Patents

Literature

77results about How to "Reduce hot cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

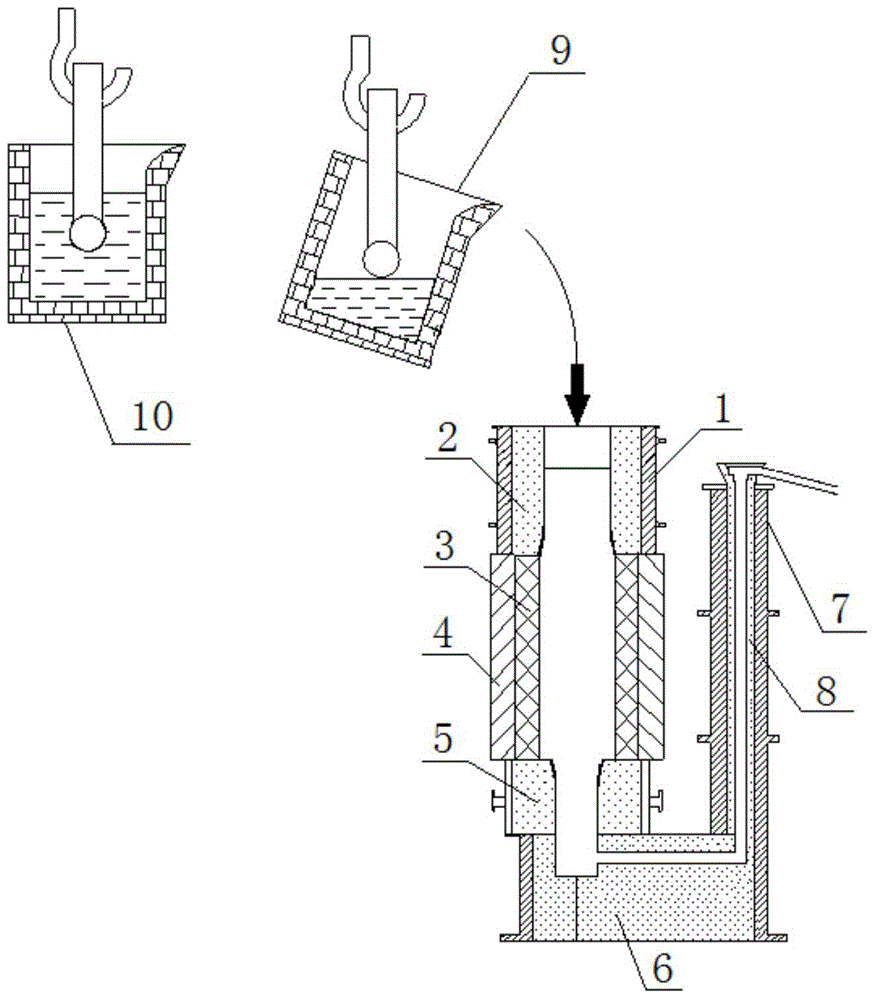

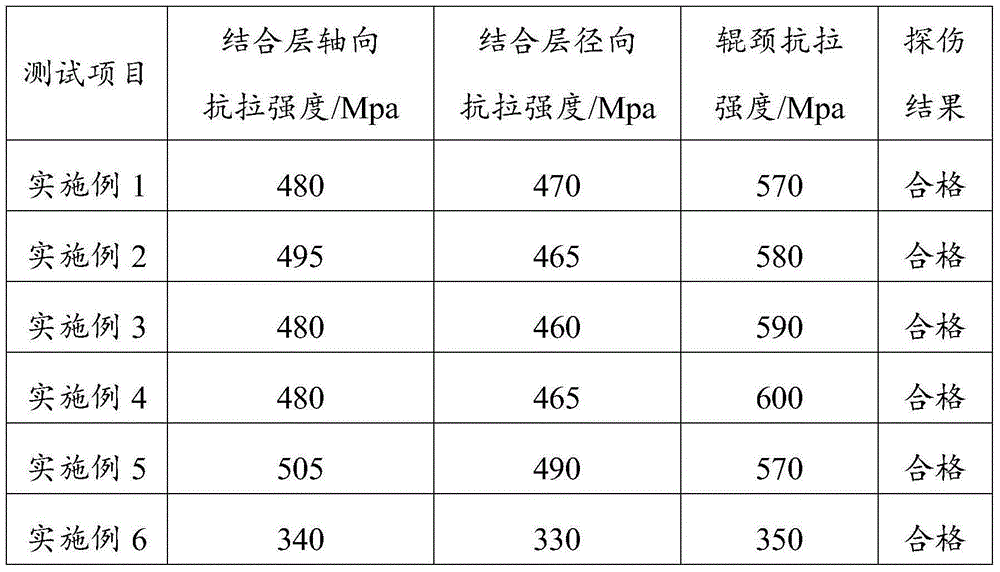

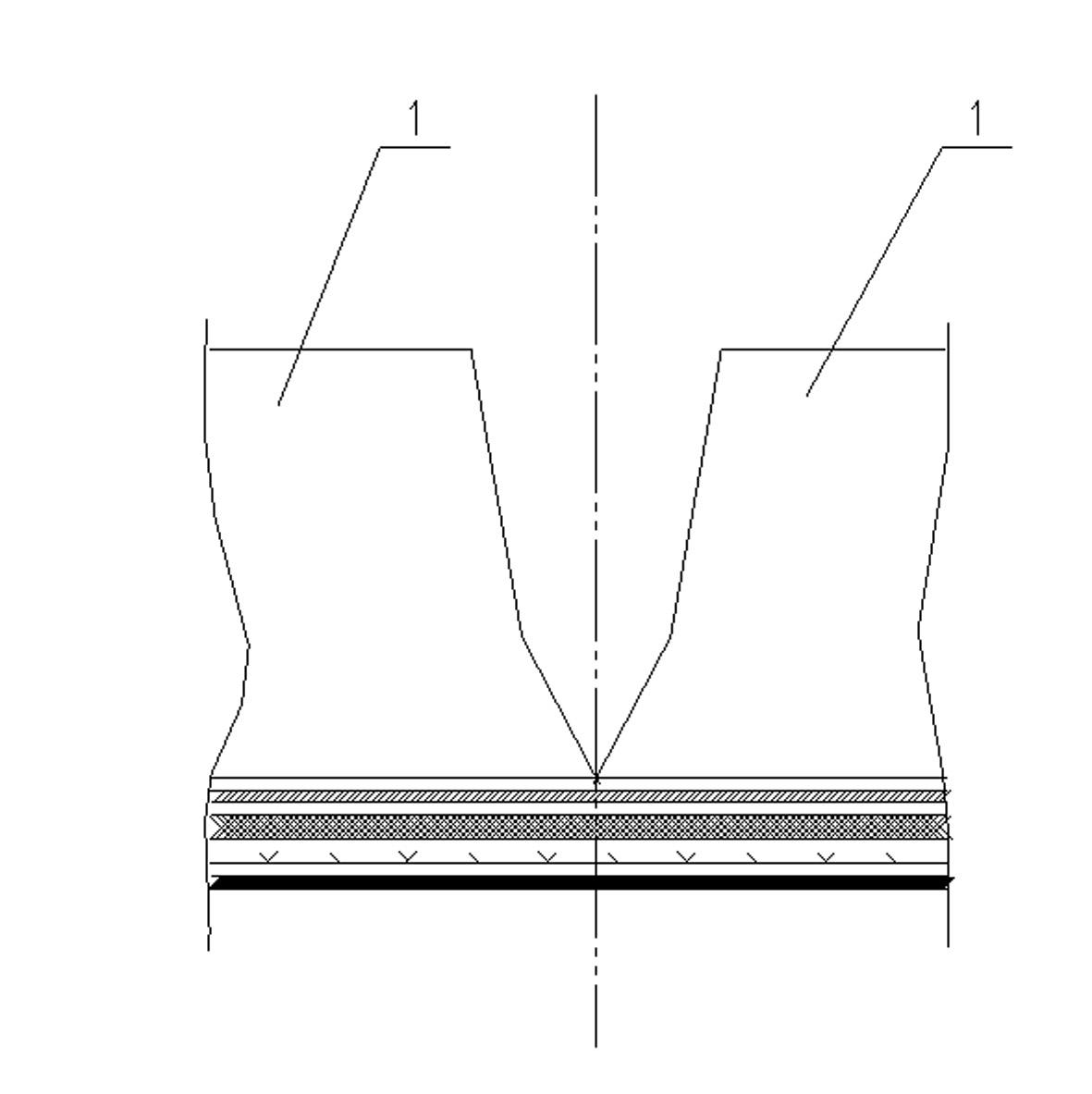

High-speed steel roller manufacturing method

ActiveCN104525889AHigh bonding strengthEnhanced resistance to peelingCarbideUltimate tensile strength

The invention discloses a high-speed steel roller manufacturing method which is suitable for small steel rolling machines and bar mills. The manufacturing method comprises the three process steps of raw material smelting, casting moulding, machining and heat treatment. On the basis that high-speed molten iron is centrifugally poured, firstly, transition layer molten iron is poured, and then the complete replacement of the transition layer molten iron is achieved by pouring core part molten iron. According to the high-speed steel roller manufacturing method, the combination strength of outer layer high-speed steel and the core part molten iron is obviously increased and increased to 500 Mpa or higher from around 350 Mpa in the past, and thus the anti-stripping performance of the combination layer of a roller body of a high-speed steel roller is greatly improved. Meanwhile, the amount of carbide forming elements generated by corrosion to the outer layer by the core part molten iron can be effectively reduced, so that the texture of a roller neck is improved, the tensile strength of the roller neck is increased, and the phenomenon of roller breakage in the using process is effectively eradicated.

Owner:邢台轧辊线棒辊有限责任公司

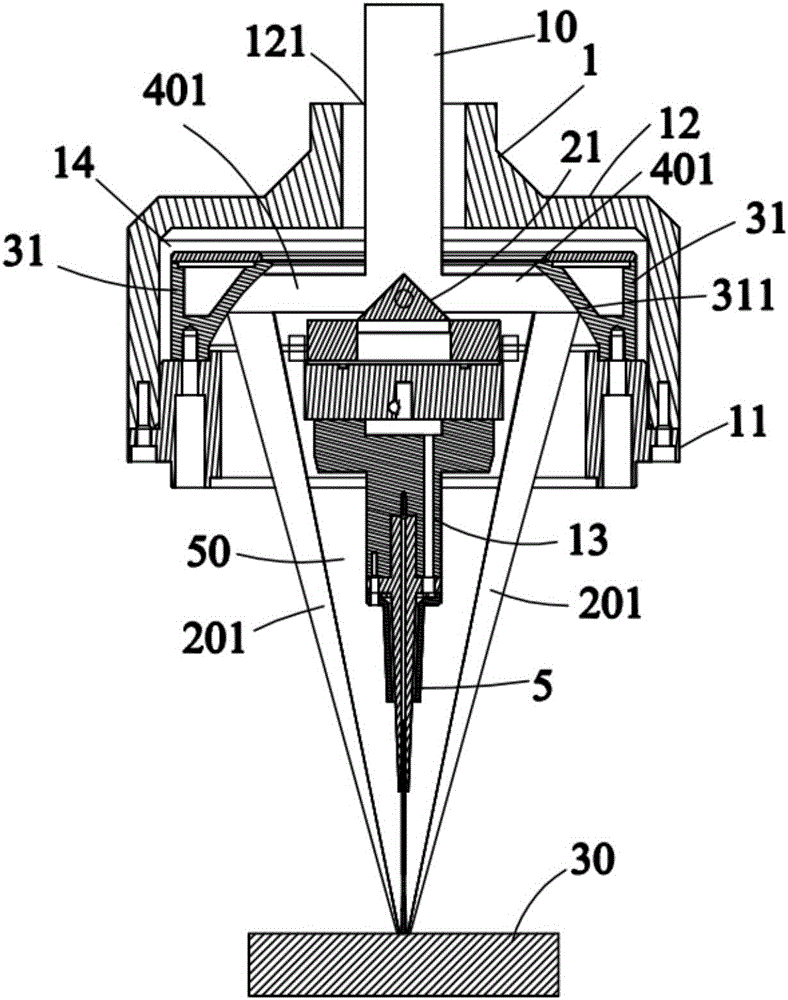

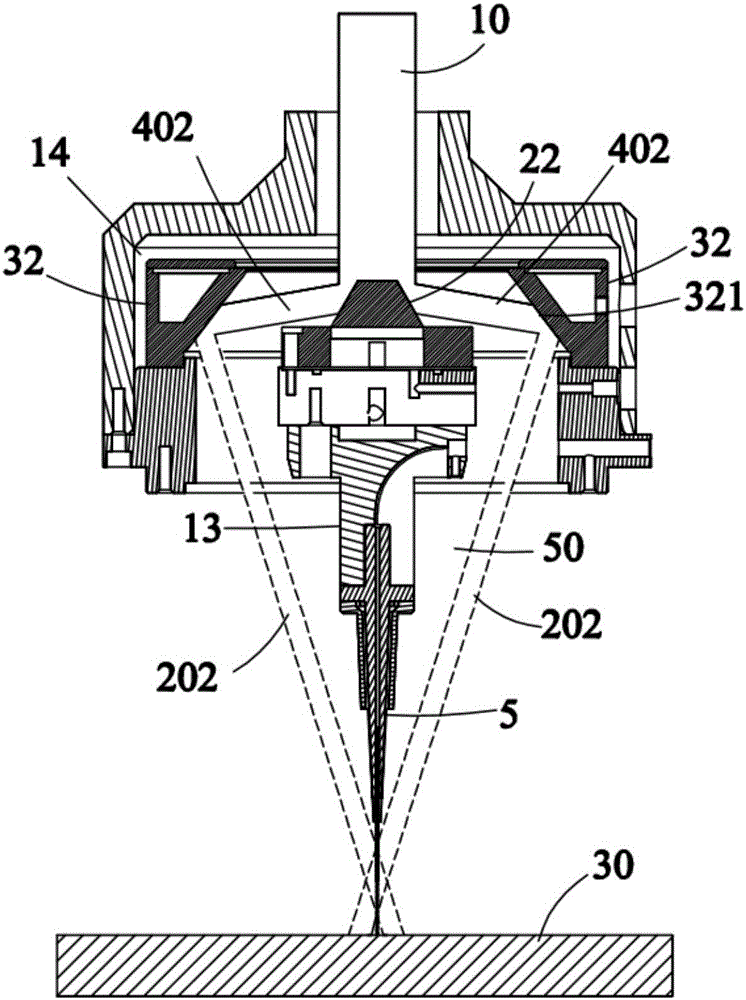

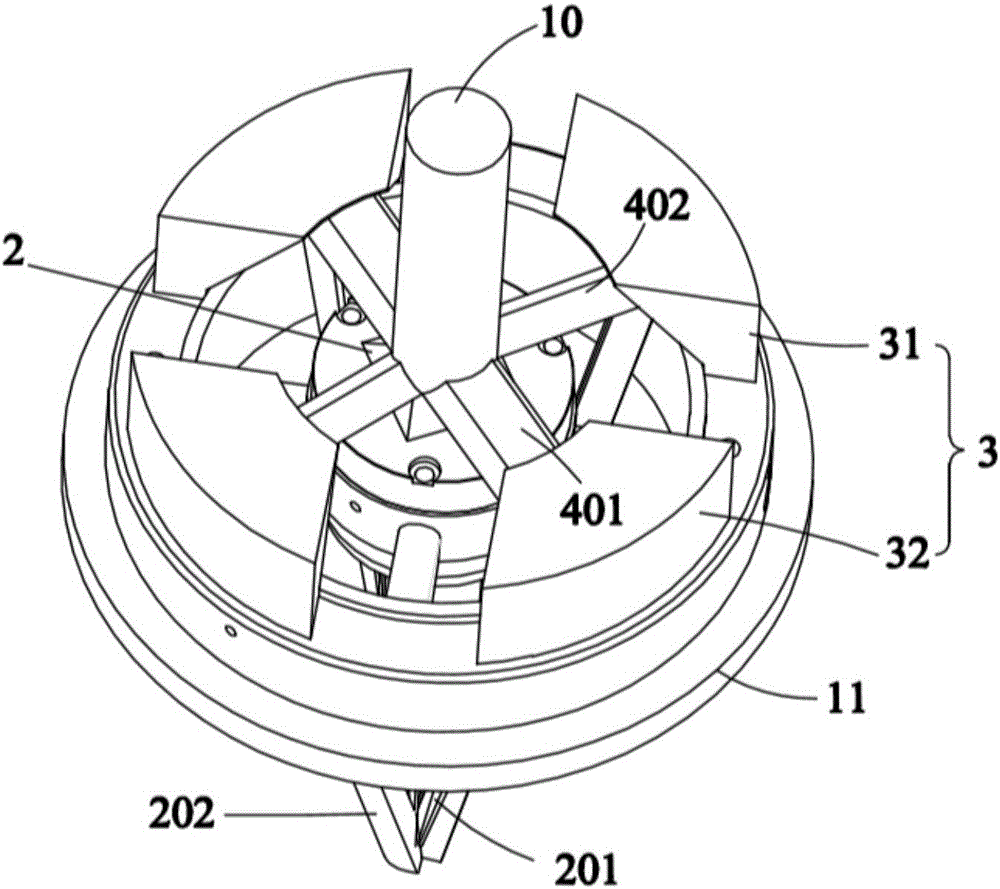

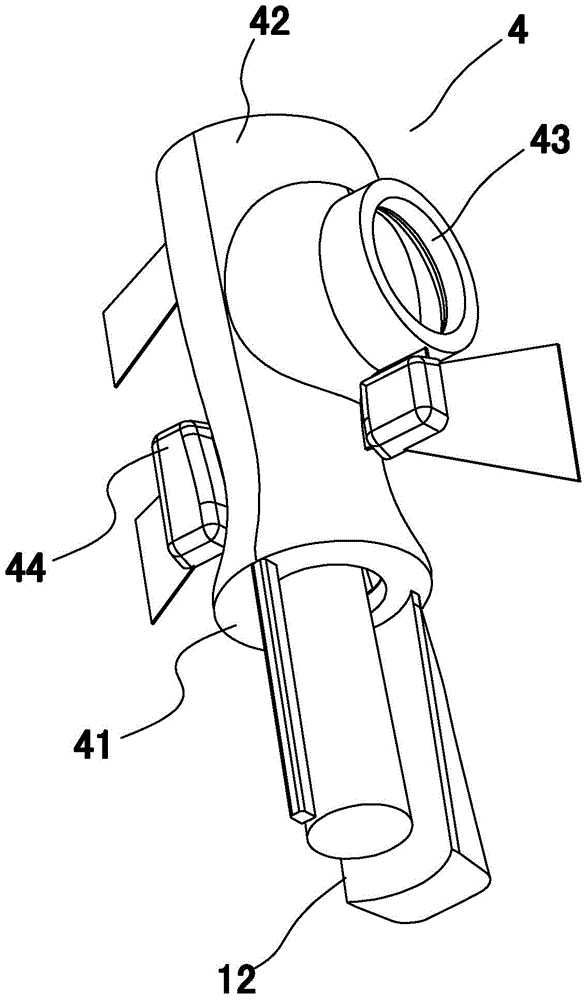

Multi-beam laser cladding device

ActiveCN106583726AReduce thermal stressImprove cladding efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyBeam splitterLight beam

The invention relates to a multi-beam laser cladding device comprising a beam splitter and a reflecting-focusing assembly. The beam splitter comprises at least two first mirror surface portions and at least two second mirror surface portions, the first mirror surface portions and the second mirror surface portions are arranged alternately in the circumferential direction of the central axis of the beam splitter, part of incident beams are received and reflected by the first mirror surface portions so as to form first reflected beams, part of the incident beams are received and reflected by the second mirror surface portions so as to form second reflected beams, the first reflected beams and the second reflected beams are reflected in the circumferential direction of the central axis of the beam splitter, and the reflection angle of the first reflected beams is different from the reflection angle of the second reflected beams. The reflecting-focusing assembly comprises a reflecting-focusing lens and a reflector, the first reflected beams are reflected and focused by the reflecting-focusing lens so as to form cladding beams, and the second reflected beams are reflected by the reflector so as to form preheating beams.

Owner:SUZHOU ZHONGKE INNOVATION INST OF LASER INTELLIGENT MFG

Welding solid wire

ActiveUS20100206130A1Sufficient low-temperature toughnessHigh absorption energyElectric discharge heatingWelding/cutting media/materialsManganeseOxygen

It is an object of the present invention to provide a similar composition metal type welding solid wire capable of forming a welded joint having excellent cryogenic characteristics, such as ensuring a low-temperature toughness equivalent to that of the cryogenic base metal, and in addition, further having a high crack initiation resistance, and a weld metal thereof. The welding solid wire of the present invention is an iron base welding solid wire including carbon: 0.10 mass % or less (not inclusive of 0%), silicon: 0.15 mass % or less (not inclusive of 0%), nickel: 8.0 to 15.0 mass %, manganese: 0.10 to 0.80 mass %, and Al: 0.1 mass % or less (not inclusive of 0%), and oxygen in an amount of 150 ppm or less (inclusive of 0), characterized by including: a REM: 0.005 to 0.040 mass %, or chromium: 4.0 mass % or less (not inclusive of 0%).

