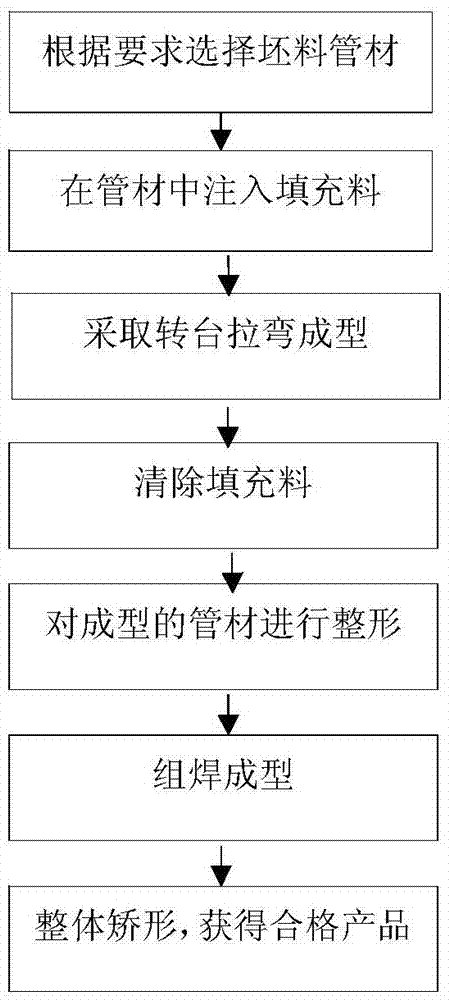

Method for machining metal pipe with tapered elbow

The invention belongs to the field of material machining, particularly relating to a method for machining a metal pipe with a tapered elbow. The method is characterized by comprising the following specific steps: selecting a metal pipe of which the cross section shape and wall thickness meet requirements of the final cross section shape and wall thickness of a part as a blank pipe at first, wherein the metal pipe is not curved obviously; injecting molten filling materials in the blank pipe and then tightly sealing two ends of the blank pipe; carry out stretch bending and molding by using a rotary table; inserting the blank pipe in a mold and then integrally pressing the mold and the blank pipe on a mold base to carry out stretch bending; removing the filling materials in the product; correcting the inner diameter of the product subjected to stretch bending on a prepared standard fixture; carrying out welding molding on a prefabricated welding fixture; and finally integrally correcting the obtained workpiece. The method is simple in production technology, low in cost and high in yield; the overall machined alloy pipe has relatively high strength and plasticity, has a bright surface, is good in using performance, and is suitable for being used in situations with relatively high requirements on integral performance of pipes.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

