Patents

Literature

36results about How to "Lower freezing temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing LNG storage tank

ActiveCN107052618AAvoid organizationAvoid performance changesArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthToughness

The invention discloses a full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing an LNG storage tank. According to the technical scheme, the full-automatic submerged-arc welding solid-core welding wire comprises 0.25-0.45wt% of C, 23-26wt% of Mn, 6-8wt% of Ni, 3-5wt% of W, 0.02-0.04wt% of N, less than or equal to 0.02wt% of P, less than or equal to 0.001wt% of S and the balance of Fe and inevitable impurities. The full-automatic submerged-arc welding solid-core welding wire has the advantages that the price of adopted alloy elements is low, and an alloy component system is simple; and the low-temperature toughness of weld metal formed by the prepared full-automatic submerged-arc welding solid-core welding wire is excellent, the strength of the full-automatic submerged-arc welding solid-core welding wire is matched with the strength of the ultralow-temperature high-manganese steel for preparing the LNG storage tank, and the technical requirements for the strength and the ultralow-temperature toughness of the welded LNG storage tank can be met.

Owner:WUHAN UNIV OF SCI & TECH +1

Tungsten electrode argon arc welding solid cored welding wire used for welding ultralow-temperature high manganese steel

ActiveCN107009046AAvoid performance changesReduce contentWelding/cutting media/materialsSoldering mediaUltimate tensile strengthToughness

The invention relates to a tungsten electrode argon arc welding solid cored welding wire used for welding ultralow-temperature high manganese steel. According to the technical scheme of the solid cored welding wire, the tungsten electrode argon arc welding solid cored welding wire used for welding the ultralow-temperature high manganese steel comprises the chemical components of 0.25-0.55 wt% of C, 23-26 wt% of Mn, 8-10 wt% of Ni, 3-5 wt% of W, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S and the balance Fe and inevitable impurities. The solid cored welding wire is low in price of alloy element content and simple in alloy component system; and formed weld metal has good low-temperature toughness, and the strength of the weld metal is matched with the ultralow-temperature high manganese steel, and the technical requirements for the strength and ultralow-temperature toughness of LNG devices and other devices prepared through welding.

Owner:WUHAN UNIV OF SCI & TECH +1

High-efficiency submerged arc welding metal powder-cored flux-cored wire used for ultra-low-temperature high-manganese steel

ActiveCN109530964AAvoid microstructureAvoid mechanical propertiesWelding/cutting media/materialsSoldering mediaElectrolysisSilicon alloy

The invention discloses a high-efficiency submerged arc welding metal powder-cored flux-cored wire used for ultra-low-temperature high-manganese steel, the high-efficiency submerged arc welding metalpowder-cored flux-cored wire is composed of a steel strip and a metal powder core, the chemical composition of the steel strip is as follows: C is 0.20-0.23 wt%, Si is 0.03-0.05 wt%, Mn is 6-8 wt%, P<=0.002 wt%, S <=0.001 wt%, the balance is Fe and unavoidable impurities. The chemical composition of the metal powder core is as follows: 18-20wt% of electrolytic manganese, 3-4wt% of manganese-silicon alloy, 8-10wt% of nickel powder, 6-8wt% of low-carbon ferrochromium, 4-6wt% of tungsten powder, 2.0-3.0 wt% of potash feldspar, and the balance of iron powder, and the total component content is 100%. The invention can meet the technical requirements for the strength and ultra-low temperature toughness of the welded LNG storage tank.

Owner:NANJING IRON & STEEL CO LTD +1

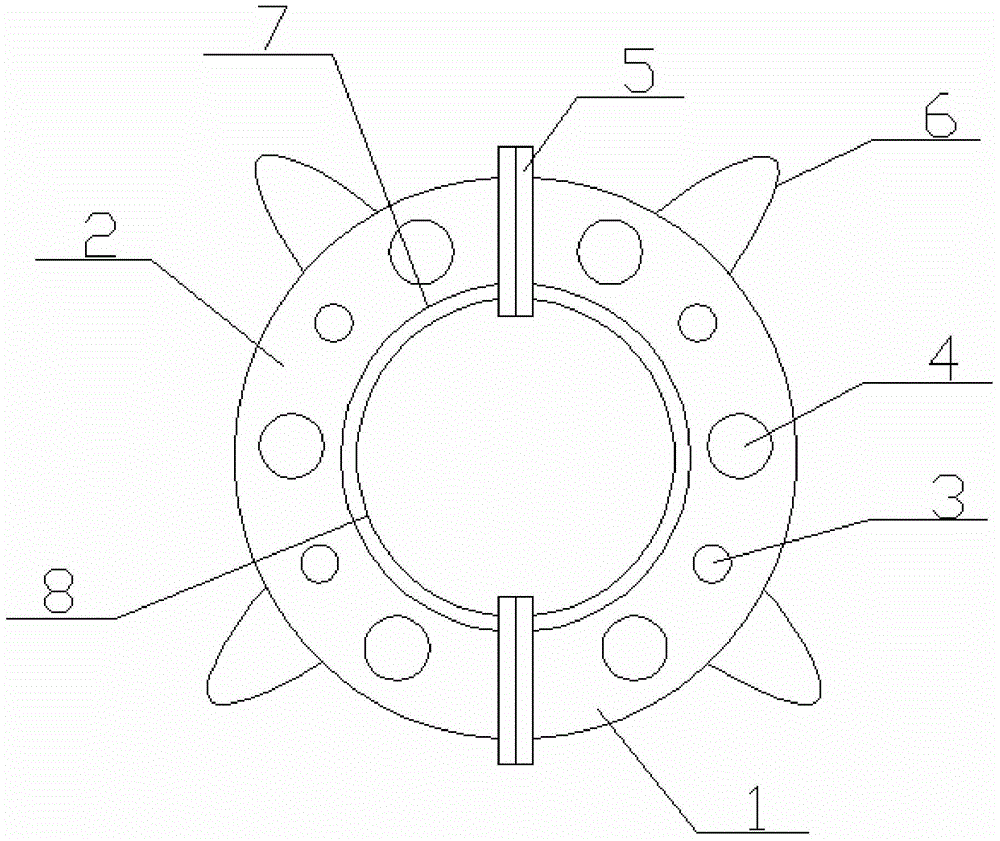

Casting process for high-temperature water-pressure-resisting combined flange

InactiveCN105689653AImprove heat resistanceHigh thermal conductivityFoundry mouldsFoundry coresFlangeHigh heat

The invention discloses a casting process for a high-temperature water-pressure-resisting combined flange. The cast high-temperature wear-resisting combined flange mainly comprises a flange body. The flange body is composed of a first flange plate and a second flange plate. The shape and the size of the second flange plate are the same as those of the first flange plate. The first flange plate and the second flange plate are each of a saddle-shaped structure. Threaded holes and through holes are evenly distributed in the first flange plate and distributed at intervals. The two ends of the first flange plate extend outwards to form fixing edges. Fixing holes are formed in the fixing edges. At least two lug plates are arranged on the edge of the outer side of the first flange plate. The first flange plate and the second flange plate are connected together in a fastened manner through bolts after butting the fixing holes in the fixing edges, and the first flange plate and the second flange plate are connected in the fastened manner to form a mounting hole. The casting process is simple and easy to implement. The cast combined flange is simple in structure and has good high-temperature water-pressure-resisting performance, the service life of the flange is prolonged, and cost is lowered.

