An environmentally friendly and high load-bearing tin-based babbitt alloy material for arc deposition

A tin-based babbitt and arc deposition technology, applied in the field of tin-based babbitt, can solve the problems of low fatigue strength, unenvironmental protection, poor bearing performance of tin-based babbitt, etc. The effect of grain, excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

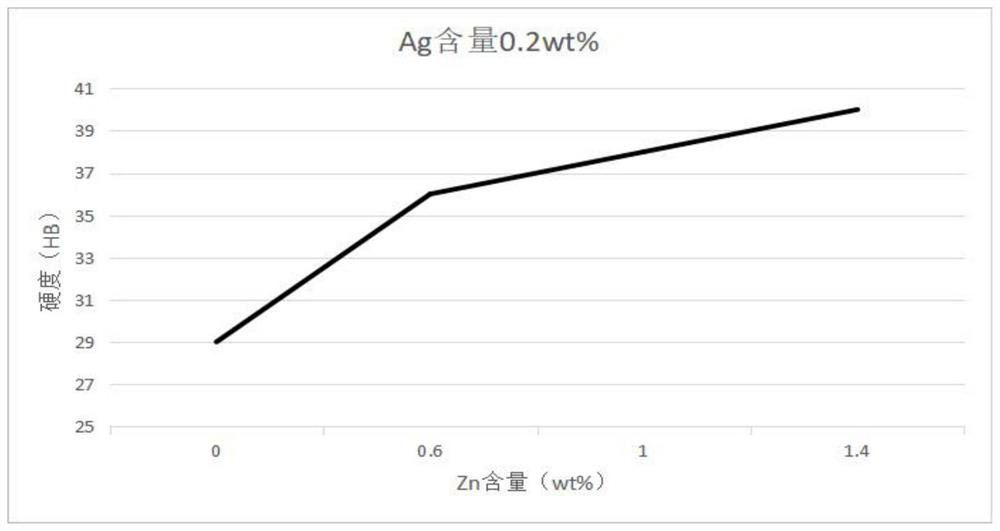

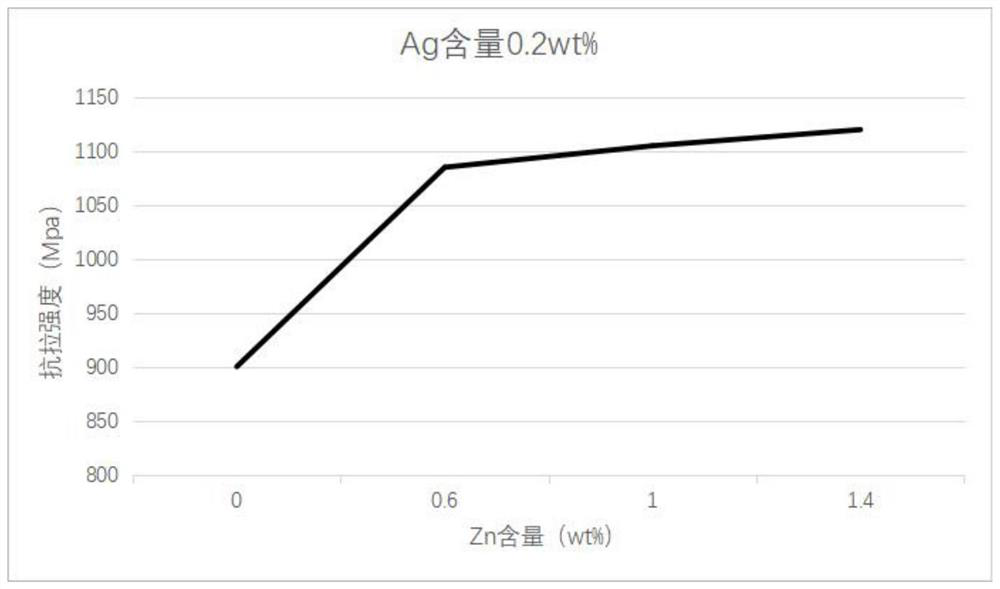

[0025] Embodiment 1: An environment-friendly high-load-bearing tin-based babbitt material for arc deposition, which includes the following components in mass percentages: Sb: 11.5%, Cu: 6.1%, Zn: 1.5%, Ag: 0.2 %, the balance is Sn. The hardness of the tin-based babbitt alloy coating layer obtained in this embodiment is 39HB, and that of ordinary ZChSnSb11-6 is 29HB, which is 34.5% higher than that. The tin-based Babbitt alloy bimetal prepared in this embodiment is made into a tensile sample, and the sample is tested for tensile strength on a CMT5105 microcomputer-controlled electronic universal testing machine. The tensile rate is 1mm / min, and the tensile strength is 1105 -1180Mpa, compared with ordinary ZChSnSb11-6, the tensile strength of the bimetal is increased by 22.8-31.1%.

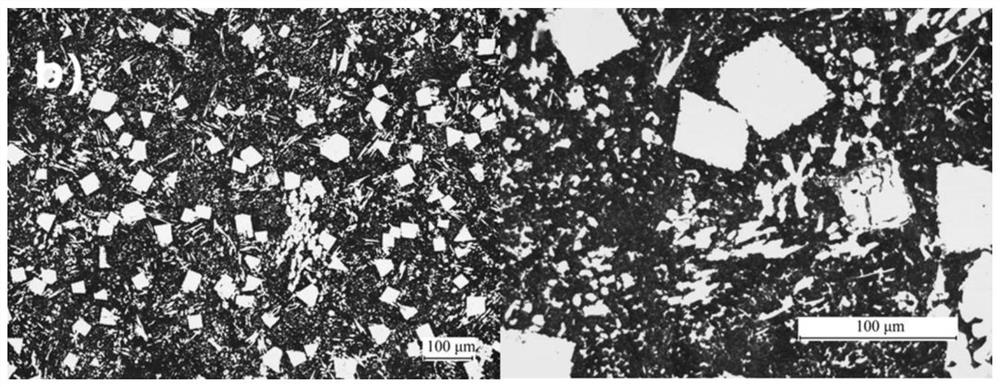

[0026] Depend on image 3 , Figure 4 It can be seen from observation that the crystal grains of the tin-based babbitt alloy material of the present invention have been significantly refined by t...

Embodiment 2