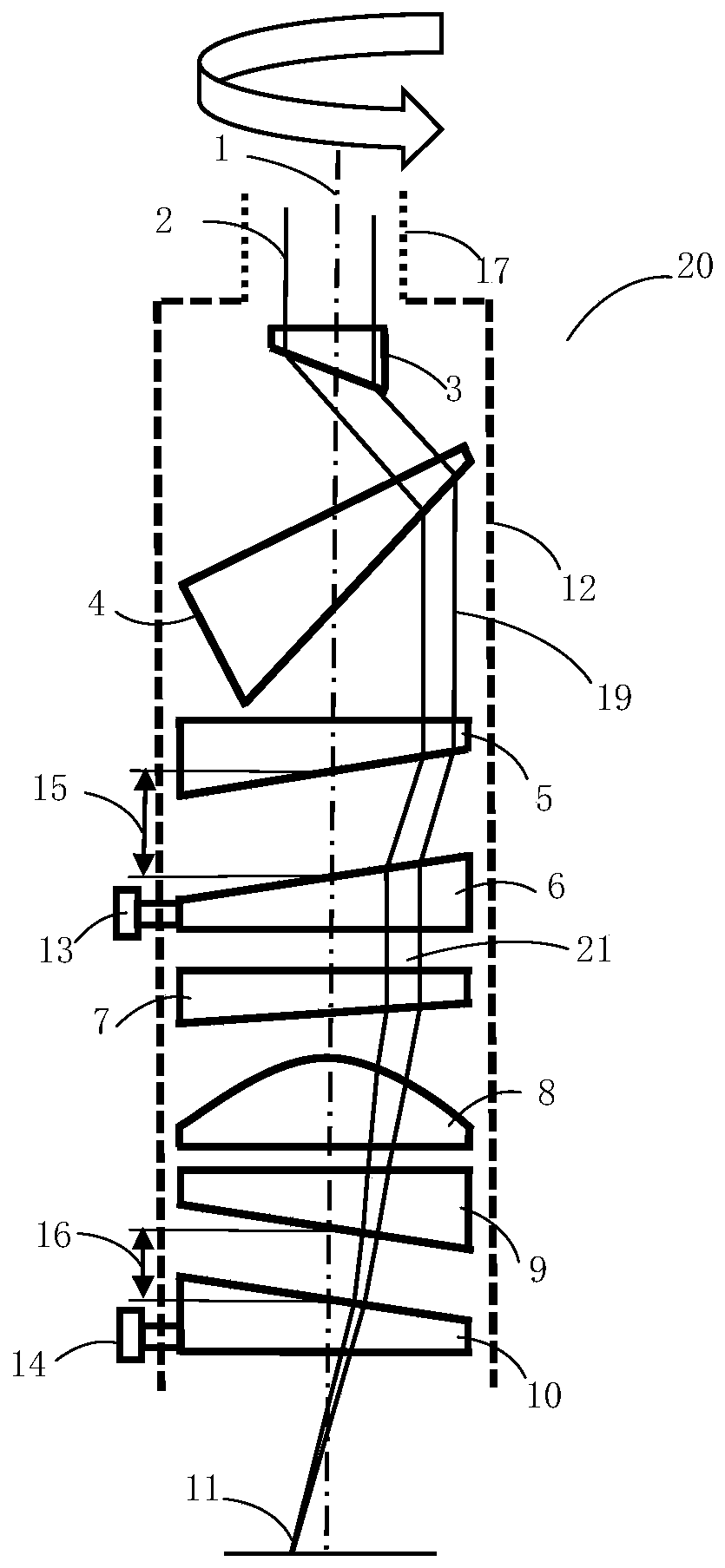

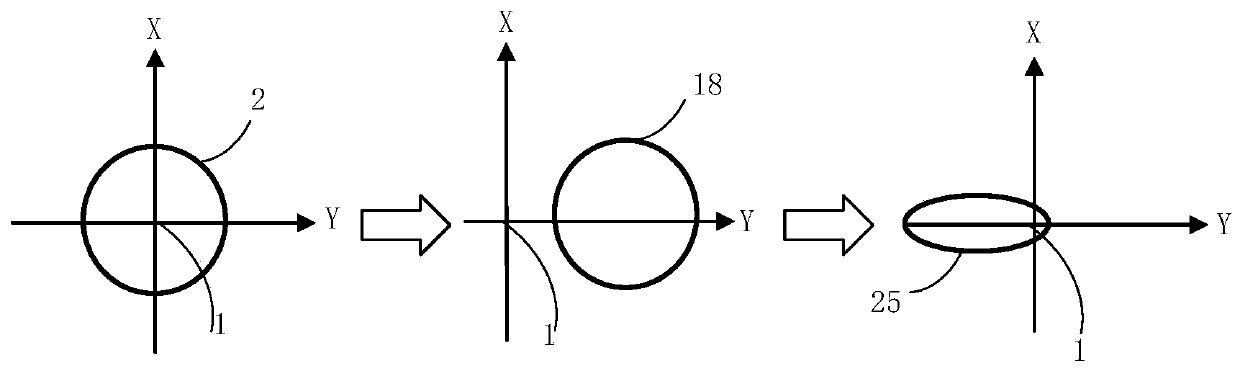

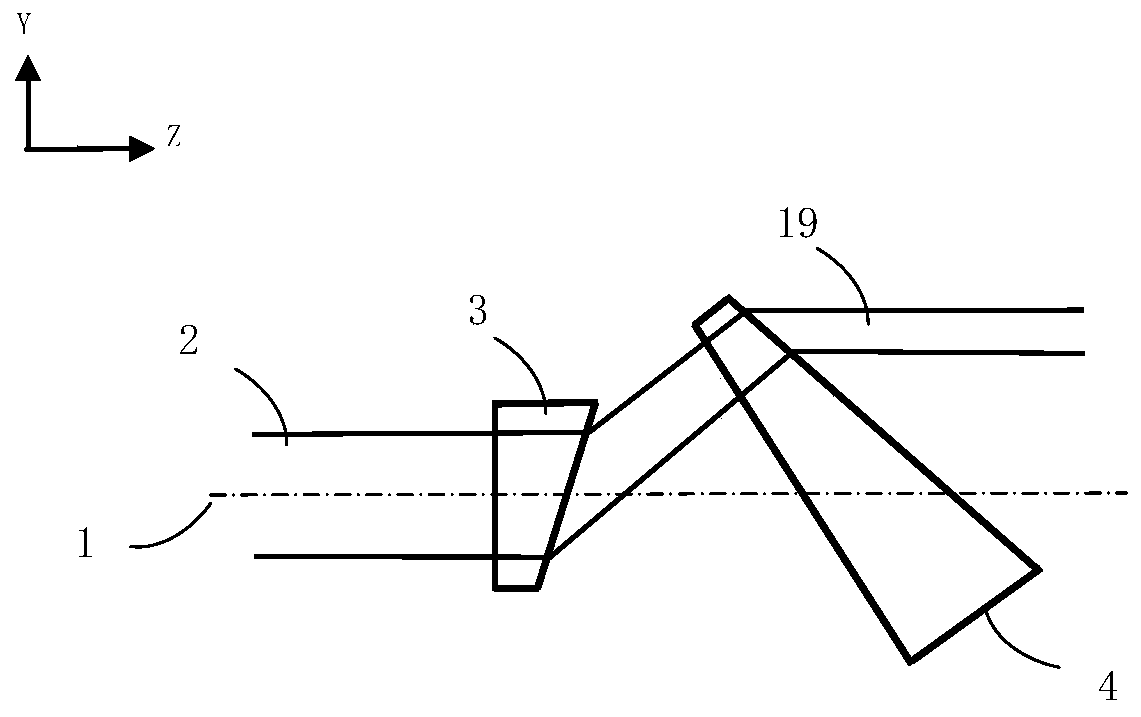

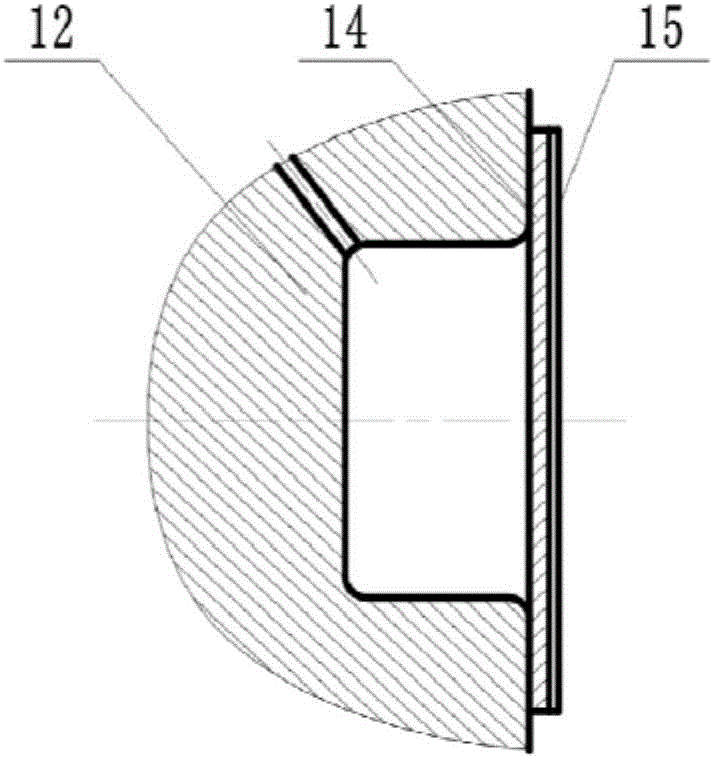

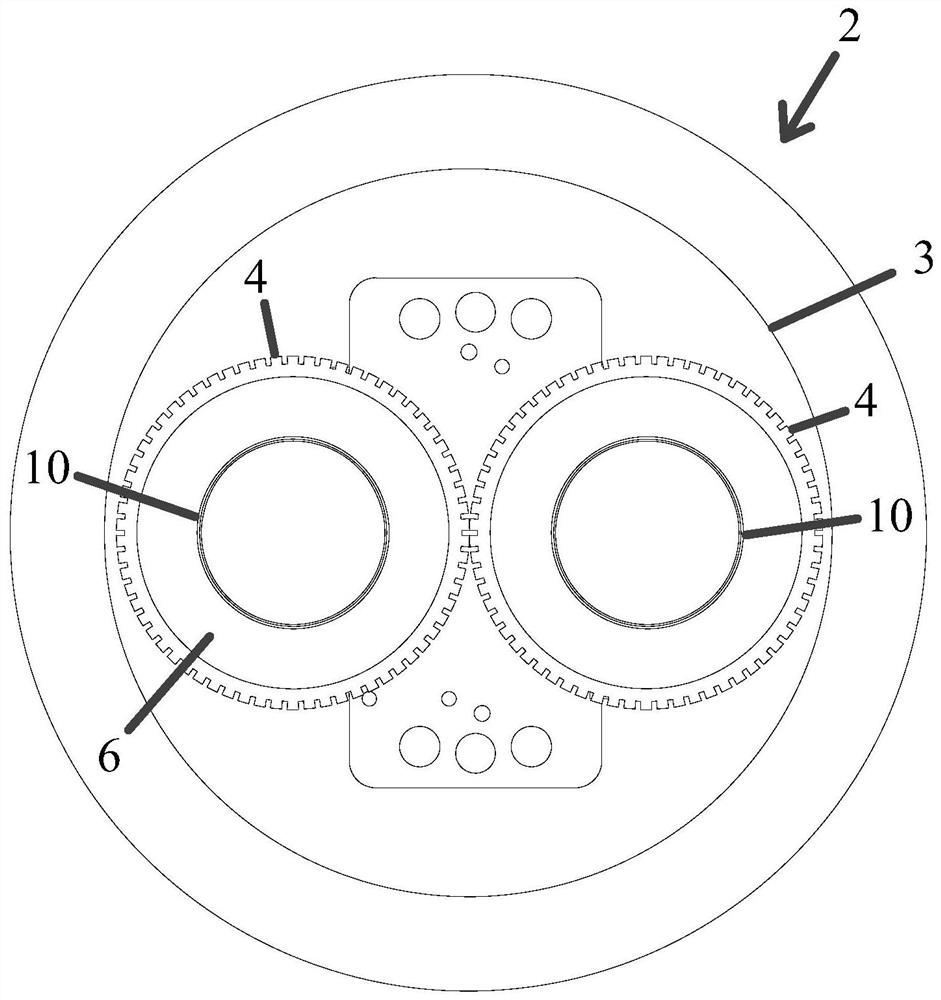

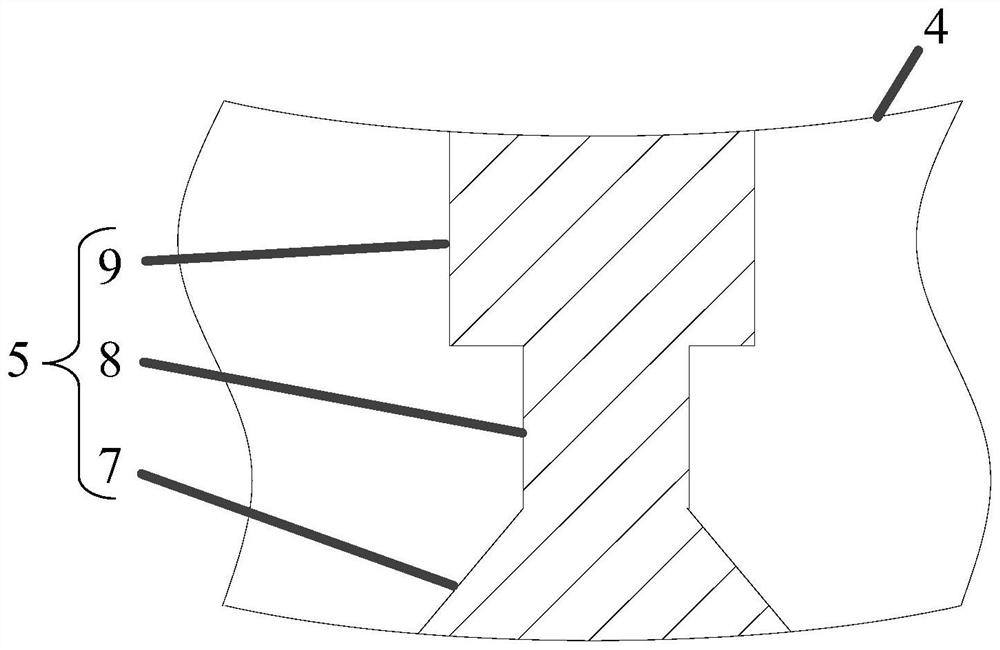

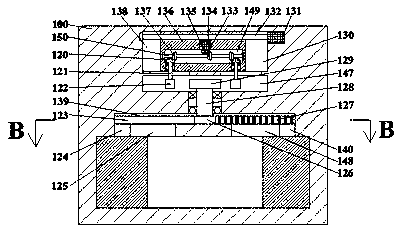

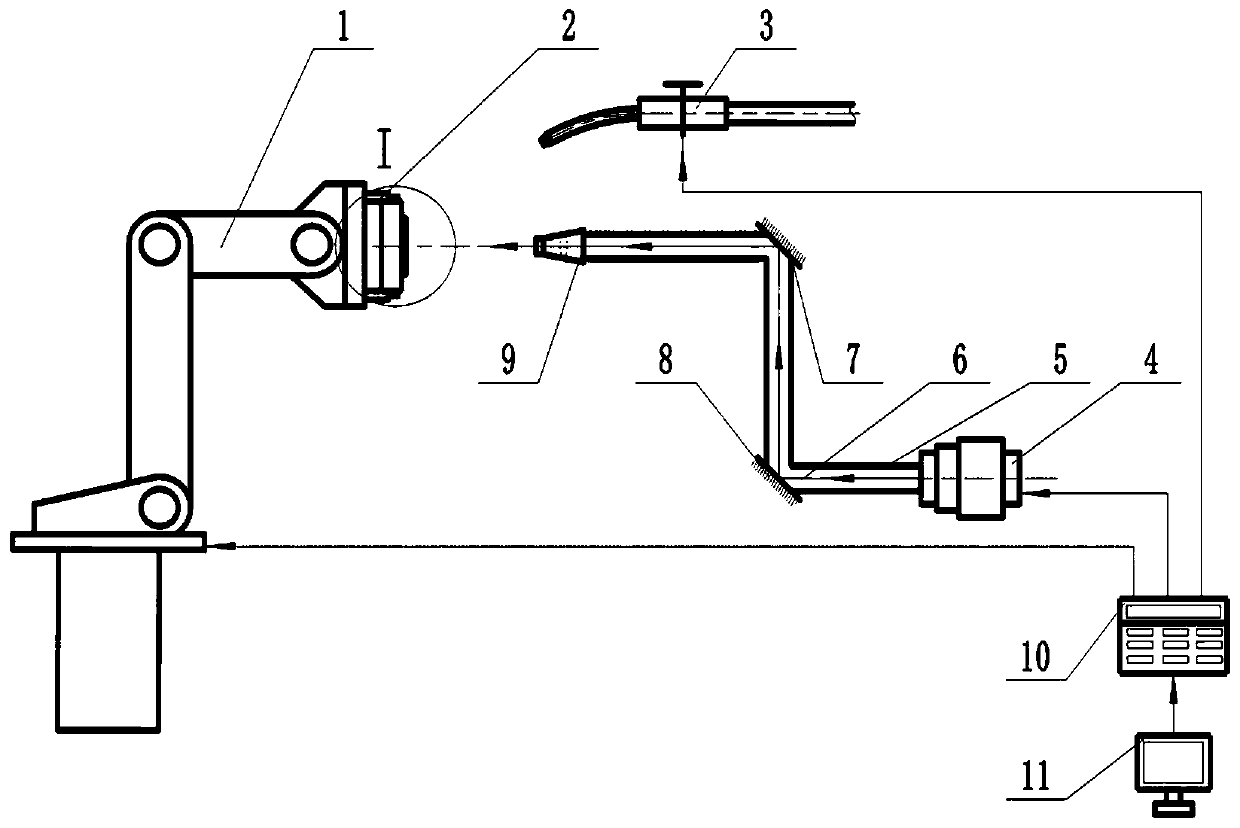

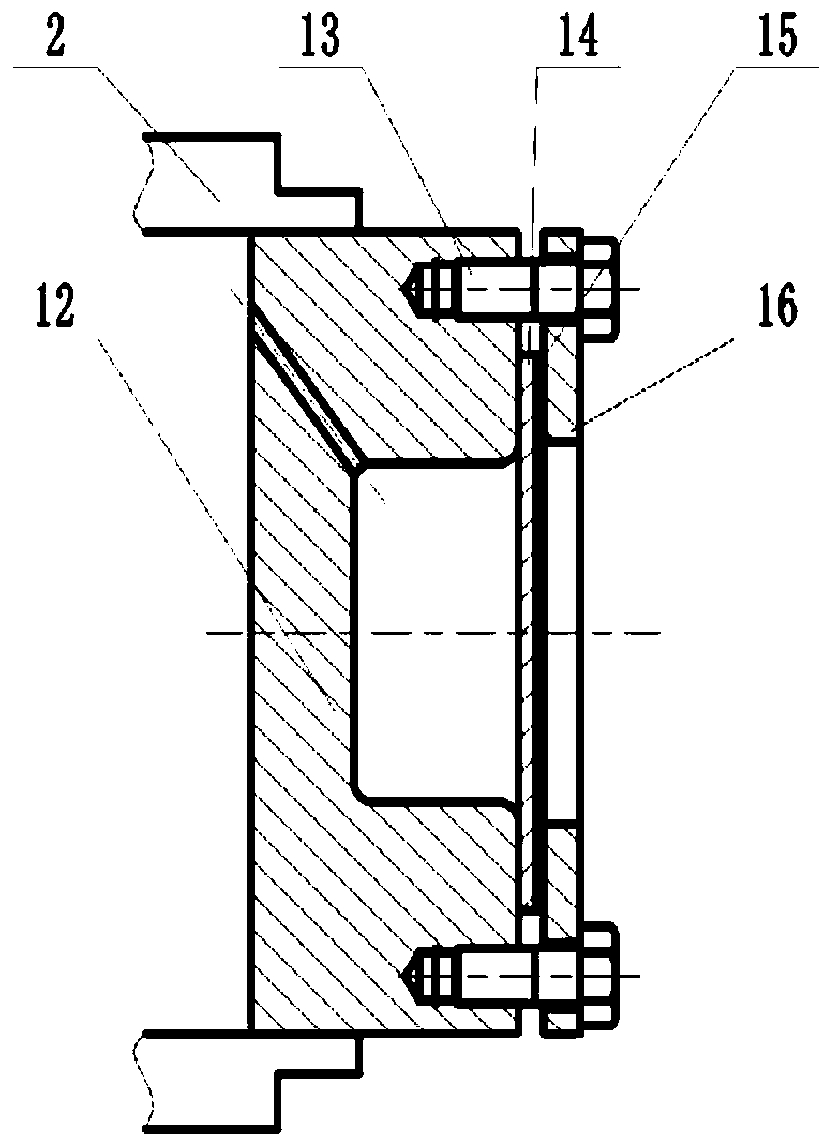

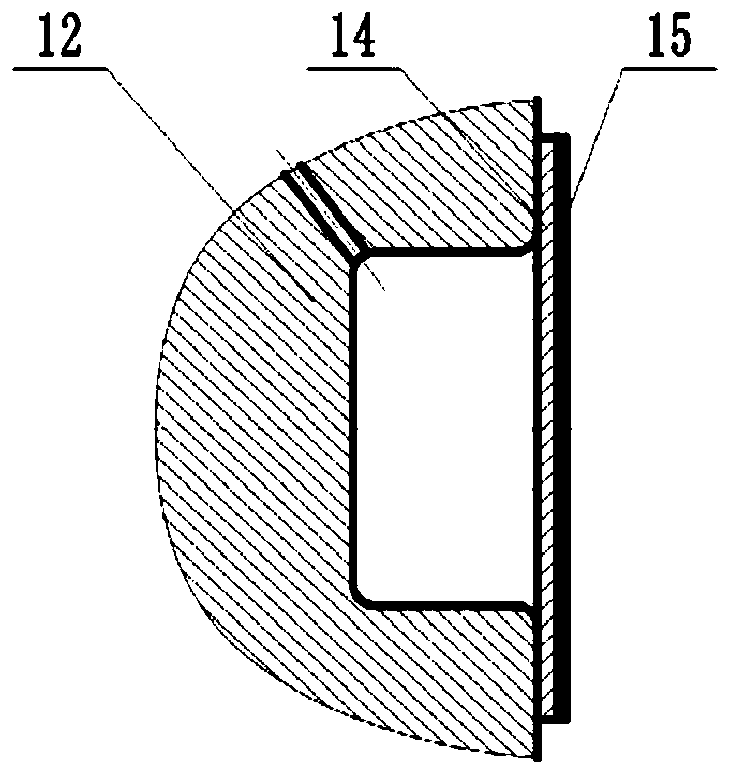

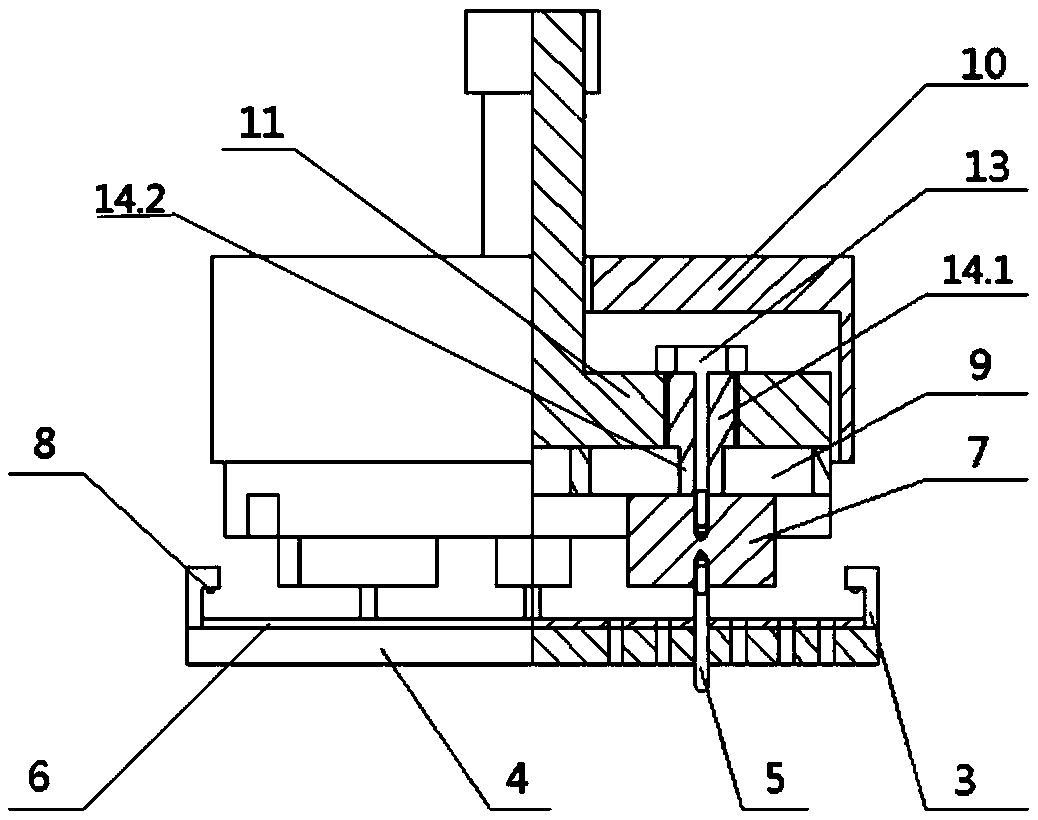

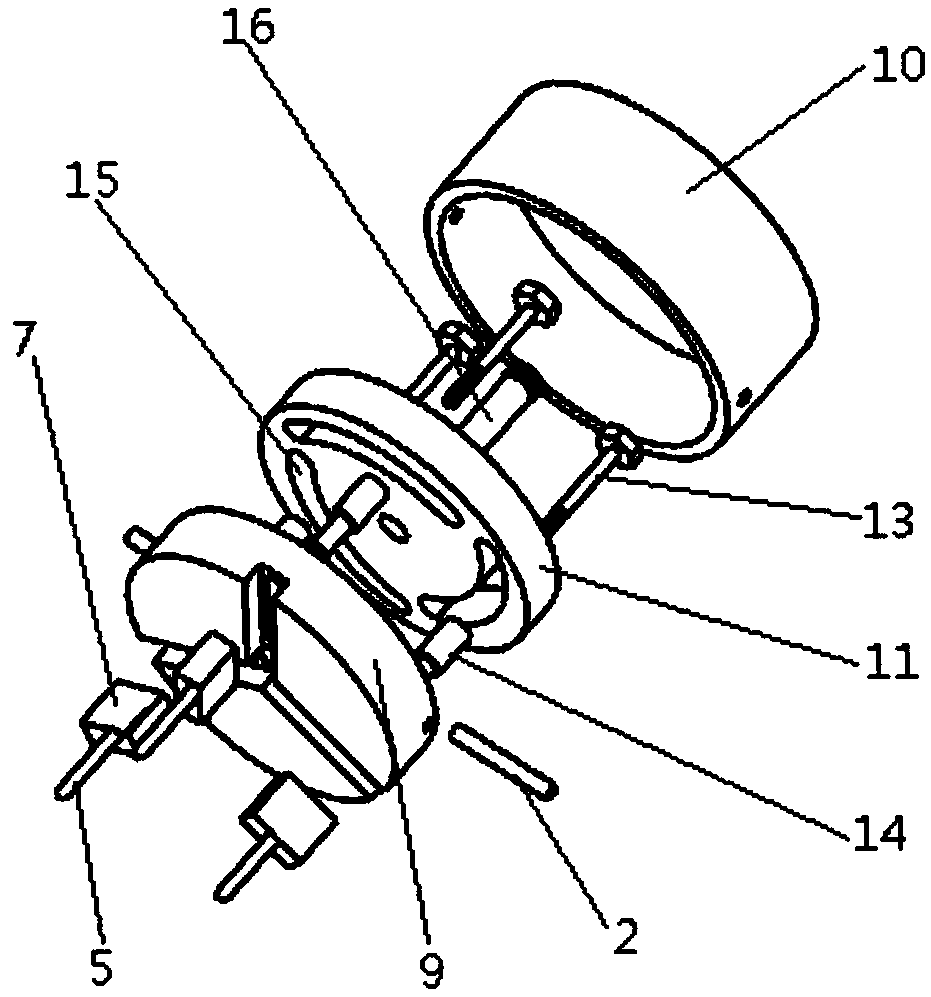

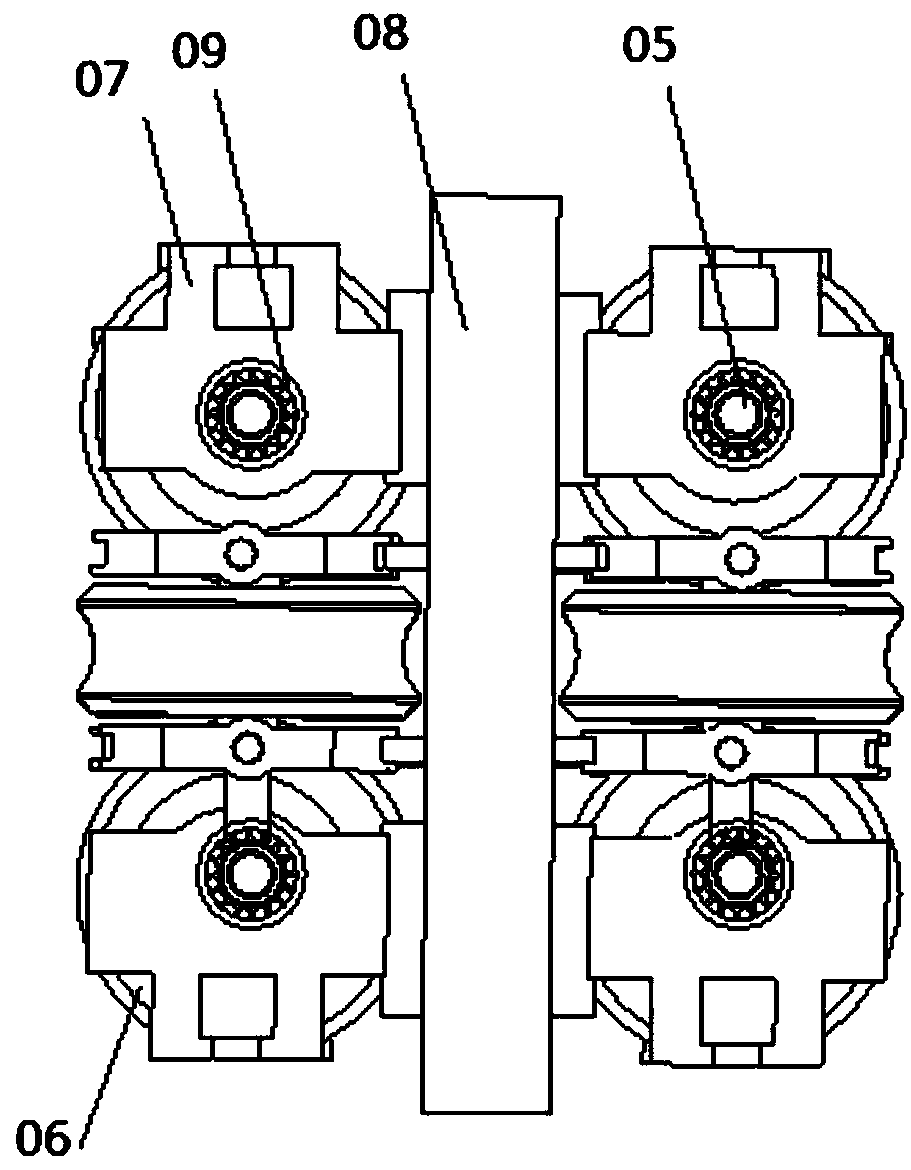

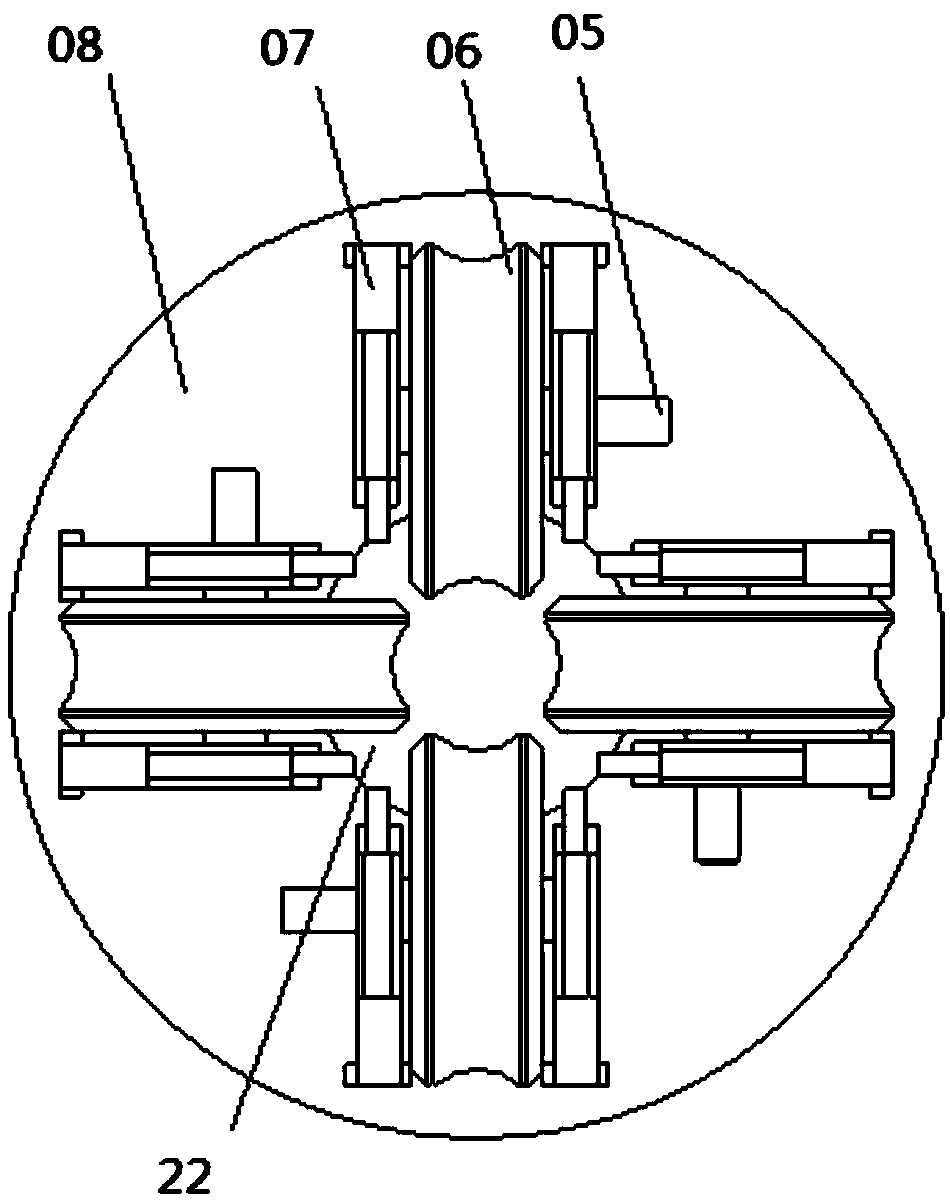

Laser variable-taper variable-diameter rotary cut hole machining optical system

ActiveCN110449731AAchieve independent regulationRealize processing and formingLaser beam welding apparatusWedge angleOptical axis

The invention belongs to the field of optical design and discloses a laser variable-taper variable-diameter rotary cut hole machining optical system. The system is provided with a rotary shaft and comprises the following optical components which are arranged in sequence along a light path and include a laser light beam one-way compression assembly, a first wedge-shaped lens set, a single-lens wedge-shaped lens (7), a focus lens (8) and a second wedge-shaped lens set, wherein the first wedge-shaped lens set is composed of two wedge-shaped lenses which are the same in wedge angle and is used foradjusting the offset of laser light beams; the single-lens wedge-shaped lens is used for inducing the laser inclination angle; and the second wedge-shaped lens set is composed of two wedge-shaped lenses which are the same in wedge angle and is used for adjusting the offset of focused light spot. By modifying composition of all the components and cooperative work modes among all the components, the laser inclination angle and the offset from the laser focal point to an optical axis can be independently adjusted in a large range, then the required hole diameter and taper proportioning can be achieved, focused light spot distortion caused by coma after laser focused light spot leaves the optical axis and inclines can be compensated, and the laser variable-taper variable-diameter rotary cut hole machining process which is good in machining effect is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

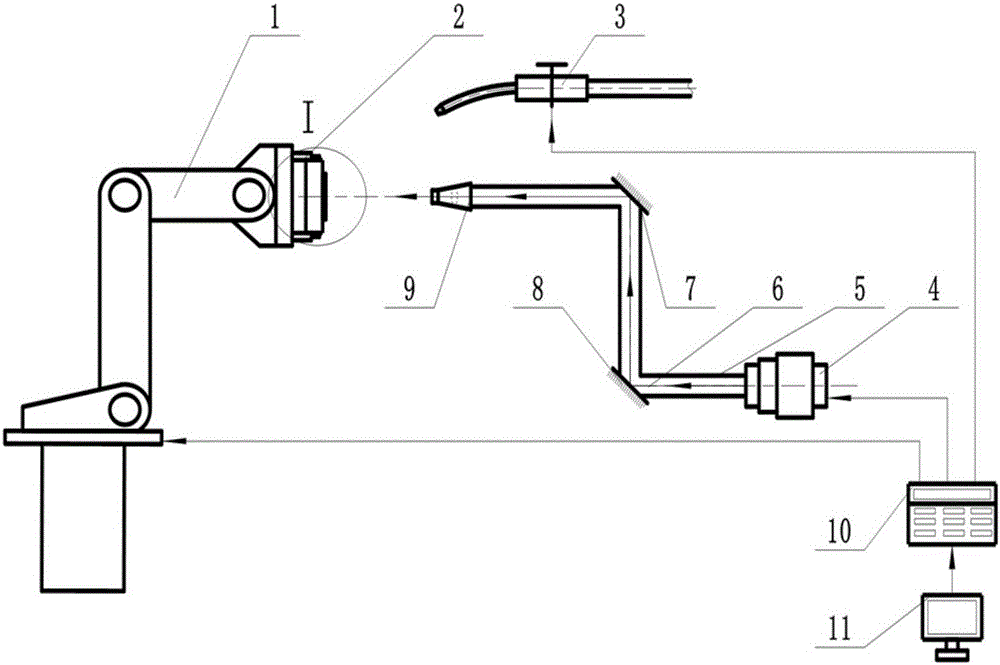

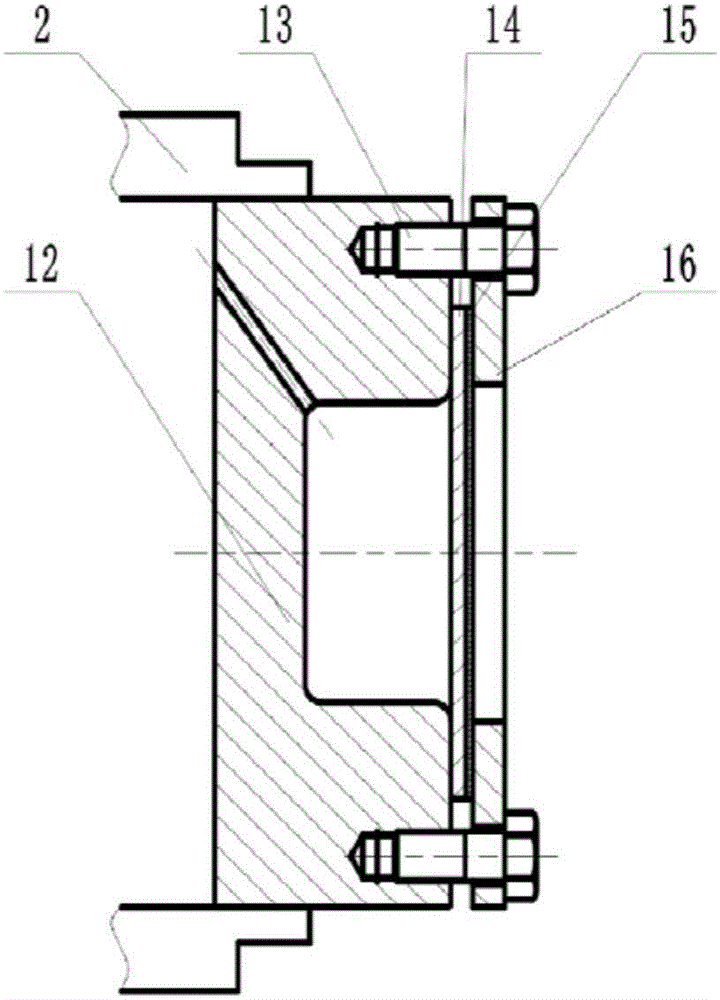

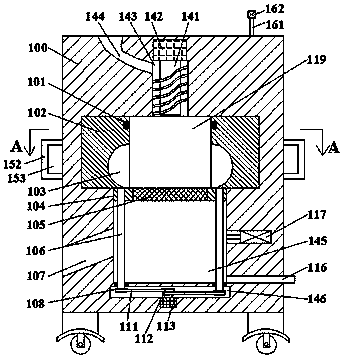

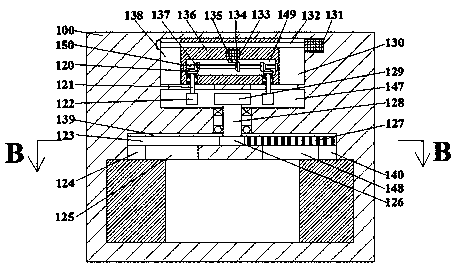

Laser shock forming method and device for straight-wall cylindrical part

The invention discloses a laser shock forming method and device for a straight-wall cylindrical part, and belongs to the field of plastic processing of near-net forming of metal parts. The method adopts a laser shock technology to carry out two-step forming on a thin plate so as to obtain a high-precision formed part and comprises the two steps that firstly, a laser with high pulse energy is used for inducing shock waves with high pressure to carry out impact on the thin plate so that the thin plate can be subjected to primary integral forming, but in the forming process, the thin plate is attached to the side wall of a die, in addition, the thin plate with extremely high deformation speed further collides with the bottom of a die cavity fiercely so that the bottom of the primary formed part can generate local reverse plastic deformation, and therefore the forming precision can be reduced; and secondly, a laser with low pulse energy is used for inducing shock waves with lower pressure to carry out impact on a reverse plastic deformation area at the bottom of the primary formed part so as to eliminate the reverse plastic deformation at the bottom of the primary formed part in the first step, and correction setting is carried out on the primary formed part so that the forming precision of the straight-wall cylindrical part can be greatly improved. According to the method, the laser shock forming precision of the thin plate can be greatly improved, and the method has wide practicability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