Owner:DAFENG HONGLIAN CAST STEEL

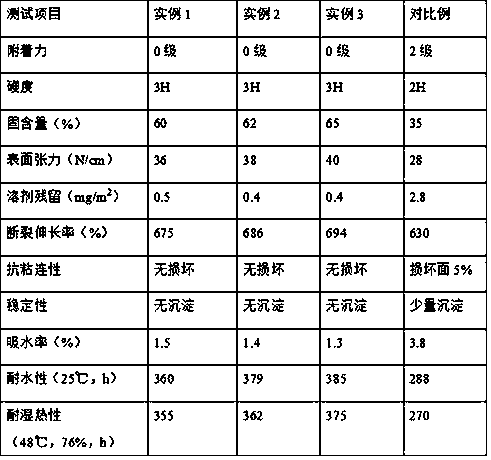

Method for preparing heat-resistant hydrophobic type water-based ink binder

The invention relates to the technical field of preparation of macromolecular materials and particularly relates to a method for preparing a heat-resistant hydrophobic type water-based ink binder. According to the method, a modified acrylic emulsion serves as a substrate, modified carbon nanotube powder and modified boric sludge powder serve as accelerants, and a polyoxyethylene-polyoxypropylene copolymer, potassium persulfate and the like are added as auxiliaries, so as to prepare the heat-resistant hydrophobic water-based ink binder; firstly, acrylic resin is modified and is effectively charged inside the water-based ink binder, and thus, the heat resistance, adhesive power and hydrophobicity of the water-based ink binder can be improved; plant essential oil is extracted from rose petalsby using a steam distillation method, and the modified carbon nanotube powder, the plant essential oil and the yoghurt are subjected to blended fermentation, so that the compatibility of the carbon nanotube powder and the substrate is improved; the boric sludge powder is used for reacting with a homemade dispersion solution, and thus, the heat resistance of the water-based ink binder is further improved, so that the water-based ink binder has an extensive application prospect.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

Preparation method for low-temperature sintered type ceramic glass

InactiveCN108164148AReduce viscosityCrystallization temperature decreasedGlass shaping apparatusOxideChloride sodium

The invention relates to the technical field of preparation of ceramic glass, and in particular relates to a preparation method for low-temperature sintered type ceramic glass. The method uses precipitate powder and modified ultrafine aluminium oxide powder as basic glass, uses modified boron mud powder and sheep bone powder as nucleating agents, and uses a rare earth oxide and sodium chloride asclarifying agents, and the basic glass, the nucleating agents and the clarifying agents are mixed for a reaction to obtain the low-temperature sintered type ceramic glass. According to the method provided by the invention, a precipitate obtained by centrifugation in sludge is calcined under high-temperature conditions to obtain the precipitate powder, ultrafine aluminium oxide powder is modified by a silane coupling agent, in the low-temperature sintering process, the modified ultrafine powder is formed, so that the sintering speed of the ceramic glass is improved; and boron mud powder and a self-prepared dispersion liquid are mixed, the mixed solution is uniformly dispersed on the surface of the basic glass, then the sheep bone powder is added, and the situation that the sheep bone powderis rich in phosphorus element matter is utilized, so that a final precipitated crystal has a more compact and uniform structure, the dimensional uniformity of the ceramic glass is further improved, and the method has wide application prospects.

Owner:CHANGZHOU OPTICAL MATERIAL

Preparation method of high-storing-capacity high-thermal-stability oxygen storage material

InactiveCN107694556AImprove adhesionLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsOxygen preparationCerium nitrateAluminium hydroxide

The invention relates to the technical field of preparation of oxygen storage materials, in particular to a preparation method of a high-storing-capacity high-thermal-stability oxygen storage material; a solution of hydrogen peroxide, white sugar and polyethylene glycol is used to modify cerium nitrate, zirconium nitrate, aluminum nitrate and yttrium nitrate, high-temperature calcining is performed then; the white sugar may bind with other ingredients in the oxygen storage material; by adding polyethylene glycol solution, ions can be dispersed evenly, the specific surface area is increased, and oxygen-storing capacity of the oxygen storage material is improved. The surfactant, the polyethylene glycol solution, added herein may be effectively protected during calcining. Precipitate convertsslowly into oxide during calcining, and thermal stability and oxygen-storing capacity of the oxygen storage material are improved. Boric sludge and aluminum hydroxide are added, the modified aluminumhydroxide is decomposed into alumina at high temperature during reaction, and accordingly the thermal stability of the oxygen storage material is further improved; the preparation method has a promising application prospect.

Owner:高俊

Single-phase alpha magnesium-lithium alloy with excellent high-temperature mechanical performance and processing technique of single-phase alpha magnesium-lithium alloy

The invention discloses single-phase alpha magnesium-lithium alloy with excellent high-temperature mechanical performance and a processing technique of the single-phase alpha magnesium-lithium alloy. The single-phase alpha magnesium-lithium alloy is prepared from the following ingredients by weight percent: 2.0 to 6.0 percent of Li, 0.2 to 0.4 percent of Ca, 0.1 to 0.3 percent of Hf, 0.1 to 0.3 percent of Mo, 0.1 to 0.4 percent of Pb, 0.1 to 0.2 percent of Th, and the balance of magnesium. The invention provides a solution of a novel materials science for the sharp decrease and worsening of mechanical performance of the magnesium-lithium alloy at about 100 DEG C. The material has the mechanical performance of the traditional magnesium-lithium alloy: the elastic modulus is 50 to 70 GPa, the yield strength is 90 to 120 MPa, the tensile strength is 140 to 160 MPa, and ductility is 6 to 18 percent. The single-phase alpha magnesium-lithium alloy has the high-temperature mechanical performance that the traditional magnesium-lithium alloy does not have: the yield strength is 140 to 150 MPa at a temperature lower than 100 DEG C, and the yield strength of the traditional magnesium-lithium alloy is 65 MPa at a temperature lower than 100 DEG C. While the high-temperature mechanical performance is ensured, the service life of the alloy is further prolonged, and the industrialized mass application is facilitated. The magnesium-lithium alloy of the invention can be used at the temperature lower than 100 DEG C and has a significant light-weight effect.

Owner:GUANGZHOU YUZHI TECH CO LTD

Preparation method of high-compressive-strength heat-proof foam glass plate

InactiveCN107473569AHigh compressive strengthGood compatibilityGlass shaping apparatusPolymer scienceVegetable oil

The invention discloses a preparation method of a high-compressive-strength heat-proof foam glass plate and in particular relates to the technical field of preparation of building materials. The preparation method is characterized in that a silane coupling agent is used for modifying basalt and quartzite, and the modified basalt and quartzite are put into vegetable oil and biogas slurry microorganisms to be blended and fermented, so that compatibility between rocks and high polymers is enhanced, and homogeneous dispersion strength of the rocks and high polymers is also improved; a water-soluble silane coupling agent, sodium fluorosilicate and glass fibers are added into resin, so that compressive strength of the foam glass plate is further improved; and by adding boric sludge, fly ash, modified aluminum hydroxide and boric acid, viscosity of glass melt is further improved, compressive strength performance and heat resistance of the foam glass plate are obviously improved, the boric acid not only can accelerate melting but also can improve foam structures, so that foams are uniform and small, and the compressive strength of the foam glass plate can be beneficially improved.