Owner:KOBE STEEL LTD

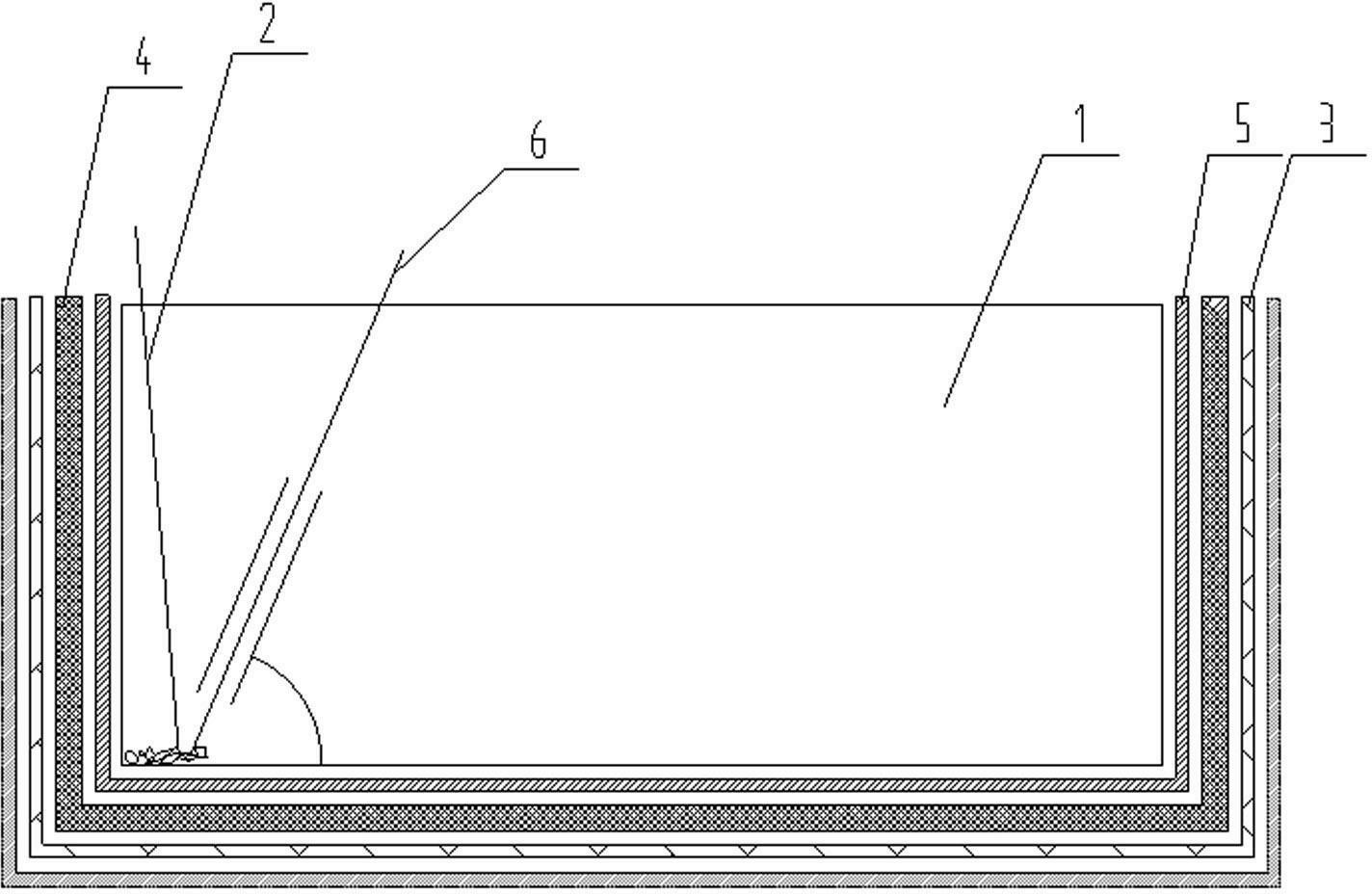

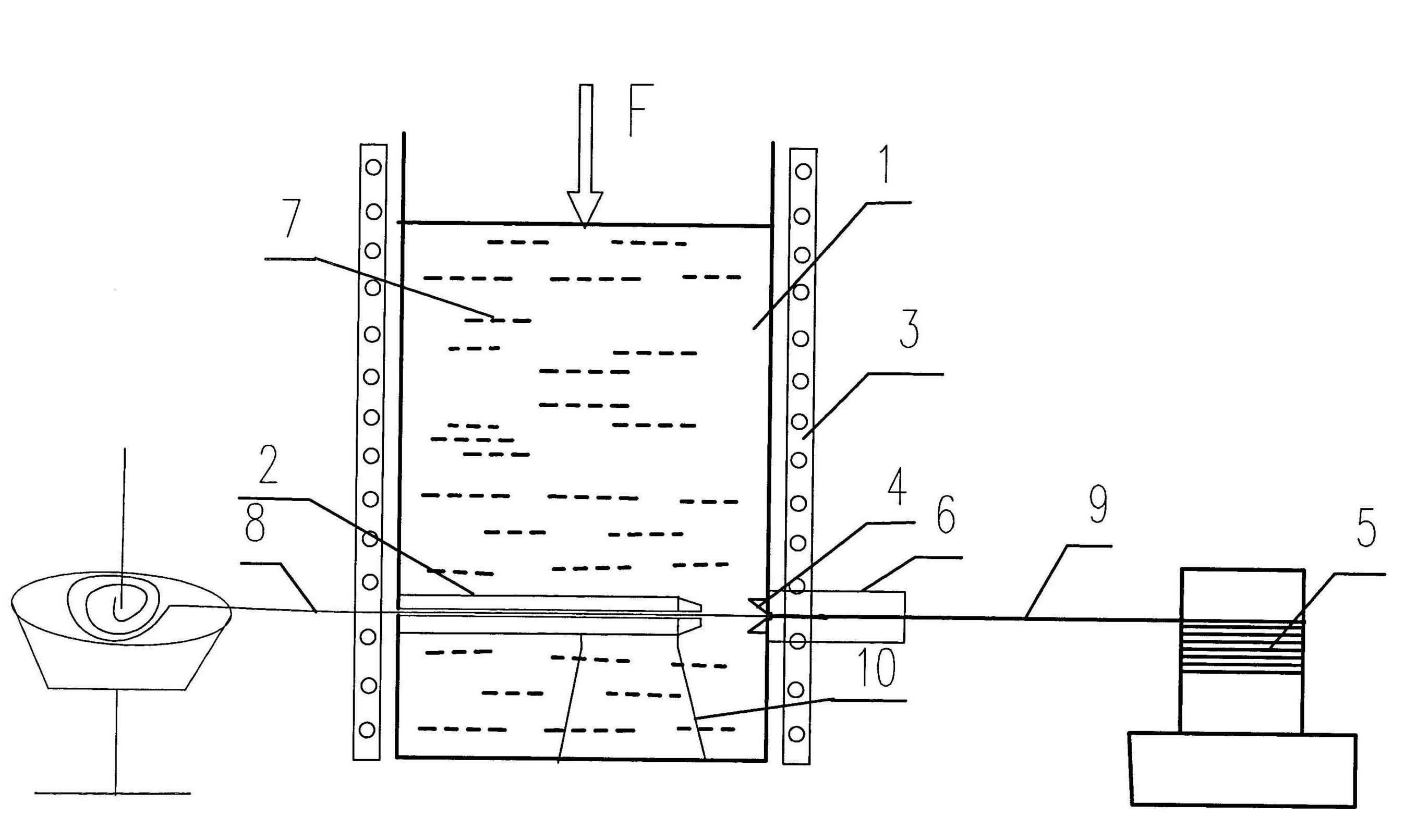

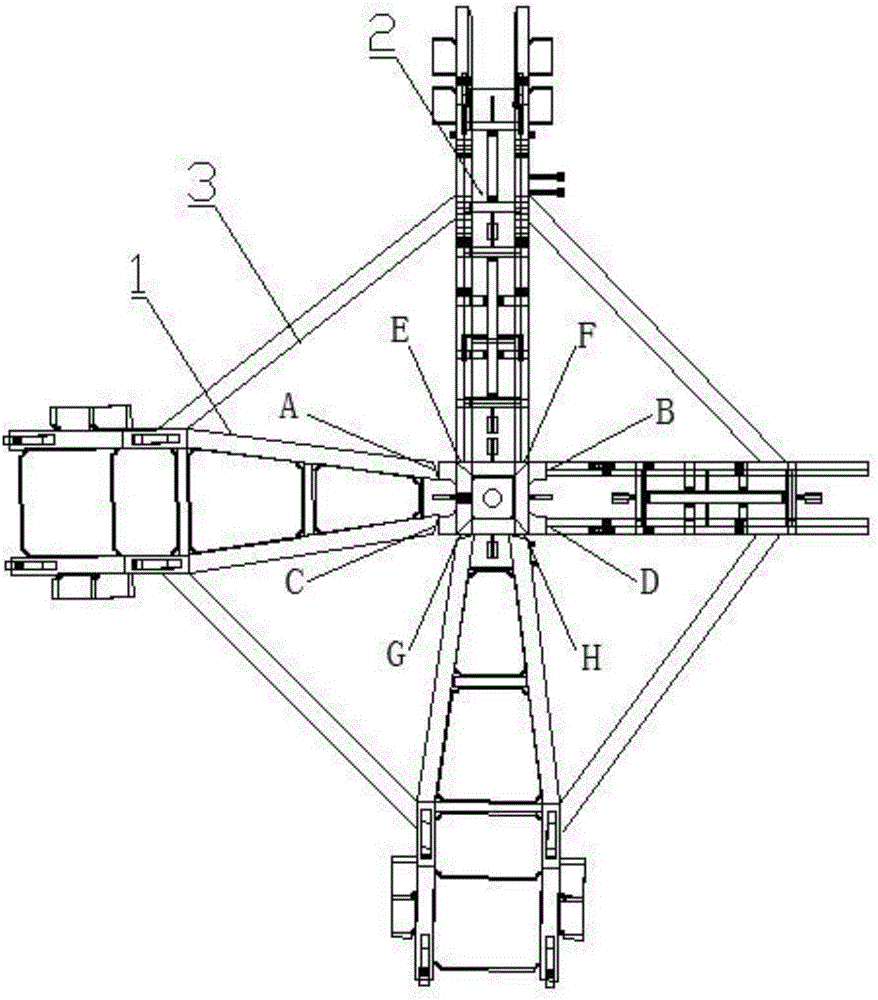

Horizontally laid large-section aluminum bus welding construction method

ActiveCN102126072AHigh deposition rateLower the temperature of the molten poolWelding accessoriesAluminiumEngineering

In order to solve the problems of welding deformation and hot cracks in the process of welding large-section aluminum buses and improve welding efficiency, the invention provides a horizontally laid large-section aluminum bus welding construction method. In the method, aluminum buses to be welded are paired and fixed, and arranged in a welding pool crystallization tank with a heater, semi-automatic metal inert-gas (MIG) double pulse argon arc welding is adopted, and an aluminum bar serving as a welding material is directly inserted into the welding pool for welding simultaneously; before welding, two ends of welding positions of the buses are pre-heated at the temperature of between 150 and 250DEG C; and in the welding process, the temperature of the welding positions of the aluminum buses is always kept in a range of 150-250DEG C. Compared with the prior art, the method has the advantages that: the temperature of the welding pool can be reduced and the welding speed can be improved by filling the welding material; and the crystallization tank heats the welding positions in the welding process, so that air holes of welding lines are reduced and the welding deformation and hot cracks are reduced.

Owner:CHINA CHEM ENG SECOND CONSTR +1

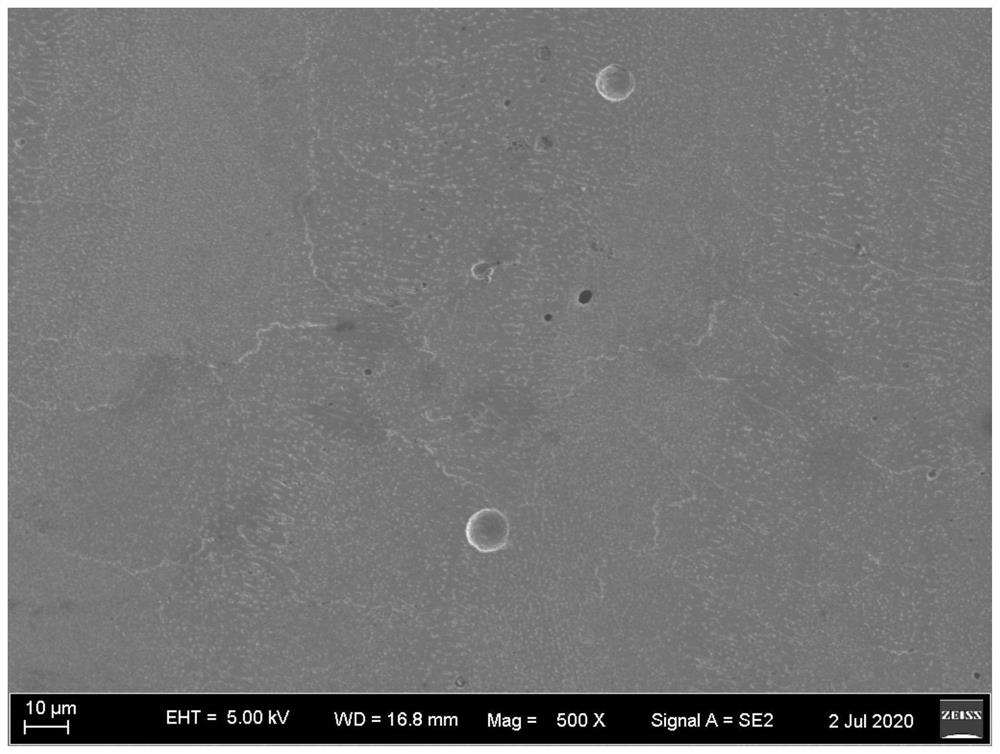

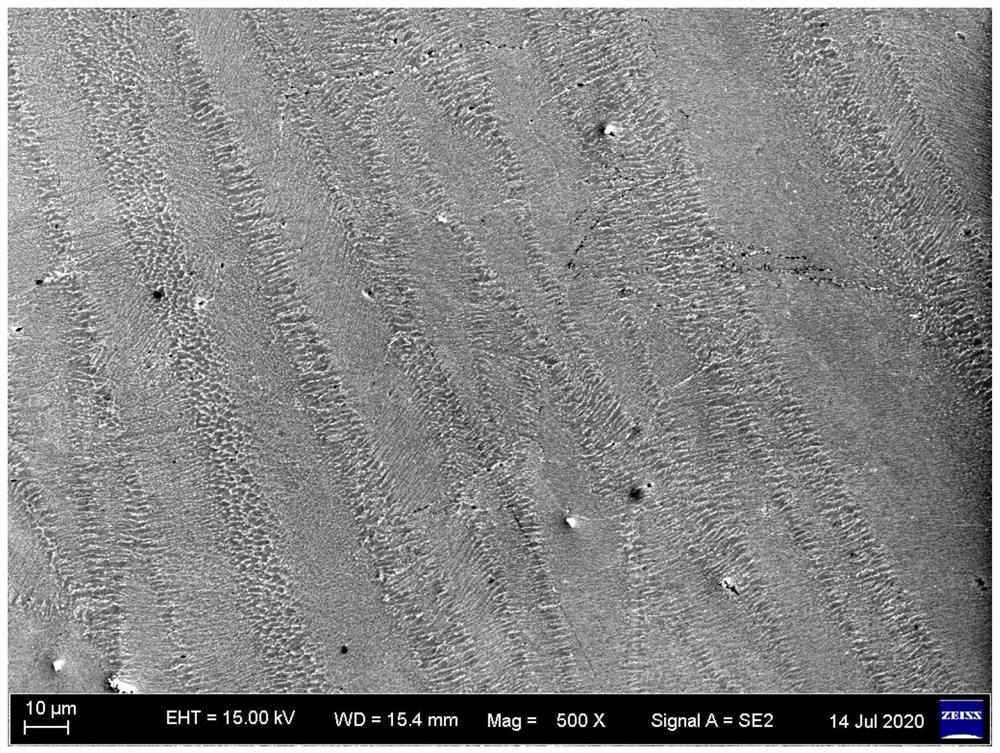

Preparation technique of continuous casting crystallizer copper plate surface cermet coating

ActiveCN103614687AUniform and flat microscopic surfaceImprove corrosion resistanceMolten spray coatingCrack resistanceHeat treated

The invention discloses a preparation technique of a continuous casting crystallizer copper plate surface cermet coating, which comprises the following steps: copper plate surface oil removal, copper plate surface sandblasting, coating preparation and hot spraying subsequent treatment, wherein the hot spraying subsequent treatment is vacuum heat treatment or hole sealing treatment. The preparation technique of the technical scheme is simple to operate, and has the advantages of fewer steps and high efficiency. After being subjected to vacuum heat treatment or hole sealing treatment, the cermet coating has the advantages of high microhardness, small internal stress, favorable wear resistance, favorable thermal crack resistance, high bonding strength, favorable bonding property and low thermal conductivity, can lower the thermal crack of the crystallizer copper plate in the high-temperature region, can effectively decelerate the heat conduction inside crystallizer (especially the meniscus surface), and can be widely used in continuous casting of a medium / low-speed continuous caster.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Preparation technique of continuous casting crystallizer copper plate surface cermet coating

ActiveCN103614724AUniform and flat microscopic surfaceImprove corrosion resistanceMolten spray coatingSuperimposed coating processBonding strengthCopper

The invention discloses a preparation technique of a continuous casting crystallizer copper plate surface cermet coating, which comprises the following steps: copper plate surface oil removal, copper plate surface sandblasting, transition layer preparation, coating preparation and heat treatment. The detection indicates that the microhardness of the cermet coating is 1532-1746HV, and the internal stress is 127-136 MPa, so the wear resistance and thermal crack resistance are good; the bonding strength of the coating is 176-189 MPa, so the bonding property is good; the thermal conductivity is 15.2-16.5W / (m.k); and the cermet coating can lower the thermal crack of the crystallizer copper plate in the high-temperature region, can effectively decelerate the heat conduction inside crystallizer (especially the meniscus surface), and can be widely used in continuous casting of a high-speed continuous caster.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Hardened-tooth-surface gear and hardened-tooth-surface gear repair technology

ActiveCN103075490AReduce scrap rateReduce noisePortable liftingMetallic material coating processesSocial benefitsRejection rate

Owner:WUHAN KAIMING HIGH TECH

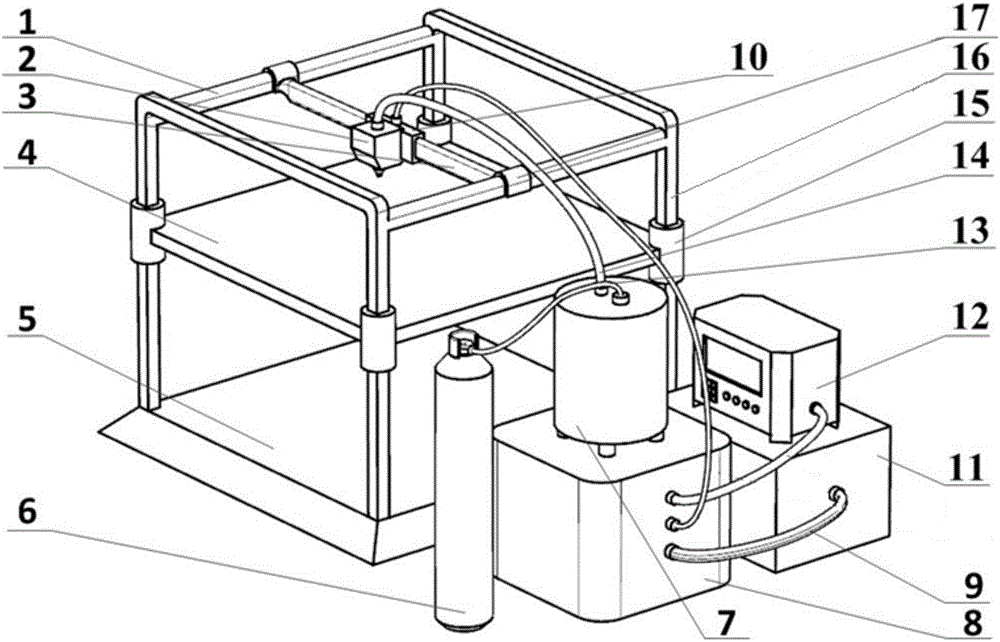

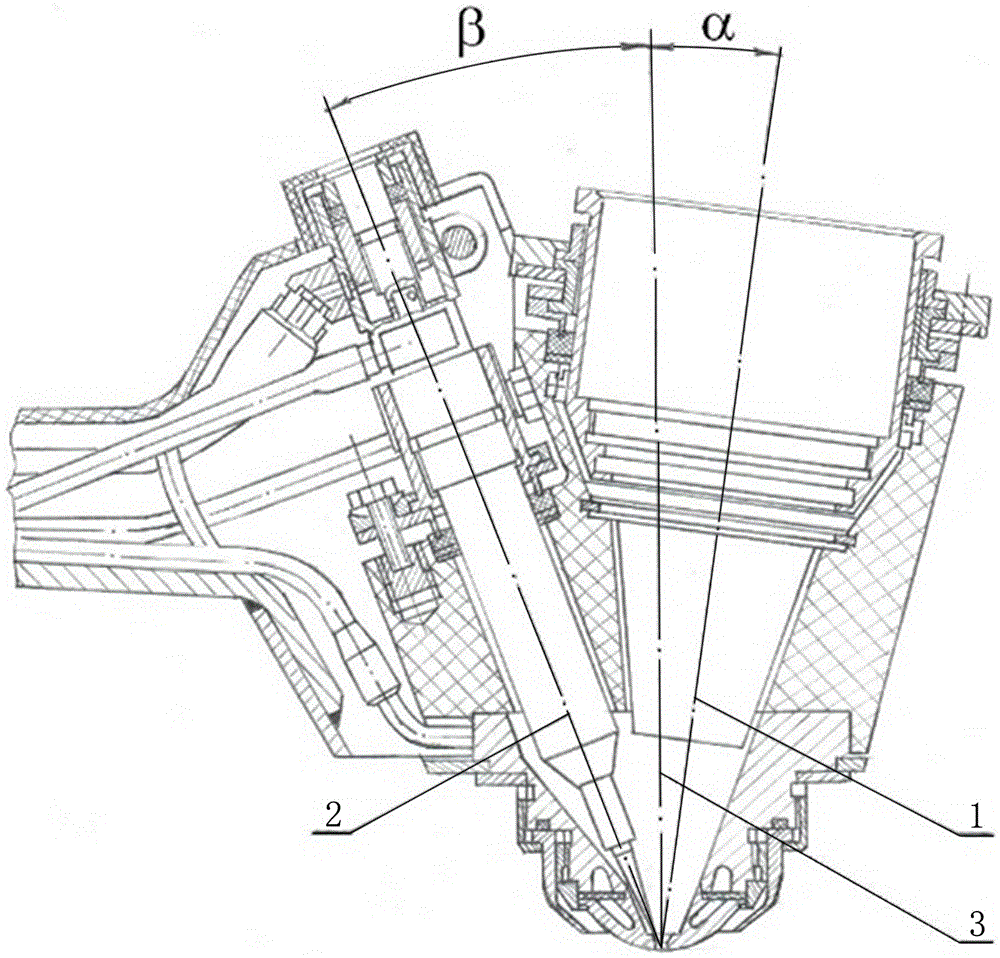

Equipment and method for 3D printing of architectural ornaments

ActiveCN105799172ABroaden the thinking spaceLow heat inputAdditive manufacturing apparatusSprayerControl system