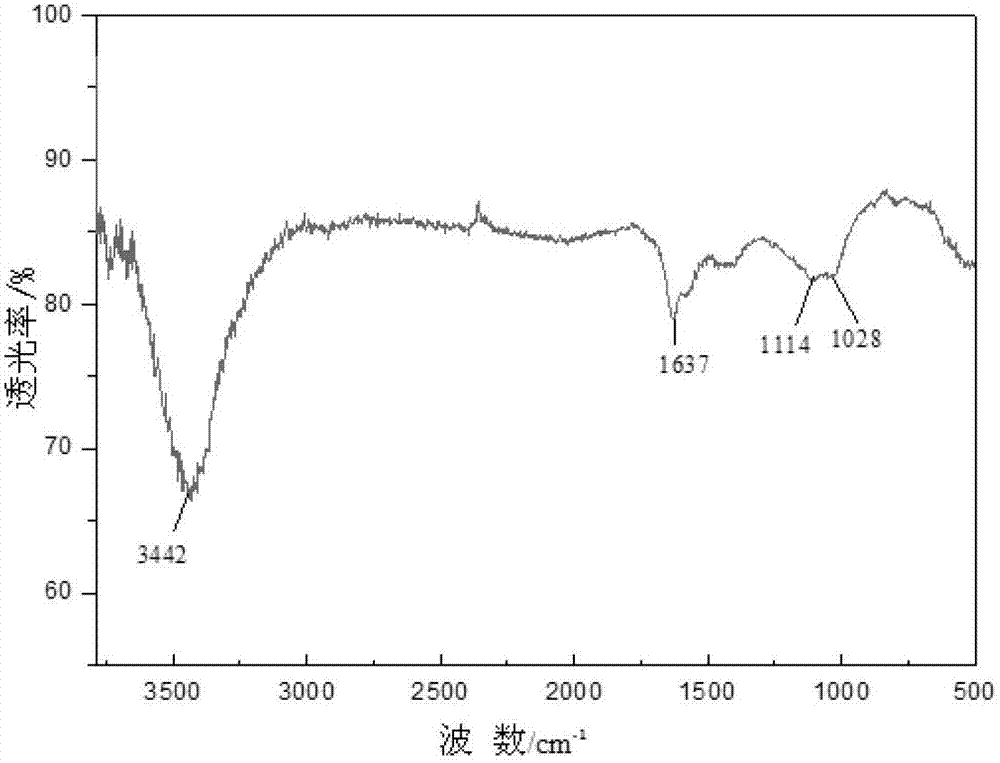

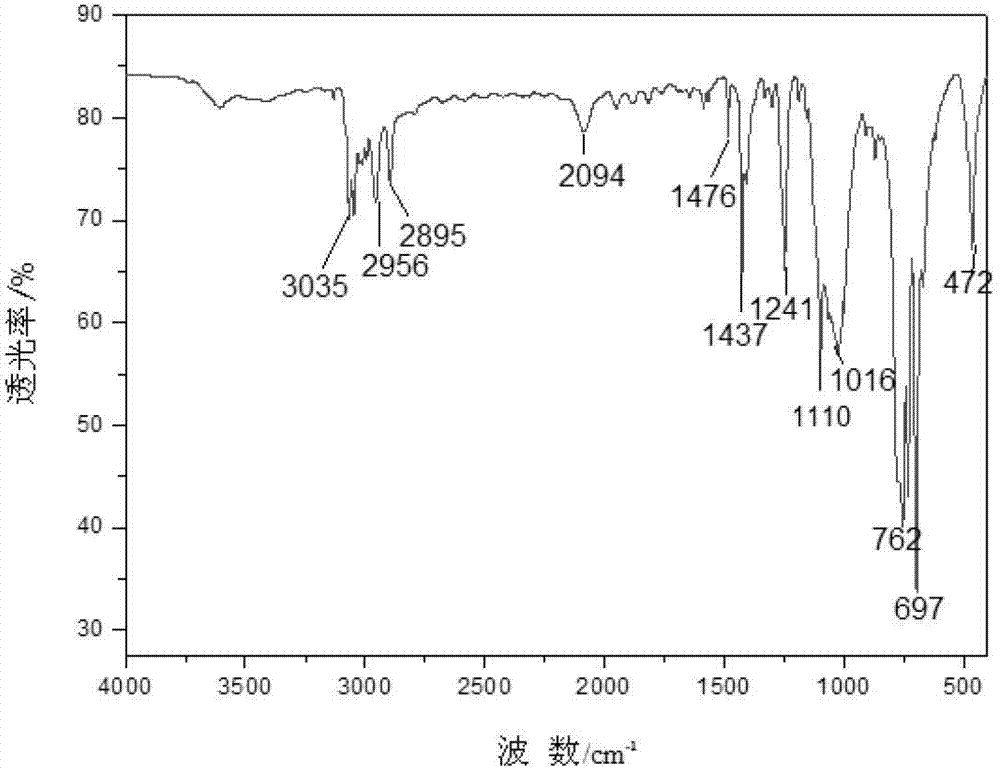

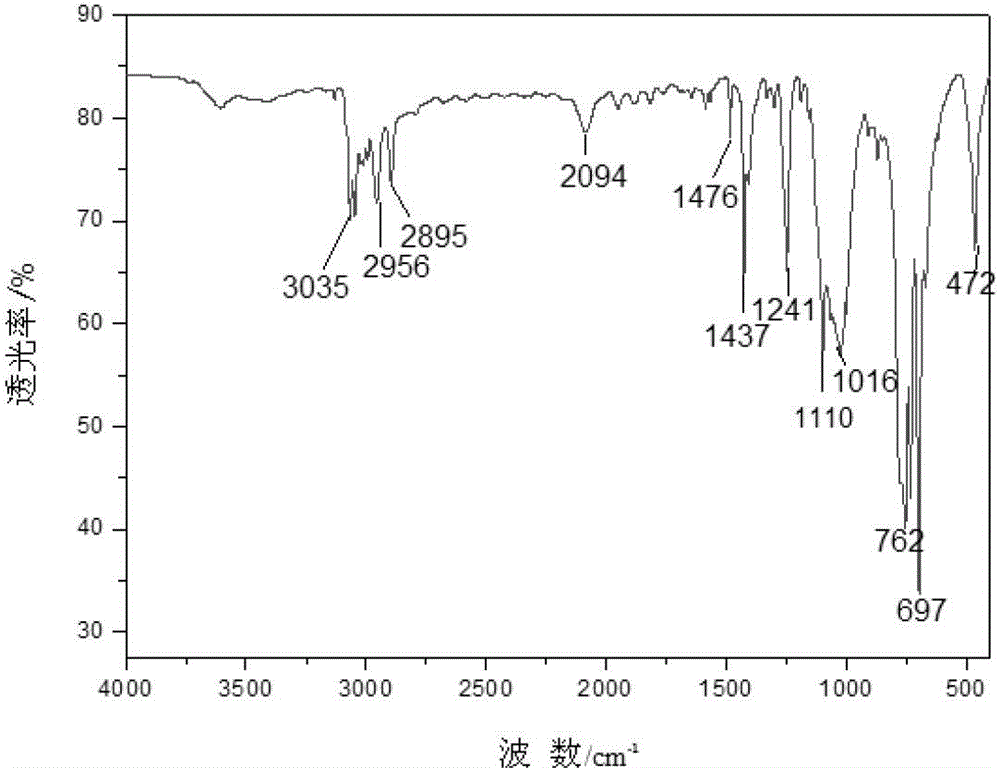

Polysilane azide-multiwalled carbon nanotube composite material and preparation method thereof

The invention discloses a polysilane azide-multiwalled carbon nanotube composite material and a preparation method thereof, and relates to a polysilane-multiwalled carbon nanotube composite material and a preparation method thereof, aiming at solving the problems that the existing preparation method of polysilane-multiwalled carbon nanotube composite material is complicated in preparation process and the completeness of the multi-walled carbon nanotube is damaged. The polysilane azide-multiwalled carbon nanotube composite material is prepared from an acid solution, an organic solvent, polysilane azide and a multiwalled carbon nanotube. The preparation method comprises the following steps of: (I) calcining; (II) purifying and (III) carrying out azidation to obtain the polysilane azide-multiwalled carbon nanotube composite material. The preparation method disclosed by the invention is mainly used for preparing the polysilane azide-multiwalled carbon nanotube composite material.

Owner:HARBIN UNIV OF SCI & TECH

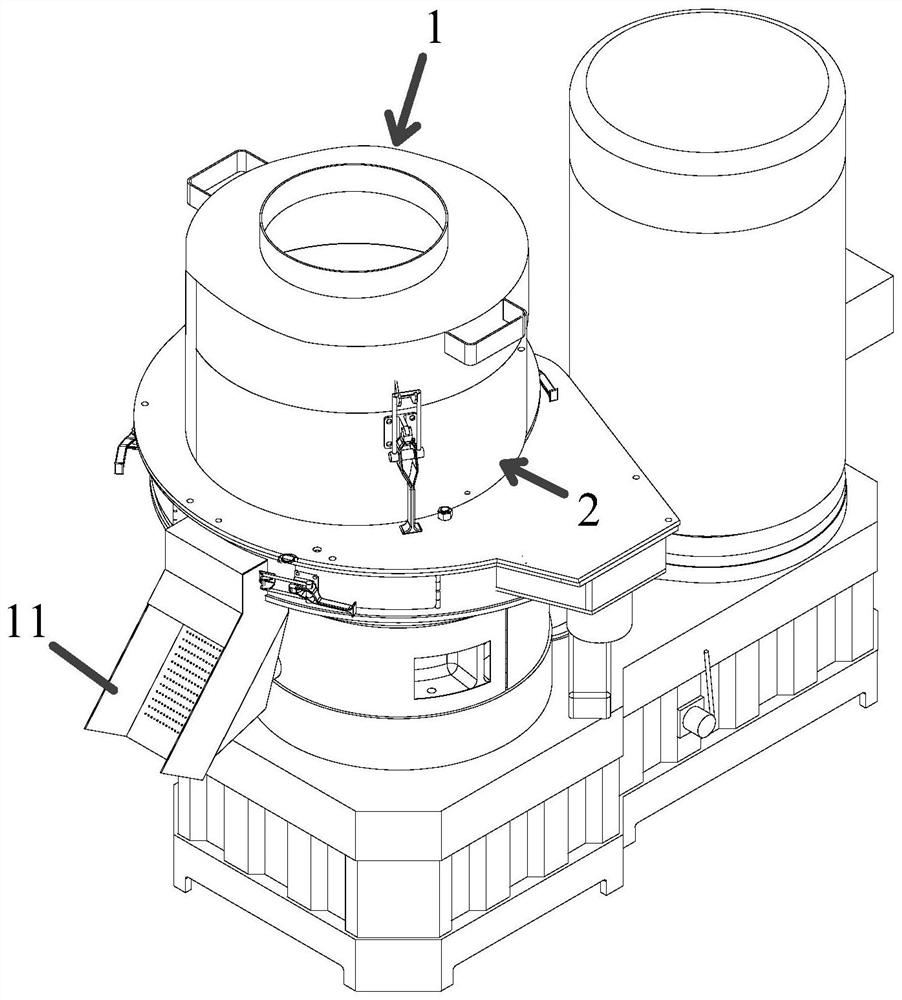

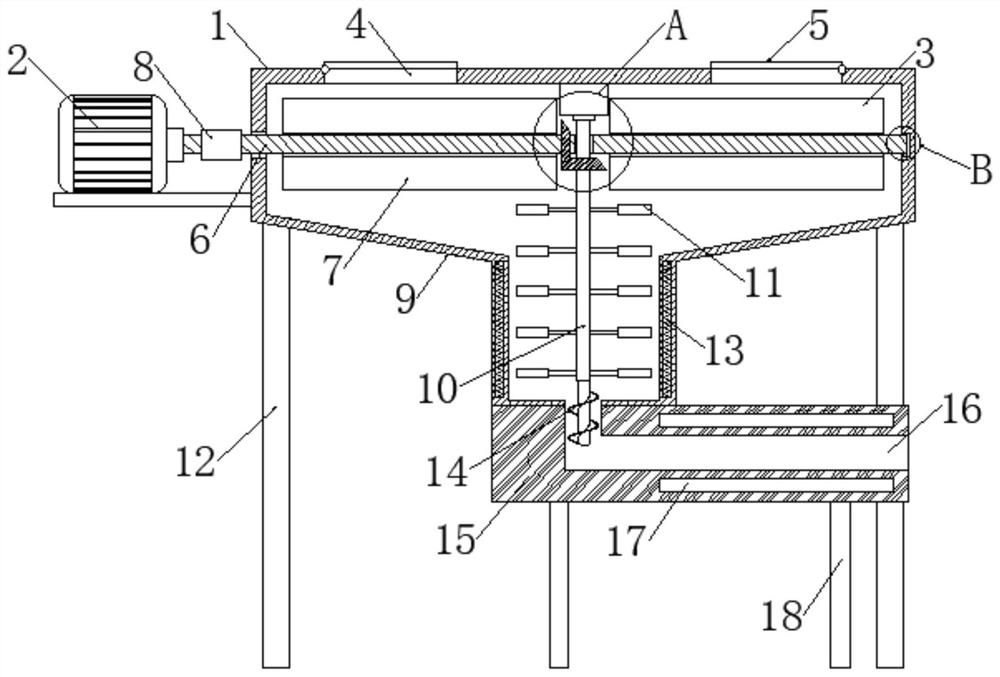

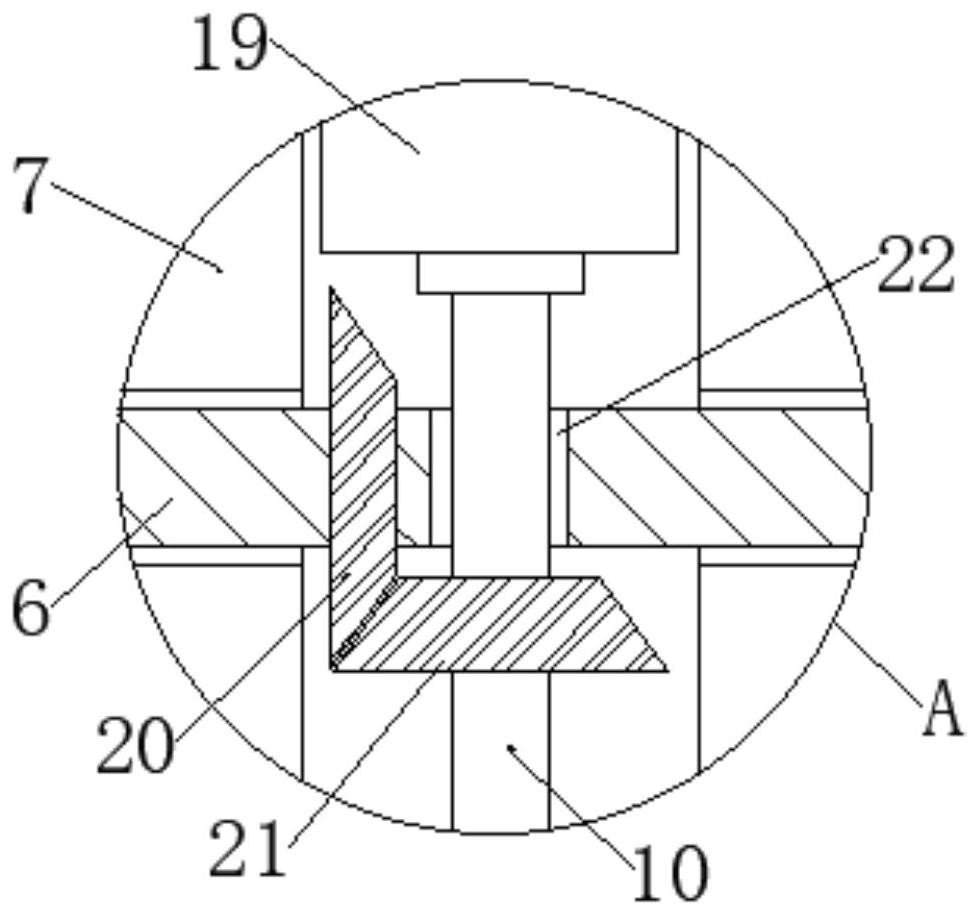

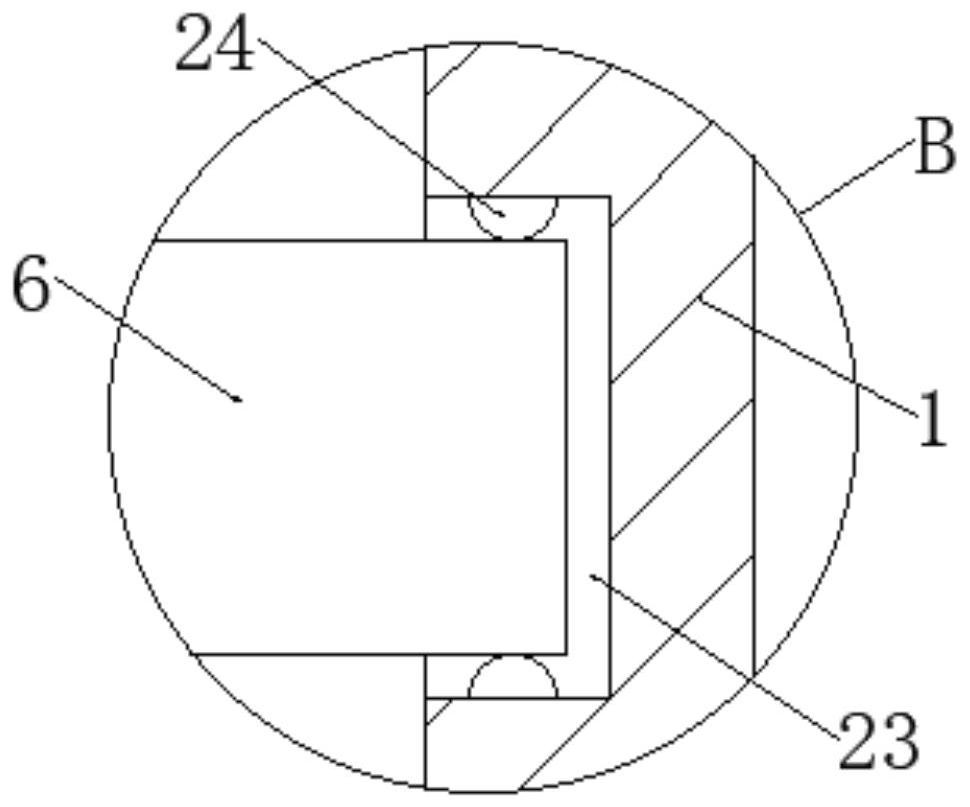

Oppositely-rolling granulator for organic fertilizer

InactiveCN114272847AImprove drying effectIntegrity guaranteedGranulation by material expressionDrying solid materialsMolding machineAgricultural engineering

The invention relates to the technical field of machinery, and provides an opposite-rolling granulator for organic fertilizers, which comprises a feeding mechanism, a granulating mechanism and a granulating mechanism, a forming mechanism; the forming mechanism comprises a forming chamber and pressing rollers which are arranged in the forming chamber and are oppositely arranged; a material forming hole is formed in the edge of the outer contour of the pressing roller, a feeding cavity used for transferring formed materials out of the forming mechanism is formed in the pressing roller, and the material forming hole communicates with the feeding cavity. And a drying mechanism. Through the pressing rollers which are driven to rotate oppositely, materials can be effectively and respectively transferred into the feeding cavities of the two pressing rollers, so that the two heated pressing rollers are used for respectively carrying out extrusion forming work and drying work on the materials. Compared with the prior art with only one working channel for the materials to pass through, the double-roller granulator provided by the invention performs double-channel drying on the materials, so that the organic fertilizer is subjected to double moisture evaporation compared with the prior art, the drying capacity of the granulator is effectively improved, and the integrity of the materials is effectively ensured.