Owner:郦璋

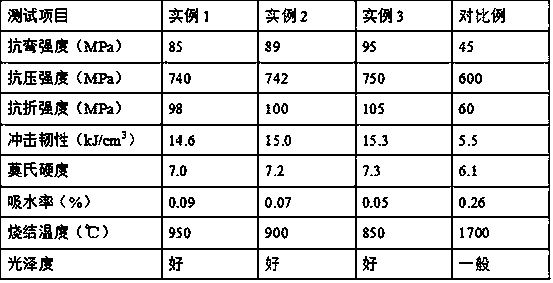

Powder for additive manufacturing and preparation method and application thereof

PendingCN114535563AReduce hot cracksIncrease the freezing temperature rangeAdditive manufacturing apparatusTransportation and packagingMechanical propertyAdditive layer manufacturing

In order to solve the problems that an aluminum alloy part obtained through existing additive manufacturing is prone to having the hot crack defect, and the material formability and the mechanical property are affected, the powder for additive manufacturing is provided and comprises, by weight, 92-98 parts of aluminum alloy powder and 2-8 parts of nano Ni powder. Wherein the average particle size of the aluminum alloy powder is 1-100 microns, and the average particle size of the nano Ni powder is 10-800 nanometers. Meanwhile, the invention further discloses a preparation method and application of the powder for additive manufacturing. According to the powder for additive manufacturing, the laser input efficiency is improved, meanwhile, hot cracks of an aluminum alloy part obtained through additive manufacturing are effectively reduced, and the mechanical property of the aluminum alloy part is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Oxidation-resistant Pb-Li-V lead-lithium alloy with high thermal stability

The invention discloses an oxidation-resistant Pb-Li-V lead-lithium alloy with high thermal stability. The alloy comprises the following components in percentage by weight: 1.4-1.8% of Li, 0.2-0.5% ofV, 0.5-0.8% of Sm, 0.3-0.8% of B, 1.4-1.9% of Ge, 0.4-0.6% of Zn, and the balance lead. The lead-lithium alloy has the high thermal stability which is not realized by a traditional lead alloy for a shielding material; and moreover, the lead-lithium alloy is high in oxidation resistance; the lead-lithium alloy is applicable to the fields such as the fields of nuclear piles, medical radioactive source shielding, and nuclear waste treatment in a tropical environment; with the adoption of the lead-lithium alloy, a nuclear reactor system can effectively safely run, and the service life of the system can be prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

3D printing repair ink material and method for steel rolling and method

ActiveCN109604586AGuaranteed StrengthLower freezing temperature rangeAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a 3D printing repair ink material and method for steel rolling. The ink material is a powder material. The 3D printing repair ink material is characterized by comprising 0.4wt%of C, 89wt% of Fe, 0.2wt% of Si, 3wt% of Mn, 2wt% of Cr, 0.4wt% of V, 1wt% of W, 1wt% of Ti and the balance impurity. The 3D printing technology adopts a selective laser sintering technology or a selective laser melting technology. According to the 3D printing repair ink material and method for steel rolling, the metal powder is molten and covers a repaired surface by the reasonable 3D printing technology, the geometric dimensions of the base material are recovered, and the physical and chemical properties of the base material are not changed.

Owner:NANJING IRON & STEEL CO LTD

High-strength high-conductivity Pb-Li-Sc lead-lithium alloy for shielding material

The invention discloses high-strength high-conductivity Pb-Li-Sc lead-lithium alloy for a shielding material and a processing technology thereof. The high-strength high-conductivity Pb-Li-Sc lead-lithium alloy comprises, by weight, 0.8-1.6wt.% of Li, 0.4-0.8wt.% of Sc, 0.2-0.5wt.% of Nb, 0.6-1.4wt.% of Co, 0.4-0.8wt.% of Sb, 0.1-0.2wt.% of Th, and the balance lead. The lead-lithium alloy has the high-strength high-conductivity performance which is not provided for traditional lead alloy for the shielding material. The high-strength high-conductivity Pb-Li-Sc lead-lithium alloy is applied to the fields of nuclear piles, medical radioactive source shielding, nuclear waste processing and the like, safe operation of a nuclear reactor system can be effectively ensured, and the system operationlife is prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-strength corrosion-resistant Pb-Li-Si lead-lithium alloy for shielding material

The invention discloses high-strength corrosion-resistant Pb-Li-Si lead-lithium alloy for a shielding material and a processing technology thereof. The alloy comprises the following components of, byweight, 0.4-2.5 wt.% of Li, 1.8-3.6 wt.% of Si, 1.4-2.3 wt.% of Bi, 0.8-1.2 wt.% of Ni, 0.2-0.4 wt.% of Sn, 0.1-0.2 wt.% of La and the balance lead. The lead-lithium alloy has the high strength and the corrosion resistance which are not possessed by the lead alloy used by the traditional shielding material. The alloy and the method can be effectively applied to the fields of nuclear reactors, medical radiation source shielding, nuclear waste treatment and the like; and the production process is simple, the equipment requirement is low, and the large-scale industrial application is faciliated.

Owner:GUANGZHOU YUZHI TECH CO LTD

A kind of preparation method of metal glass composite pipe

Owner:嘉兴晟源工业设计有限公司

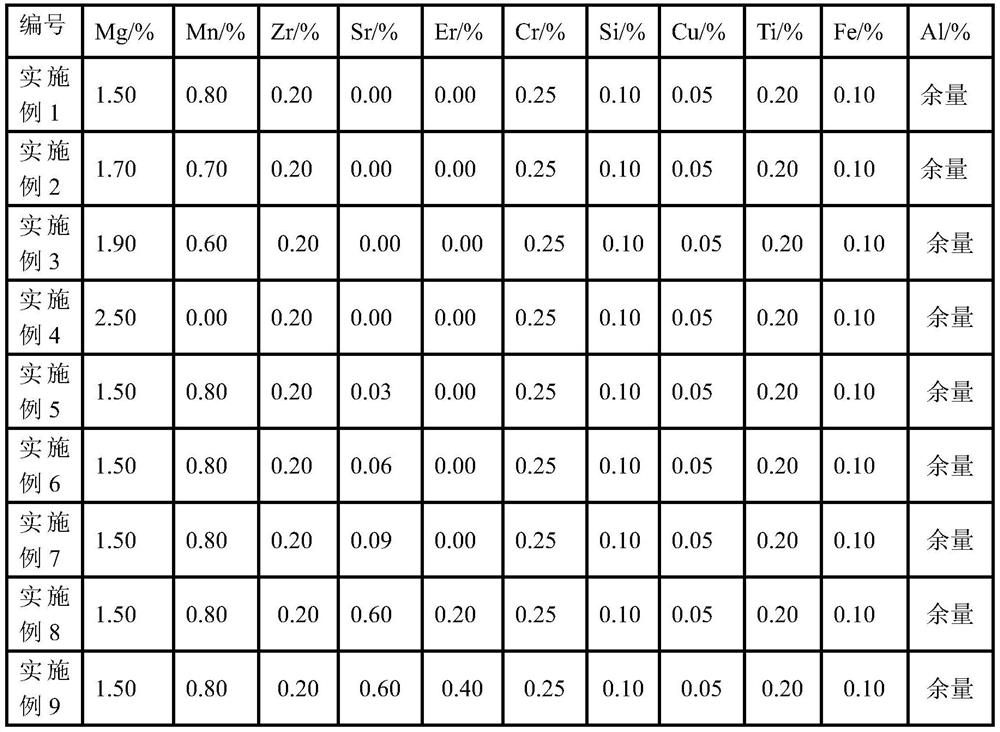

A high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ships and its production process

The invention discloses a high-throughput continuous casting and rolling aluminum-magnesium-manganese alloy plate for ships and a production process thereof. The chemical composition of the aluminum-magnesium-manganese alloy is calculated by mass percentage: Mg: 0.80-2.80%, Mn: 0.00-1.40 %, Zr: 0.10‑0.50%, Cr: 0.15‑0.35%, Sr: 0.00‑0.10%, Er: 0.00‑0.60%, Si: 0.10‑0.40%, Cu: 0.01‑0.10%, Ti: 0.01‑0.05% , Fe: 0.00‑0.40%, the balance is Al. The production process mainly includes smelting and melt treatment, continuous casting, continuous rolling and cold rolling process. This invention solves the problem of high-throughput continuous casting and rolling to produce aluminum for ships Magnesium-manganese sheets have problems such as easy segregation, low strength and toughness, and poor formability.