The invention discloses equipment and a method for 3D printing of architectural ornaments. The equipment mainly comprises Y-axis guide rails, an X-axis guide rail, Z-axis guide rails, a movable forming platform, a wire feeder, a CMT power source system, a CMT sprayer, a water-cooling machine, a protective gas device, a central control system and the like, and the movable forming platform is arranged on the Z-axis guide rails. By means of connection, combination and control of the Z-axis guide rails, the Y-axis guide rails, the X-axis guide rail and other parts, accuracy in the Y direction, X direction and Z direction is achieved, objects in any shape can be rapidly formed, structures which cannot be obtained through traditional manufacturing methods can be perfectly printed, creativity of designers is freed, unrestrained imagination of the designers is met, and the aesthetic property and the grade of architectural ornament parts are improved. Compared with the mode adopting a laser, the CMT system is adopted by the equipment, the heat input amount is lower, a heat affected zone is smaller, deformation is smaller, the forming precision is higher, and the size error is smaller. Compared with traditional preparation processes for the architectural ornament parts, the cost is greatly reduced, and the precision is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

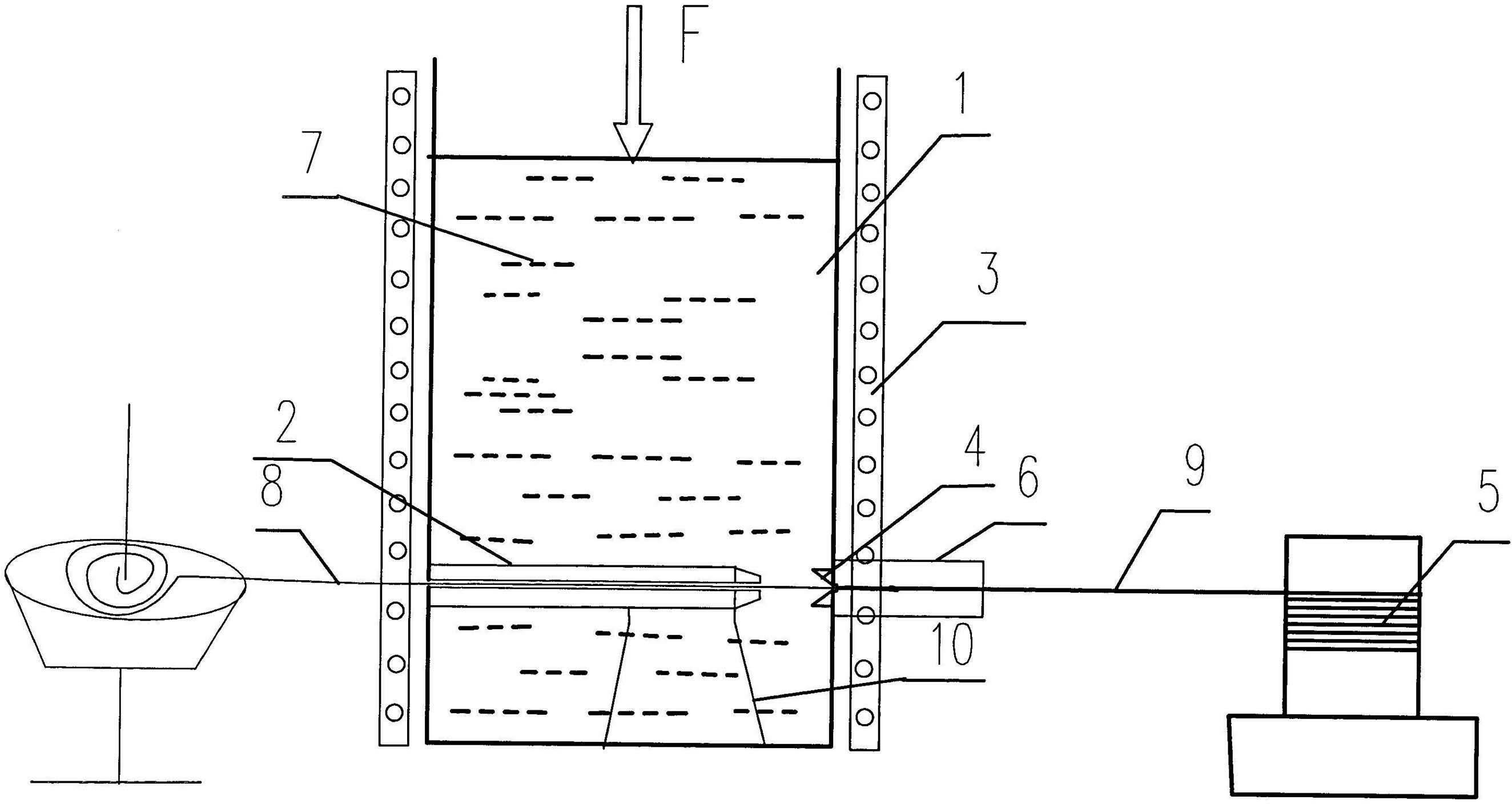

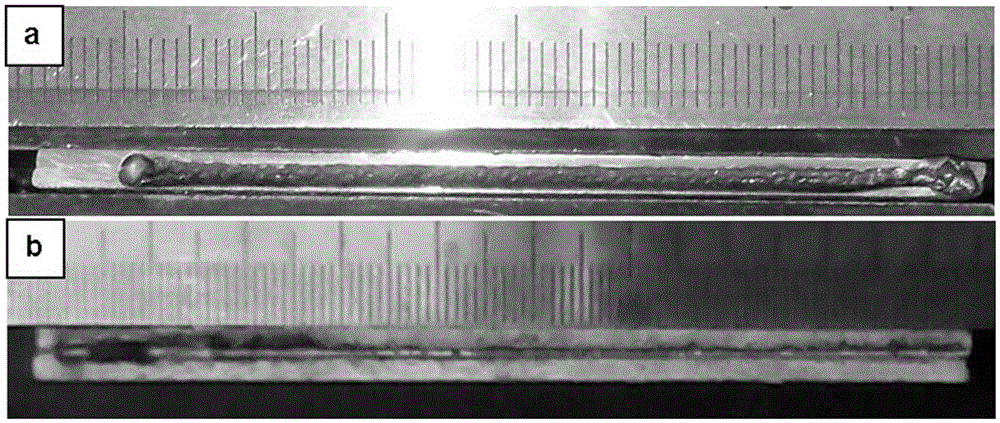

Active core silver solder for soldering ceramics and preparation method thereof

InactiveCN102319964ALow melting pointReduce hot cracksWelding/cutting media/materialsSoldering mediaElemental compositionAlloy

The invention relates to an active core silver solder for soldering ceramics and a preparation method thereof, and the active core silver solder comprises two parts, namely a core part and an outer layer, wherein the core part is composed of an active alloy containing active elements and the outer layer is composed of a silver alloy. The active core silver solder comprises the following main components by weight percent: 2-6% of the active alloy comprising three elements, namely Ti, Zr and Hf, wherein the active alloy contains 0.1-5wt% of the Zr, 0-3wt% of the Hr and the balance of the Ti; and 94-98% of the silver alloy comprising the elements of Ag, Cu and Ge, wherein the silver alloy contains 66-72wt% of the Ag, 26-27.9wt% of the Cu and 0.1-8wt% of the Ge. The threadlike active core silver solder can be directly obtained by adopting a method of wrapping an active core at the interior by extrusion through semi-molten metal. Compared with the characteristic of low melting point of thesolder of domestic like products, the preparation process is high in production efficiency and a new way is opened for manufacturing the solder which is difficult to machine and form due to brittle intermetallic compounding.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