Owner:山东金格瑞机械有限公司

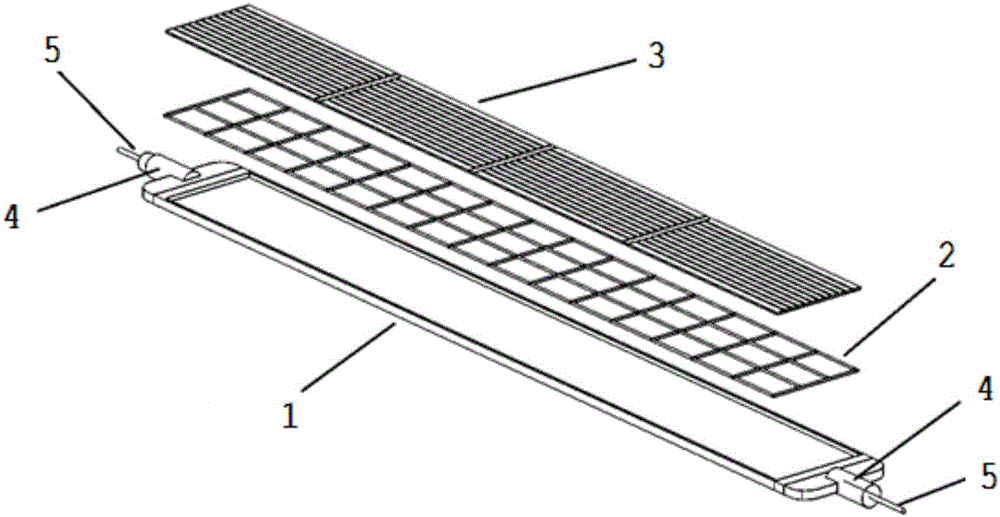

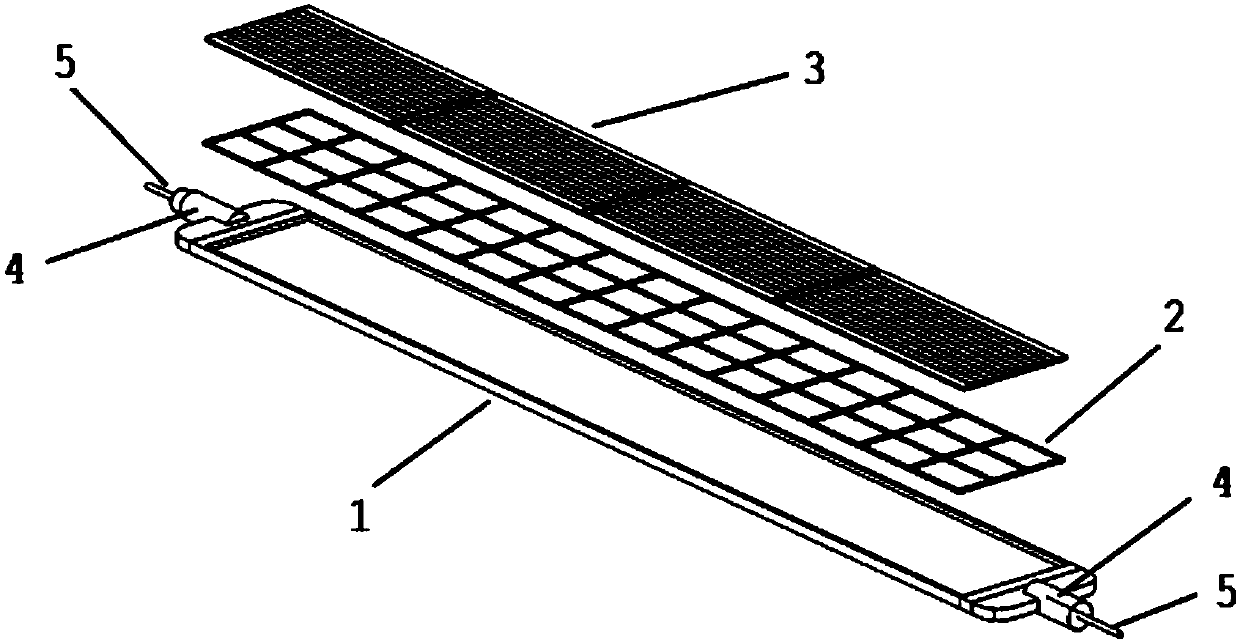

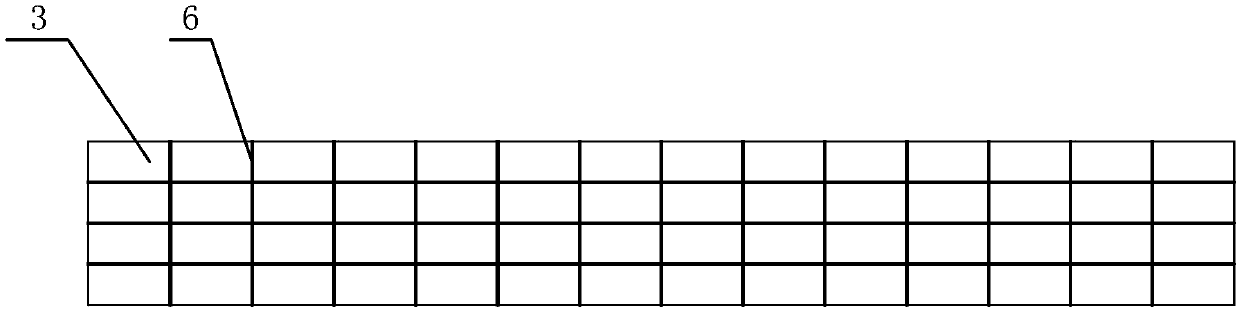

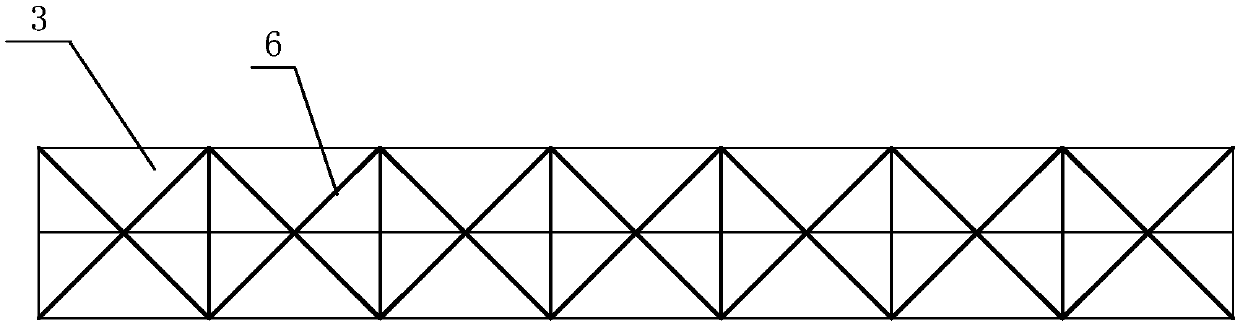

Integrated high-rigidity light photovoltaic cell component and photovoltaic shutter

ActiveCN106252438ARealize processing and formingReduce weightClimate change adaptationPhotovoltaicsWeather resistanceDrive shaft

The invention relates to an integrated high-rigidity light photovoltaic cell component, which comprises photovoltaic blades which are in shutter structure arrangement on the whole, wherein the photovoltaic blades are provided with transmission shafts (4) and bus wires (5); the transmission shafts (4) are used for fixing and rotating the photovoltaic blades; single photovoltaic blade is of a laminated composite structure and comprises a composite a composite plastic layer (1), a prestressed steel wire mesh (2) and a bar photovoltaic cell (3) which are sequentially arranged; the transmission shafts (4) and the bus wires (5) are arranged at two ends of the corresponding bar photovoltaic cells (3); each composite plastic layer (1) is a plastic layer which is integrally molded in an injection manner; and each internal prestressed steel wire mesh (2) is connected with the corresponding bar photovoltaic cell (3). Compared with the prior art, the integrated high-rigidity light photovoltaic cell component has the advantages of being light, high in rigidity, low in warping degree and high in weather resistance, and integrates sun-shading and power generation.

Owner:SHANGHAI MODIER METAL STRUCTURE TECH CO LTD

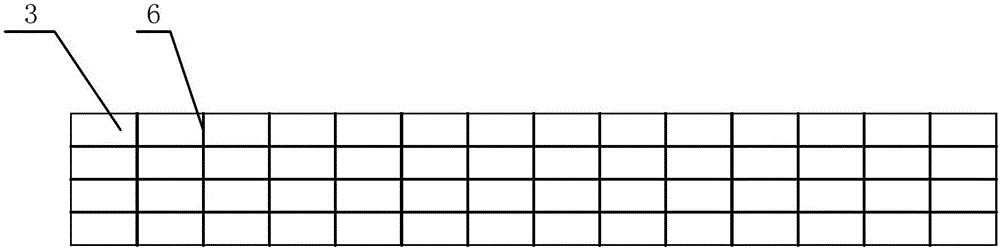

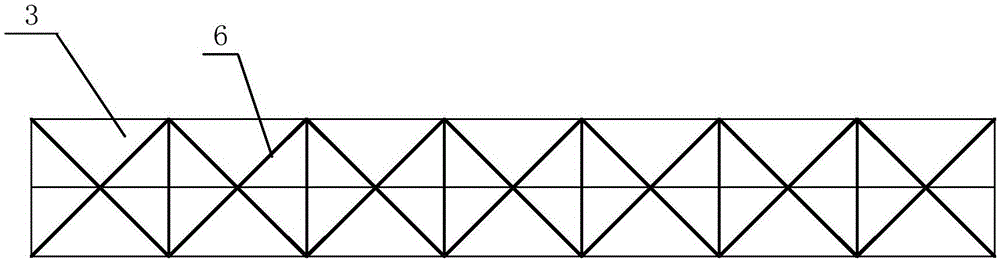

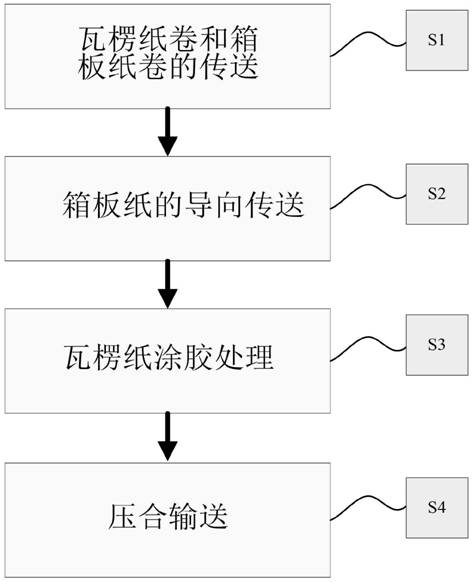

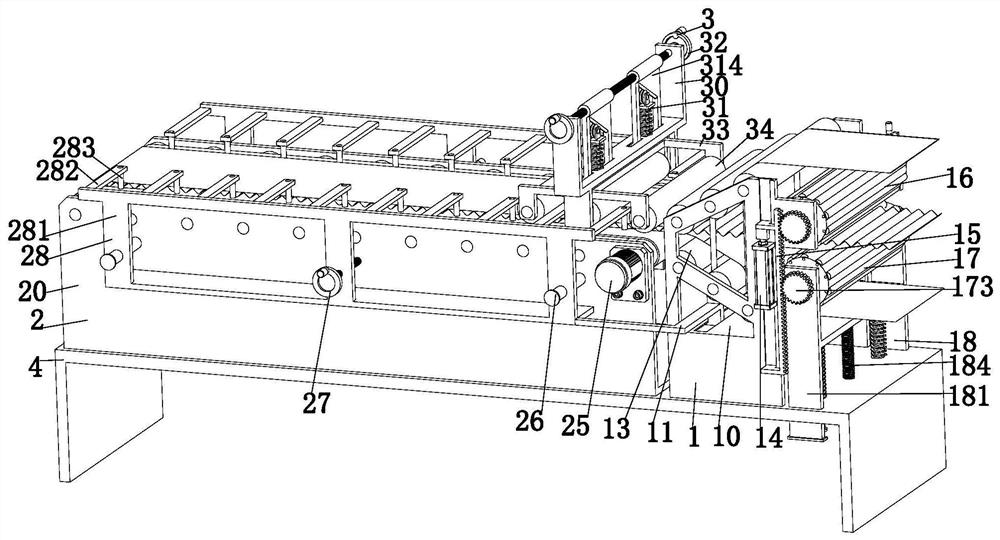

Logistics packaging box corrugated board processing method

ActiveCN113478941ARealize spacing distance adjustmentMeet coating spacing requirementsBox making operationsPaper-makingCardboardLogistics management

The invention provides a logistics packaging box corrugated board processing method, which comprises a roll coating mechanism, a transmission mechanism, a rolling mechanism and a main beam cross frame. The problems as follows are solved: an existing device for coating corrugated paper with glue has limitation, only the corrugated paper with one height size can be coated during glue coating, and corresponding equipment needs to be replaced for coating treatment when the corrugated paper with different height sizes is replaced; the glue is prone to deposition and solidification in the coating process, the viscosity of glue is reduced, and the gluing quality of cardboard paper and corrugated paper is influenced; the coating flow rate of glue is difficult to control, the edges of corrugated paper and cardboard paper cannot be aligned, applied and glued easily due to the fact that the corrugated paper and the cardboard paper do not have a guide movement track in the conveying process, deviation can occur, and the forming quality of the corrugated paper board is affected; and the height cannot be adjusted in the rolling, applying and gluing process of the corrugated paper board, and the pressing requirements of corrugated boards with different thicknesses cannot be met.

Owner:佛山市傲彩包装制品有限公司

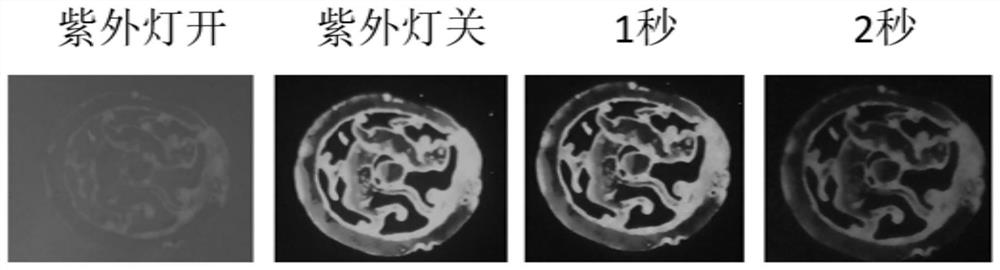

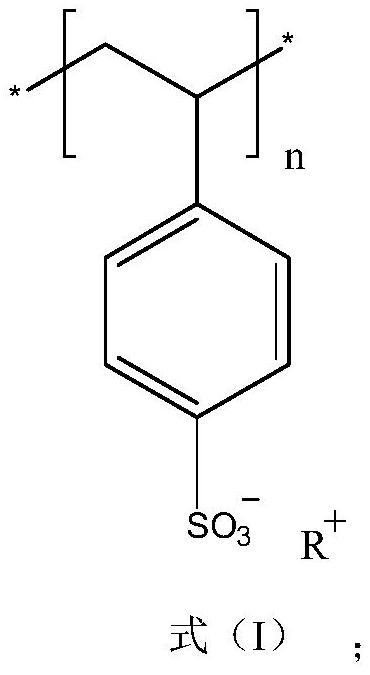

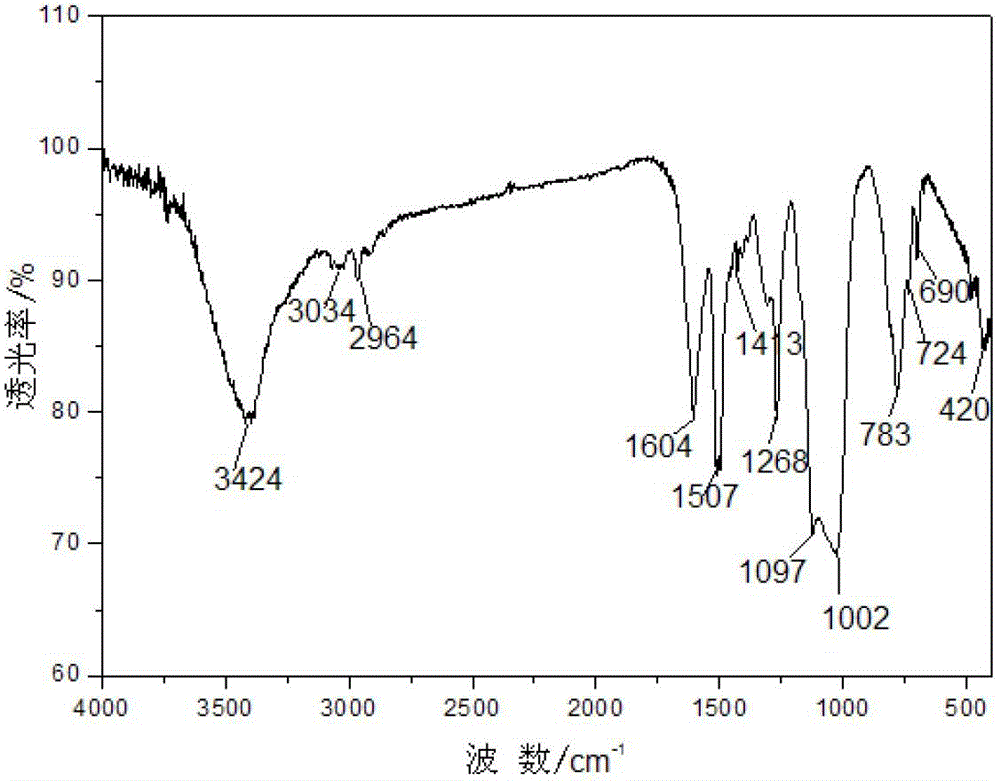

Application of polyvinyl benzene sulfonic acid or salt thereof as room-temperature phosphorescent material

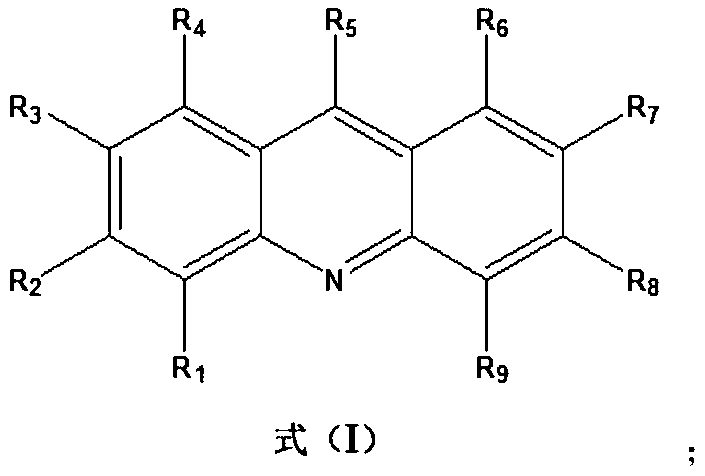

The invention discloses application of polyvinyl benzene sulfonic acid or salt thereof as a room-temperature phosphorescent material. The structure of the polyvinyl benzene sulfonic acid or the salt thereof is represented by formula (I) shown in the description, and in the formula (I), R<+> is a hydrogen ion, a metal cation or an organic cation. The halogen-free and water-based printable room-temperature phosphorescent material disclosed by the invention has a very strong luminescent property at room temperature, the phosphorescent external quantum efficiency can reach 7-20%, the luminescent life is relatively long and is generally 1-3 seconds, and the luminescent range from blue to green can be covered; and the raw materials are simple and easy to obtain, the preparation method is simpleand rapid, the cost is low, no toxic halogen element exists, water can be used as a solvent in the whole processing process, and no organic solvent is used, so the method has obvious advantages in environmental protection, is suitable for industrial preparation and has good practical application and popularization value. .

