Method for preparing heat-resistant hydrophobic type water-based ink binder

A water-based ink and hydrophobic technology, applied in ink, household utensils, applications, etc., can solve problems such as poor adhesion, poor heat resistance, and poor water resistance, and achieve improved hydrophobicity, initial drying, and improved hydrophobicity , The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

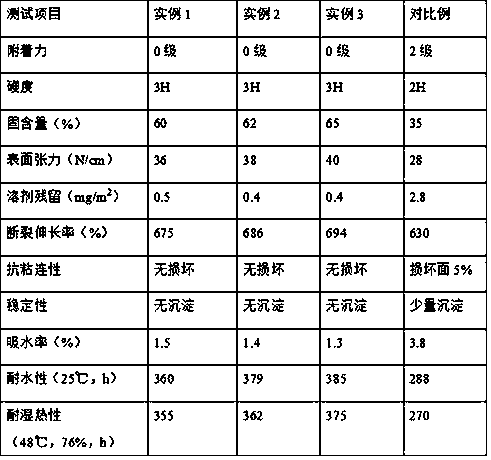

Examples

example 1

[0025] Mix rose petals and deionized water at a mass ratio of 1:5 and place them in a four-necked flask equipped with a thermometer, a condenser and a stirrer, feed water vapor into the four-necked flask, and first distill with a low distillation rate of 90L / h 1h, control the temperature of the condensed water at 35°C, then distill with a high distillation rate of 110L / h for 45min, heat up to 36°C to obtain an emulsion, add 7% sodium chloride of the emulsion mass to the emulsion Mix and oscillate, pour into a separatory funnel after oscillating and let stand for stratification for 2 minutes, discharge the lower water phase after stratification, and finally absorb the residual water with anhydrous sodium sulfate, let stand and age for 1 day, filter to remove solid sodium sulfate, take out The filtrate is rose essential oil; 20g of carbon nanotubes is weighed and poured into a ball mill, and ball milled for 45min at a rotating speed of 85r / min to obtain a carbon nanotube powder, ...

example 2

[0027] Mix rose petals and deionized water at a mass ratio of 1:5 and place them in a four-necked flask equipped with a thermometer, a condenser and a stirrer, feed water vapor into the four-necked flask, and first distill with a low distillation rate of 95L / h 2h, control the temperature of the condensed water at 38°C, then distill with a high distillation rate of 119L / h for 53min, heat up to 39°C to obtain an emulsion, add 7% sodium chloride of the emulsion mass to the emulsion Mix and oscillate. After oscillating, pour it into a separatory funnel and let it stand for stratification for 3 minutes. After the stratification, discharge the lower water phase. Finally, absorb the residual water with anhydrous sodium sulfate, let it stand and age for 1.5 days, filter to remove solid sodium sulfate, and take out The filtrate is rose essential oil; 22g of carbon nanotubes is weighed and poured into a ball mill, and ball milled for 53min at a speed of 90r / min to obtain carbon nanotube ...

example 3

[0029] Mix rose petals and deionized water at a mass ratio of 1:5 and place them in a four-necked flask equipped with a thermometer, a condenser and a stirrer, feed water vapor into the four-necked flask, and first distill with a low distillation rate of 100L / h 3h, control the temperature of the condensed water at 40°C, then distill with a high distillation rate of 125L / h for 60min, heat up to 42°C to obtain an emulsion, add 7% sodium chloride of the emulsion mass to the emulsion Mix and oscillate, pour into a separatory funnel after oscillating and let stand for stratification for 4 minutes, discharge the lower aqueous phase after stratification, and finally absorb the residual water with anhydrous sodium sulfate, let it stand for 2 days, filter to remove solid sodium sulfate, take out The filtrate is rose essential oil; weigh 24g of carbon nanotubes and pour them into a ball mill, and ball mill them for 60 minutes at a speed of 85-95r / min to obtain carbon nanotube powders, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com