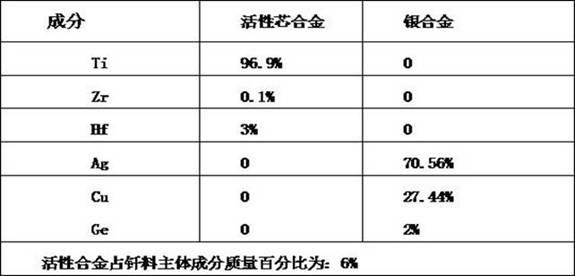

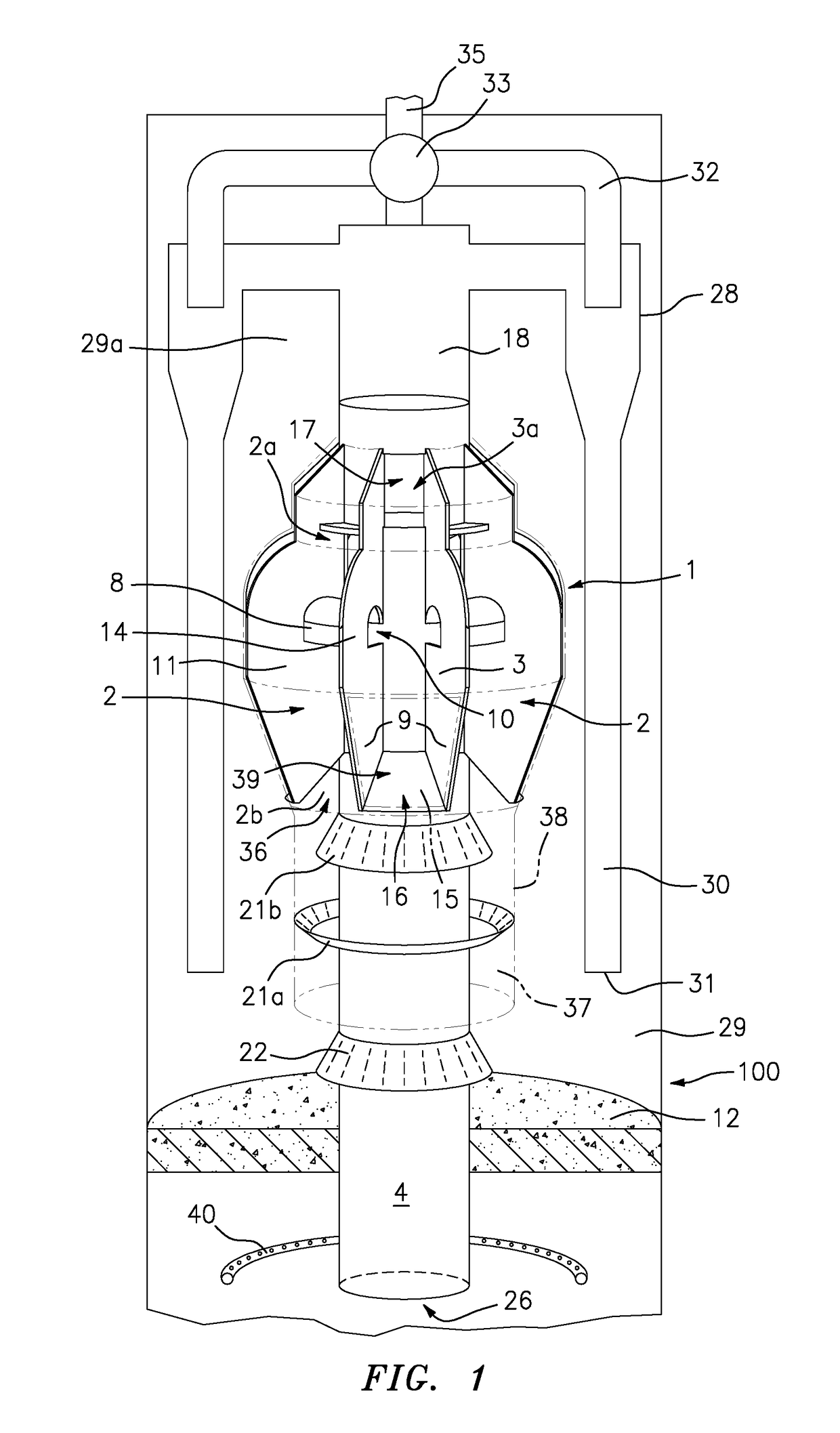

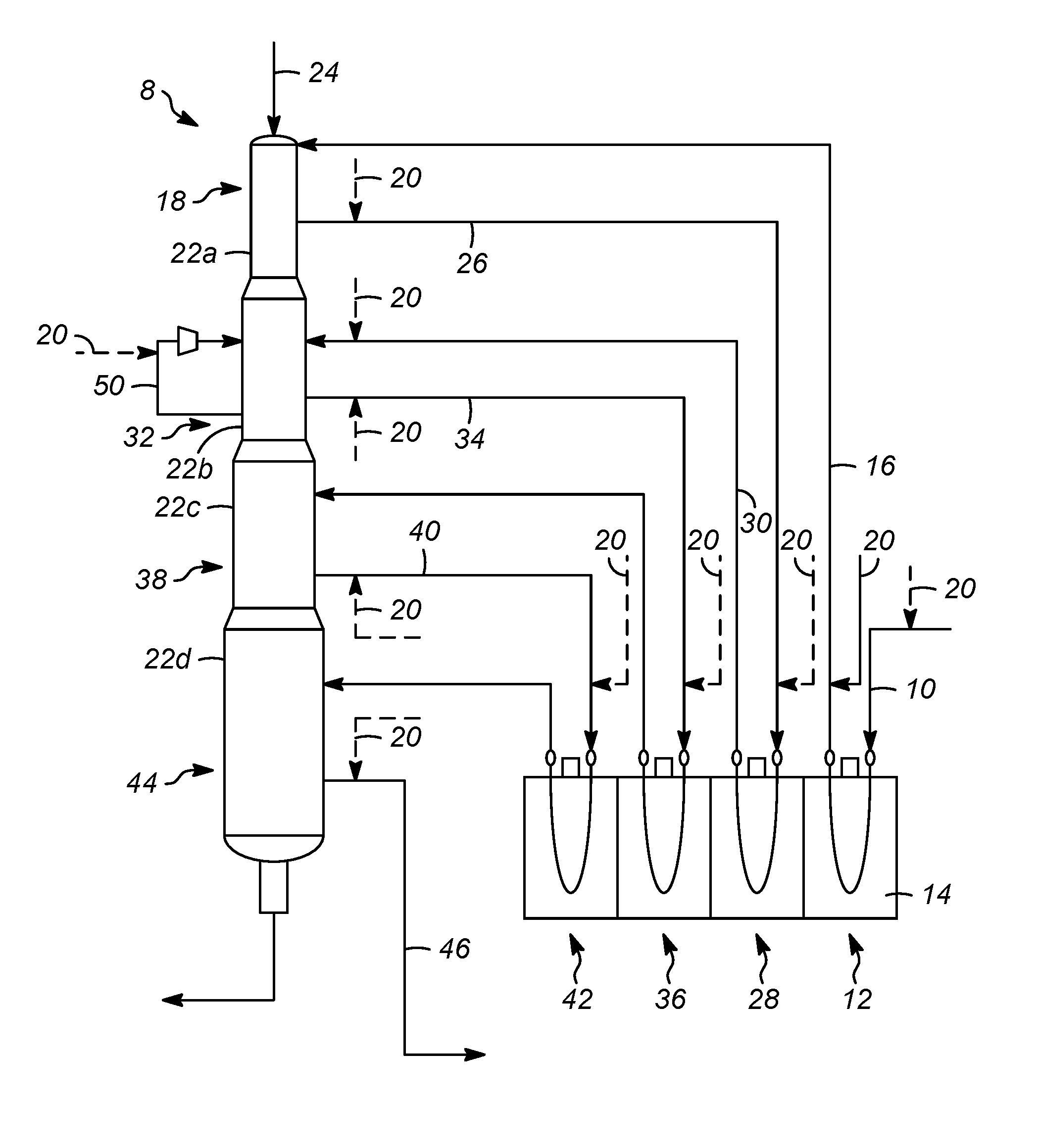

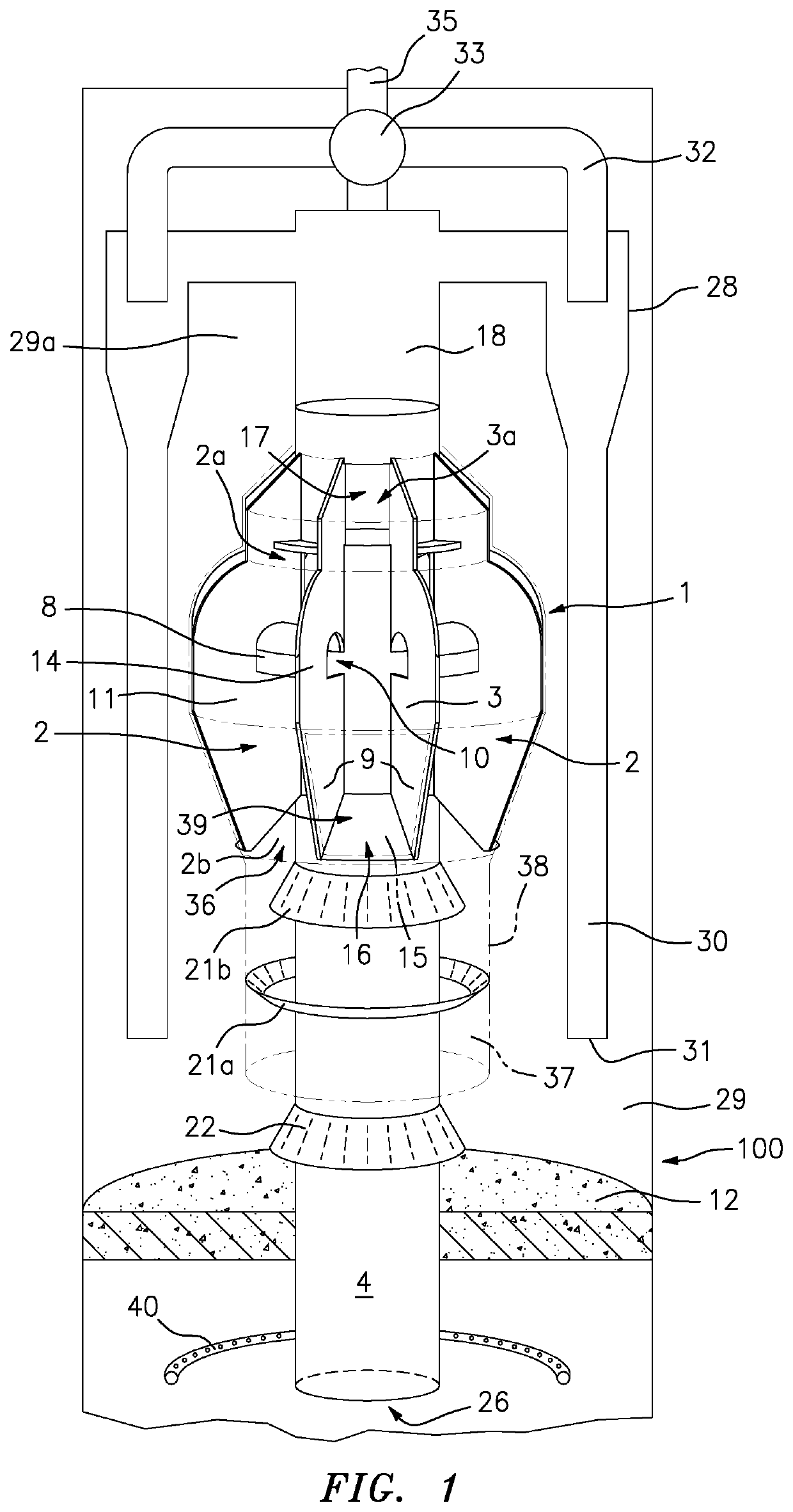

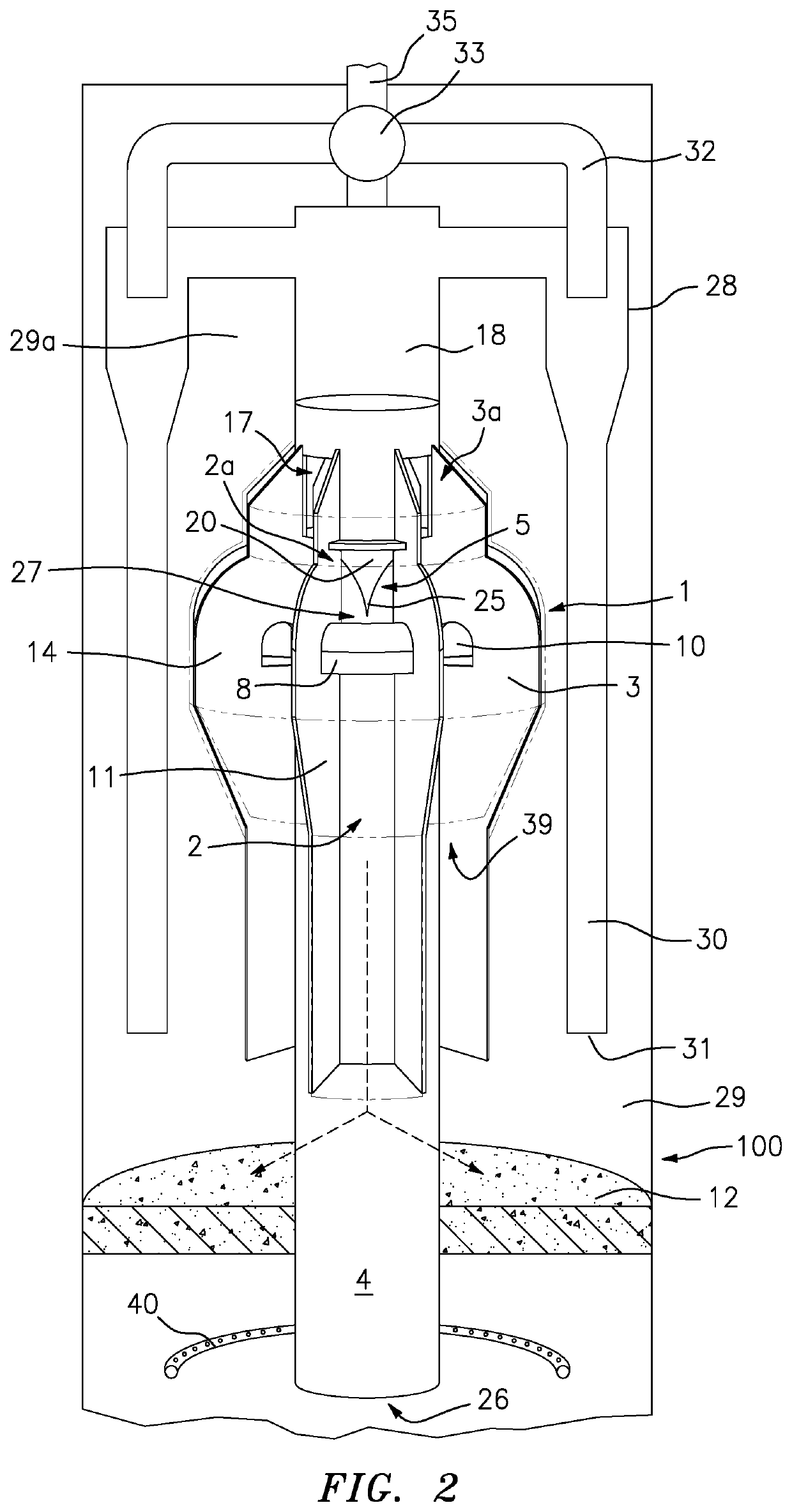

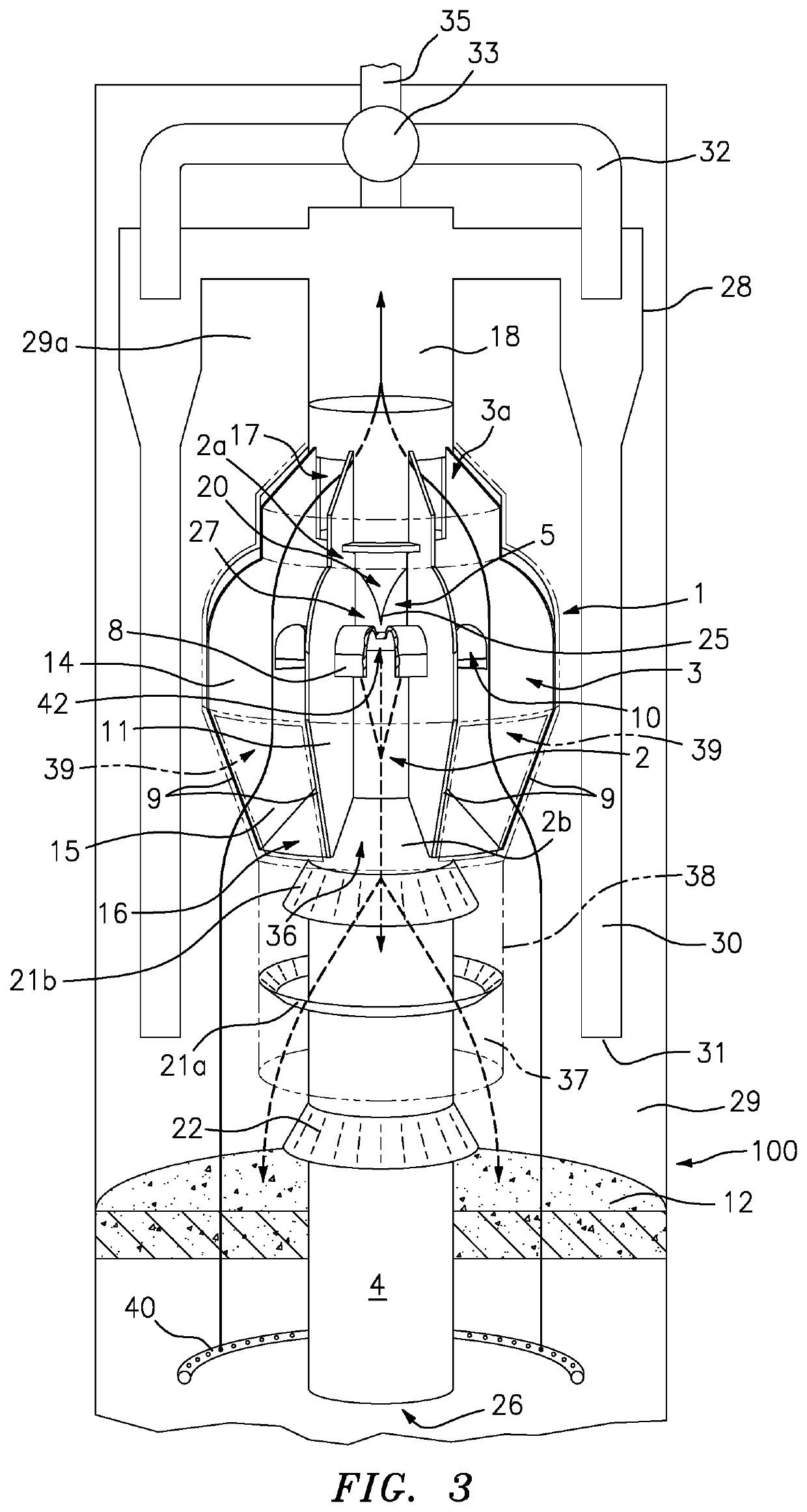

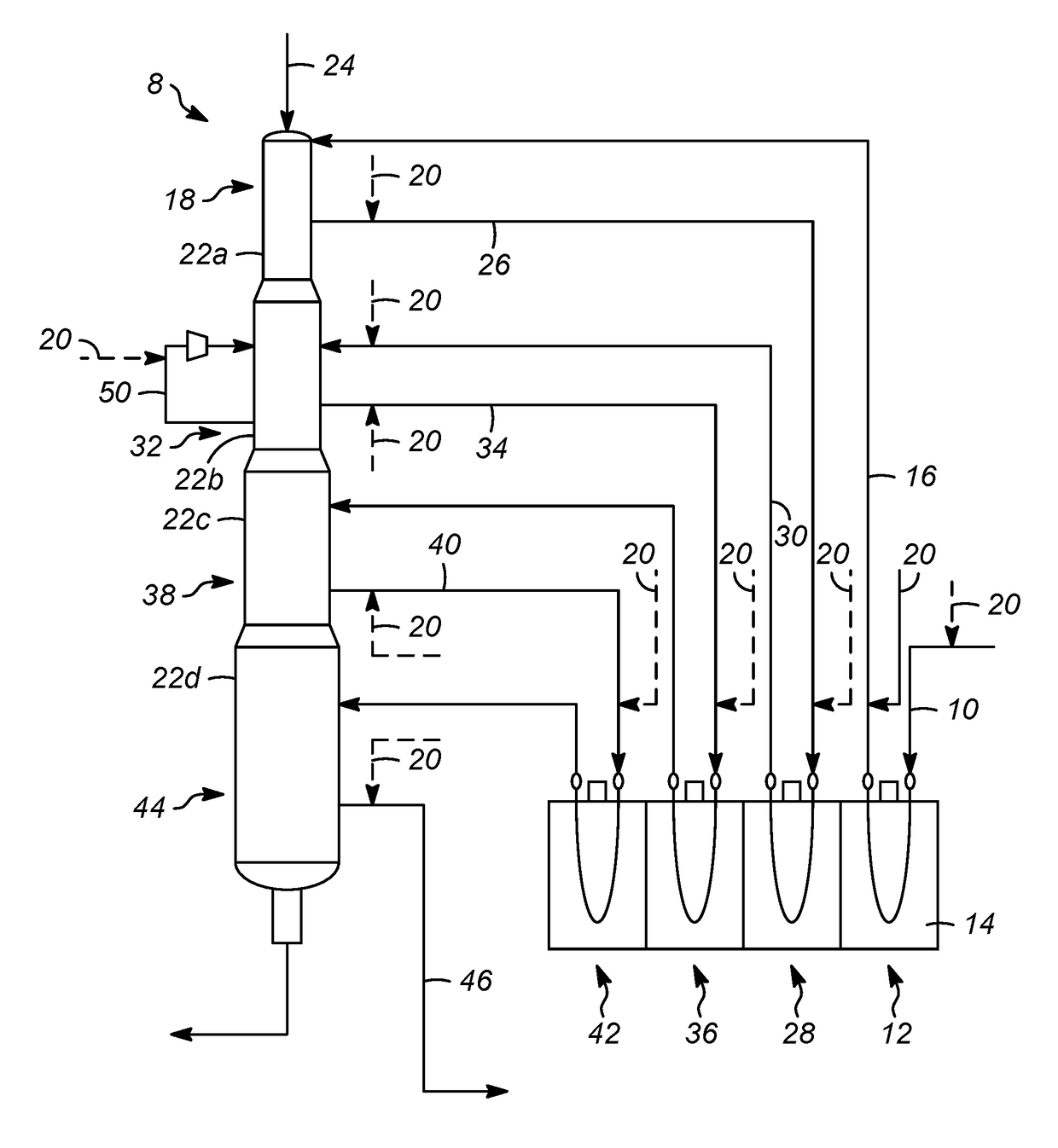

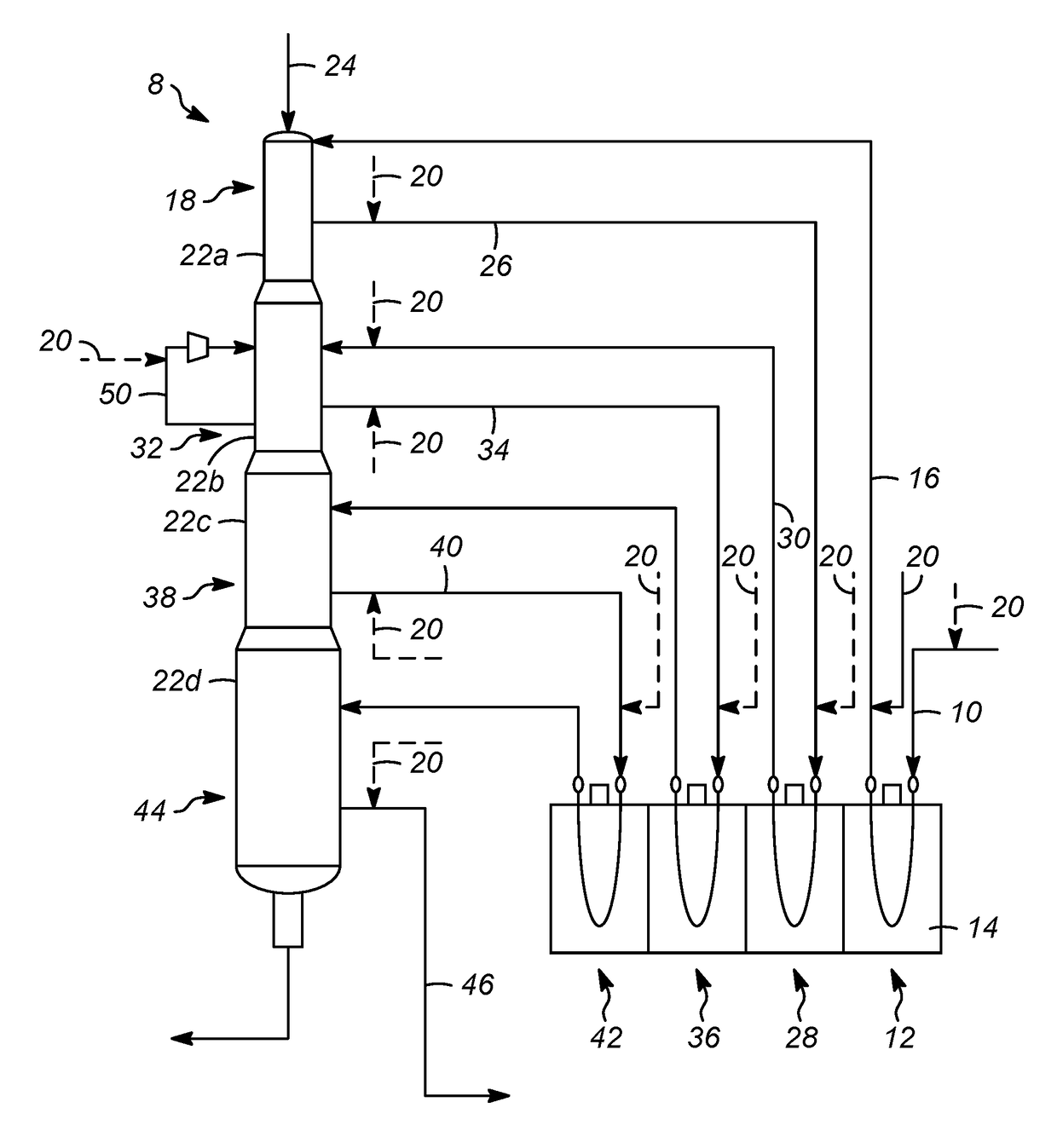

Riser separation system

ActiveUS20180216012A1Improve separationSmoothly flowCatalytic crackingDispersed particle separationProcess engineeringResidence time

The present disclosure is directed to an apparatus and a compact riser separation system for separating a gaseous mixture from a stream of particles entering from a central riser reactor used for cracking a hydrocarbon feed with the stream of particles. The apparatus provides improved gas solid separation efficiency and maximize containment of the hydrocarbon and minimize residence time in the separation system and thereby minimizing undesired post riser cracking reactions.

Owner:TECH PRECESS TECH INC

Nickel-chromium-molybdenum alloy welding wire for surfacing welding of ball valves

ActiveCN110977245AReduce generationImprove high temperature strengthWelding/cutting media/materialsSoldering mediaSmelting processIngot

The invention provides a nickel-chromium-molybdenum alloy welding wire for surfacing welding of ball valves. The nickel-chromium-molybdenum alloy welding wire includes the following chemical components including, by mass percentage, 0.01% of C, not larger than 0.3% of Si, not larger than 0.5% of Mn, not larger than 0.015% of P, not larger than 0.01% of S, not larger than 0.2% of Al, not larger than 0.3% of Ti, 21.5%-22.2% of Cr, not larger than 0.3% of Fe, 8.5%-9% of Mo, 3.5%-3.8% of the sum of Nb and Ta and the balance Ni. According to the nickel-chromium-molybdenum alloy welding wire, the type and content of elements in the alloy composition are strictly controlled, an alloy is conveniently processed into thinner welding wires, and element ratio control helps to reduce the occurrence ofhot cracks during welding; and a vacuum smelting and electroslag double smelting process is adopted, and a refining method combining high-temperature instantaneous refining and low-temperature long-term refining is adopted in the vacuum smelting process, the purity and the degassing effect are further improved, the quality and performance of alloy ingots are improved, and plasticity and impact toughness are improved.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

300 MPa-grade high-strength and high-plasticity non-heat treatable self-strengthening die-casting aluminum alloy and manufacturing method

The invention discloses a 300MPa-grade high-strength and high-plasticity non-heat treatable self-strengthening die-casting aluminum alloy and a manufacturing method. The 300MPa-grade high-strength andhigh-plasticity non-heat treatable self-strengthening die-casting aluminum alloy is prepared from components in percentage by mass as follows: 7.5%-8.5% of Si, 1.0%-1.3% of Cu, 0.1%-0.3% of Fe, 0.7%-1.0% of Mn, 0.35%-0.5% of Mg, 0.1%-0.2% of Ti, 0.05%-0.1% of Cr, 0.02%-0.03% of Sr and the balance Al. The manufacturing method comprises the following steps: after remelting a pure aluminum ingot, melting in other components, and after complete melting, uniformly stirring the components until no sediments exist at the bottom of a furnace; keeping molten metal at 720 DEG C at constant temperaturefor 30 min, performing deslagging and degassing, decreasing the temperature of the molten metal to 680-690 DEG C, and pressing pure Mg wrapped by aluminum foil into molten aluminum by a bell jar; carrying out uniform stirring for 5-10 min after complete smelting, and carrying out deslagging; and after smelting, casting the molten metal into a metal die by a horizontal cold chamber die-casting machine to obtain an alloy casting. The manufactured non-heat treatable self-strengthening die-casting aluminum alloy has tensile strength up to 300 MPa or above and elongation larger than or equal to 8%before heat treatment, so that the aluminum alloy is a novel high-strength and high-plasticity aluminum alloy and can be popularized and used in the industry.