Owner:广州市韩泰生物科技有限公司

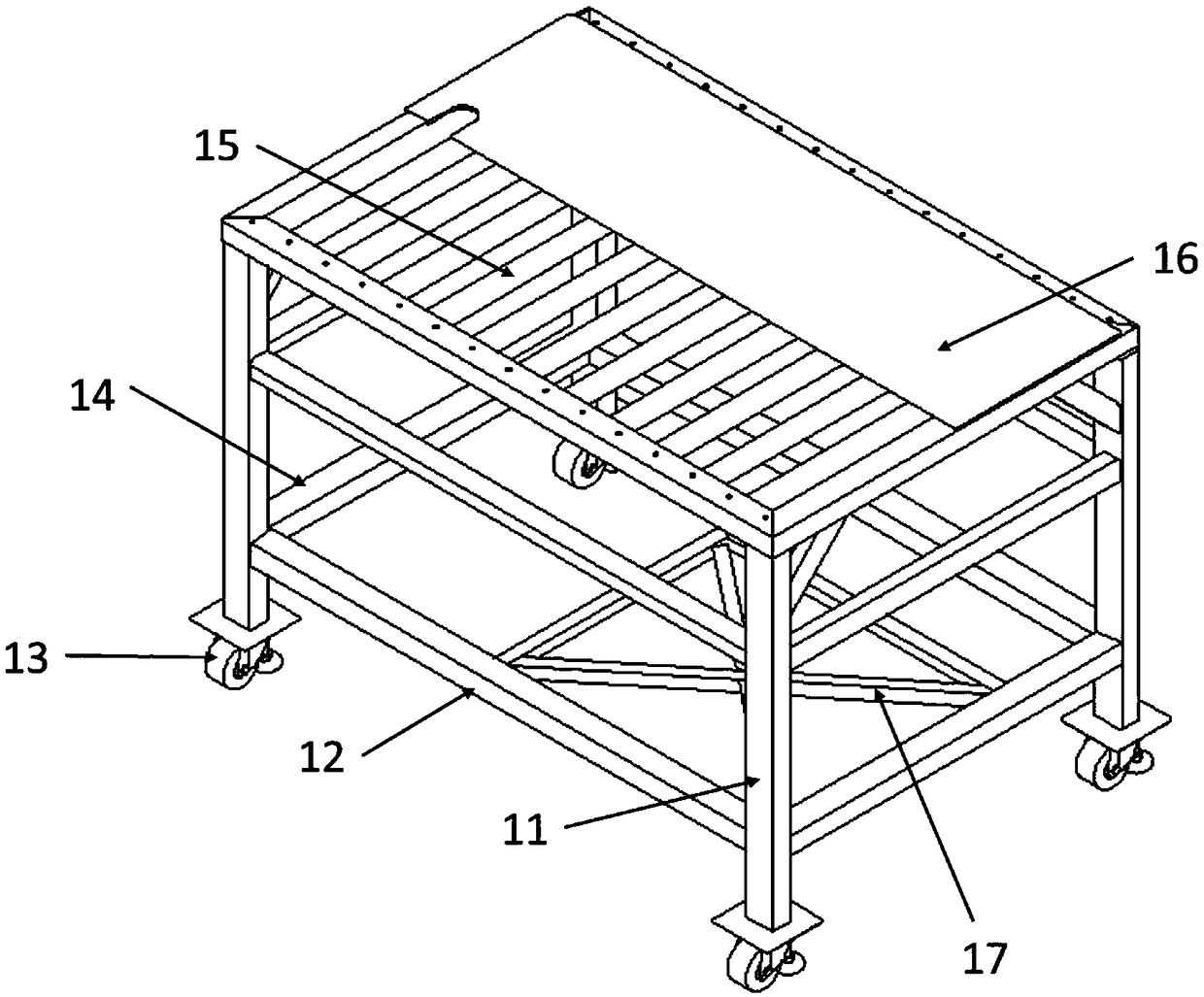

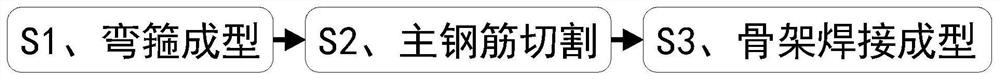

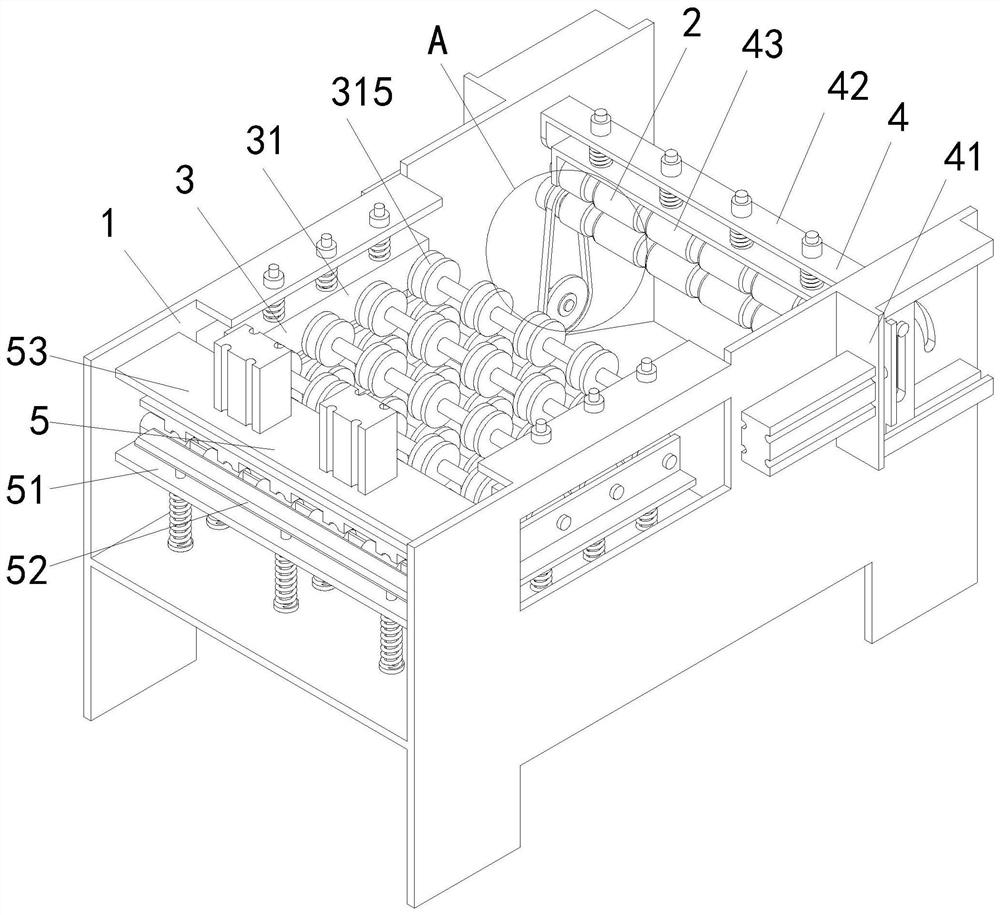

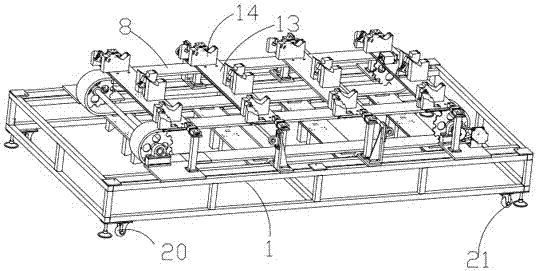

Manufacturing method of building steel-concrete structure stand column metal framework

The invention relates to a manufacturing method of a building steel-concrete structure stand column metal framework, in particular to a manufacturing and forming device of the building steel-concretestructure stand column metal framework. The manufacturing and forming device comprises a rack, a steel bar conveying mechanism, a conveying guide mechanism, a bending mechanism and a steel bar cuttingmechanism. The steel bar cutting mechanism, the conveying guide mechanism and the steel bar conveying mechanism are all arranged on the rack and sequentially distributed in the horizontal linear direction. The bending mechanism is installed on the rack and is close to the steel bar conveying mechanism. According to the device related to the method, the problem that steel bar hoop bending formingequipment in the prior art can only machine one steel bar is solved, batched machining and forming can be achieved through multiple stations, and the machining and production efficiency is greatly improved.

Owner:佛山沃瀚建材贸易有限公司

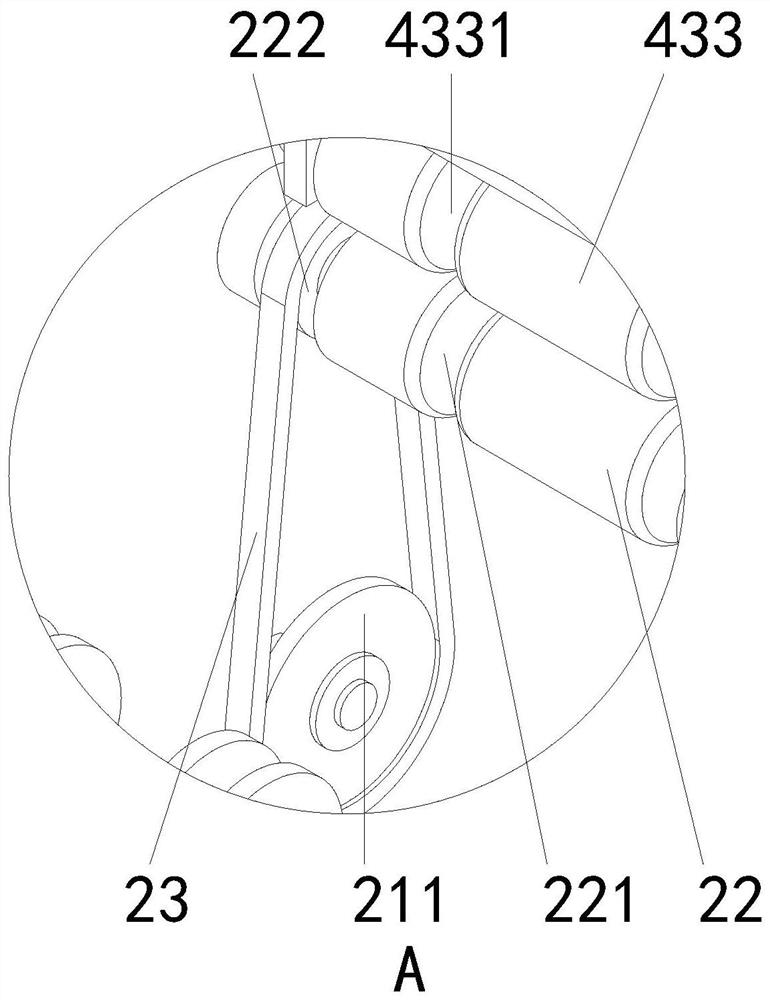

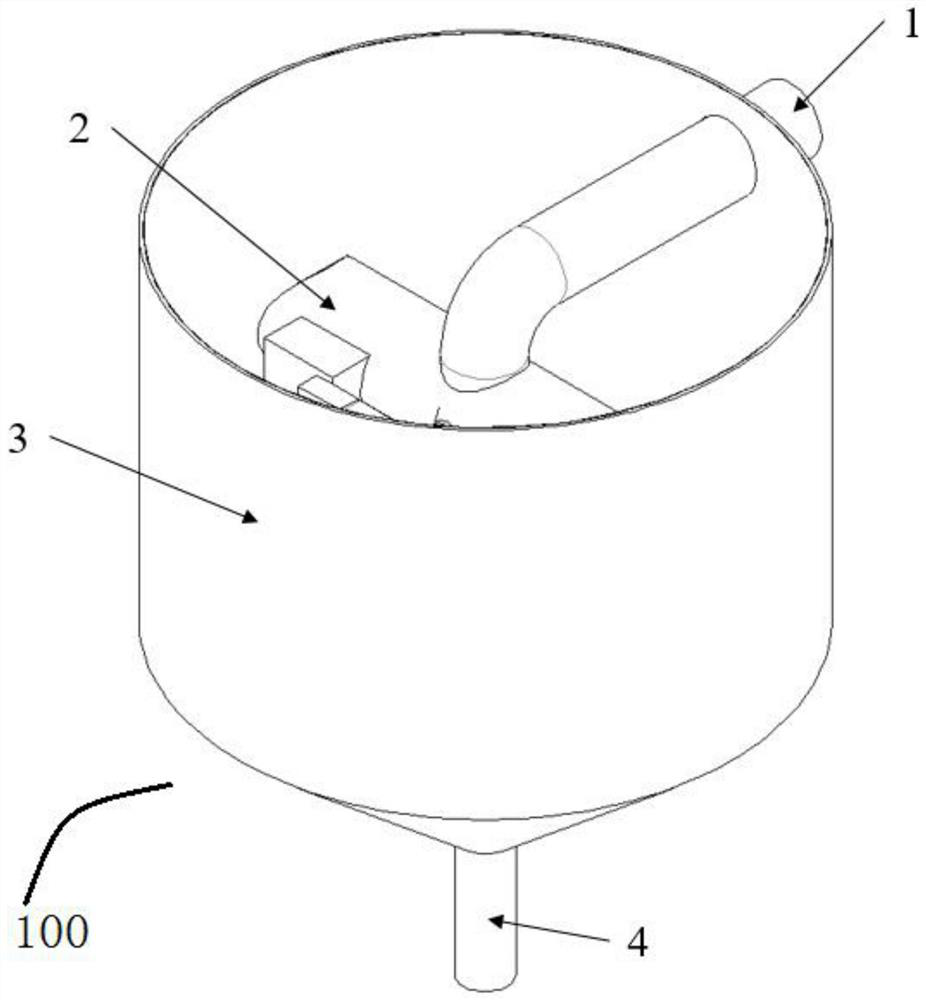

Extrusion type three-dimensional (3D) printing concrete extrusion system

ActiveCN112873476ARealize processing and formingExtended service lifeAdditive manufacturing apparatusFeeding arrangmentsReciprocating motionElectric machinery

The invention discloses an extrusion type three-dimensional (3D) printing concrete extrusion system, and relates to the technical field of 3D printing mechanical equipment. The extrusion type 3D printing concrete extrusion system comprises a horizontally-arranged material extruding bin, wherein the top end of the middle of the material extruding bin is communicated with a feeding pipe; an extruder is movably arranged in the material extruding bin; an arc-shaped groove is formed in one side of the extruder; the center line of the arc-shaped groove coincides with the horizontal center line of the material extruding bin; the two ends of the extruder are fixedly connected with extruder rods respectively; the ends, away from the extruder, of the extruder rods are arranged in extruder rod fixing pipes in a penetrating mode respectively; the ends, away from the extruder rods, of the extruder rod fixing pipes are fixedly arranged on the inner walls of the two ends of the material extruding bin; the bottoms of the two ends of the material extruding bin communicate with the two ends of a conveying pipe of a U-shaped structure correspondingly; the bottom of the conveying pipe communicates with a discharging pipe; a motor is arranged on one side of the material extruding bin; an output shaft of the motor is connected with a Z-shaped transmission rod; and the tail end of the Z-shaped transmission rod is arranged in the arc-shaped groove in a sliding mode. According to the extrusion type 3D printing concrete extrusion system provided by the invention, uniform and stable extrusion of printable materials is achieved through reciprocating motion of the extruder.