Owner:ZHENGZHOU UNIV

Tungsten argon arc welding solid wire for ultra-low temperature high manganese steel welding

ActiveCN107009046BAvoid performance changesReduce contentWelding/cutting media/materialsSoldering mediaUltimate tensile strengthToughness

The invention relates to a tungsten electrode argon arc welding solid cored welding wire used for welding ultralow-temperature high manganese steel. According to the technical scheme of the solid cored welding wire, the tungsten electrode argon arc welding solid cored welding wire used for welding the ultralow-temperature high manganese steel comprises the chemical components of 0.25-0.55 wt% of C, 23-26 wt% of Mn, 8-10 wt% of Ni, 3-5 wt% of W, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S and the balance Fe and inevitable impurities. The solid cored welding wire is low in price of alloy element content and simple in alloy component system; and formed weld metal has good low-temperature toughness, and the strength of the weld metal is matched with the ultralow-temperature high manganese steel, and the technical requirements for the strength and ultralow-temperature toughness of LNG devices and other devices prepared through welding.

Owner:WUHAN UNIV OF SCI & TECH +1

MIG/MAG welding wire for -196°C working temperature

ActiveCN106938375BLow content priceReduce manufacturing costWelding/cutting media/materialsSoldering mediaWorking temperatureImpurity

The invention relates to a melting electrode gas shielded welding wire suitable for the working temperature of -196°C. The technical solution is: the chemical composition of the metal gas shielded welding wire is: C is 0.30~0.55wt%, Mn is 24~26wt%, Ni is 6.4~8.2wt%, W is 2.5~4.0wt%, P≤0.002wt%, S≤0.001wt%, the balance is Fe and unavoidable impurities. The invention has low preparation cost and simple alloy composition system; the formed weld metal has the characteristics of ultra-low temperature and high toughness, its strength matches that of ultra-low temperature high manganese steel, and the welded joint has high strength and excellent mechanical properties of ultra-low temperature toughness, which can meet the requirements of Specifications for strength and cryogenic toughness of devices to be welded at ‑196°C.

Owner:WUHAN UNIV OF SCI & TECH

White-cooper alloy with light-weight characteristics used for Tibetan area buddha casting and process of white-cooper alloy

The invention discloses a white-cooper alloy with light-weight characteristics used for Tibetan area buddha casting and a process of the white-cooper alloy. The alloy comprises the following components of, in percentage by weight, 1.5 wt.%-3.0 wt.% of Li, 8.0 wt.%-12.0 wt.% of Mg, 0.2 wt.%-0.4 wt.% of Sc, 5.0 wt.%-6.0 wt.% of Bi, 5.0 wt.%-8.0 wt.% of Ni, 20.0 wt.%-28.0 wt.% of Al, 2.0 wt.%-3.0 wt.% of Au, 8.0 wt.%-10.0 wt.% of Ag and the balance copper. The material provides a light-weight solution for the white-cooper alloy used for Tibetan area buddha casting, and the appearance of the obtained product has a white impression. The implementation and industrialization of the material can effectively promote the updating and industry upgrading requirements of new materials in the religiousdecoration industry in China.

Owner:GUANGZHOU YUZHI TECH CO LTD

A 3D printing repair ink material and method suitable for rolling steel

ActiveCN109604586BGuaranteed StrengthLower freezing temperature rangeAdditive manufacturing apparatusIncreasing energy efficiency3d printSelective laser sintering

The invention discloses a 3D printing repair ink material and method suitable for rolling steel products. The ink material is a powder material, which is characterized in that it contains: C: 0.4wt%, Fe: 89wt%, Si: 0.2wt%, Mn : 3wt%, Cr: 2wt%, V: 0.4wt%, W: 1wt%, Ti: 1wt%, and the rest are impurities. The 3D printing process uses a selective laser sintering process or a laser selective melting process. The invention uses a reasonable 3D printing process to clad the metal powder on the repaired surface, restore the geometric size of the base material without changing the physical and chemical properties.

Owner:NANJING IRON & STEEL CO LTD

High-strength low-temperature-resistant Pb-Li-Mn lead-lithium alloy for shielding material

The invention discloses a high-strength low-temperature-resistant Pb-Li-Mn lead-lithium alloy for a shielding material and a processing technology thereof. The alloy comprises the following components, by weight percentage: 0.8-2.4wt% of Li, 0.6-1.8wt% of Mn, 0.2-0.4wt% of Se, 0.6-1.5wt% of Cr, 0.2-0.4wt% of Ba, 0.6-0.9wt% of In and the balance Pb. The lead-lithium alloy has the high strength which a traditional lead alloy for a shielding material does not have, and excellent plasticity can be achieved at extremely low temperature. The lead-lithium alloy is applied to the fields of nuclear reactor polar environment, medical radioactive source shielding, nuclear waste treatment and the like in the polar environment, safe operation of a nuclear reactor system can be effectively guaranteed, and the service life of the system can be prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