Owner:ANHUI SCI & TECH UNIV

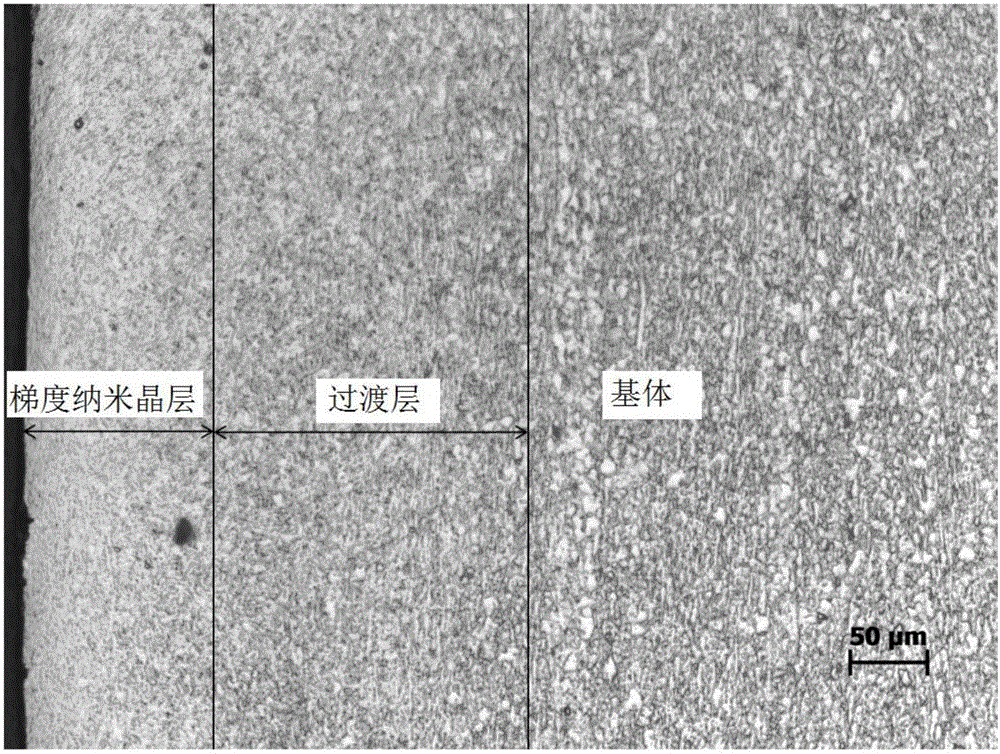

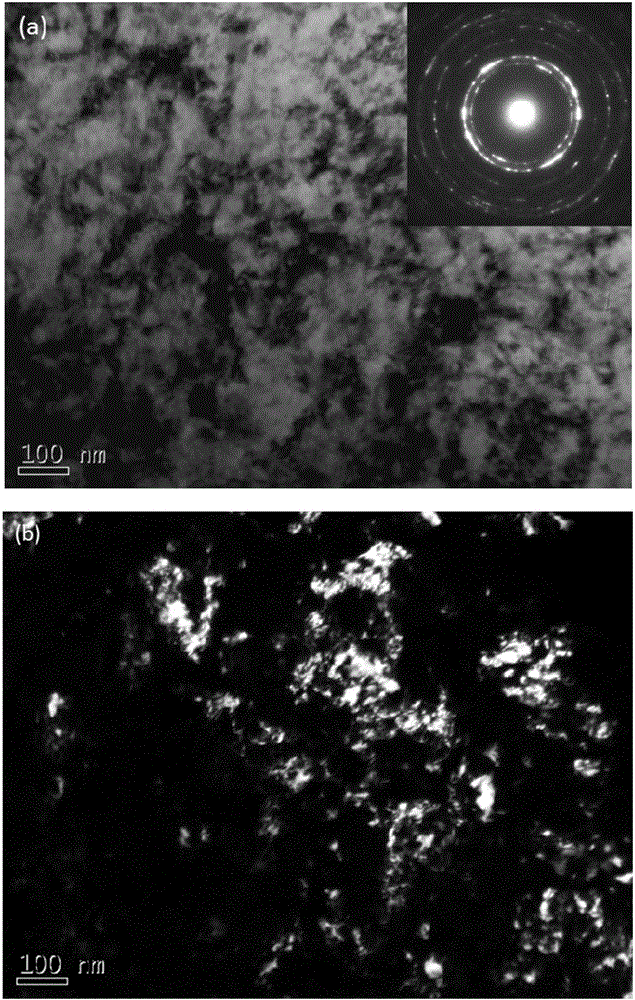

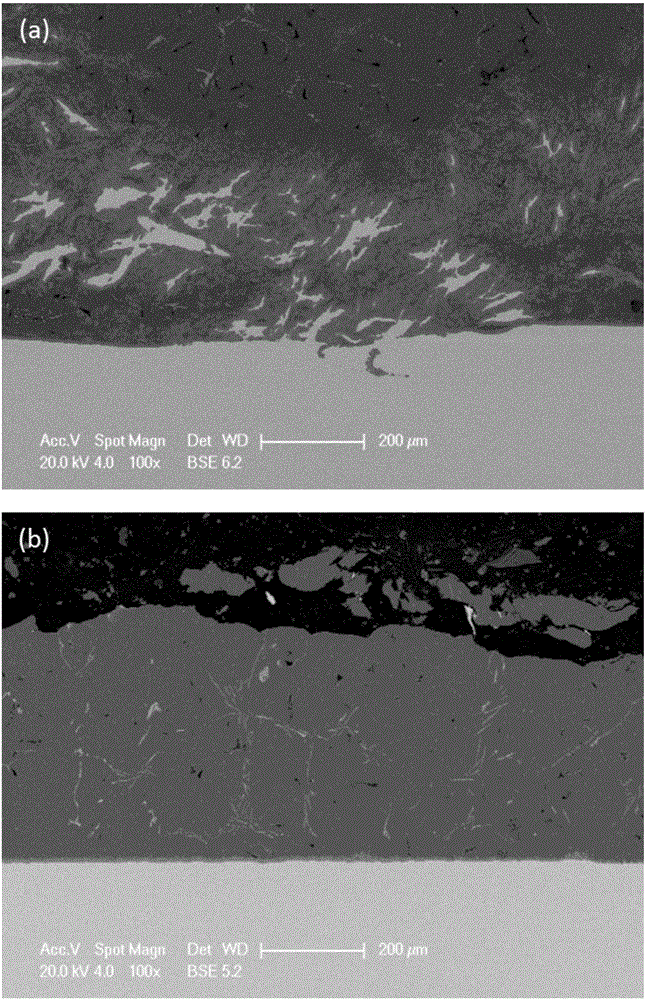

Preparation method for liquid aluminizing composite coating on surface of titanium alloy

ActiveCN105734486AEasy to operateReduce hot cracksSolid state diffusion coatingDiffusion reactionTitanium alloy

The invention discloses a preparation method for a liquid aluminizing composite coating on the surface of titanium alloy. The preparation method comprises the steps of 1, carrying out nanocrystallization treatment on the surface of a titanium alloy sample for forming a gradient nanocrystal layer on the surface of the titanium alloy sample; 2, carrying liquid aluminizing treatment on the titanium alloy sample subjected to the surface nanocrystallization treatment for obtaining the composite coating on the surface of the titanium alloy sample. The preparation method is simple and convenient to operate. Compared with traditional liquid aluminizing methods, the preparation method has the advantages that thicker coatings can be obtained at the same temperature and in the same treatment time or the coatings with the same thickness can be obtained at lower temperature and in shorter treatment time, and therefore the cost can be saved, and the formation tendency of hot cracks of the coatings can be weakened; a diffusion reaction layer of a gradient structure and staggered interfaces can be obtained on the surface of the titanium alloy, and therefore the bonding force between the coating and a base body can be greatly increased, and the coating does not peel off or get cracked easily under the effect of heat stress.

Owner:WUHAN UNIV

Novel high carbon graphite steel roll ring and preparation method thereof

ActiveCN106636876AReduce exclusivityReduce casting stressFurnace typesHeat treatment furnacesAntioxidant capacityHigh carbon

The invention relates to a preparation method of a novel high carbon graphite steel roll ring. The roll ring is prepared by the following steps: adopting a centrifugal three-layer composite casting process, by adding alloy of special carbide elements V, Nb, Mo and the like, tapping when the temperature of a liquid phase reaches +120-150 DEG C, carrying out spheroidization treatment with 0.30-0.60 percent of BaCa, carrying out inoculation with 0.50-0.60 percent of CaSi as an inoculant after spheroidization, then carrying out killing for 3-8min and pouring, and carrying out special heat treatment by cold opening a box to obtain a finished product with the roll ring surface hardness and the matrix microstructure according with the requirements. Compared with an ordinary roll ring, according to the novel high carbon graphite steel roll ring, by adding the special carbide elements, through spheroidization treatment by the BaCa and inoculation by the CaSi as the inoculant, special fine grained carbides which are distributed uniformly and spheroidal graphite with the antioxidant capacity and the lubrication action are cultivated, so that the comprehensive performance of the roll ring is improved, and the service life of the roll ring is prolonged.

Owner:江苏凯达重工股份有限公司

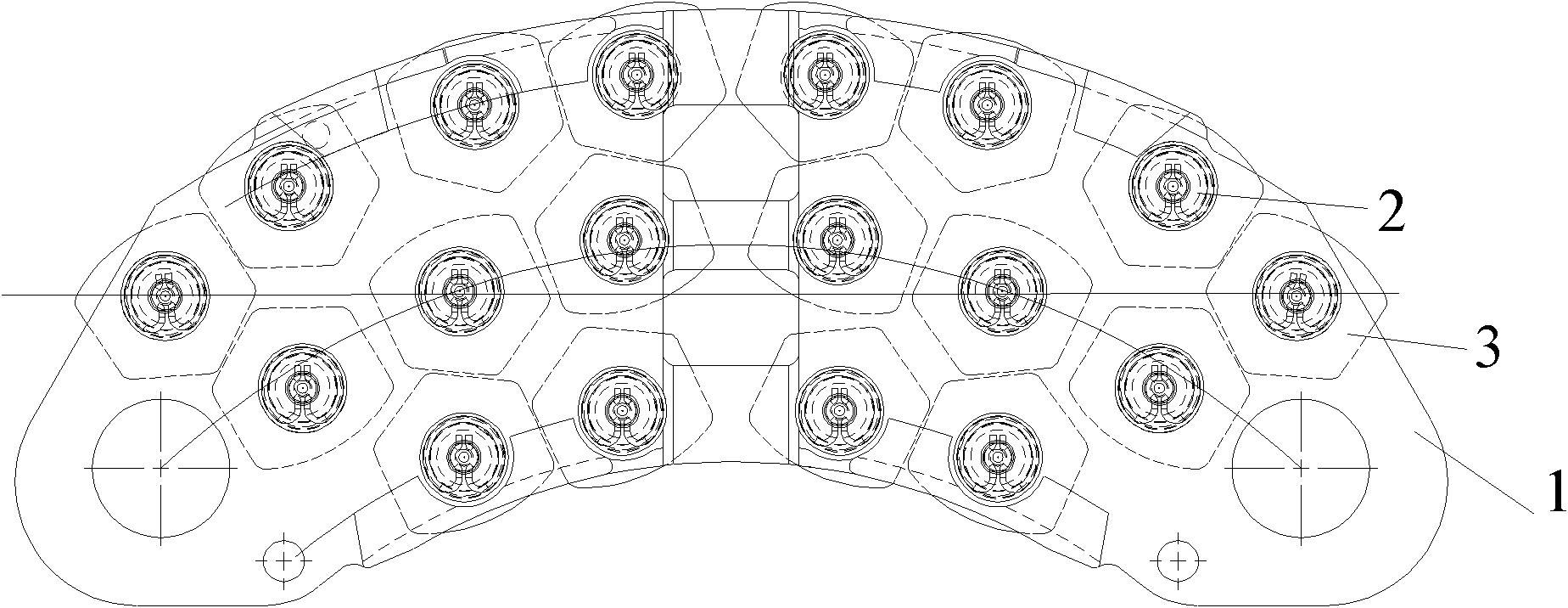

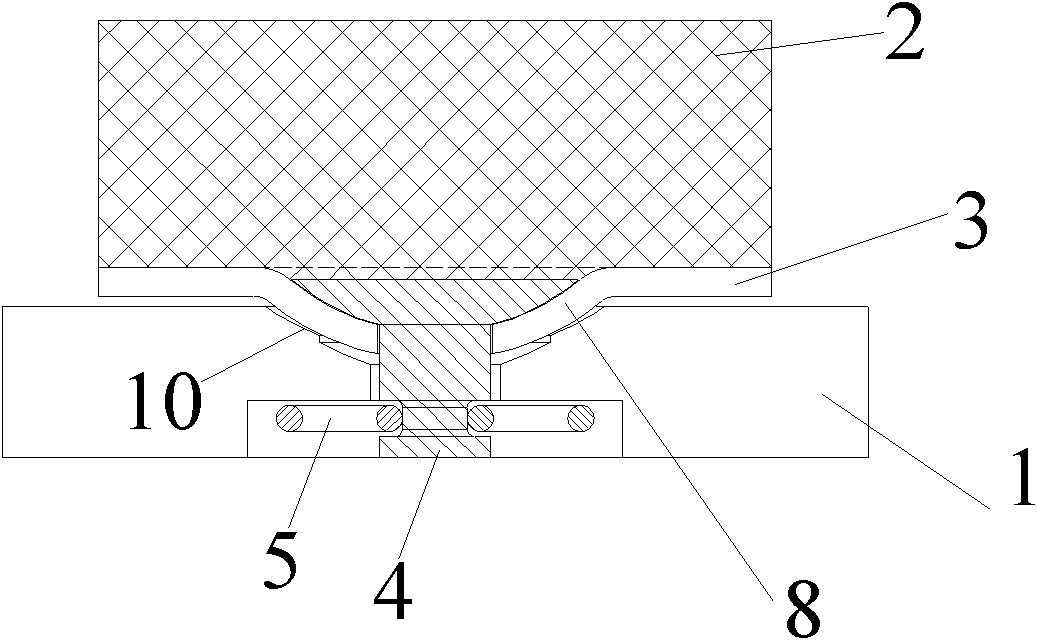

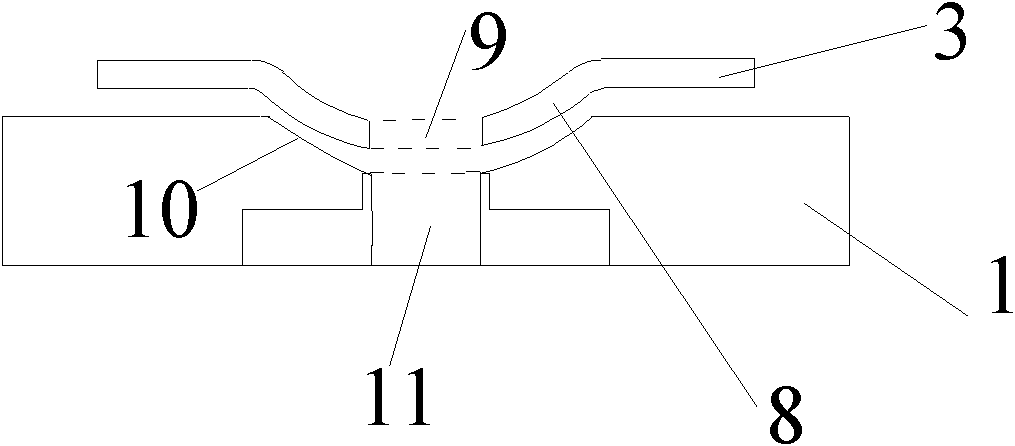

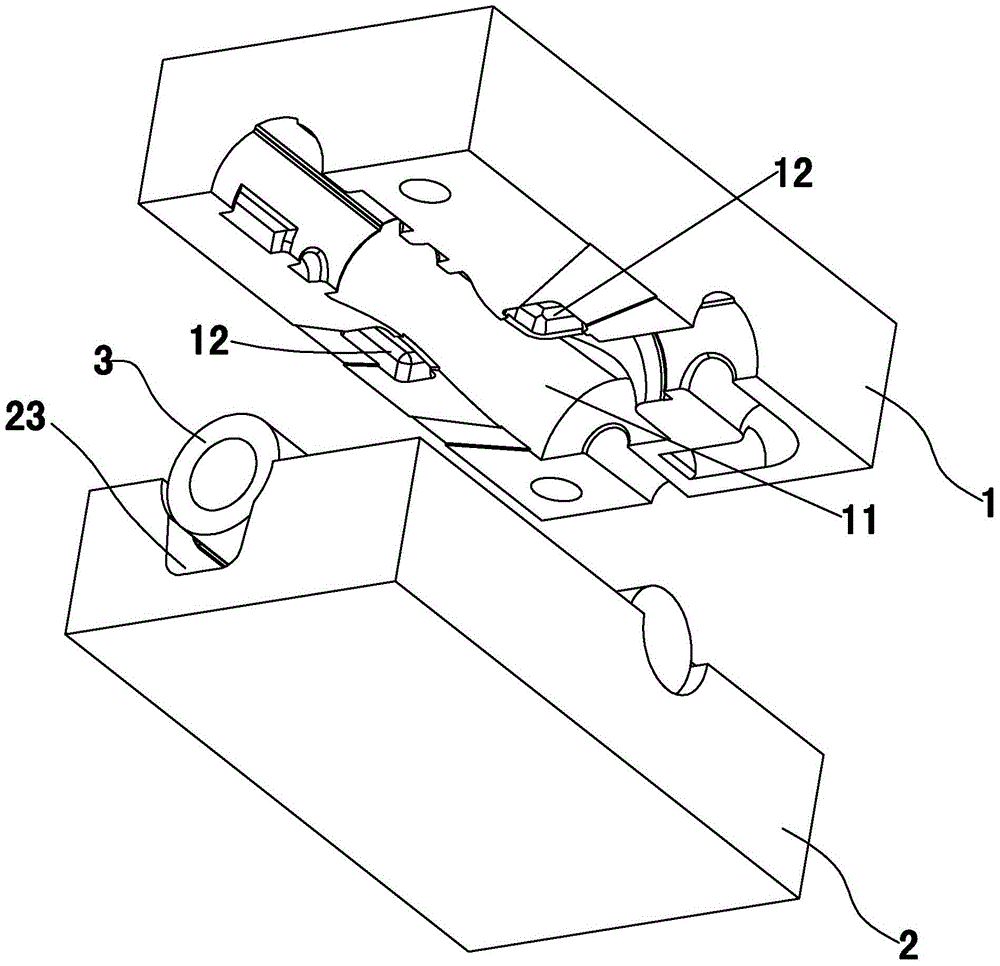

Brake pads for high-speed train braking systems

InactiveCN102261409AImprove operational efficiencyImprove braking efficiencyFriction liningEngineeringSpring steel

The invention discloses a brake pad for a high-speed train braking system, which comprises: a first steel back with an integral structure, and more than one spaced apart friction blocks are arranged above the first steel back; each friction block and the A second steel back is arranged between the first steel backs, and the middle area of the second steel back has a raised portion facing the first steel back; hole, and a concave part is provided on the side of the first steel back that contacts the second steel back, and the concave part is matched with the raised part, and the fixed pin is provided on the concave part to freely pass through the first steel back. The first installation hole of the back; on the side of the first steel back and away from the second steel back, there is a snap ring that snaps onto the other end of the fixing pin, and the snap ring is located on the first steel back Inside. The above-mentioned brake pads can withstand relatively high thermal loads, and can reduce the eccentric wear phenomenon of the friction blocks in the brake pads, so that the friction surfaces of the corresponding brake discs are evenly stressed, and the braking efficiency is improved.

Owner:MIN OF RAILWAY TRANSPORT BUREAU +1

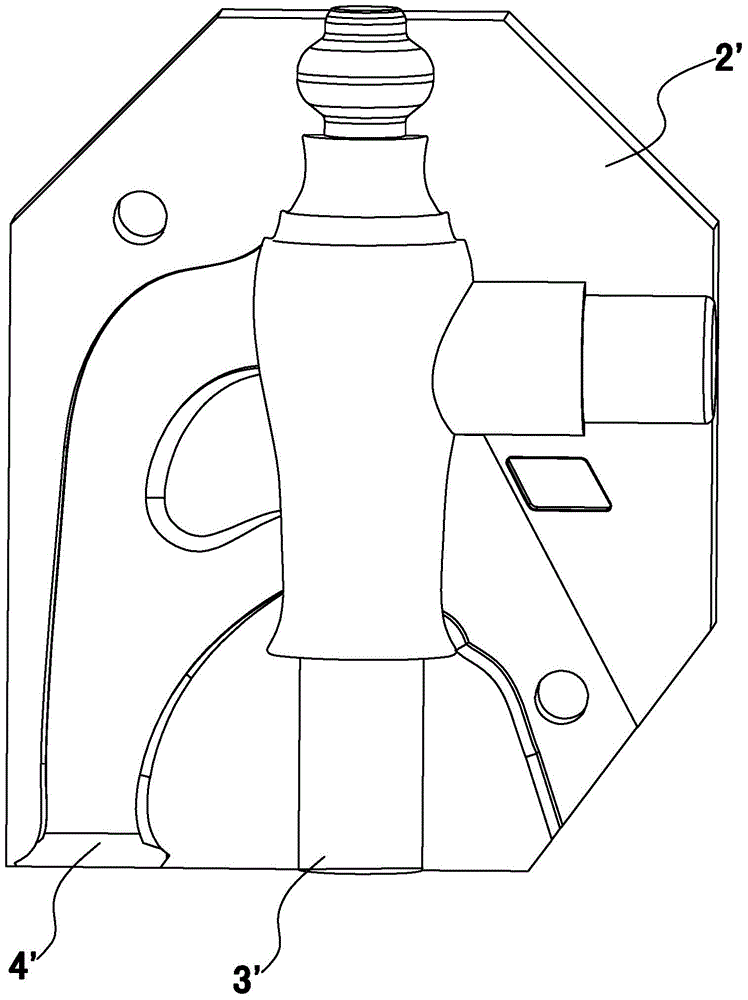

Gravity casting process of lead-free brass tap

The invention provides a gravity casting process of a lead-free brass tap, which has the advantages that a flowing distance of a product in a casting process is short, the simultaneous solidification is achieved, hot cracks are reduced; a heat balance effect of a mould is good, so that heat balance of the product is facilitated, and the stress micro-cracks during cooling are reduced. The gravity casting process of the lead-free brass tap comprises the following step of casting and forming lead-free brass liquid through a gravity casting device, wherein the gravity casting device comprises an upper half mould, a lower half mould and a sand core, wherein mould cavities matched with a tap body in shape are respectively and correspondingly arranged between the upper half mould and the lower half mould, the sand core is arranged in the mould cavities between the upper half mould and the lower half mould, the shape of the sand core is matched with the shapes of a water inlet part and a water outlet part of the tap and an inner cavity of an installing part of a valve core, a casting cavity is formed between the sand core and the mould cavity, a sprue in which lead-free molten copper is cast is arranged in the lower half mould, the sprue is connected with the casting cavity, the sprue is provided with an internal sprue and an external sprue, and the internal sprue is correspondingly arranged at the casting cavity for forming the water inlet part of the tap body.