Owner:HEBEI UNIV OF TECH

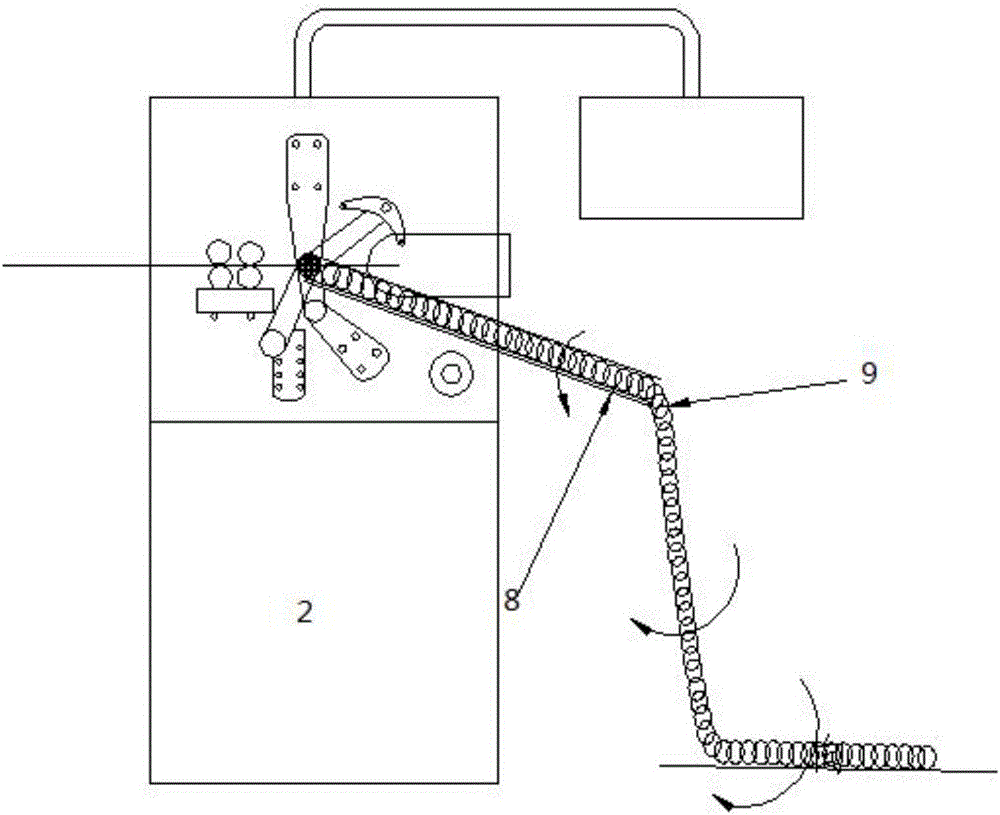

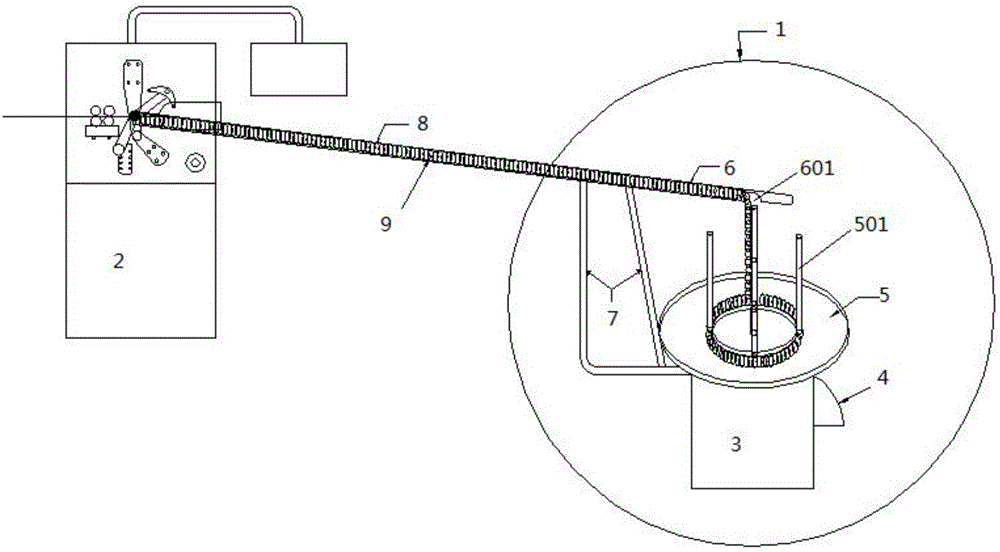

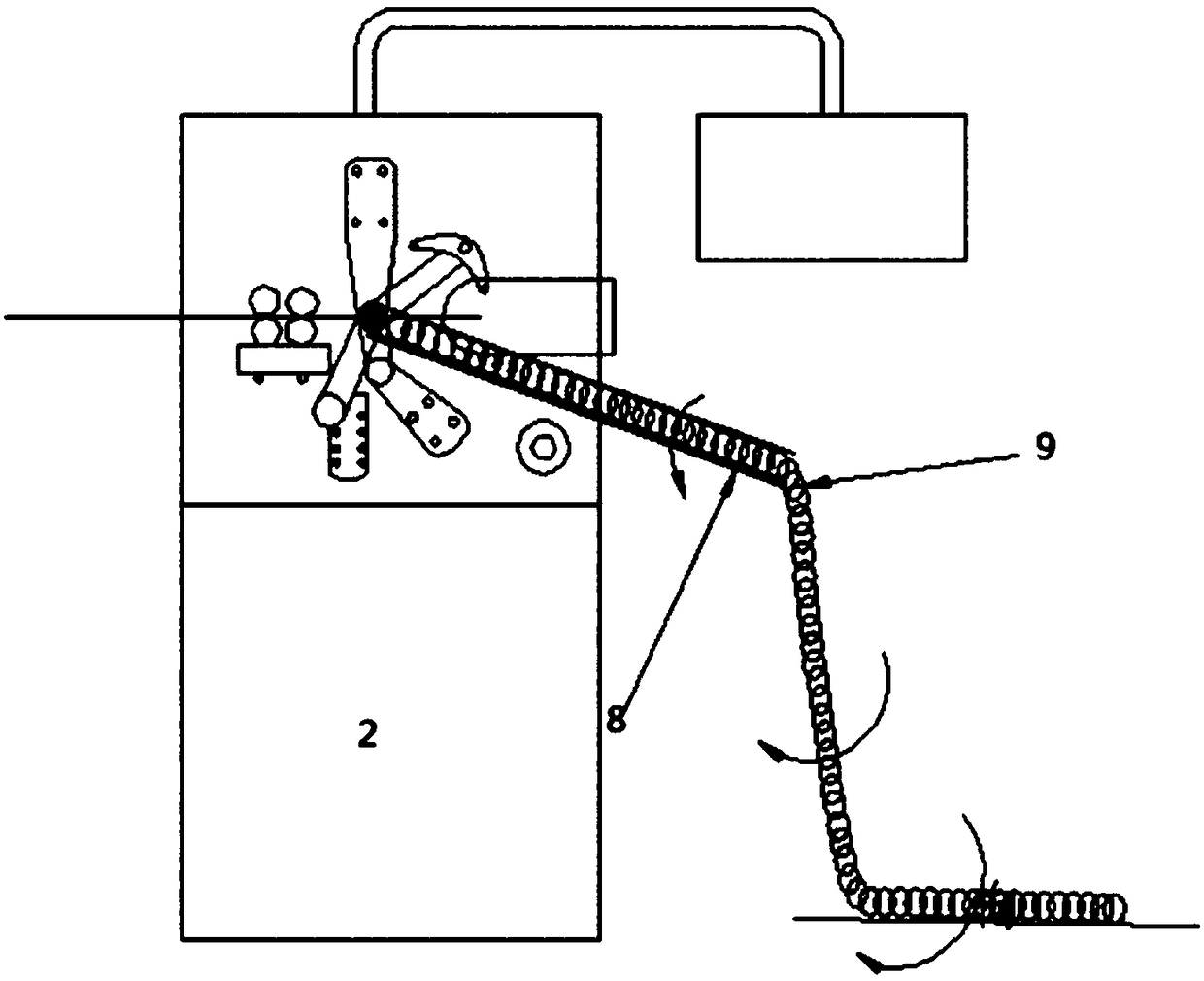

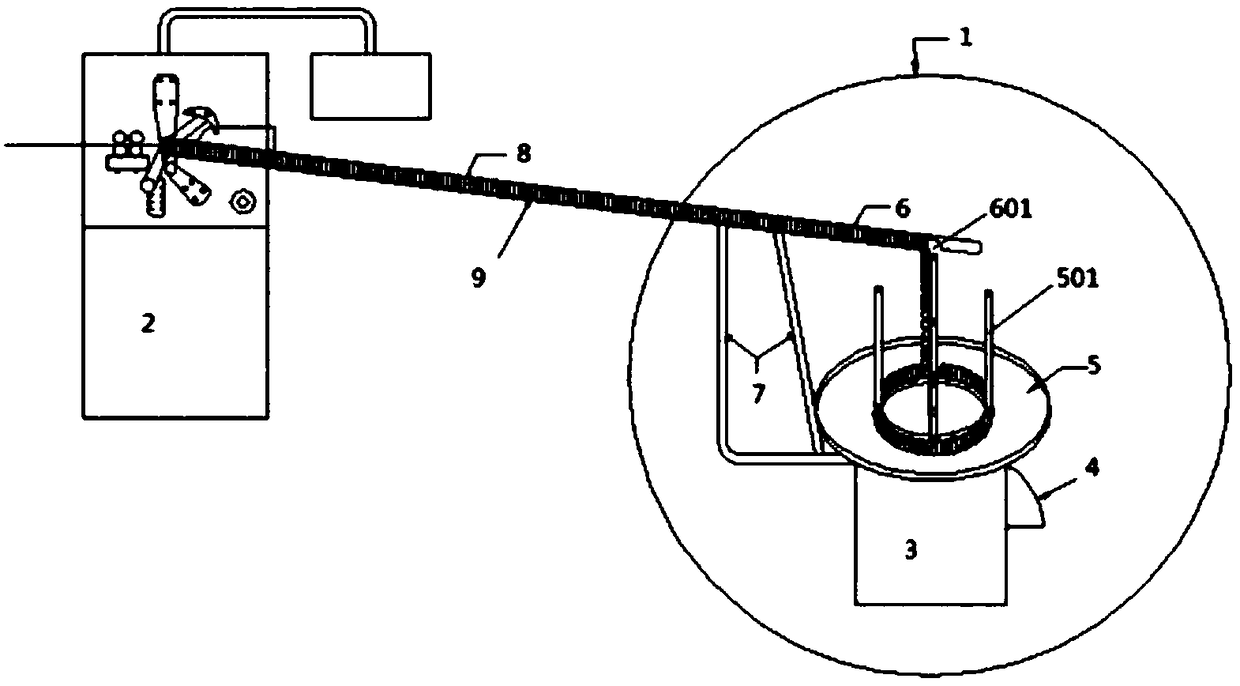

Spring collecting device and machining device for coiling ultra-long spring

The invention provides a spring collecting device and a machining device for coiling an ultra-long spring and relates to the technical field of spring machining. The spring collecting device comprises a spring coiling machine, wherein a guiding groove is formed in the spring forming outlet position of the spring coiling machine, and a spring collecting device is arranged at the outlet end of the guiding groove. The problem that the ultra-long spring is difficult to machine and form is solved, the spring coiling machine is connected with a device for driving a spring body to perform synchronous rotation, and the machining device is applied to ultra-long spring coiling and achieves ultra-long spring machining and forming.

Owner:西安亿利华弹簧科技股份有限公司

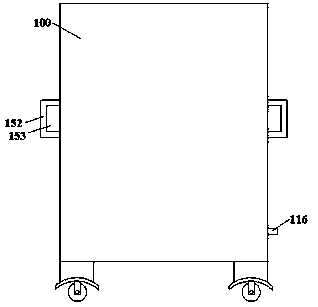

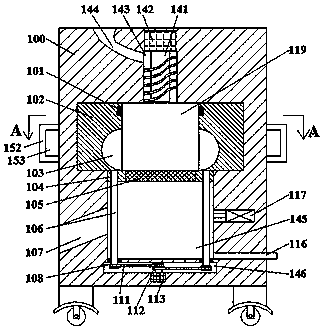

Novel anti-coronary heart disease drug device

The invention discloses a novel anti-coronary heart disease drug device. The device comprises a seat body, a material pressing cavity and a material discharging cavity, wherein the material pressing cavity is arranged inside the seat body, and the material discharging cavity is formed in the bottom of the material pressing cavity in a communicating mode; handheld frames are symmetrically arrangedon the left side and the right side of the seat body, handheld holes are formed in the handheld frames in a front-back penetrating mode, and a first hole groove is formed in the bottom of the materialdischarging cavity; the top of the material pressing cavity is provided with a crushing cavity in a communicating mode, and a second hole groove, a third hole groove and a fourth hole groove are formed in the rear end of the material pressing cavity from front to back in sequence; the interior of the inner wall of the left end of the crushing cavity is provided with a feeding cavity in a communicating mode, the top of the feeding cavity penetrates through the top end face of the seat body, and a first motor is embedded inside the inner wall of the top of the crushing cavity; and the tail endof the bottom of the first motor is in power connection with a downward extending crushing shaft. According to the device, the structure is simple, operation is convenient, and movement and transportation are convenient; and meanwhile, the processing and forming efficiency as well as the effect are improved.

Owner:广州燃烧医疗技术开发有限公司

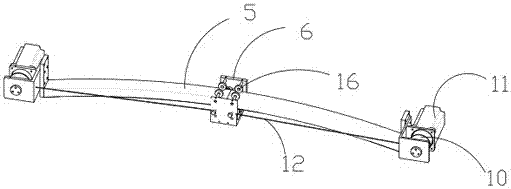

Automatic surface processing machine

ActiveCN105798708BRealize processing and formingSimple processing equipmentFeeding apparatusLarge fixed membersEngineeringMoving frame

The invention provides a full-automatic curved surface processing machine. The machine comprises a rack with a frame structure; the rack includes a base, side brackets vertically arranged on two sides of the base, and top beams fixedly arranged at the tops of the side brackets on two sides; a workpiece transfer frame is arranged on the base; multiple moving frames are slidingly arranged on the top beams in the horizontal direction, and are all provided with curved surface slide rails; the multiple curved surface slide rails are distributed at equal intervals corresponding to the top beams; curved surfaces of the curved surface slide rails are matched with curved surfaces of to-be-processed workpieces; first driving mechanisms for driving the moving frames to slide are respectively arranged between the top beams and the two ends of all the moving frames; slide pieces are slidingly arranged on the curved surface slide rails along the curved surfaces, and are provided with processing devices for processing the surfaces of the to-be-processed workpieces; and second driving mechanisms for driving the slide pieces to slide are arranged between the slide pieces and the curved surface slide rails. The machine uses the concept of curve modules for realizing processing of the curved surfaces of the workpieces, and is simple in structure and high in automation degree.

Owner:JIANGYIN DASHANG ROBOT CO LTD

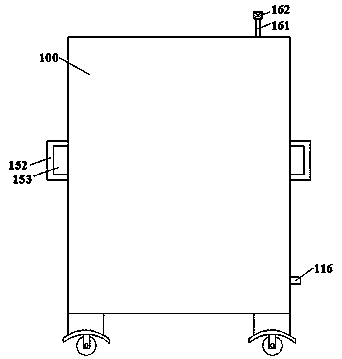

An anti-coronary heart disease drug processing device

ActiveCN108246481BEasy loadingEasy to handlePharmaceutical product form changeGrain treatmentsMedicineCoronary heart disease

The invention discloses an anti-coronary heart disease medicine device which comprises a base, a material pressing cavity formed in the base and a discharging cavity arranged at the bottom of the material pressing cavity in an interconnected mode, wherein hand-held frames are symmetrically arranged at the left and right sides of the base; hand-held holes are formed in the hand-held frames in a forward and backward penetrated mode; a first hole groove is formed in the bottom of the discharging cavity; a pulverizing cavity is formed in the top of the material pressing cavity in an interconnectedmode; a second hole groove, a third hole groove and a fourth hole groove are successively formed in the rear end of the material pressing cavity from front to back; a material feeding cavity is formed in the inner wall of the left end of the pulverizing cavity in an interconnected mode; the top of the material feeding cavity penetrates through the end surface of the top of the base; a first motoris embedded in the inner wall of the top of the pulverizing cavity; and the tail end of the bottom of the first motor is in power connection with a downward-extended pulverizing shaft. The device disclosed by the invention is simple in structure and convenient to operate, move and carry and improves the machine-shaping efficiency and effect.

Owner:ZHEJIANG YONGNING PHARMA

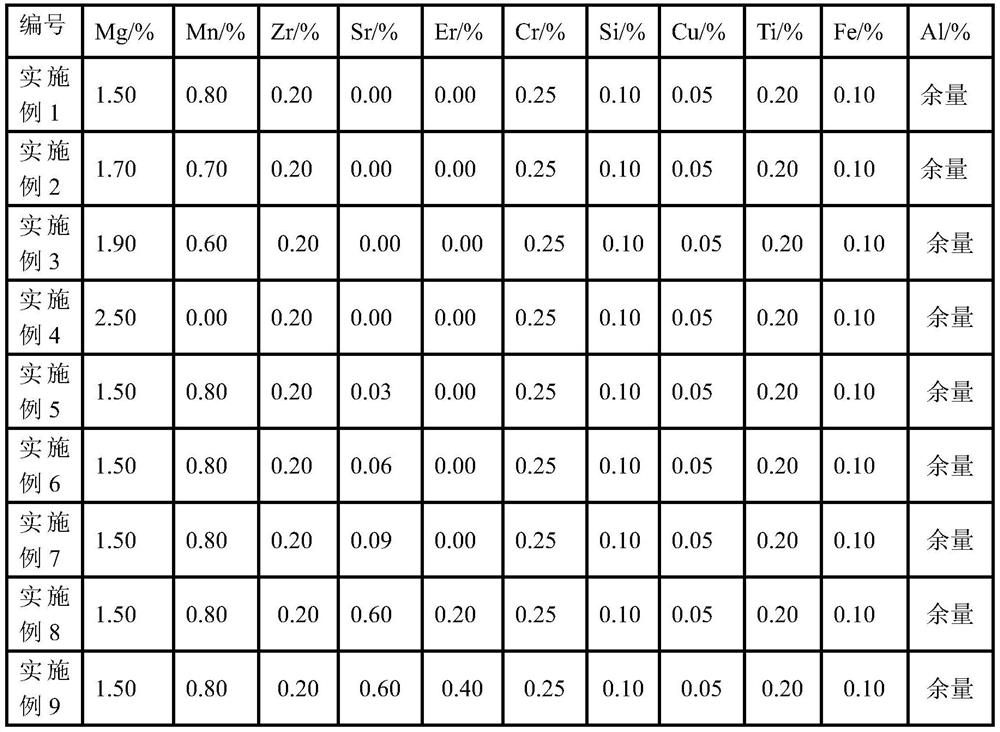

A high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ships and its production process

The invention discloses a high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ships and a production process thereof. The chemical composition of the aluminum-magnesium-manganese alloy is calculated by mass percentage: Mg: 0.80-2.80%, Mn: 0.00-1.40 %, Zr: 0.10‑0.50%, Cr: 0.15‑0.35%, Sr: 0.00‑0.10%, Er: 0.00‑0.60%, Si: 0.10‑0.40%, Cu: 0.01‑0.10%, Ti: 0.01‑0.05% , Fe: 0.00‑0.40%, the balance is Al. The production process mainly includes smelting and melt treatment, continuous casting, continuous rolling and cold rolling process. This invention solves the problem of high-throughput continuous casting and rolling to produce aluminum for ships Magnesium-manganese sheets have problems such as easy segregation, low strength and toughness, and poor formability.

Owner:ZHENGZHOU UNIV

Spring gathering unit and machining equipment used for coiling overlong springs

The invention provides a spring gathering unit and machining equipment used for coiling overlong springs, and relates to the technical field of spring machining. The invention further provides a spring coiling machine, a guide groove is formed in the position of a spring molding outlet of the spring coiling machine, and the spring gathering unit is arranged at the outlet end of the guide groove. The spring gathering unit solves the problem that the overlong springs are difficult to machine and mold, the spring coiling machine is connected with a device for driving a spring body to rotate synchronously, the spring gathering unit and machining equipment is applied for coiling the overlong springs, and machining molding of the overlong springs is achieved.

Owner:JIANGSU XIANGYING HARDWARE SPRING CO LTD

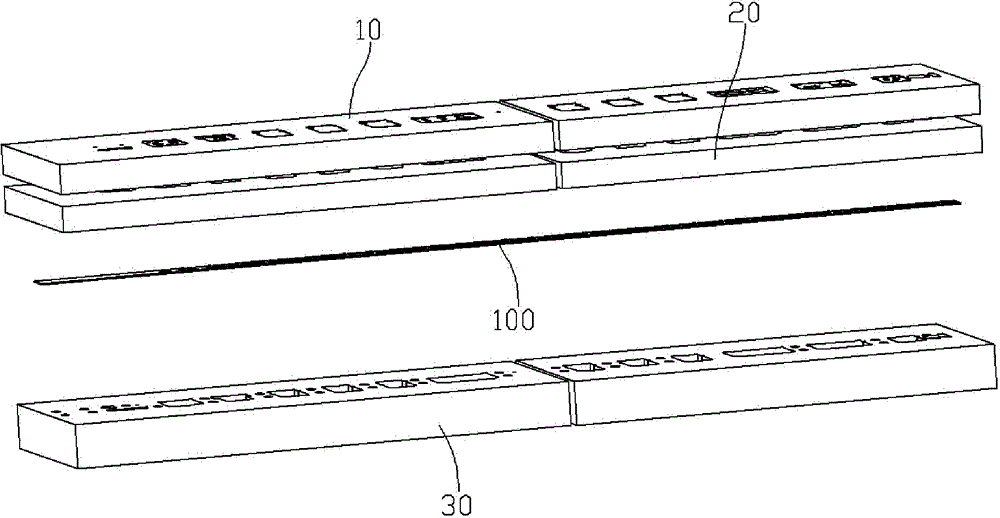

Continuous forging die

ActiveCN102641981BRealize processing and formingIncrease productivityOther manufacturing equipments/toolsEngineeringAluminium alloy

The invention discloses a continuous forging die comprising an upper die, an upper die stripping plate, and a lower die, wherein the body of the upper die is provided with a stamping punch pin, an upper die forging and forming block and a bent blanking punch pin which are continuously arranged, and the body of the lower die is provided with a corresponding lower stamping die, a corresponding lower die forging and forming block and a corresponding lower bent blanking punch pin. The continuous forging die disclosed by the invention combines a forging technology and a stamping technology onto one set of die, so as to realize the processing and forming of small aluminum alloy and small stainless steel pieces with thickness difference and characteristics of complex curved surfaces. Meanwhile, the continuous forging die has the characteristics of high production efficiency, high volume production, low production cost and favorable product quality.