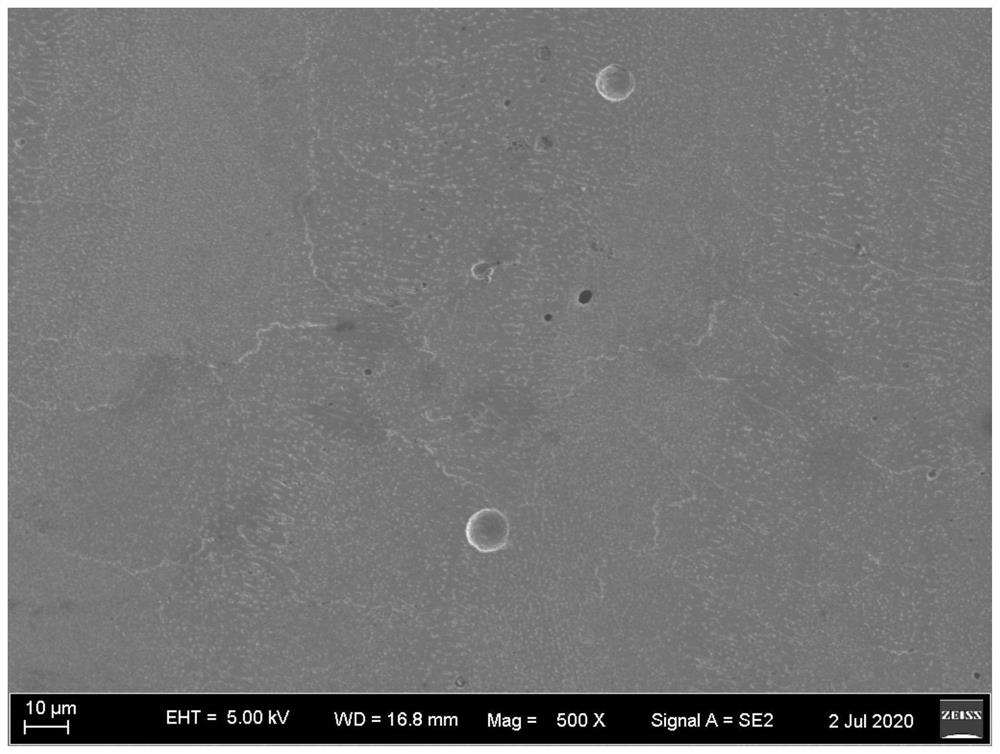

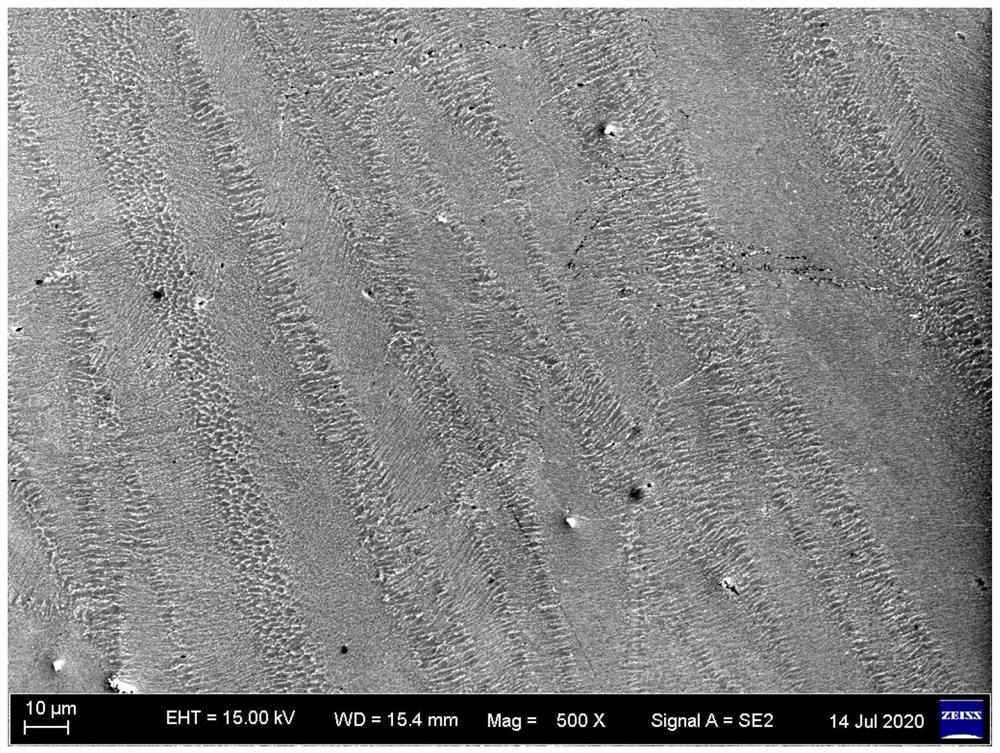

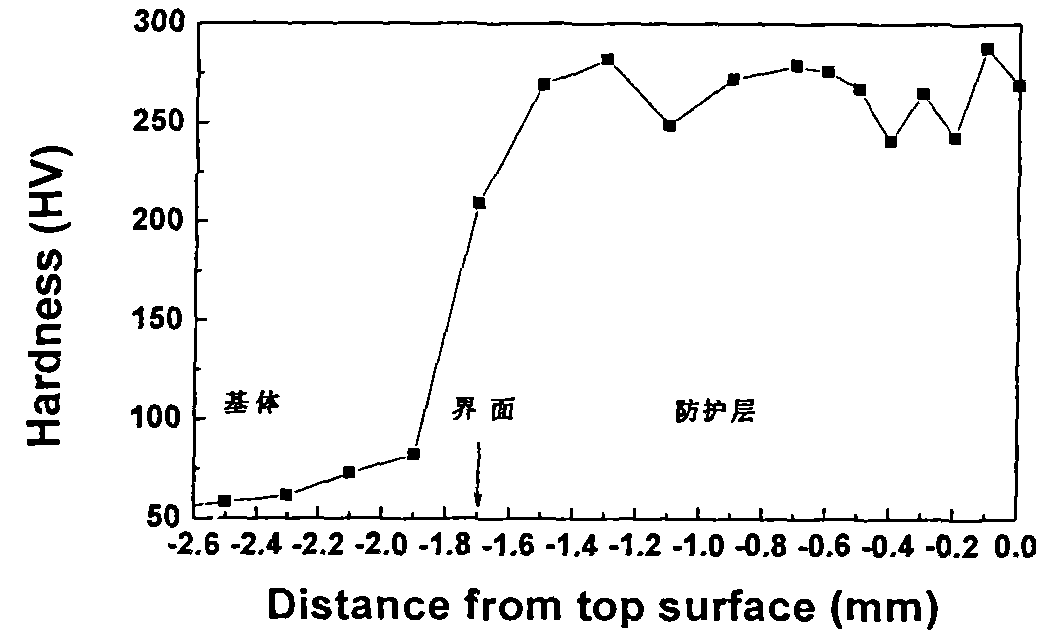

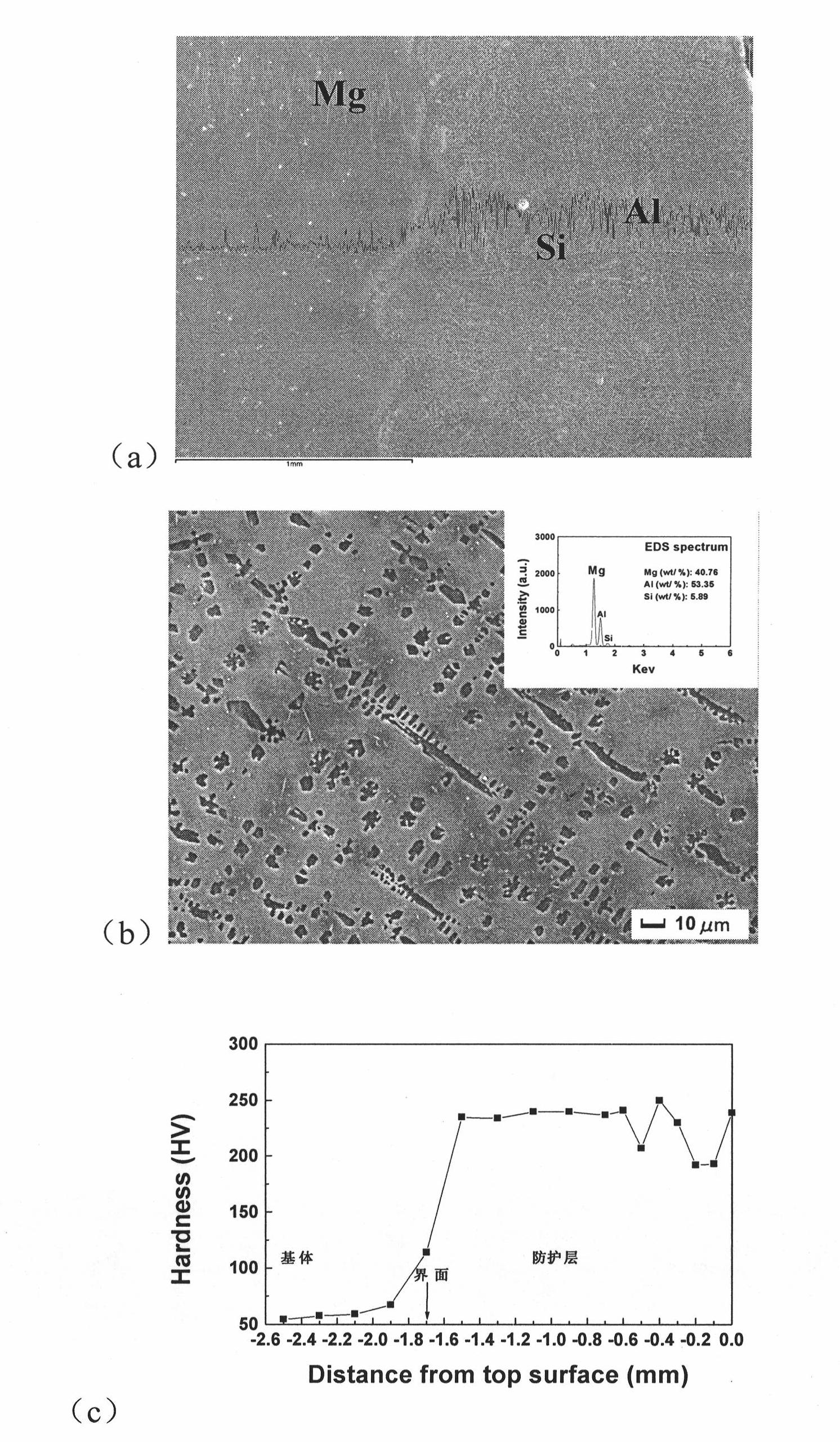