Owner:LONGYAN HONGHANG SANITARY WARE CO LTD

Titanium carbonitride-based hard alloy high-speed wire guide wheel material and preparation method thereof

The invention relates to the technical field of hard alloys and specifically discloses a titanium carbonitride-based hard alloy high-speed wire guide wheel material. The titanium carbonitride-based hard alloy high-speed wire guide wheel material is prepared from the following components in percentage by weight: 39.5%-45.5% of TiC, 9%-15% of TiCN, 4.5%-10.5% of WC, 2%-5% of MoC and 33%-39% of Ni. The invention also discloses a preparation method of the titanium carbonitride-based hard alloy high-speed wire guide wheel material. The titanium carbonitride-based hard alloy high-speed wire guide wheel material is effectively improved in both abrasive resistance and red hardness as the components and the contents thereof are selected, so that the service life of the guide wheel can be remarkably increased; besides, the material is simple in components, low in grinding allowance and controllable in production cost.

Owner:成都西顿硬质合金有限公司

Aluminum-copper alloy powder for 3D printing and preparation method thereof

InactiveCN111872404AGood mechanical propertiesPowder preparation technology is convenient and fastAdditive manufacturing apparatusTransportation and packagingSelective laser meltingSilicon alloy

The invention relates to a preparation method of aluminum-copper alloy powder for 3D printing, and belongs to the technical field of 3D printing of metal powder. After being heated and molten, aluminum-copper alloy raw materials are fully mixed evenly; aluminum-copper alloy powder is prepared by a gas atomization technology; after gas atomization, the aluminum-copper alloy powder is sieved to obtain the aluminum-copper alloy powder for 3D printing within the required particle size range; and the proportion of aluminum and copper in the aluminum-copper alloy raw materials meets the aluminum-copper alloy powder for 3D printing, specifically, the Cu content is 1.00%wt to 8.00%wt, the Mg content is 0.10%wt to 4.00%wt, the Si content is 0.05%wt to 3.00%wt, the Mn content is 0.04%wt to 2.50%wt,the Zr content is 0.01%wt to 3.00%wt, and the balance is Al. The strength of a sample prepared by selective laser melting (SLM) of the aluminum-copper alloy powder is equal to that of an SLM aluminum-silicon alloy, but the elongation of the sample is obviously higher than that of the common SLM aluminum-silicon alloy, the using demands for an aluminum alloy in most cases can be met, the complex post-treatment process of the malleable aluminum alloy is reduced, and energy and the cost are saved.

Owner:TONGJI UNIV

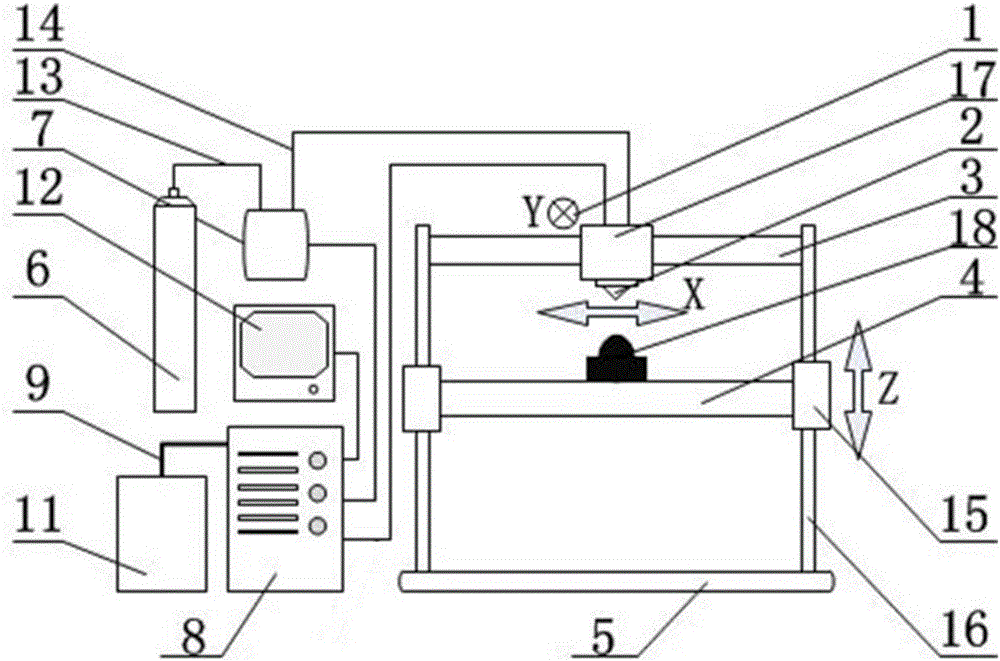

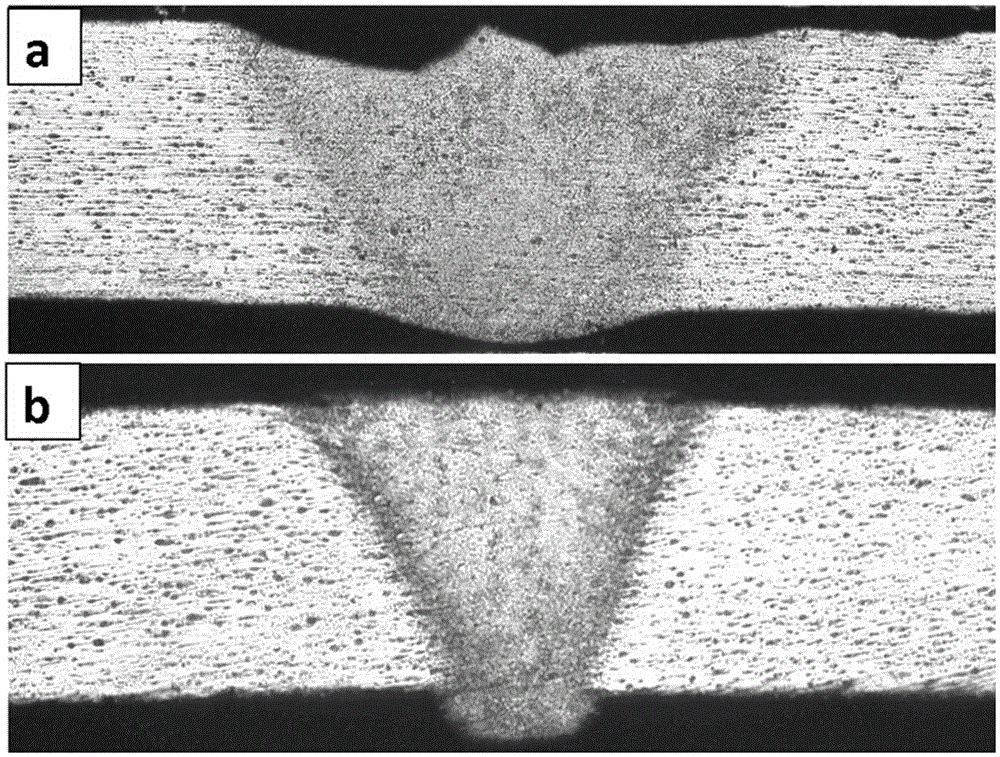

High-efficiency and high-quality laser-micro-plasma hybrid welding method

ActiveCN105618933AImprove absorption conditionsImprove absorption efficiencyWelding/soldering/cutting articlesMetal working apparatusShielding gasLaser beams

The invention discloses a high-efficiency and high-quality laser-micro-plasma hybrid welding method, which is characterized by comprising the following steps: selecting a light metal structure material of which the thickness is 1 to 4mm to be served as a to-be-welded workpiece; then combining a laser beam with a plasma arc and integrating into a same welding gun; then, enabling a focused laser beam and the plasma arc to jointly act on a same point and directly act on the to-be-welded workpiece to form a same molten pool; and taking argon gas as plasma generating gas and a welding shielding gas. According to the high-efficiency and high-quality laser-micro-plasma hybrid welding method disclosed by the invention, as welding is performed by combining the laser with micro-plasma, and a laser absorption condition can be improved through combined action of the laser and the plasma, absorption efficiency of metal on a heat source is increased, and effective action of a whole process is increased; a welding rate can be effectively increased, and a welding line and a heat affected zone are reduced, therefore strength and impact toughness of a joint are increased, and residual stress of a welded piece is also reduced; moreover, equipment cost is reduced, and meanwhile, stability of plasma discharge can be increased, quality of the welded joint is increased, and quality of the joint is kept stable.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

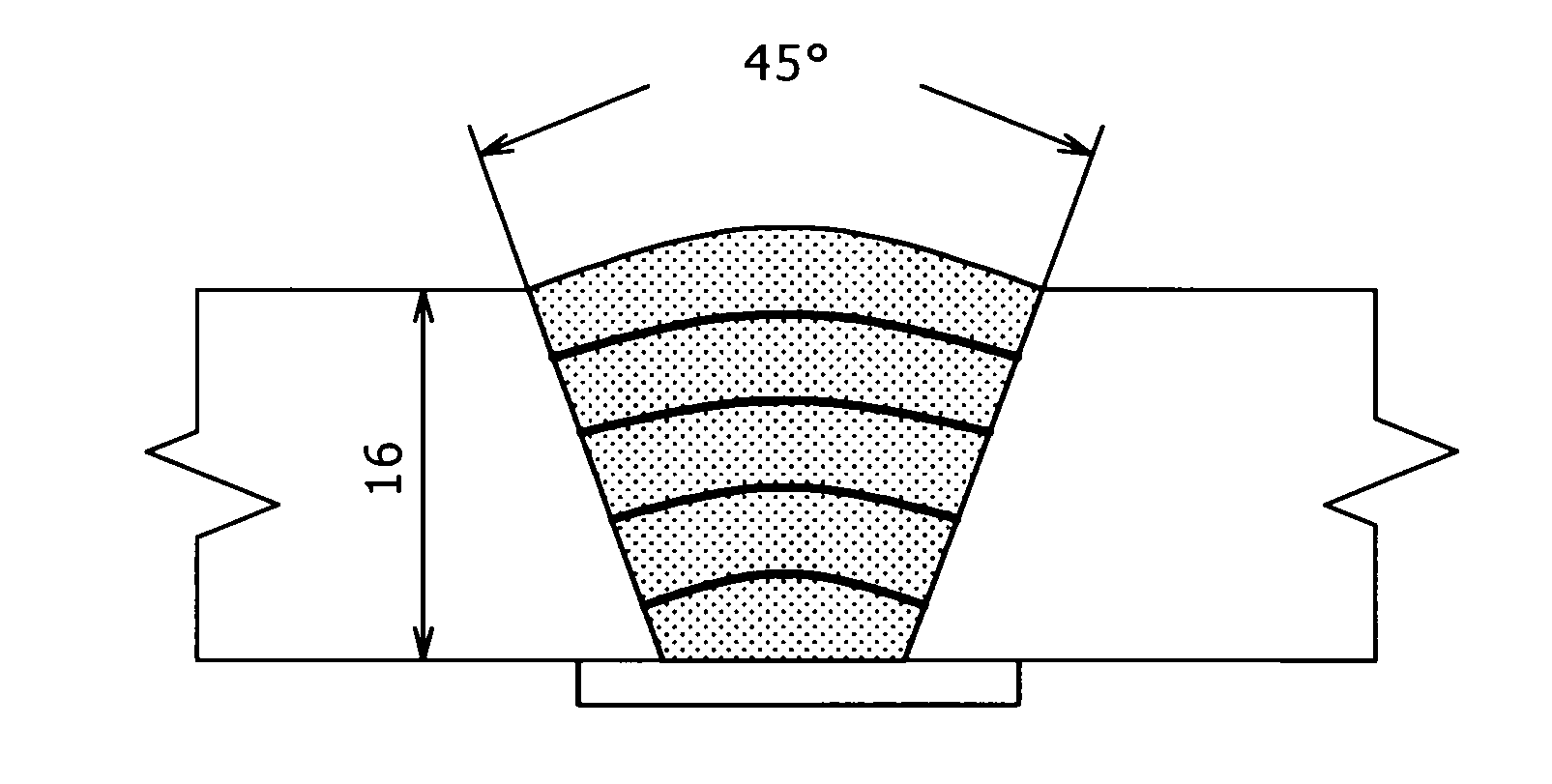

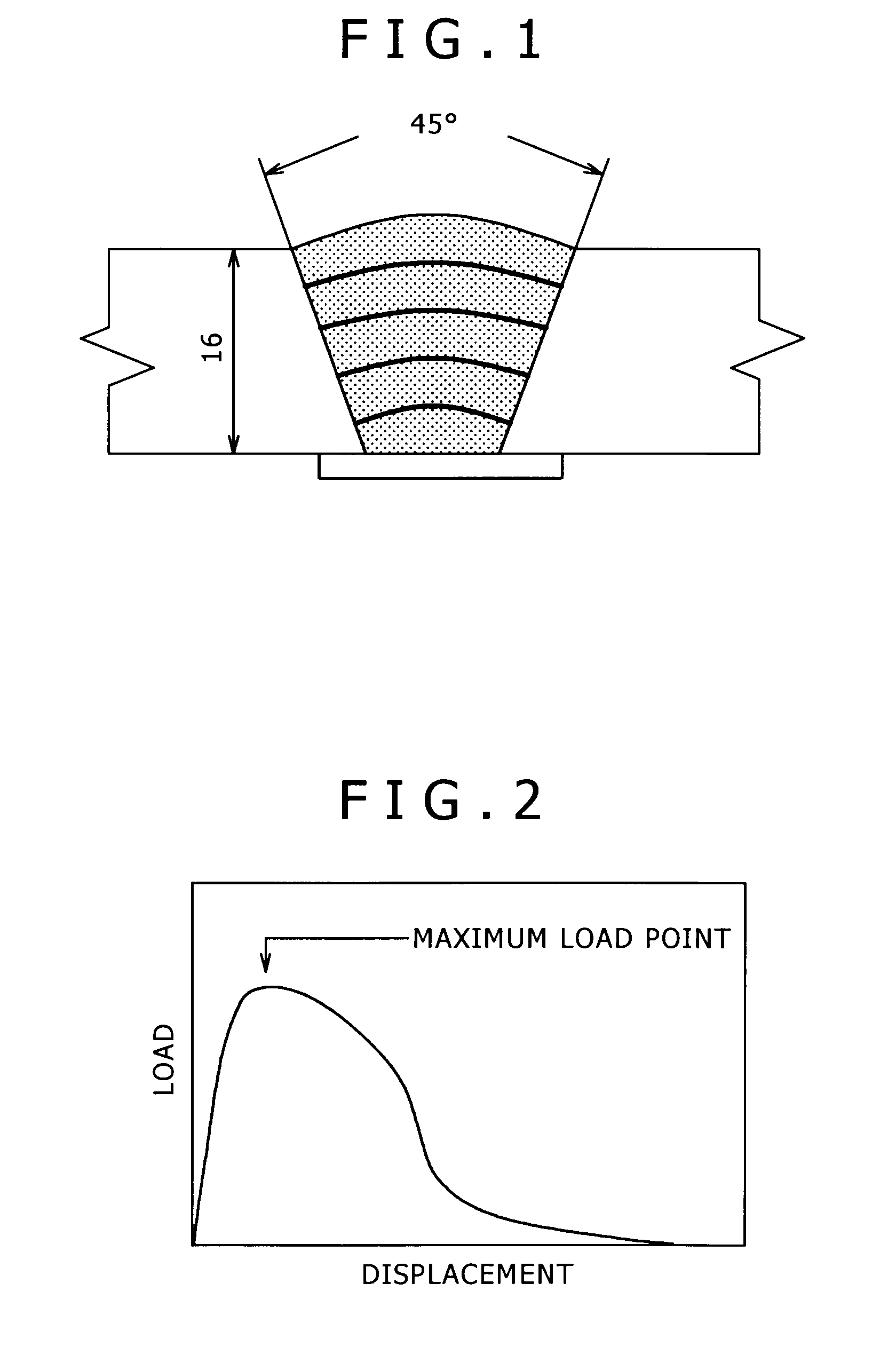

Forged steel piece welding method

ActiveCN105904063AGuarantee welding qualityReduce cold cracksGas flame welding apparatusTemperature controlEngineering

The invention belongs to the technical field of welding, and specifically relates to a forged steel piece welding method. The forged steel piece welding method comprises the following steps of: (A) assembly and cleaning before welding: a forged steel piece is assembled; and a welding line needing to be welded is cleaned; (B) preheating before welding: the welding line is preheated; (C) welding: the welding line is welded by adoption of a layering and a laning backward welding mode, and the temperature of the welding line is controlled in the welding process; and (D) post-heating of the welding line: the welding line is heated and is then subjected to insulation treatment. The welding method guarantees the welding quality through rigorous preparation before welding, reasonable welding process sequence and standard temperature control measures, effectively reduces generation of cold cracks and hot cracks, and prevents welding deformation.

Owner:CHINA CONSTR STEEL STRUCTURE WUHAN

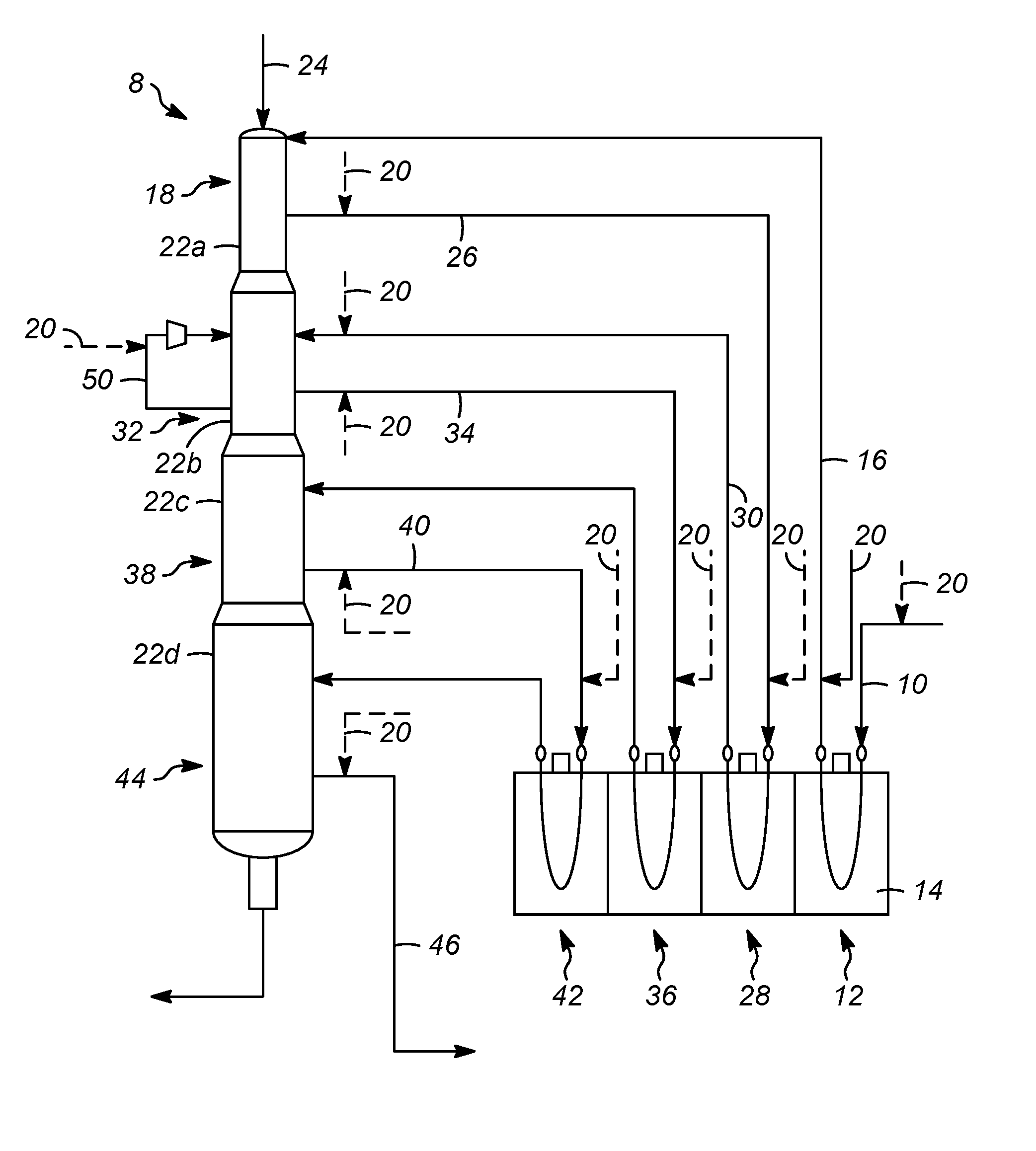

Catalytic reforming processes

ActiveUS20160369179A1Reduce the amount requiredMinimizing yield lossCatalytic naphtha reformingNaphtha treatmentCatalytic reformingAlkene

Processes for catalytic reforming in which a cracking inhibitor, such as an olefin, or a light olefin, is used to inhibit thermal cracking of larger hydrocarbons in non-reactive zones. The cracking inhibitor may be added at various positions through the processes, such as in the recycle gas stream, before a heater, before a stream is passed into a reforming zone, after an effluent stream is recovered from a reforming zone. A molar ratio of cracking inhibitor to hydrocarbons in stream may be between 0.01 and 0.2.