Owner:SHENZHEN XINMAOXIN IND CO LTD

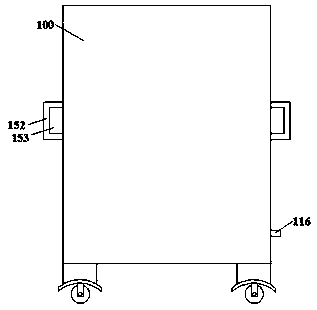

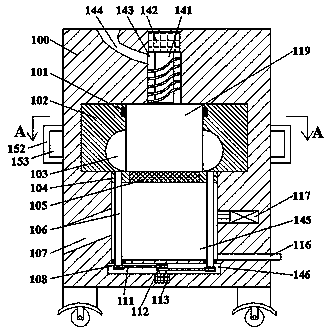

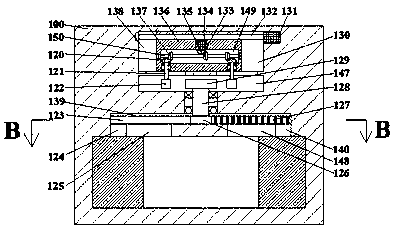

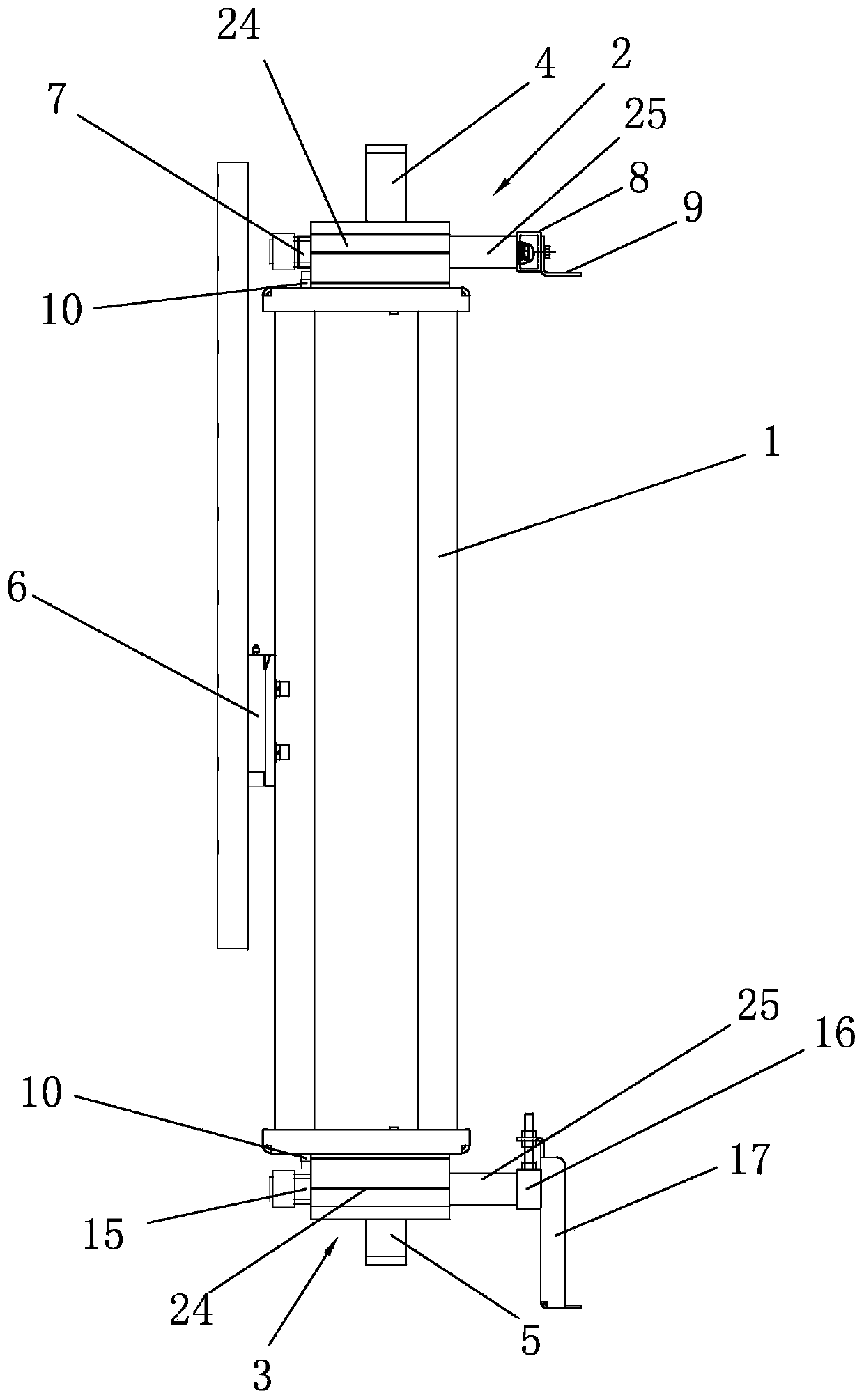

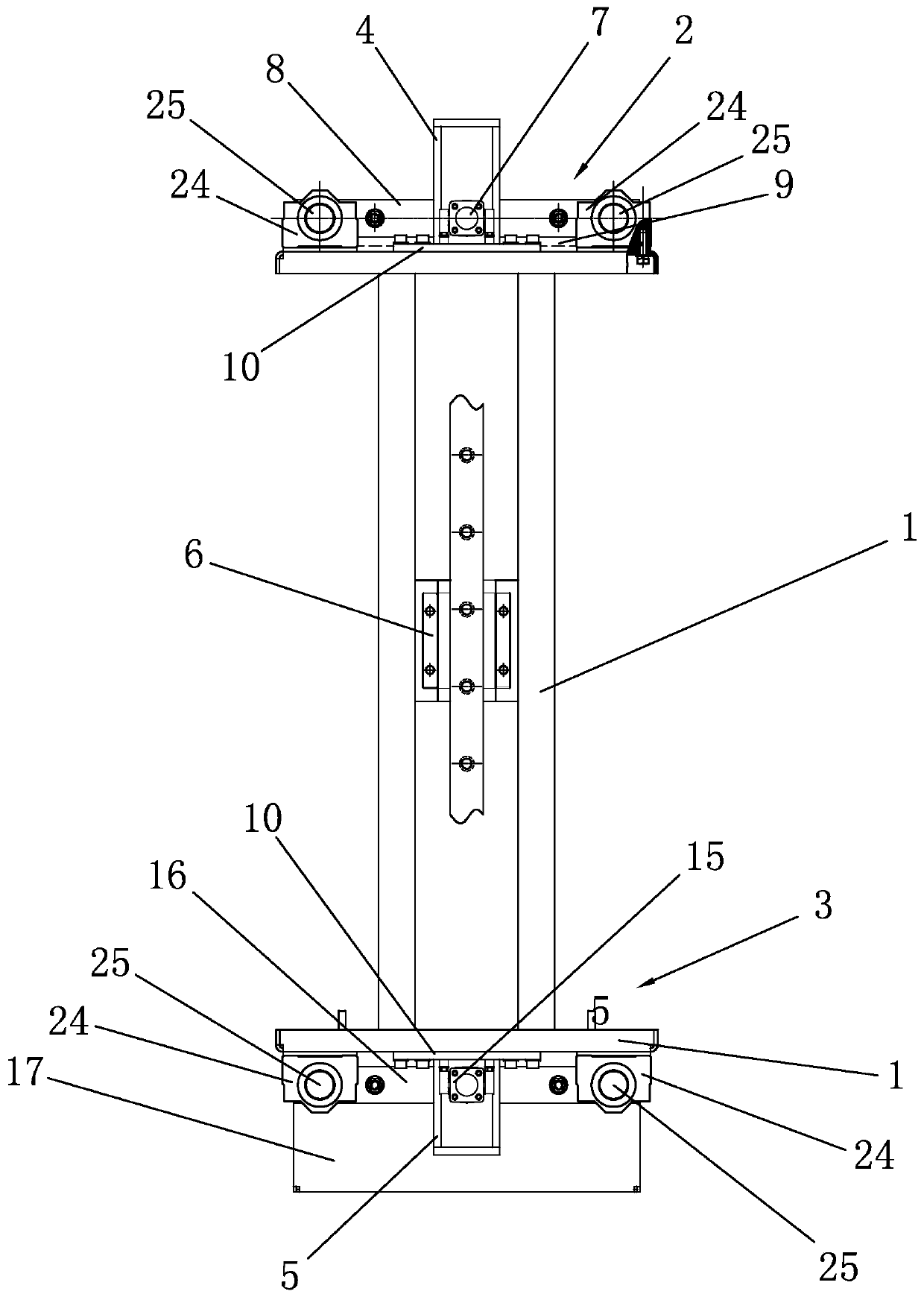

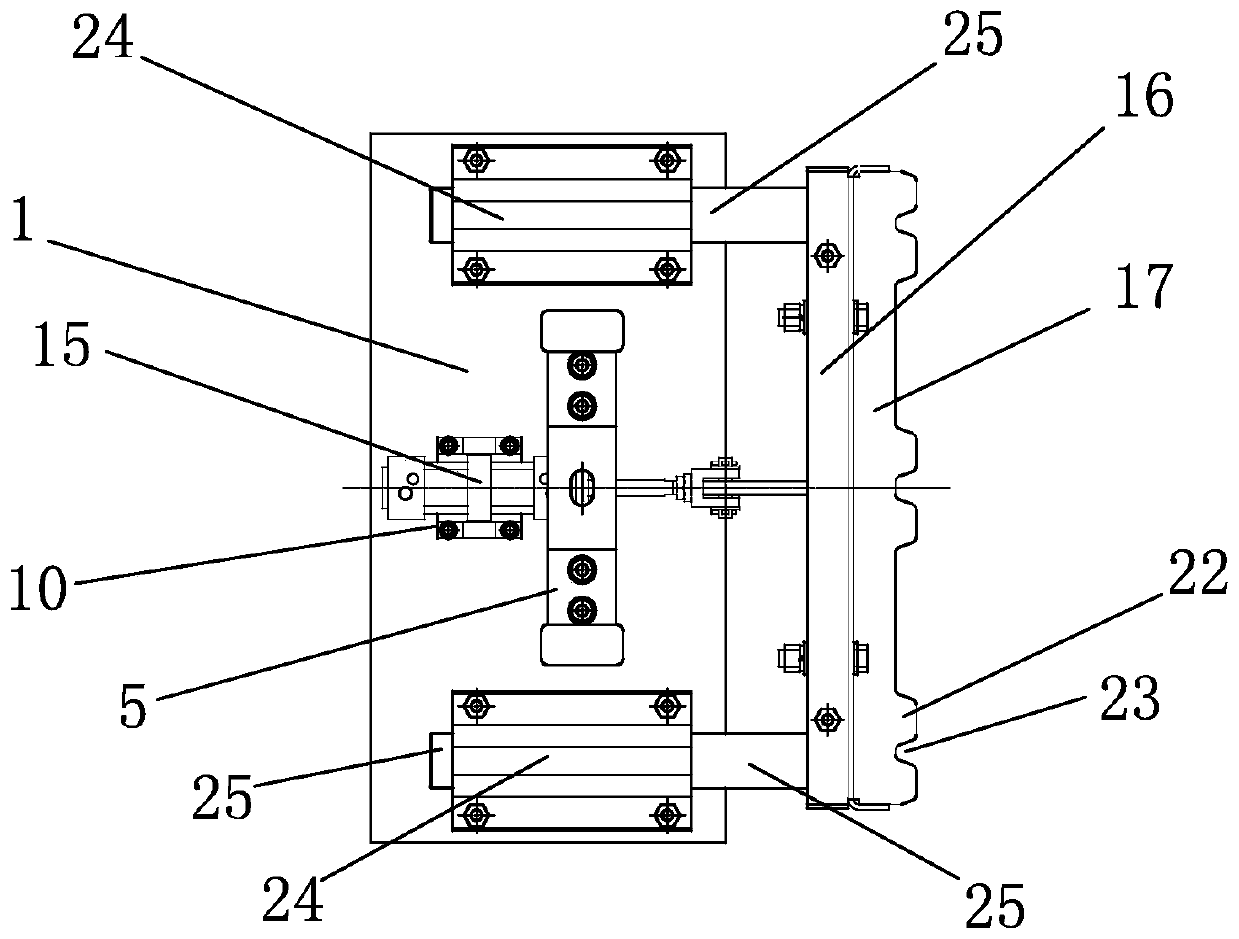

Lifting body for frame body splitting machine

PendingCN111137803AImprove structural strengthEasy to installNon-rotating vibration suppressionLifting framesAnimal scienceEngineering

The invention discloses a lifting body for a frame body splitting machine. The lifting body comprises a frame, an upper supporting claw mechanism and a lower supporting claw mechanism, the upper supporting claw mechanism is located on the upper part of the frame, and the lower supporting claw mechanism is located on the lower part of the frame. According to the lifting body, overall structural design is ingenious and reasonable, through the combined action of the upper supporting claw mechanism and the lower supporting claw mechanism, a breeding frame stack can be overall lifted, thus lower breeding frames are gradually separated from the upper breeding frame stack, stream line operation of breeding frame cocoon harvesting is more facilitated, thus whole operation is more automated, and the manual labor intensity is effectively lowered; and the lower supporting claw mechanism plays a main supporting role, the upper supporting claw mechanism plays an auxiliary supporting role, thus thewhole breeding frame stack is more stable in the lifting process, the phenomenon that only the bottom of the breeding frame stack is supported and lifted, and the upper part of the breeding frame stack is prone to shaking and toppling is avoided, thus the accident rate in the operation process is effectively decreased, and the operation process is safer and more reliable.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

Laser shock forming method and device for straight-wall cylindrical parts

The invention discloses a laser shock forming method and device for a straight-wall cylindrical part, and belongs to the field of plastic processing of near-net forming of metal parts. The method adopts a laser shock technology to carry out two-step forming on a thin plate so as to obtain a high-precision formed part and comprises the two steps that firstly, a laser with high pulse energy is used for inducing shock waves with high pressure to carry out impact on the thin plate so that the thin plate can be subjected to primary integral forming, but in the forming process, the thin plate is attached to the side wall of a die, in addition, the thin plate with extremely high deformation speed further collides with the bottom of a die cavity fiercely so that the bottom of the primary formed part can generate local reverse plastic deformation, and therefore the forming precision can be reduced; and secondly, a laser with low pulse energy is used for inducing shock waves with lower pressure to carry out impact on a reverse plastic deformation area at the bottom of the primary formed part so as to eliminate the reverse plastic deformation at the bottom of the primary formed part in the first step, and correction setting is carried out on the primary formed part so that the forming precision of the straight-wall cylindrical part can be greatly improved. According to the method, the laser shock forming precision of the thin plate can be greatly improved, and the method has wide practicability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

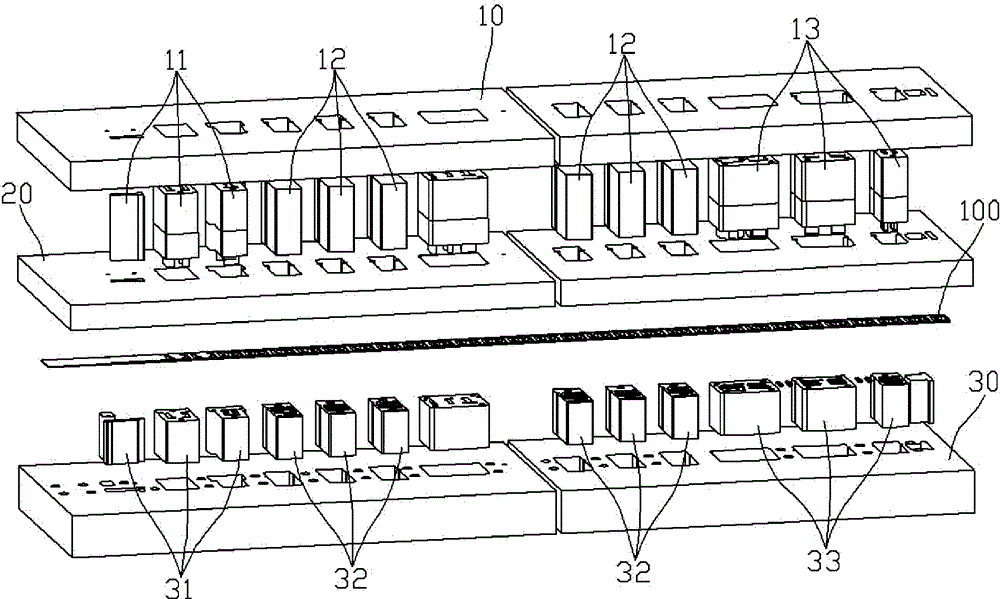

A Dense Array High-Speed Micro-Stamping Equipment

ActiveCN107971391BGuarantee stamping qualityIncrease productivityPerforating toolsPunchingDense array

Owner:SHANDONG UNIV OF SCI & TECH

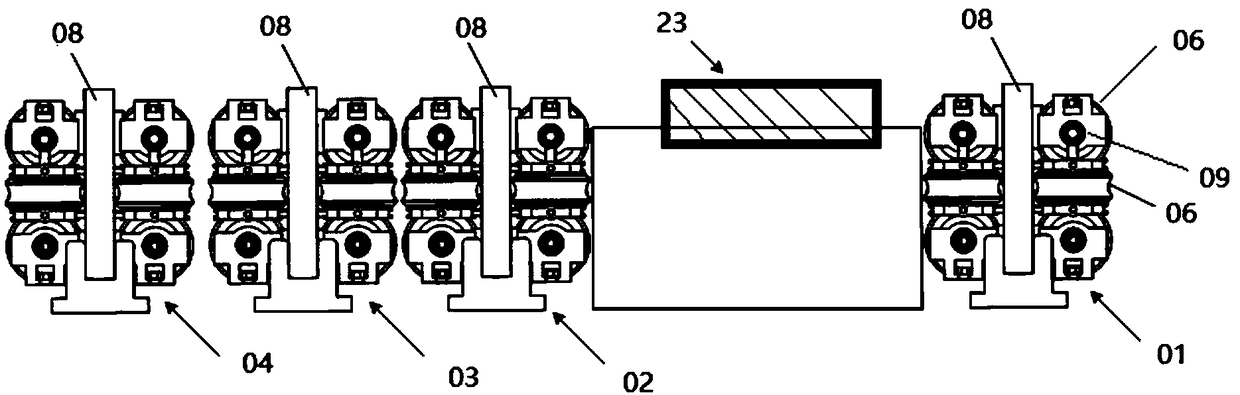

Continuous moldless forming device and method for metal bellows

ActiveCN106964680BRealize processing and formingAvoid the disadvantages of choosing welding processShaping toolsMetal-working feeding devicesMetallurgyMetal

The invention provides a continuous moldless forming device and method for metal corrugated pipes. The device includes: at least one first metal pipe feeding assembly, a metal pipe corrugating forming assembly, and at least a third metal pipe which are sequentially arranged along the metal pipe feeding direction. a pipe feeding assembly and at least one second metal pipe feeding assembly; the first metal pipe feeding assembly is used to feed metal pipes at a first feeding speed; the second metal pipe feeding assembly, a third metal pipe feeding assembly The pipe feeding assembly is used to feed the metal pipe at a second feeding speed; the first feeding speed is greater than the second feeding speed; and the metal pipe corrugation forming assembly is used to form corrugations on the metal pipe wall. The above-mentioned device can meet the requirements for the production of metal bellows with long axial distance and continuous or discontinuous corrugations.

Owner:NORTHEASTERN UNIV LIAONING

An extrusion 3D printing concrete extrusion system

ActiveCN112873476BRealize processing and formingExtended service lifeAdditive manufacturing apparatusFeeding arrangmentsReciprocating motionElectric machinery

The invention discloses a squeeze-type 3D printing concrete extrusion system, which relates to the technical field of 3D printing machinery and equipment; it includes a horizontally arranged extrusion bin, a feed pipe is connected to the top of the middle part of the extrusion bin, and a squeezer is movable in the feed bin. The extruder has an arc groove on one side of the extruder, and the center line of the arc groove coincides with the horizontal center line of the extrusion bin; the two ends of the extruder are respectively fixedly connected with an extruder rod, and the extruder rod The ends far away from the extruder are respectively installed in the fixed tube of the extruder rod, and the ends of the fixed tube of the extruder rod away from the extruder rod are fixedly arranged on the inner walls of both ends of the extruder; The two ends of the conveying pipe of the type structure are connected, and the bottom of the conveying pipe is connected with the discharge pipe; a motor is installed on one side of the extrusion bin, and the output shaft of the motor is connected with a Z-shaped transmission rod, and the end of the Z-shaped transmission rod is slid to set in an arc inside the groove. The invention utilizes the reciprocating motion of the extruder to realize uniform and stable extrusion of printable materials.

Owner:HEBEI UNIV OF TECH

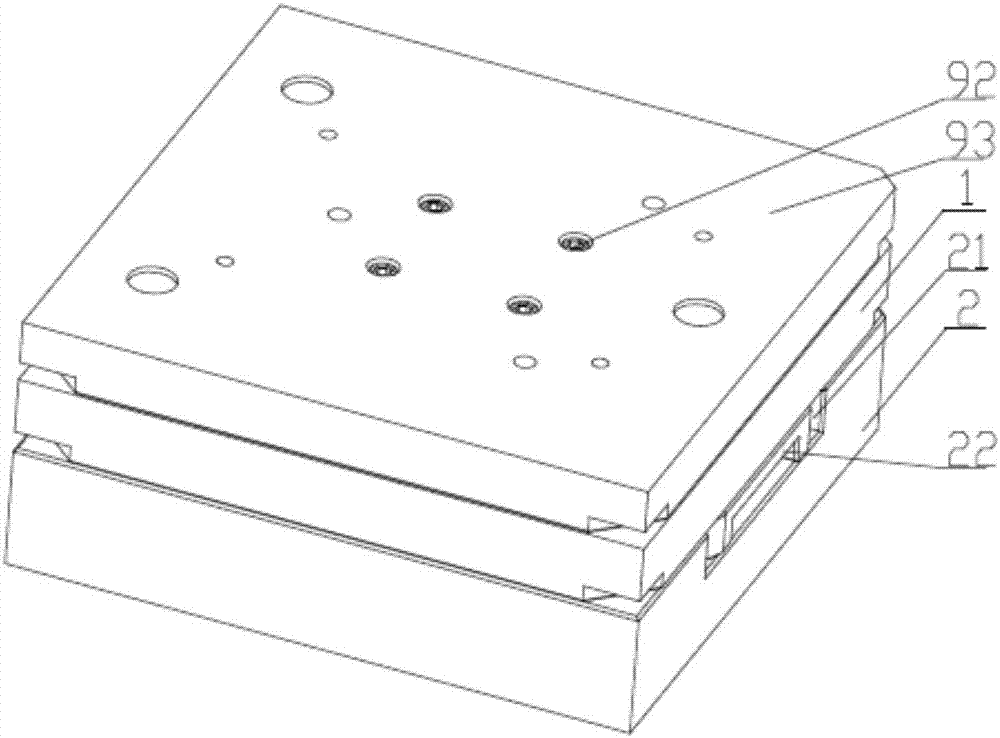

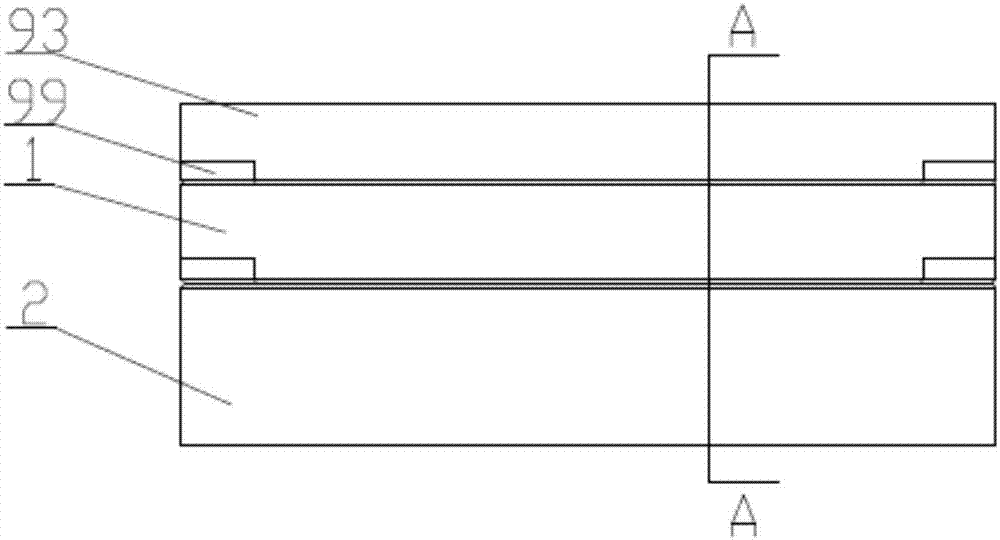

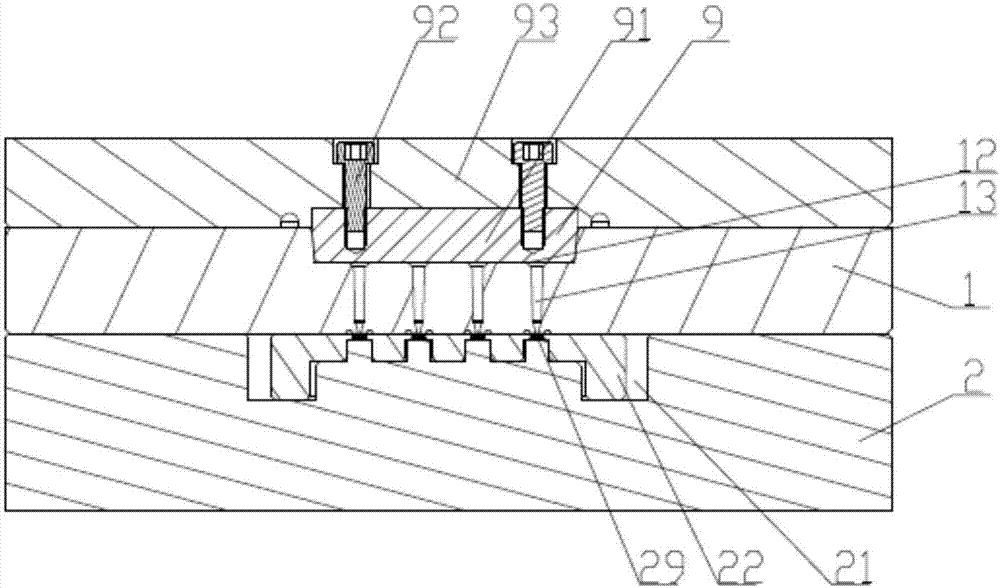

High-precision silica gel injection mould

The invention discloses a high-precision silica gel injection mould at least comprising an upper mould plate and a lower mould plate. A groove is formed in the lower mould plate. A mould core is arranged in the groove. A first positioning mechanism is arranged between the mould core and the lower mould plate. A mould cavity used for moulding of a part is formed in the mould core. A raw material groove for containing injection moulding raw materials is formed in the upper mould plate and communicates with the mould cavity by means of flow channels in the upper mould plate. Injection moulding of the part is completed by matching of the raw material groove, the flow channels and the mould cavity. A second positioning mechanism is further arranged between the lower mould plate and the upper mould plate. A pressing mechanism for squeezing the raw materials in the raw material groove to the flow channels is further arranged on the upper mould plate. The high-precision silica gel injection mould mainly has the advantages that the blocking phenomenon, caused by the rough edge of a parting line, of inner holes of the product is avoided; and meanwhile, the machining-moulded part can be taken out timely through a manipulator, so that the working efficiency is improved to a great extent.