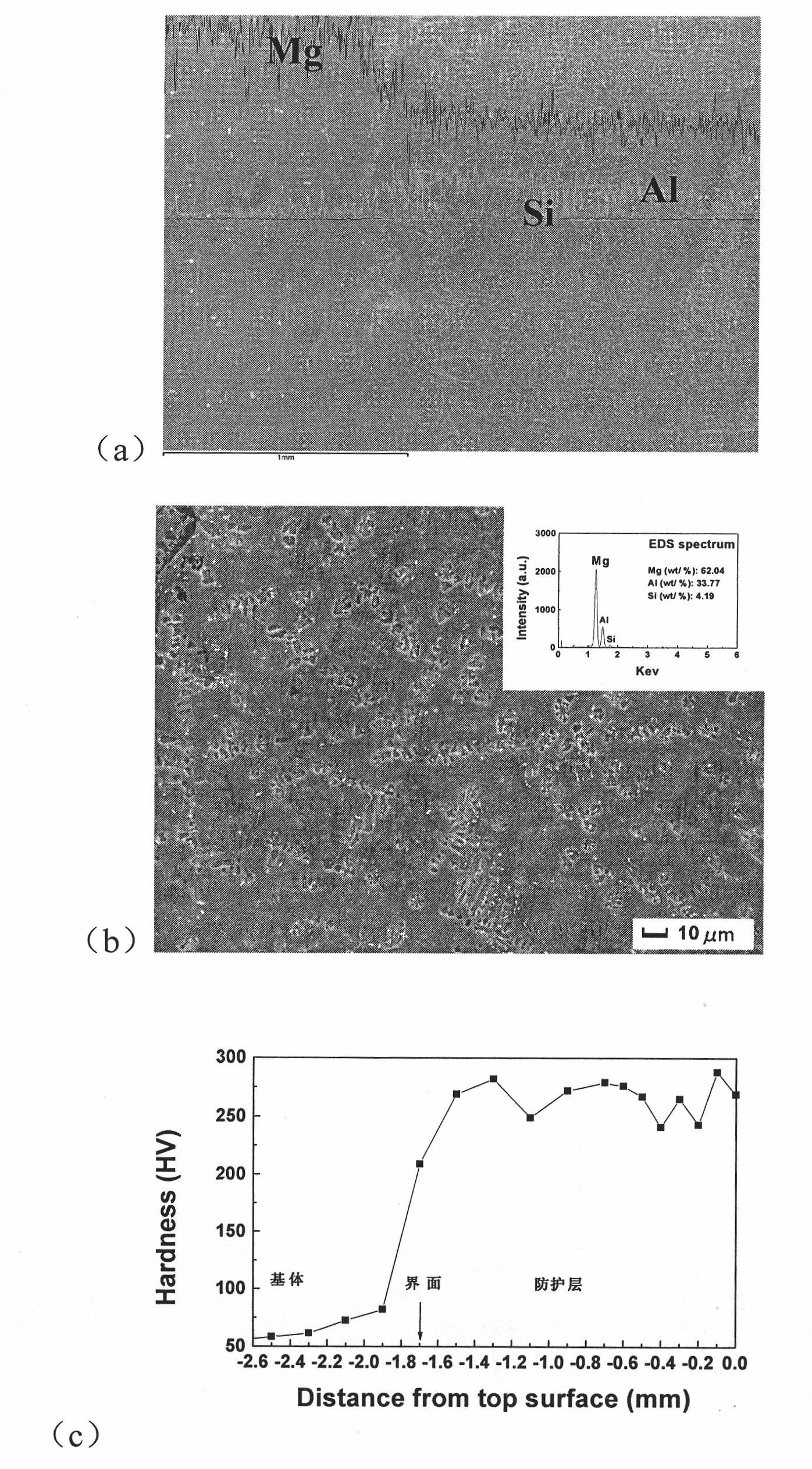

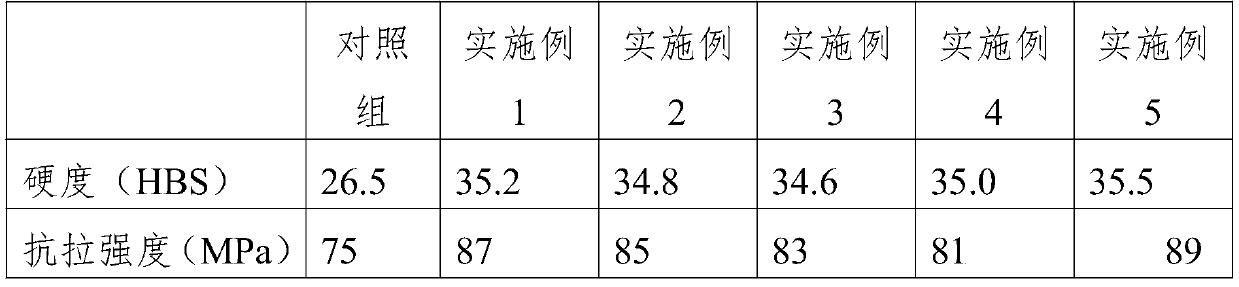

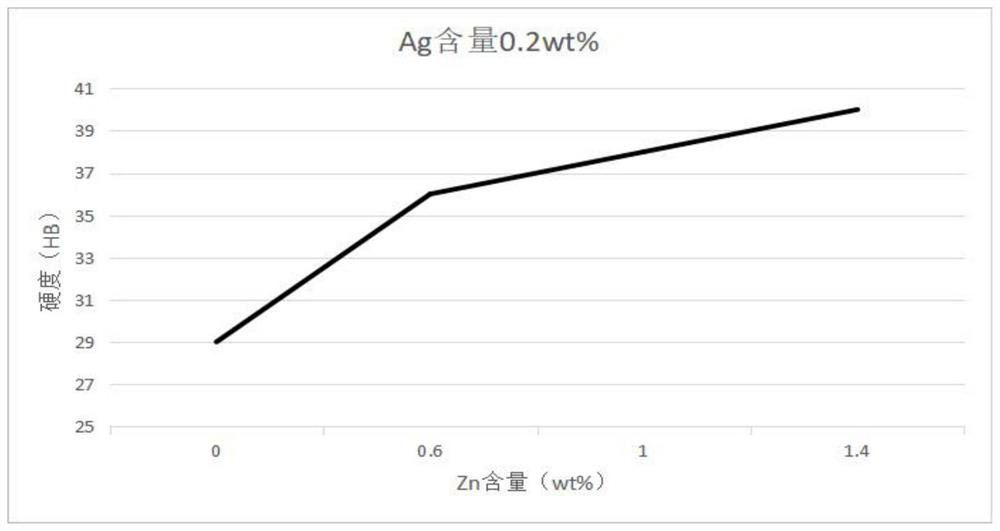

Process for preparing compact thick protection layers on magnesium alloy surfaces