Owner:UOP LLC

Welding solid wire

ActiveUS8043407B2Avoid lack of toughnessHigh energyElectric discharge heatingWelding/cutting media/materialsManganeseOxygen

It is an object of the present invention to provide a similar composition metal type welding solid wire capable of forming a welded joint having excellent cryogenic characteristics, such as ensuring a low-temperature toughness equivalent to that of the cryogenic base metal, and in addition, further having a high crack initiation resistance, and a weld metal thereof. The welding solid wire of the present invention is an iron base welding solid wire including carbon: 0.10 mass % or less (not inclusive of 0%), silicon: 0.15 mass % or less (not inclusive of 0%), nickel: 8.0 to 15.0 mass %, manganese: 0.10 to 0.80 mass %, and Al: 0.1 mass % or less (not inclusive of 0%), and oxygen in an amount of 150 ppm or less (inclusive of 0), characterized by including: a REM: 0.005 to 0.040 mass %, or chromium: 4.0 mass % or less (not inclusive of 0%).

Owner:KOBE STEEL LTD

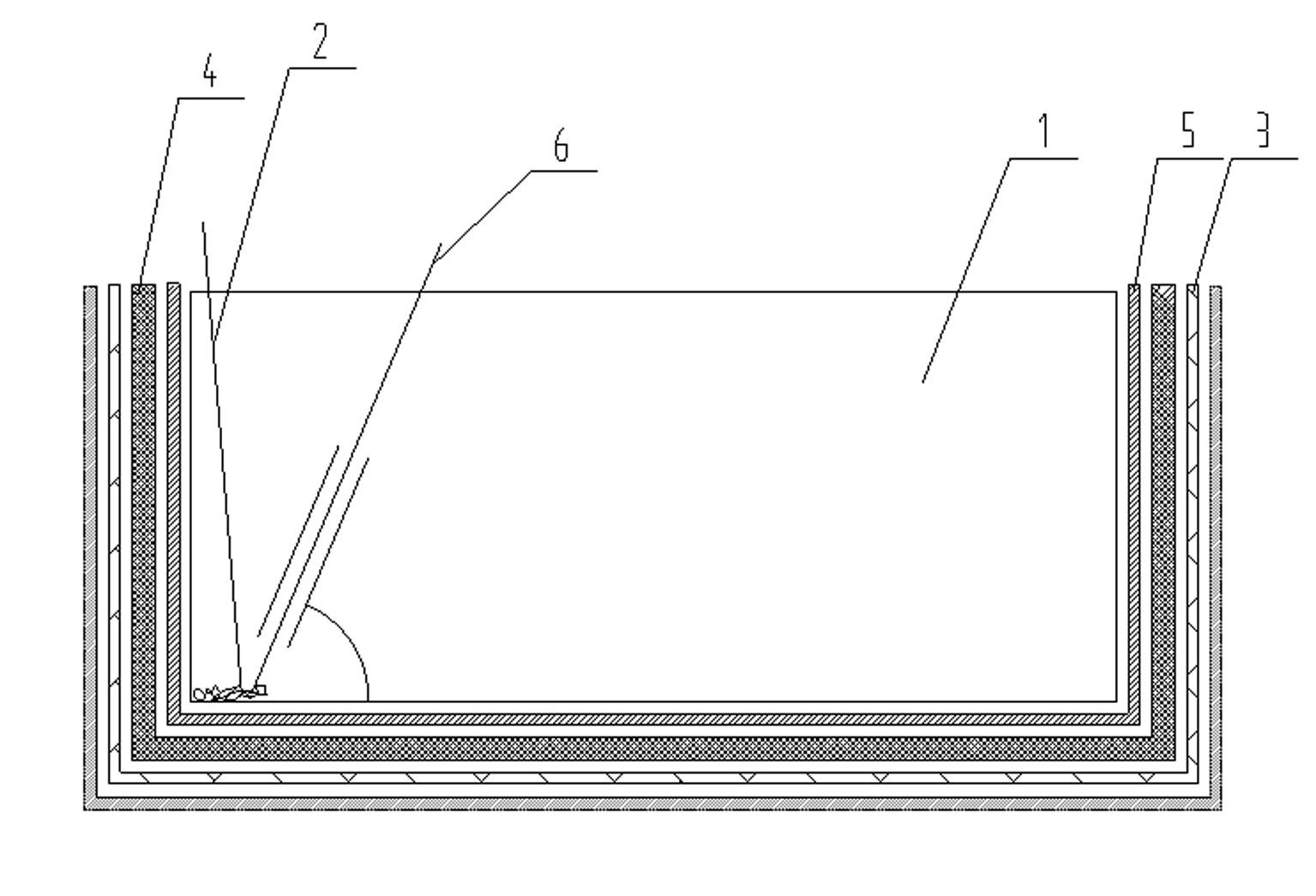

Investment casting process for complex thin-wall hollow aluminum alloy aviation part

InactiveCN112139451ASolve sinkingSpeed up the flowFoundry mouldsFoundry coresInvestment castingSlurry

The invention belongs to the technical field of investment casting processes, and relates to an investment casting process of a complex thin-wall hollow aluminum alloy aviation part. The investment casting process comprises the following steps that a water-soluble ceramic core is manufactured by adopting a 3D printing mode, the water-soluble ceramic core is coated with an organic waterproof coating, and drying is carried out on the water-soluble ceramic core; a wax injection mold is manufactured according to the shape of a casting, a water-soluble ceramic core is placed in the wax injection mold, a wax material is injected into the wax injection mold after mold closing to form a wax mold, the wax mold is coated with gypsum slurry, and after the gypsum slurry is hardened, heating dewaxing and roasting are carried out to obtain a gypsum casting mold; and molten metal is poured into the gypsum casting mold by adopting a vacuum pouring and pressurizing solidification method to obtain a casting mold, and finally the casting mold is put into clear water to dissolve and remove the water-soluble ceramic core to obtain the needed complex thin-wall hollow aluminum alloy aviation part. According to the investment casting process of the complex thin-wall hollow aluminum alloy aviation part, the water-soluble ceramic core and the gypsum casting mold are combined, so that the problem that along and narrow inner cavity of the gypsum casting mold sinks is solved, and forming of looseness, cold shut and hot cracks in the casting is reduced through vacuum pouring and pressurizing solidification.

Owner:HENAN ZHENGXU TECH CO LTD

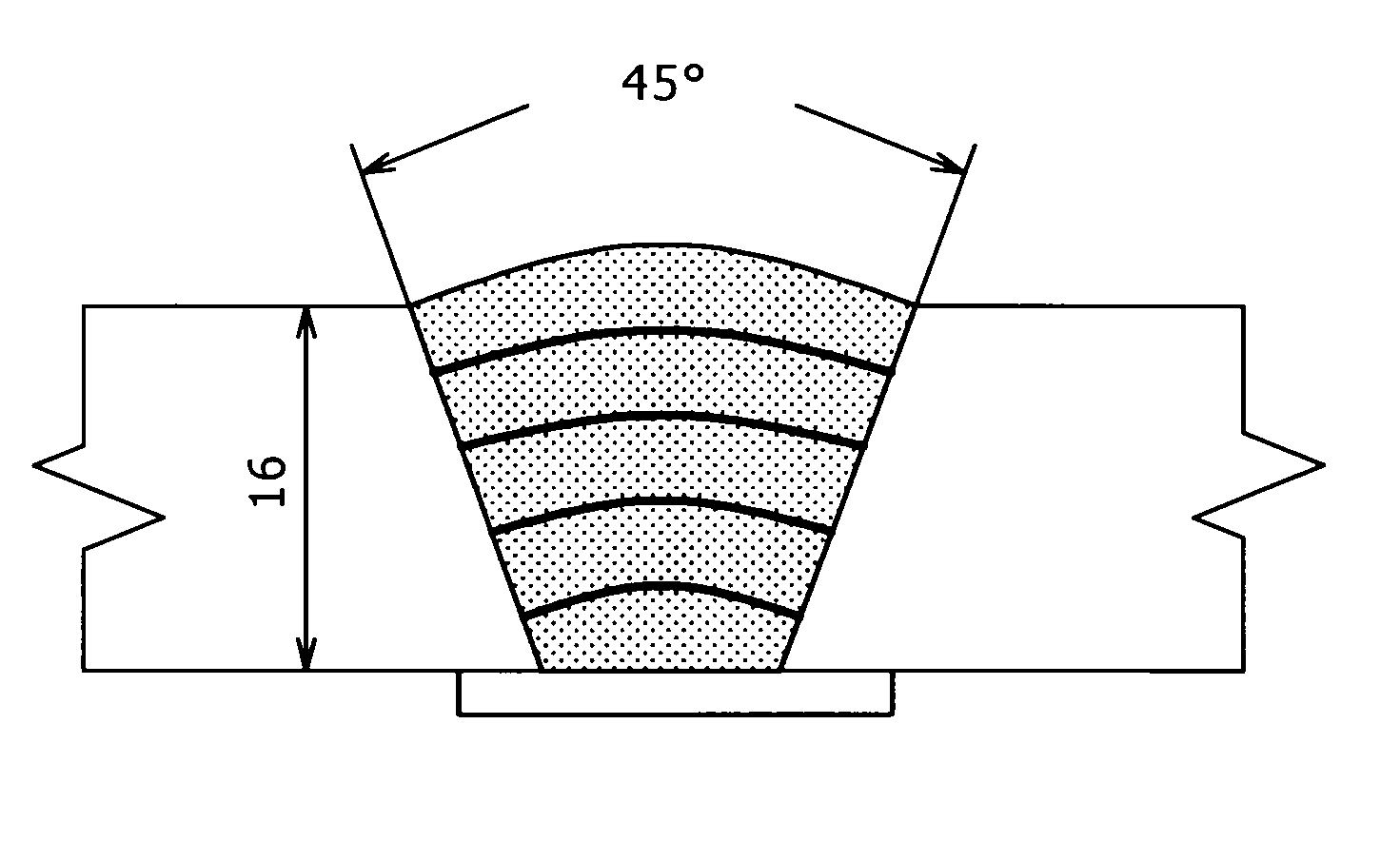

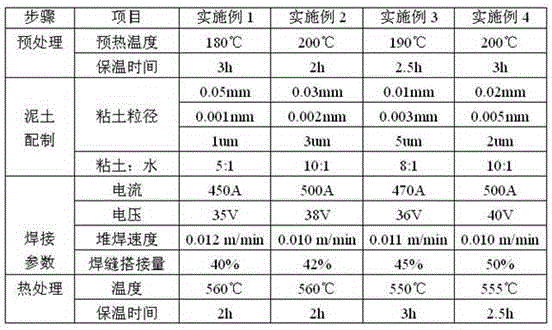

Surface overlaying method of foot roll of continuous casting machine

The invention, which belongs to the technical field of the overlaying, discloses a surface overlaying method of a foot roll of a continuous casting machine. The method comprises the following steps: (1), carrying out pretreatment of a foot roll of a continuous casting machine; (2), carrying out soil preparation; (3), carrying out soil filling; (4), carrying out surface overlaying; (5), removing the filling soil; (6), carrying out heat processing in a heating furnace under the temperature of 550 DEG C to 560 DEG C, carrying out heat preservation for 2 to 3 hours, and then drawing the processed member out of the furnace for cooling; and (7), carrying out rough machine at a tool and flaw detection, and then carrying out fine machine to enable the member to have the required dimension. The method has the following advantages: the steps of the method are linked in order and reasonably; and the operation process is simple and convenient. The surface of the foot roll of the continuous casting machine is flat and smooth; the flexibility and abrasive resistance are high; and the Rockwell hardness HRC can reach over 45. Hot cracks of an overlapping layer and a welding joint are reduced; the service life of the foot roll of the continuous casting machine is prolonged; the maintenance cost is lowered; the using effect of the continuous casting machine during billet production can be improved to the maximum extent; and the product quality can be guaranteed to meet the requirement.

Owner:MAANSHAN BAIYUAN MACHINERY CO LTD

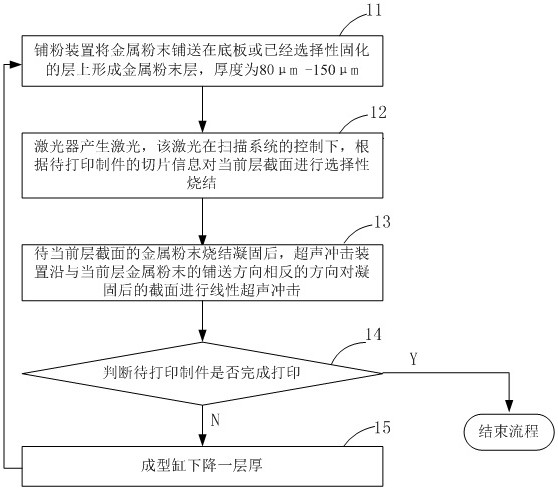

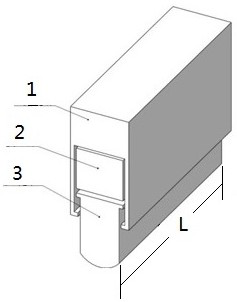

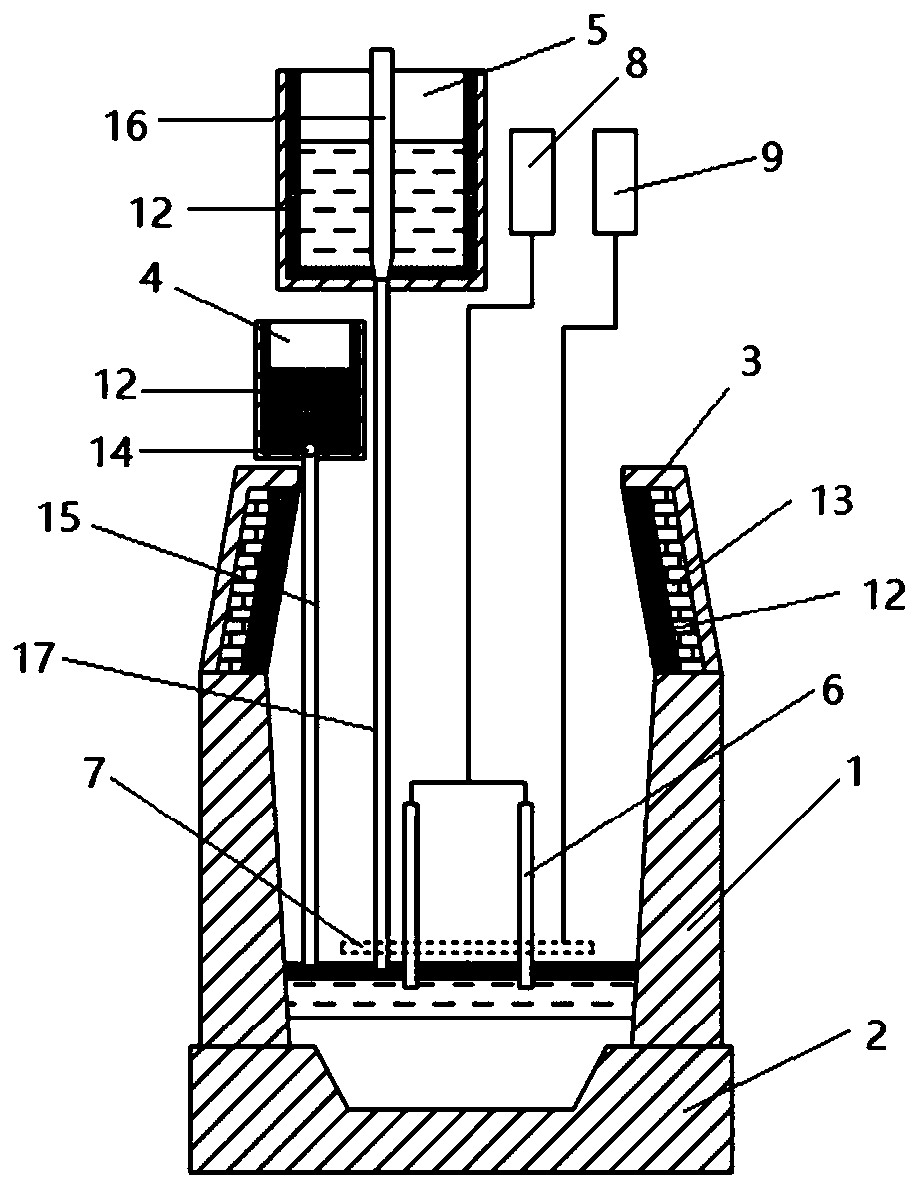

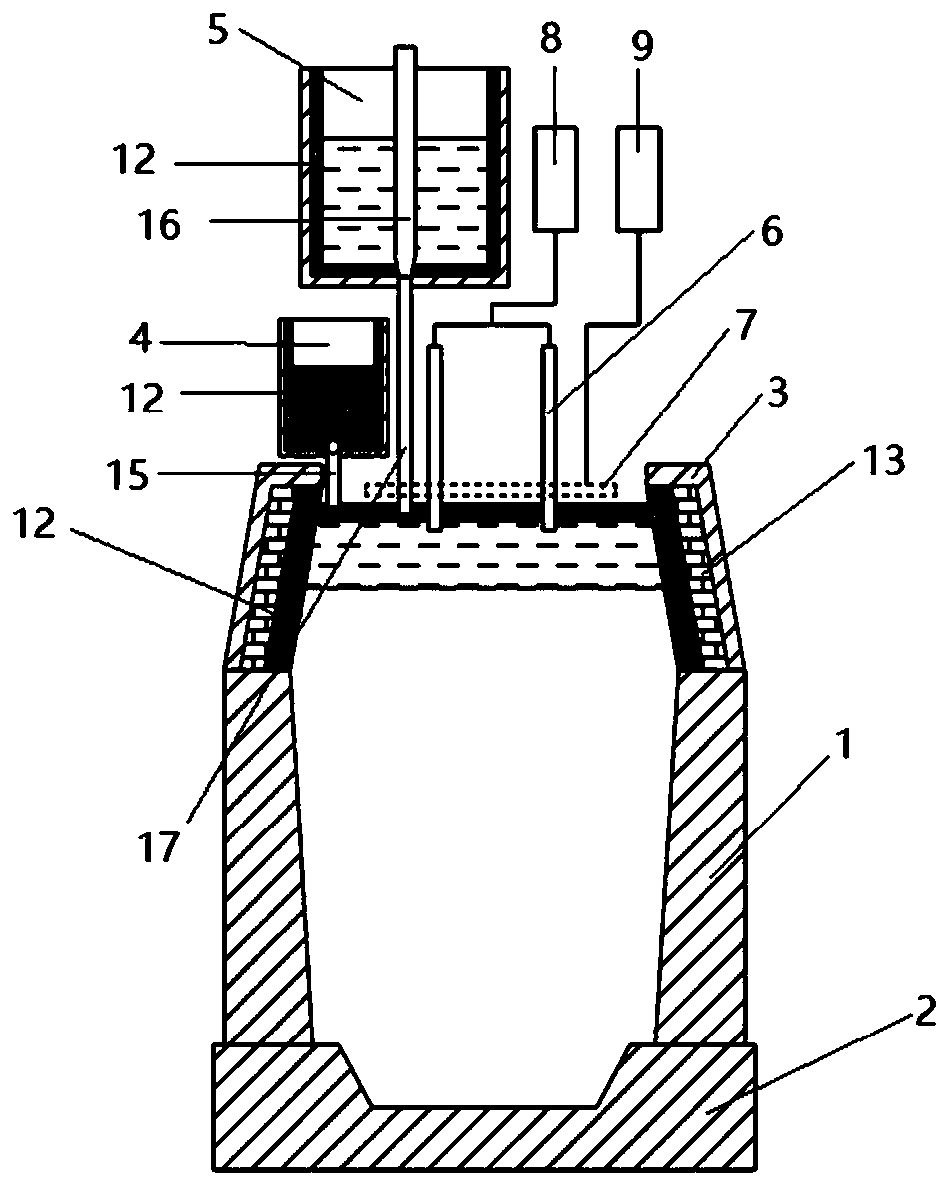

Additive manufacturing method and additive manufacturing equipment

ActiveCN113649597AEliminate microwarpingReduce stress levelsAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyErbium lasers

The invention discloses an additive manufacturing method and additive manufacturing equipment. The method comprises the steps that a powder laying device is used for laying metal powder on a bottom plate or a selectively solidified layer to form a metal powder layer, wherein the thickness of the metal powder layer is 80-150 microns; a laser device generates laser, and the laser selectively sinter the current layer section according to the slicing information of the to-be-printed piece under the control of a scanning system; after metal powder of the current layer section is sintered and solidified, an ultrasonic peening device conducts linear ultrasonic peening on the solidified section in the direction opposite to the laying and conveying direction of the metal powder of the current layer; and a forming cylinder descends by one layer thickness, and the step 1 is executed again. Compared with the prior art, the layer thickness is increased by 2-3 times, and the printing efficiency is greatly improved; and by conducting linear ultrasonic peening on the solidified section, local compression deformation is introduced into the workpiece, so that holes and micro cracks in the workpiece can be closed, micro buckling deformation of the workpiece is eliminated, and the quality of the printed workpiece is improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Device and method for preparing large cast ingot through slag protection based multi-layer casting magnetic field current compound treatment

ActiveCN110369682ASpeed up the flowHigh degree of homogenizationIngot casting plantsPorosityMelting tank

The invention discloses a device and method for preparing large cast ingot through slag protection based multi-layer casting magnetic field current compound treatment. The device comprises a steel ingot mould, a dead head, a slag ladle and a tundish, wherein movable type parallel electrodes and a movable type magnetic field coil are further separately arranged on the upper part of the steel ingotmould; during casting, amount of needed molten steel is firstly determined according to the specification of the large cast ingot, and the amount of the molten steel is divided into a plurality of parts according to the property of easily segregating elements in the molten steel; content of elements which are easily segregated in each part is regulated, so that casting powder is added before the first part of the molten steel is cast, tapping in a slag layer is guaranteed, and impurities are adsorbed; under action of magnetic fields and / or current, the next part of the molten steel is added while the first part of the molten steel is gradually solidified till a molten pool is relatively small, and protective slag is supplemented till all of the molten steel is cast to prepare the cast ingot. The casting method disclosed by the invention can purify the molten steel, relieves and even eliminates gross segregation, and alleviates shrinkage cavity and porosity.