[0028] Embodiment 2: An environment-friendly high-load-bearing tin-based babbitt material for arc deposition, which includes the following components in mass percentages: Sb: 11.5%, Cu: 6.2%, Zn: 1.0%, Ag: 0.1 %, the balance is Sn. The hardness of the babbitt alloy coating layer obtained in this embodiment is 38HB, and that of ordinary ZChSnSb11-6 is 29HB, which is 31% higher than that. Using the same test method as in Example 1, the performance test of the tin-based Babbitt alloy of the present example is carried out, and the tensile strength obtained is 1101-1150Mpa. Compared with ordinary ZChSnSb11-6, the tensile strength of the bimetal has increased by 22.7- 27.8%.

Embodiment 3

[0029] Embodiment 3: An environment-friendly high-load-bearing tin-based babbitt material for arc deposition, which includes the following components in mass percentages: Sb: 11.5%, Cu: 6.5%, Zn: 1.5%, Ag: 0.5% %, the balance is Sn. The hardness of the babbitt alloy coating obtained in this embodiment is 36.5HB, and that of ordinary ZChSnSb11-6 is 29HB, which is 28.5% higher than that. Using the same test method as in Example 1, the tin-based babbitt alloy of the present embodiment is tested for performance, and the tensile strength obtained is 1060-1127Mpa. Compared with ordinary ZChSnSb11-6, the tensile strength of the bimetal has improved by 17.8- 25.2%.

[0030] The ZChSnSb11-6 or ordinary ZChSnSb11-6 mentioned in this application document are all the same substance, and there is this grade in the national standard of Babbitt alloy, so those skilled in the art will see ZChSnSb11-6 or ordinary ZChSnSb11-6 Specific material standards will come to mind when a brand is selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com