ActiveCN101693986BApparent elemental diffusionImprove antioxidant capacityMolten spray coatingHydrofluoric acidSilicon alloy

A process for preparing compact thick protection layers on magnesium alloy surfaces, which includes steps of surface pretreatment, flame plating alloy powder, laser remelting and the like, is added with a surface pretreatment procedure of deoxidation galvanization, and reasonably determines key process parameters. The process is particularly characterized in that solution of the deoxidation galvanization is water solution prepared by hydrofluoric acid (50ml / L) and zinc sulfate heptahydrate (50g / L), time of the deoxidation galvanization procedure ranges from 15 seconds to 20 seconds, preheating temperatures of primary plating and secondary plating of the flame plating are respectively 60-120 DEG C and 150-200 DEG C, laser power of the laser remelting ranges from 1250 W to 1500 W, scanning speed thereof is 500mm / min, and light spot diameter thereof is 4mm. The thickness of a protection layer obtained by preparing flame plating aluminium-silicon alloy powder and laser remelting achieves over 1.5mm, the protection layer is compact in structure without shortages of pores and the like, rigidity of the protection layer ranges from 225HV to 270 HV( which is 4.5-4.9 times of that of a substrate, the thickness direction of the protection layer seldom changes, the component (by mass percentage) of the protection layer is 33.77-53.35Al-62.04-40.76Mg-4.19-5.89Si, and boundaries of the protection layers are in alloy combination.

Owner:JIANGSU UNIV

High-thermal-conductivity Co-containing lead-lithium alloy with excellent die-casting performance

The invention discloses a high-thermal-conductivity Co-containing lead-lithium alloy with the excellent die-casting performance and a processing technology thereof. The lead-lithium alloy comprises the following components of, by weight, 1.2-1.8 wt% of Li, 0.8-1.2 wt% of Co, 0.2-0.4 wt% of Y, 0.3-0.5 wt% of In, 0.2-0.4 wt% of Eu, 0.4-0.8 wt% of Mn and the balance lead. Compared with a lead alloy for a traditional shielding material lacking excellent casting performance, the lead-lithium alloy has the excellent casting performance and the high thermal conductivity; and the Co-containing lead-lithium alloy and the processing technology thereof can be widely applied to the military and civilian fields and are significant.

Owner:GUANGZHOU YUZHI TECH CO LTD

Method for preparing tin-base bearing alloy

The invention provides a tin-based bearing alloy, which is composed of copper with a weight percentage of 5.5% to 6.5%, antimony with a weight percentage of 10% to 13%, zinc and tin with a weight percentage of 0.3% to 0.8%, The present invention also provides a preparation method of the tin-based bearing alloy. First, 50% tin, all copper and antimony are put into a furnace for mixing and melting, and after complete melting, all zinc is added at 500-550°C. After the zinc is completely melted, add the remaining tin. After the alloy is completely melted, stir and stand for 15-30 minutes. The final casting temperature is 360-450°C. The invention improves the strength and hardness of the tin-based alloy, can reduce the solidification temperature range, improve the fluidity, reduce the dispersed shrinkage cavity, reduce the gas content in the alloy liquid, and reduce the pore defects in the casting. The corrosion resistance, oxidation resistance and uniformity of the alloy improve the toughness and strength of the alloy.

Owner:上海飞轮有色冶炼厂

High-strength and high-temperature-resistance Pb-Li-Hf lead lithium alloy for shielding material

The invention discloses a high-strength and high-temperature-resistance Pb-Li-Hf lead lithium alloy for a shielding material and a machining process thereof. The alloy comprises the following components in percentage by weight: 0.8-2.0 wt.% of Li, 1.2-1.6 wt.% of Hf, 0.4-0.8 wt.% of Te, 1.2-1.6 wt.% of Co, 0.2-0.5 wt.% of Cu, 0.1-0.2 wt.% of Pr, and the balance of lead. The lead lithium alloy achieves high strength and high-temperature resistance, which are not owned to a lead alloy for a traditional shielding material. The lead lithium alloy can be effectively applied to the field of nuclearpiles, medical radioactive source shielding, nuclear waste treatment and the like. The production process is simple, low in equipment requirement and convenient for large-scale industrial application.

Owner:GUANGZHOU YUZHI TECH CO LTD

A kind of preparation method of tin-based bearing alloy

The invention relates to the technical field of bearing alloys, in particular to a preparing method for a tin-based bearing alloy. The preparing method comprises the following steps that a, a pure tiningot, a pure copper ingot, a pure antimony ingot, a pure aluminum ingot and the like are subjected to burdening according to the mass percent content of various components in the tin-based bearing alloy; b, 1 / 2 of the pure tin ingot in the above accessories is placed at the bottom of a crucible, then, 50% of a tin-silicon alloy, 10% of a tin-titanium alloy and pure boron powder are sequentiallyadded, after heating melting, the left pure tin ingot is added for temperature adjusting, and finally, the pure copper ingot, the pure antimony ingot and the pure aluminum ingot are added; c, when theheating temperature is stably increased to 500-550 DEG C, a comprehensive treatment agent can be added for refining modification treatment, and standing is conducted for a period of time after drossing; and d, a steel ingot die is preheated, alloy tin liquid obtained through the step c is poured into the steel ingot die, and cooling is conducted to the room temperature. According to the preparingmethod, the solidification temperature range can be narrowed, mobility is improved, dispersed shrinkage is reduced, the content of gas in the alloy liquid is reduced, and the air hole defect in castings is reduced.