Owner:SHANGHAI UNIV

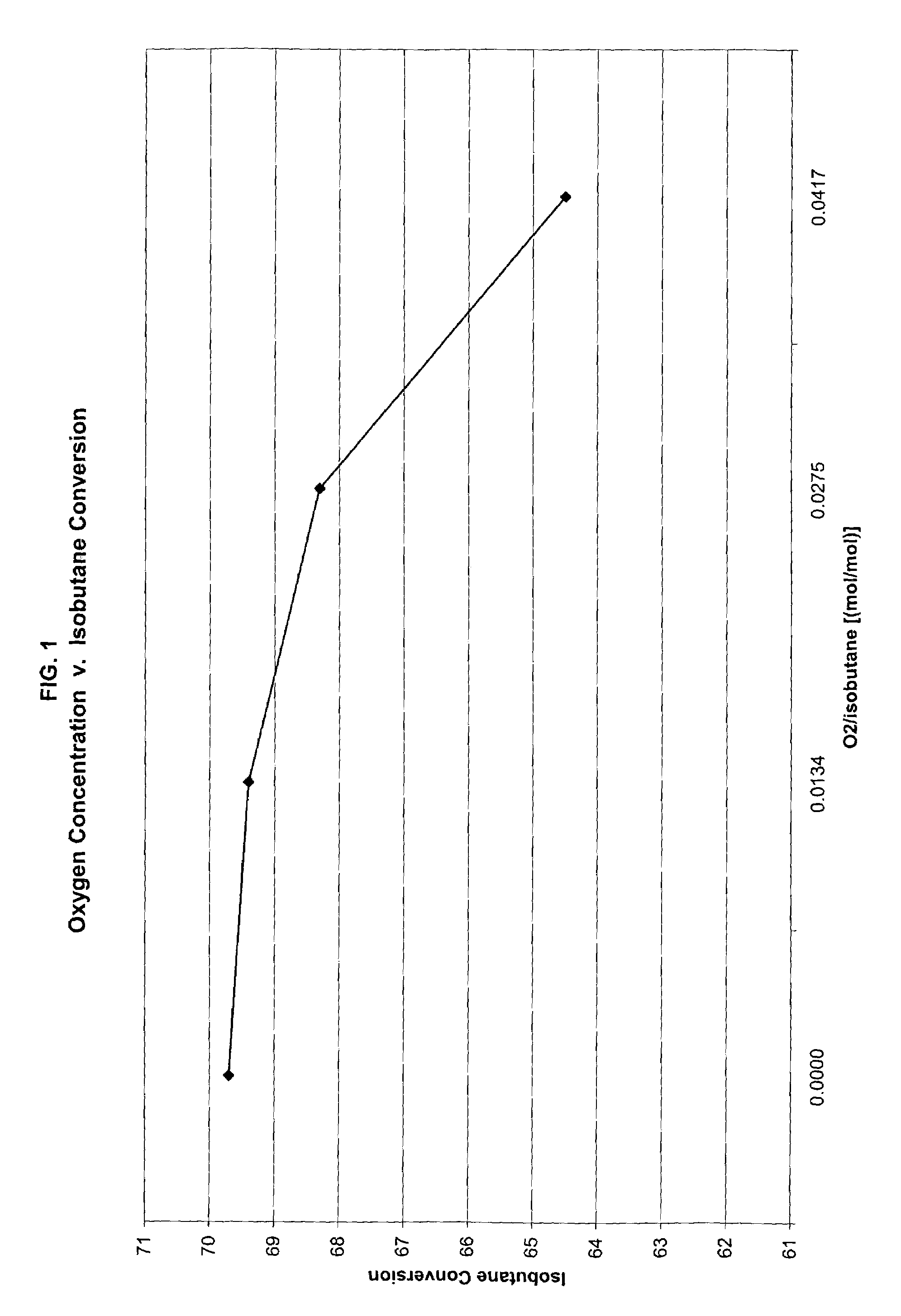

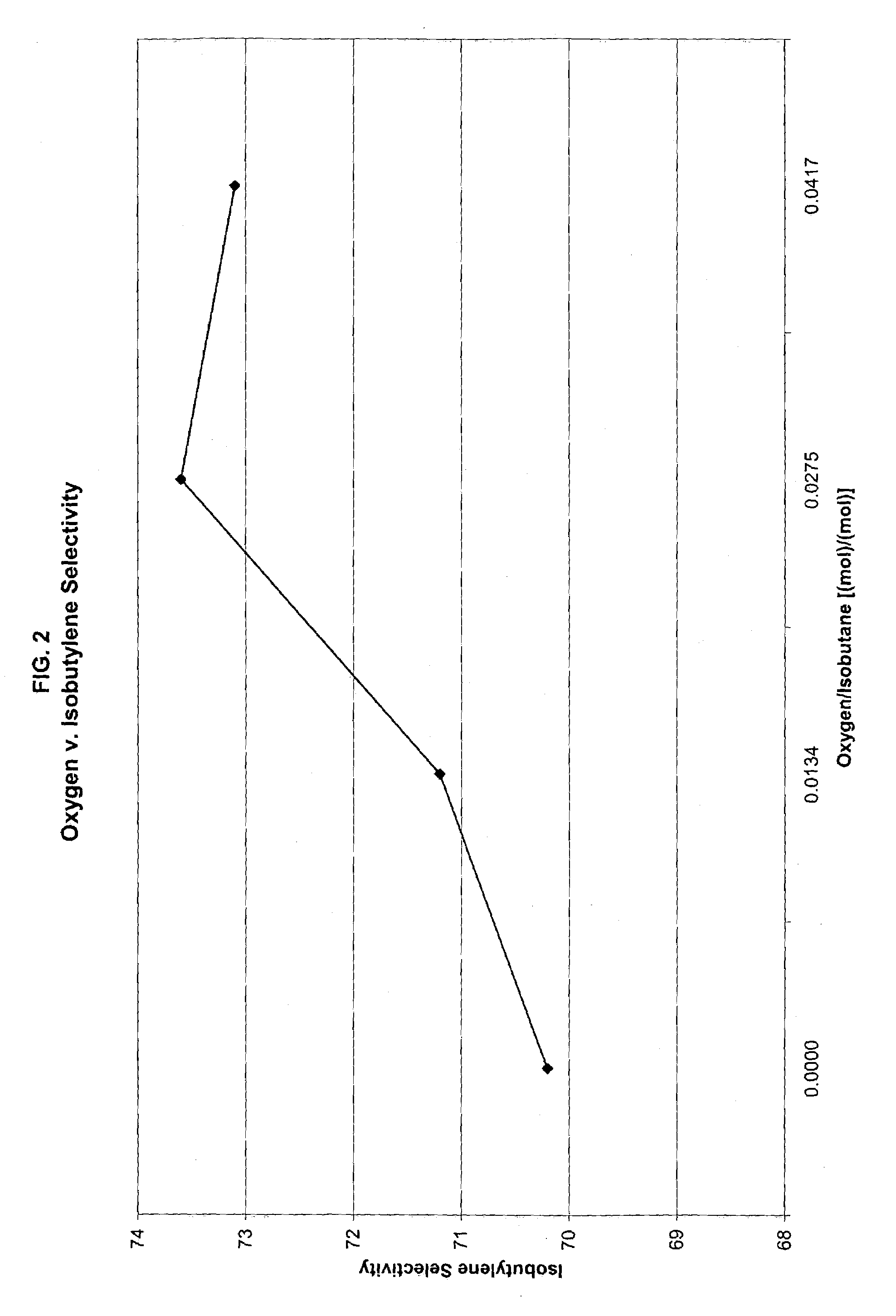

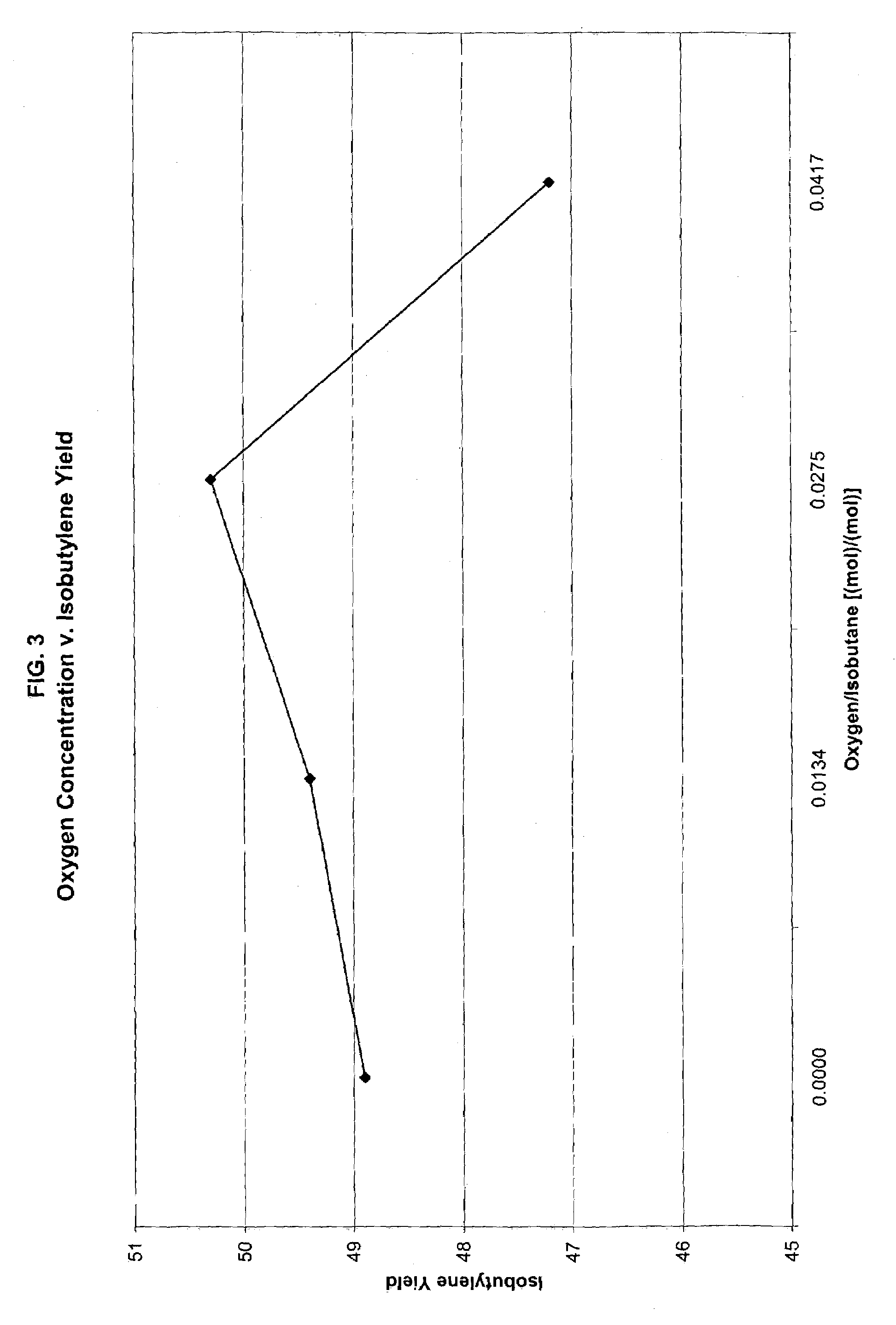

Dehydrogenation process for olefins

ActiveUS7091392B2Easy maintenanceHigh selectivityCatalystsHydrocarbon preparation catalystsAlkaneDehydrogenation

A process for the dehydrogenation of alkane hydrocarbons is disclosed. The process comprises contacting an alkane with a chromium-based dehydrogenation catalyst in the presence of molecular oxygen at a temperature of from about 400° C. to about 700° C., a pressure of from about 0.1 to about 10 atmospheres, wherein the alkane to oxygen molar ratio is between about 1:0.0001 to 1:0.04.

Owner:SAUDI BASIC IND CORP SA

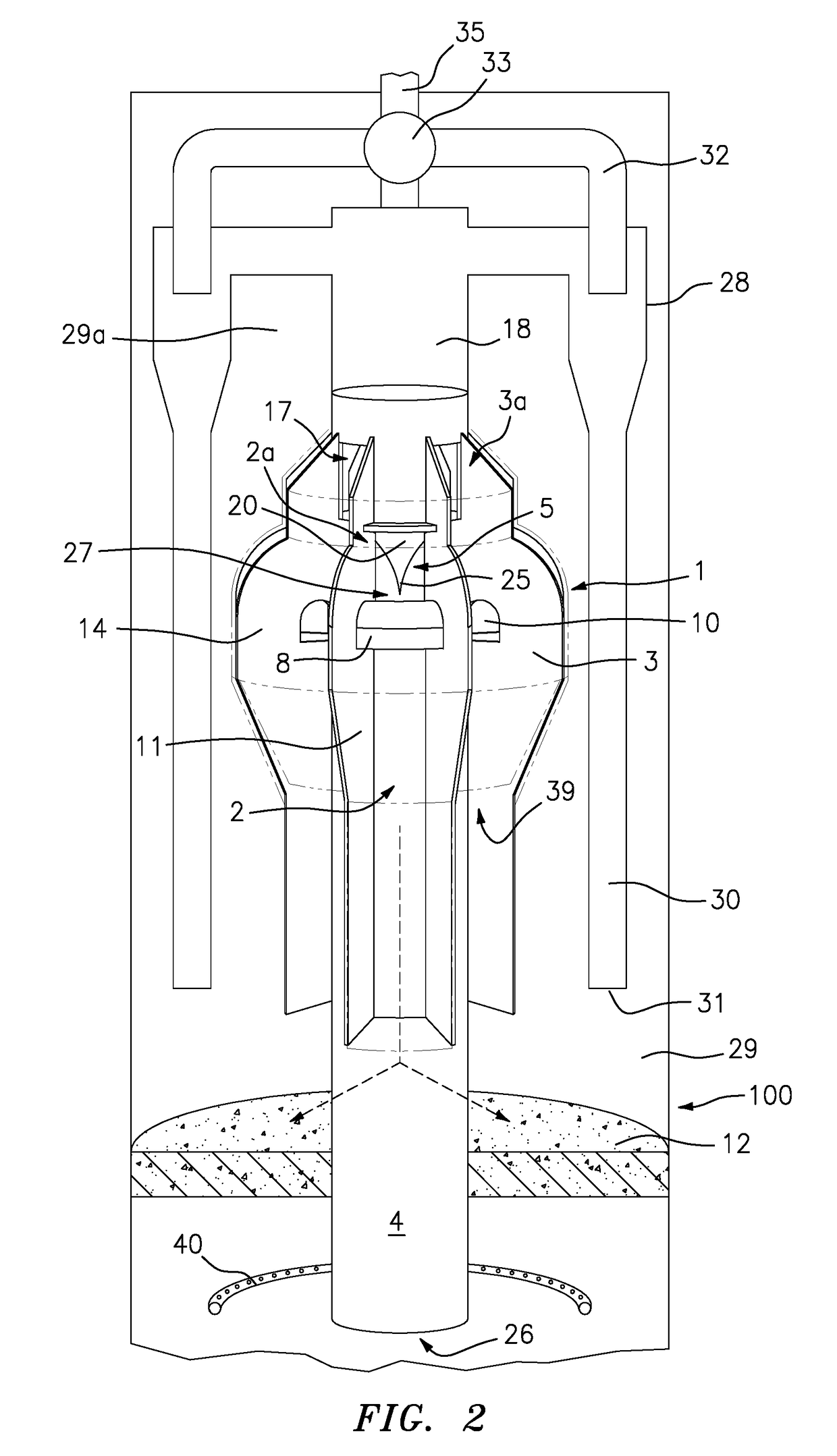

Riser separation system

ActiveUS10731086B2Easy to separateSpeed up the flowCatalytic crackingDispersed particle separationThermodynamicsParticulate flow

Owner:TECH PRECESS TECH INC

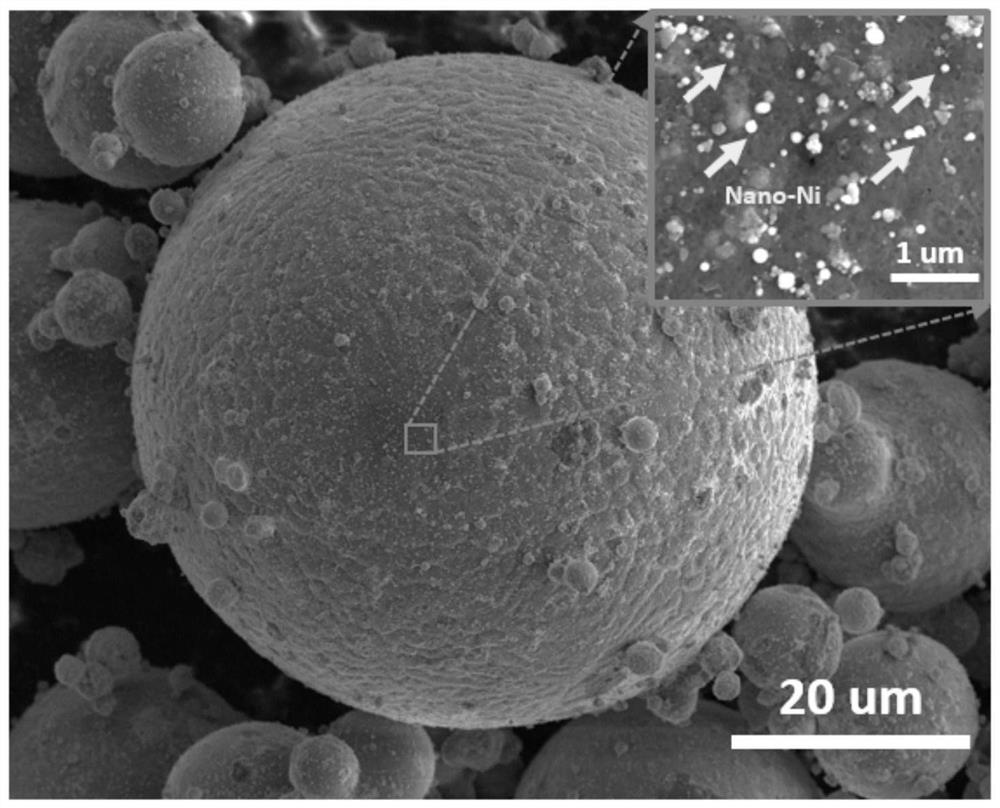

Powder for additive manufacturing and preparation method and application thereof

PendingCN114535563AReduce hot cracksIncrease the freezing temperature rangeAdditive manufacturing apparatusTransportation and packagingMechanical propertyAdditive layer manufacturing

In order to solve the problems that an aluminum alloy part obtained through existing additive manufacturing is prone to having the hot crack defect, and the material formability and the mechanical property are affected, the powder for additive manufacturing is provided and comprises, by weight, 92-98 parts of aluminum alloy powder and 2-8 parts of nano Ni powder. Wherein the average particle size of the aluminum alloy powder is 1-100 microns, and the average particle size of the nano Ni powder is 10-800 nanometers. Meanwhile, the invention further discloses a preparation method and application of the powder for additive manufacturing. According to the powder for additive manufacturing, the laser input efficiency is improved, meanwhile, hot cracks of an aluminum alloy part obtained through additive manufacturing are effectively reduced, and the mechanical property of the aluminum alloy part is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Catalytic reforming processes

ActiveUS9683179B2Reduce the amount requiredYield minimizationCatalytic naphtha reformingReforming process control/regulationCatalytic reformingHydrocarbon

Processes for catalytic reforming in which a cracking inhibitor, such as an olefin, or a light olefin, is used to inhibit thermal cracking of larger hydrocarbons in non-reactive zones. The cracking inhibitor may be added at various positions through the processes, such as in the recycle gas stream, before a heater, before a stream is passed into a reforming zone, after an effluent stream is recovered from a reforming zone. A molar ratio of cracking inhibitor to hydrocarbons in stream may be between 0.01 and 0.2.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com