Owner:SUZHOU YOULONG PLASTIC RUBBER PRECISION MFG CO LTD

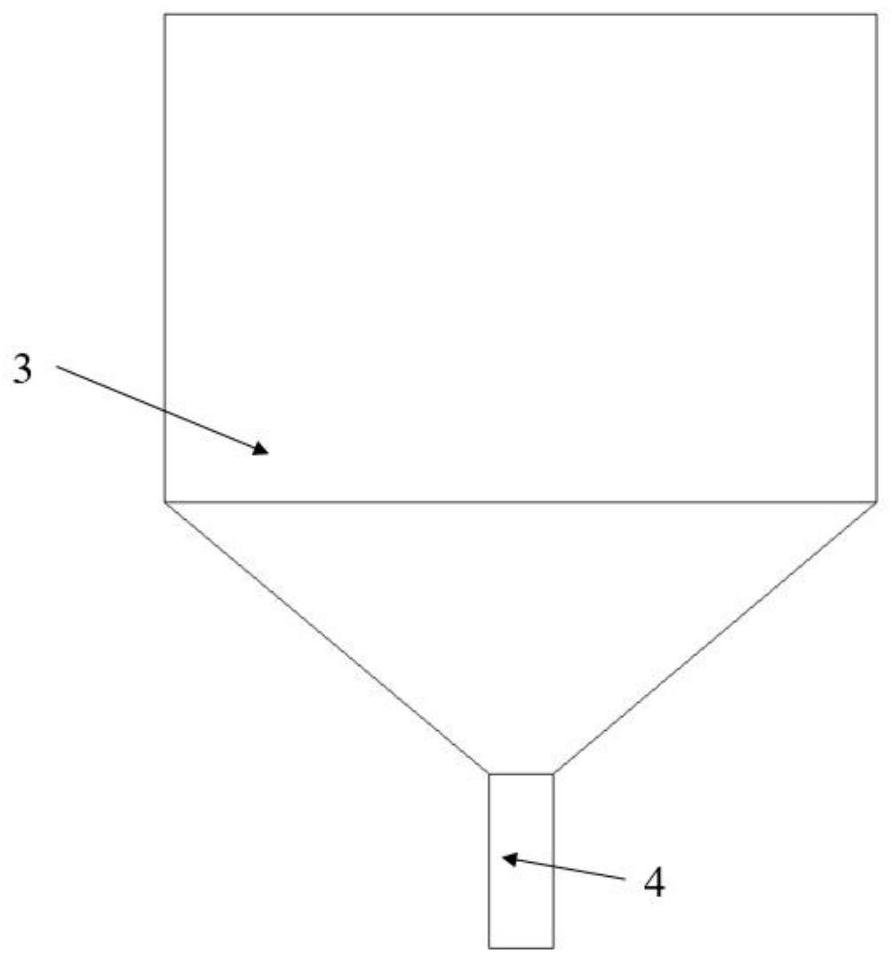

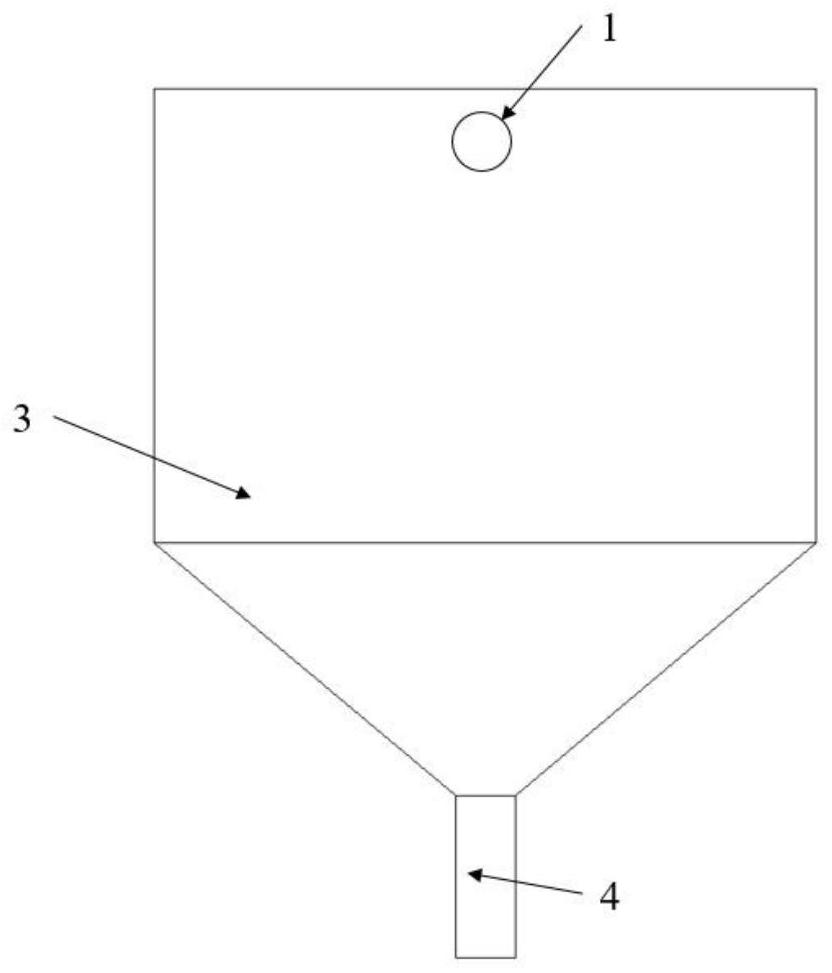

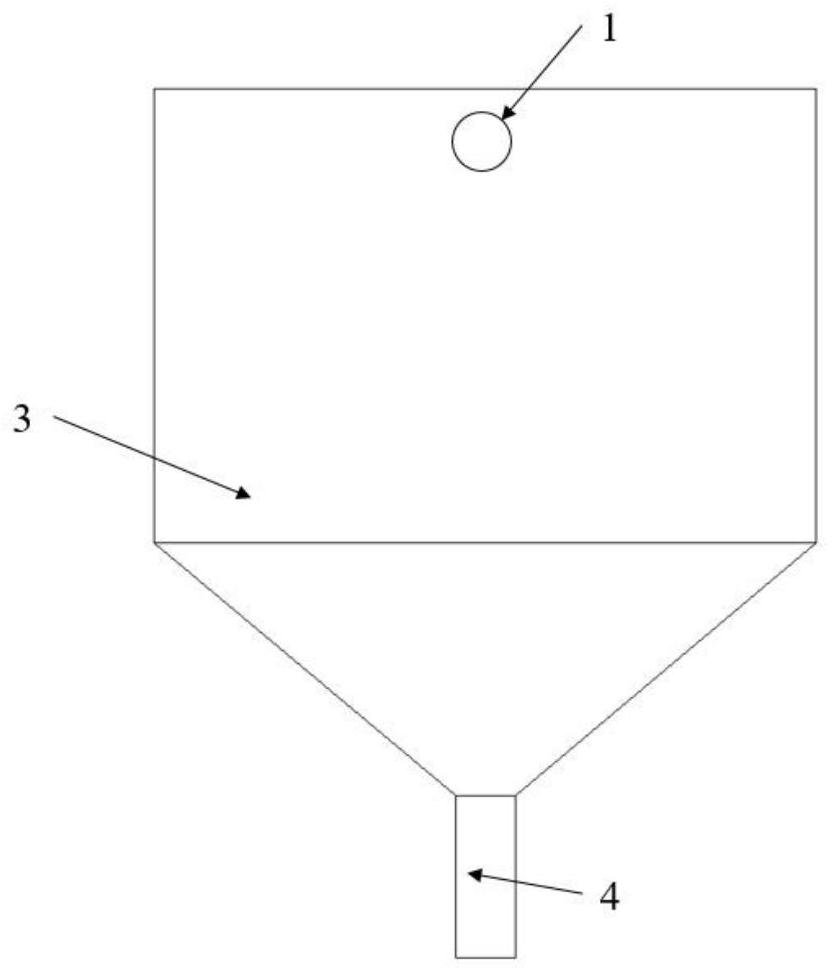

Environment-friendly equipment for co-extruded plastic wood

InactiveCN112917626AStir wellRealize processing and formingDomestic articlesFlat articlesSpiral bladeGear wheel

The invention discloses environment-friendly equipment for co-extruded plastic wood. A crushing box is included, a rotating shaft is arranged in the crushing box, one end of the rotating shaft penetrates out of the crushing box and is provided with a motor, a first crushing roller and a second crushing roller are arranged at the end, located in the crushing box, of the rotating shaft in a penetrating mode, and a third crushing roller, a fourth crushing roller and a rotating rod are arranged in the crushing box. A second gear is arranged at one end of the rotating rod, a first gear meshed with the second gear is arranged on the rotating shaft, a stirring rod is arranged on the part, located between the first crushing roller and the second crushing roller, of the rotating shaft in a penetrating mode, a second bevel gear is arranged on the stirring rod, and a first bevel gear meshed with the second bevel gear is arranged on the rotating shaft. A discharging hopper is arranged at the bottom of the crushing box, the stirring rod extends into the discharging hopper and is provided with stirring blades, an extrusion die is connected to the bottom of the discharging hopper, and a spiral blade is arranged at the bottom of the stirring rod. According to the environment-friendly equipment, all mechanisms in one device can be driven by one motor to machine and form waste materials, energy is saved, and the practicability and environment friendliness of the device are improved.

Owner:南京聚新锋新材料有限公司

Improved anti-CHD (Coronary Heart Disease) medicine device

InactiveCN108393183AEasy loadingEasy to handlePharmaceutical product form changeGrain treatmentsMedicineCoronary heart disease

The invention discloses an improved anti-CHD (Coronary Heart Disease) medicine device. The improved anti-CHD medicine device comprises a base, a material pressing cavity arranged in the base and a discharging cavity which is arranged at the bottom of the material pressing cavity in a communication manner; handheld racks are symmetrically arranged on the left and right sides of the base; a handheldhole is formed in each handheld rack in a front-and-back through manner; a first hole groove is formed in the bottom of the discharging cavity; a crushing cavity is formed in the top of the materialpressing cavity in a communication manner; a second hole groove, a third hole groove and a fourth hole groove are sequentially formed in the rear end of the material pressing cavity from front to back; a material inlet cavity is formed in the left end inner wall of the crushing cavity in a communication manner; the top of the material inlet cavity penetrates through the top end surface of the base; a first motor is embedded in the inner wall of top part of the crushing cavity; and the tail end of the bottom of the first motor is in power connection with a crushing shaft which extends downwards. The improved anti-CHD medicine device is simple in structure and convenient to operate, move and convey, and meanwhile, machining moulding efficiency and effects are improved.

Owner:广州燃烧医疗技术开发有限公司

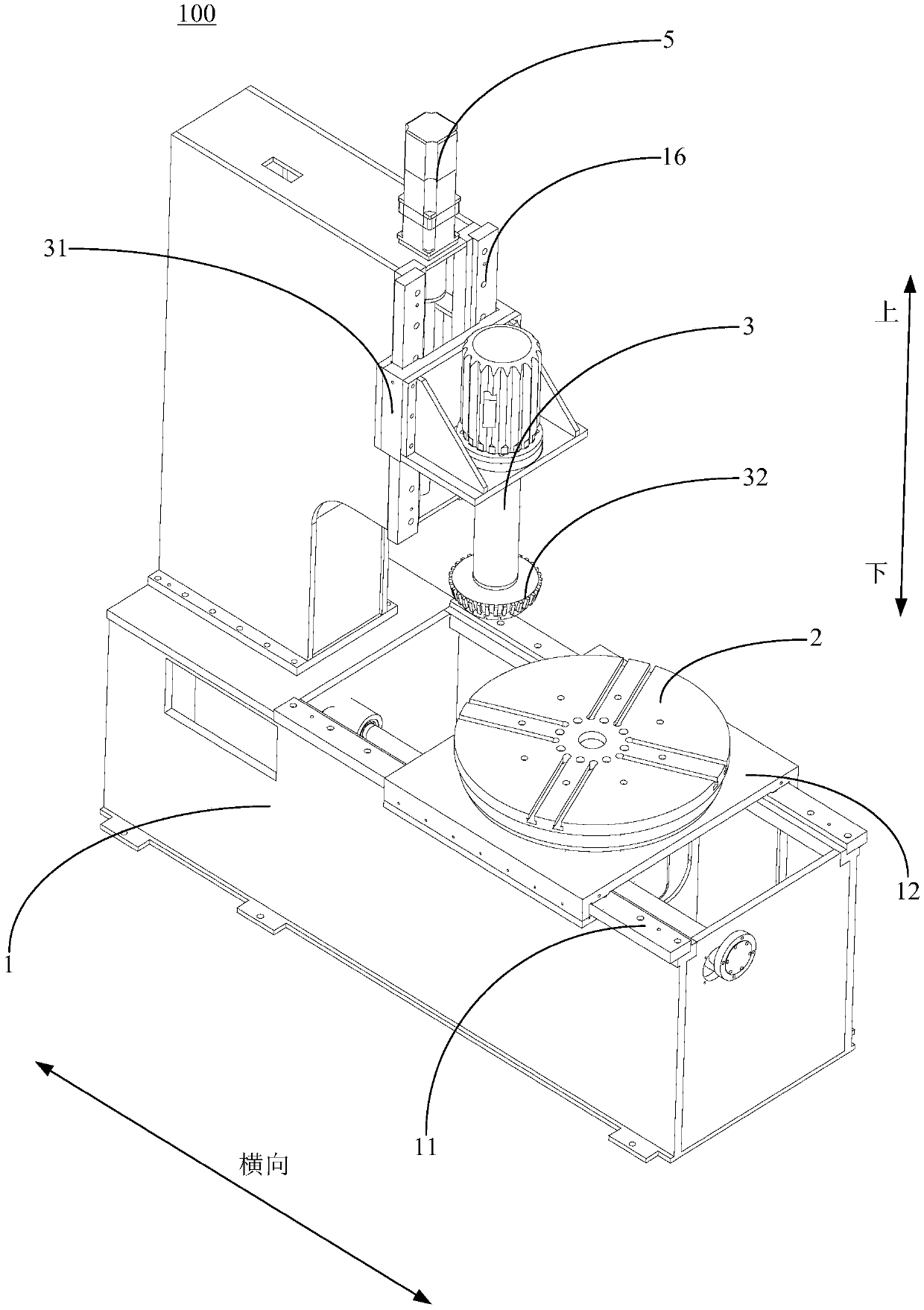

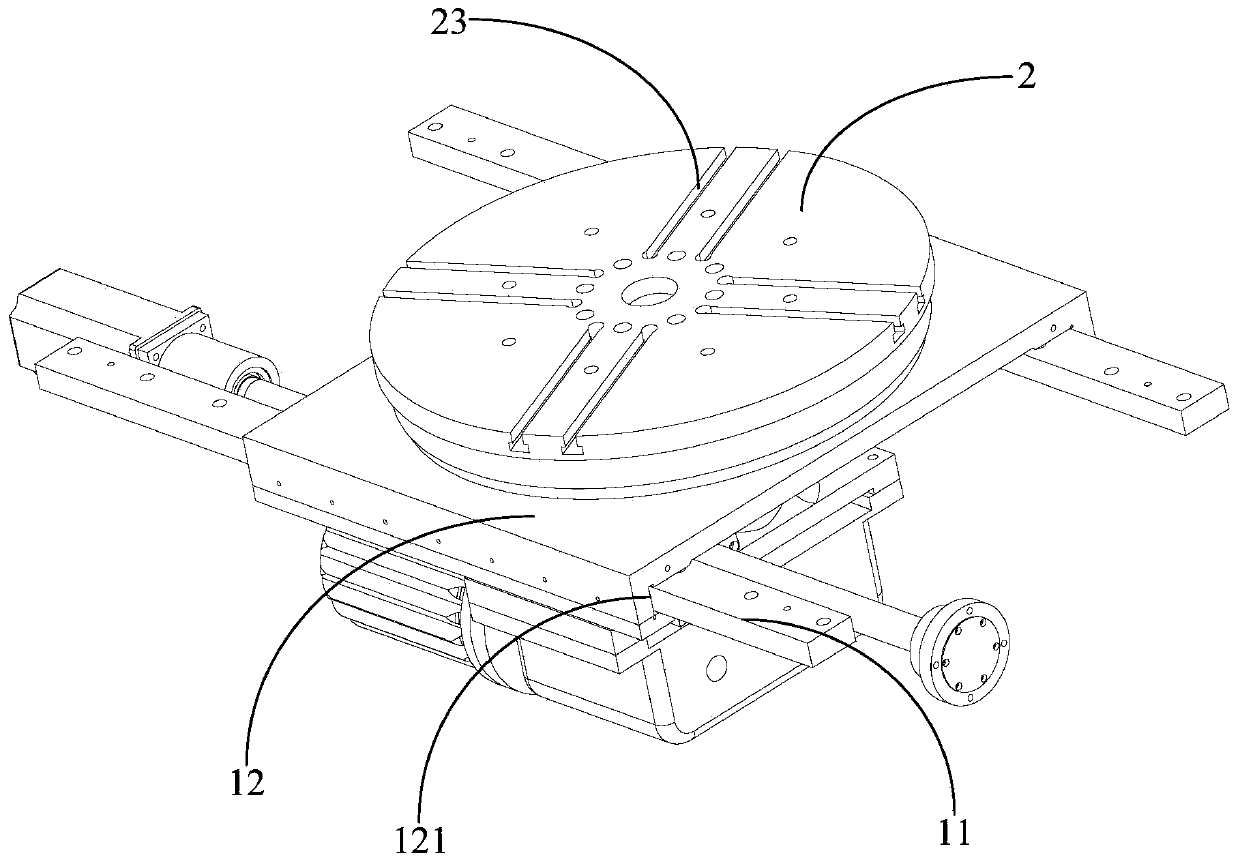

Forming machine tool for rice-milling grinding wheel

PendingCN111318766AAvoid machining errorsImprove product accuracy and efficiencyFeeding apparatusLarge fixed membersMachine toolKnife holder

The invention discloses a forming machine tool for a rice-milling grinding wheel. The forming machine tool for the rice-milling grinding wheel comprises a machine seat, a tool rest assembly, a workingdriving device and a tool rest driving device; a working table which can rotate along a vertical axis and slide horizontally is disposed on the machine seat, the tool rest assembly is installed on the machine seat vertically slideably and used for machining and forming of a plane, an inner hole and an outer circle of a workpiece on the working table; the working table driving device is used for driving the working table to rotate and horizontally slide; and the tool rest driving device is used for driving the tool rest assembly to slide up and down. In the technical scheme provided by the invention, an existing manual mode is abandoned, the forming machine tool for the rice-milling grinding wheel adopts a new numerical control technology and a new machine tool structure, machining and forming of the outer circle, the inner hole and the end surface of the rice-milling grinding wheel can be achieved by additionally arranging a combined tool structure, multiple procedures are completed once, the machining errors caused by repeated clamping are avoided, the product accuracy and the efficiency are improved, and the labor intensity of people is relieved.

Owner:湖北省鄂州市天元砂辊有限责任公司

Preparation method for polysilane azide-multiwalled carbon nanotube composite material

The invention discloses a polysilane azide-multiwalled carbon nanotube composite material and a preparation method thereof, and relates to a polysilane-multiwalled carbon nanotube composite material and a preparation method thereof, aiming at solving the problems that the existing preparation method of polysilane-multiwalled carbon nanotube composite material is complicated in preparation process and the completeness of the multi-walled carbon nanotube is damaged. The polysilane azide-multiwalled carbon nanotube composite material is prepared from an acid solution, an organic solvent, polysilane azide and a multiwalled carbon nanotube. The preparation method comprises the following steps of: (I) calcining; (II) purifying and (III) carrying out azidation to obtain the polysilane azide-multiwalled carbon nanotube composite material. The preparation method disclosed by the invention is mainly used for preparing the polysilane azide-multiwalled carbon nanotube composite material.

Owner:HARBIN UNIV OF SCI & TECH

An integrated high-rigidity light-weight photovoltaic cell module and photovoltaic shutters

ActiveCN106252438BRealize processing and formingReduce weightClimate change adaptationPhotovoltaicsWeather resistanceDrive shaft

The invention relates to an integrated high-rigidity light photovoltaic cell component, which comprises photovoltaic blades which are in shutter structure arrangement on the whole, wherein the photovoltaic blades are provided with transmission shafts (4) and bus wires (5); the transmission shafts (4) are used for fixing and rotating the photovoltaic blades; single photovoltaic blade is of a laminated composite structure and comprises a composite a composite plastic layer (1), a prestressed steel wire mesh (2) and a bar photovoltaic cell (3) which are sequentially arranged; the transmission shafts (4) and the bus wires (5) are arranged at two ends of the corresponding bar photovoltaic cells (3); each composite plastic layer (1) is a plastic layer which is integrally molded in an injection manner; and each internal prestressed steel wire mesh (2) is connected with the corresponding bar photovoltaic cell (3). Compared with the prior art, the integrated high-rigidity light photovoltaic cell component has the advantages of being light, high in rigidity, low in warping degree and high in weather resistance, and integrates sun-shading and power generation.

Owner:SHANGHAI MODIER METAL STRUCTURE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com