Owner:HONGHE COLLEGE

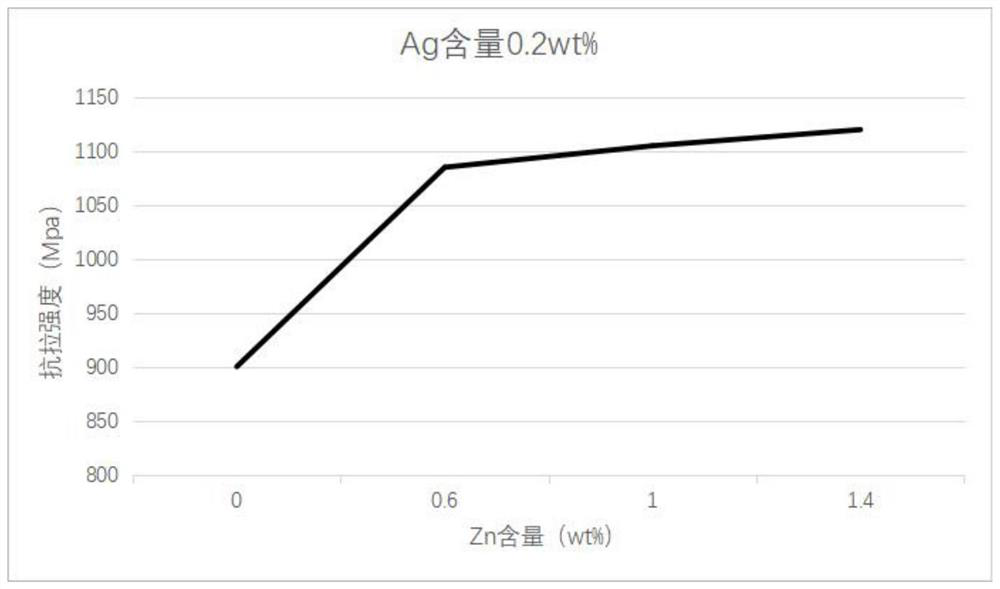

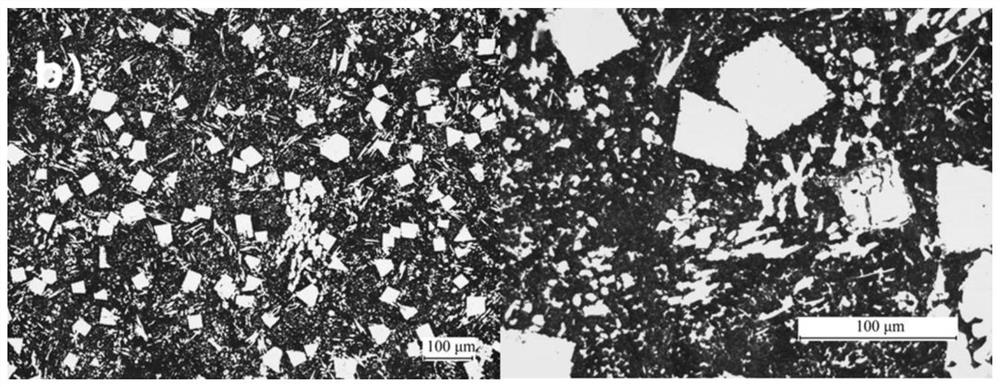

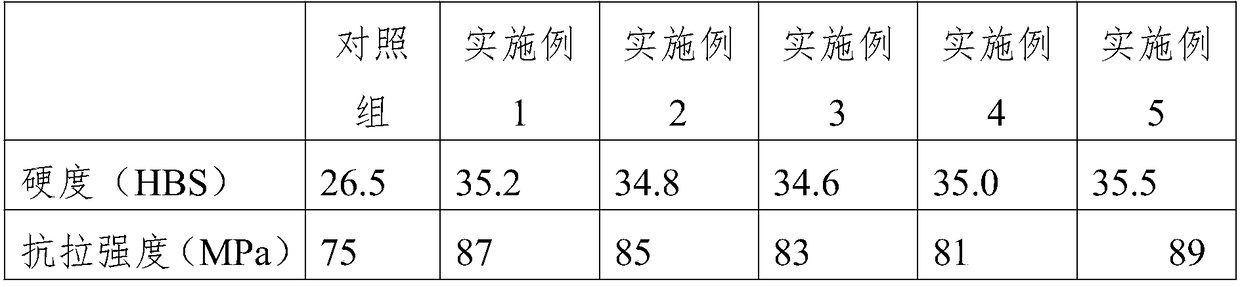

An environmentally friendly and high load-bearing tin-based babbitt alloy material for arc deposition

The invention discloses an environment-friendly high-load-bearing tin-based Babbitt alloy material for arc deposition, which solves the problems of poor load-bearing capacity and low fatigue strength of the existing Babbitt alloy, and comprises the following components in mass percentage: Sb: 6 ‑15%, Cu: 2‑8%, Zn: 0.1‑3.0%, Ag: 0.1‑2.0%, the balance is Sn; after arc deposition, the average size of tin-based babbitt alloy square SnSb phase is less than 10um, dispersed The Cu6Sn5 phase does not have any orientation. In the present invention, Zn and Ag are added to the tin-based babbitt alloy to replace the currently commonly used babbitt alloying elements As, Cd and other elements that have great pollution to the environment. The babbitt alloy of the present invention not only refines the crystal grains, It improves the wear resistance, and also has excellent toughness and weldability; it can greatly reduce spatter when used in the arc deposition process, the appearance of the weld is beautiful and tidy, and the resulting deposited layer has a strong bearing capacity and high fatigue strength.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST +1

Preparing method for tin-based bearing alloy

The invention relates to the technical field of bearing alloys, in particular to a preparing method for a tin-based bearing alloy. The preparing method comprises the following steps that a, a pure tiningot, a pure copper ingot, a pure antimony ingot, a pure aluminum ingot and the like are subjected to burdening according to the mass percent content of various components in the tin-based bearing alloy; b, 1 / 2 of the pure tin ingot in the above accessories is placed at the bottom of a crucible, then, 50% of a tin-silicon alloy, 10% of a tin-titanium alloy and pure boron powder are sequentiallyadded, after heating melting, the left pure tin ingot is added for temperature adjusting, and finally, the pure copper ingot, the pure antimony ingot and the pure aluminum ingot are added; c, when theheating temperature is stably increased to 500-550 DEG C, a comprehensive treatment agent can be added for refining modification treatment, and standing is conducted for a period of time after drossing; and d, a steel ingot die is preheated, alloy tin liquid obtained through the step c is poured into the steel ingot die, and cooling is conducted to the room temperature. According to the preparingmethod, the solidification temperature range can be narrowed, mobility is improved, dispersed shrinkage is reduced, the content of gas in the alloy liquid is reduced, and the air hole defect in castings is reduced.

Owner:HONGHE COLLEGE

Magnesium-lithium alloy having excellent high-temperature mechanical properties and containing single phase beta and machining technique of magnesium-lithium alloy

InactiveCN107419150ALower freezing temperature rangeImprove high temperature stabilityLithiumManufactured material

The invention discloses a single-phase β-magnesium-lithium alloy with excellent high-temperature mechanical properties and a processing technology thereof. In terms of weight percentage, the composition of the alloy is: Li:12.0‑18.0wt.%, Fe:0.1‑0.6wt.%, Cr:0.1‑0.2wt.%, Co:0.1‑0.2wt.%, Gd:0.1‑ 0.2wt.%, Er: 0.1‑0.2wt.%, the balance is magnesium. The invention provides a novel material science solution to the sharp decrease and deterioration of the mechanical properties of the current magnesium-lithium alloy at about 100 degrees Celsius. The material has the mechanical properties of traditional magnesium-lithium alloys: the elastic modulus is 50-70GPa, the yield strength is 90-120MPa, the tensile strength is 140-160MPa, and the elongation is 6-18%. And it has high-temperature mechanical properties that traditional magnesium-lithium alloys do not have: at 100 degrees, the yield strength is 140-150MPa, while the traditional magnesium-lithium alloy has a yield strength of about 65MPa at 100 degrees. The smelting and processing method of the casting magnesium-lithium alloy is simple, and the production cost is relatively low. While ensuring high-temperature mechanical properties, the service life of the alloy is further improved, which is convenient for large-scale industrial application. The magnesium-lithium alloy of the present invention can be used for manufacturing at an operating temperature below 100 degrees, and has an extremely significant lightening effect.

Owner:GUANGZHOU YUZHI TECH CO LTD

Oxidation-resistant Pb-Li-Ti lead-lithium alloy with extremely-low recrystallization temperature

The invention discloses oxidation-resistant Pb-Li-Ti lead-lithium alloy with an extremely-low recrystallization temperature and a processing technology thereof. The oxidation-resistant Pb-Li-Ti lead-lithium alloy comprises, by weight, 1.2%-2.0% of Li, 0.3%-0.8% of Ti, 0.1%-0.4% of Te, 0.5%-0.9% of V, 1.0%-2.0% of Sn, 0.4%-0.8% of Bi and the balance lead. The lead-lithium alloy has a high anti-oxidation property which cannot be achieved by lead alloy for a traditional shielding material, and the recrystallization temperature is low. The oxidation-resistant Pb-Li-Ti lead-lithium alloy is used inthe fields of nuclear piles, medical radioactive source shielding, nuclear waste treatment and the like in the polar region environment, safe operation of a nuclear reactor system can be effectivelyguaranteed, and the service life of the system is prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com