Device and method for preparing large cast ingot through slag protection based multi-layer casting magnetic field current compound treatment

A magnetic field current and compound processing technology, applied in the field of metallurgy and casting, can solve the problems affecting the material yield, utilization rate, forming performance, energy consumption, affecting product performance and material utilization, insufficient continuous control, natural and other problems , to improve the de-inclusion effect, improve the slag de-inclusion effect, and eliminate the effects of macrosegregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

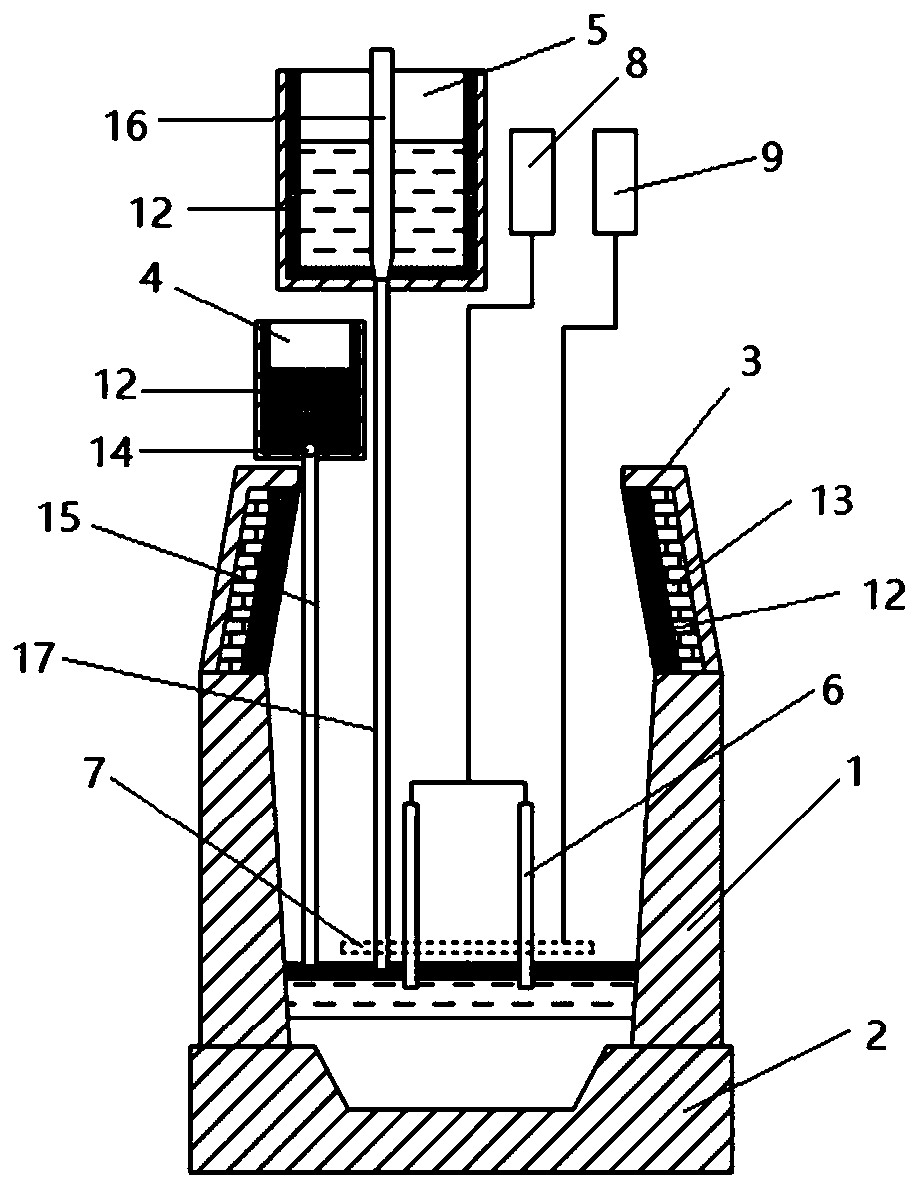

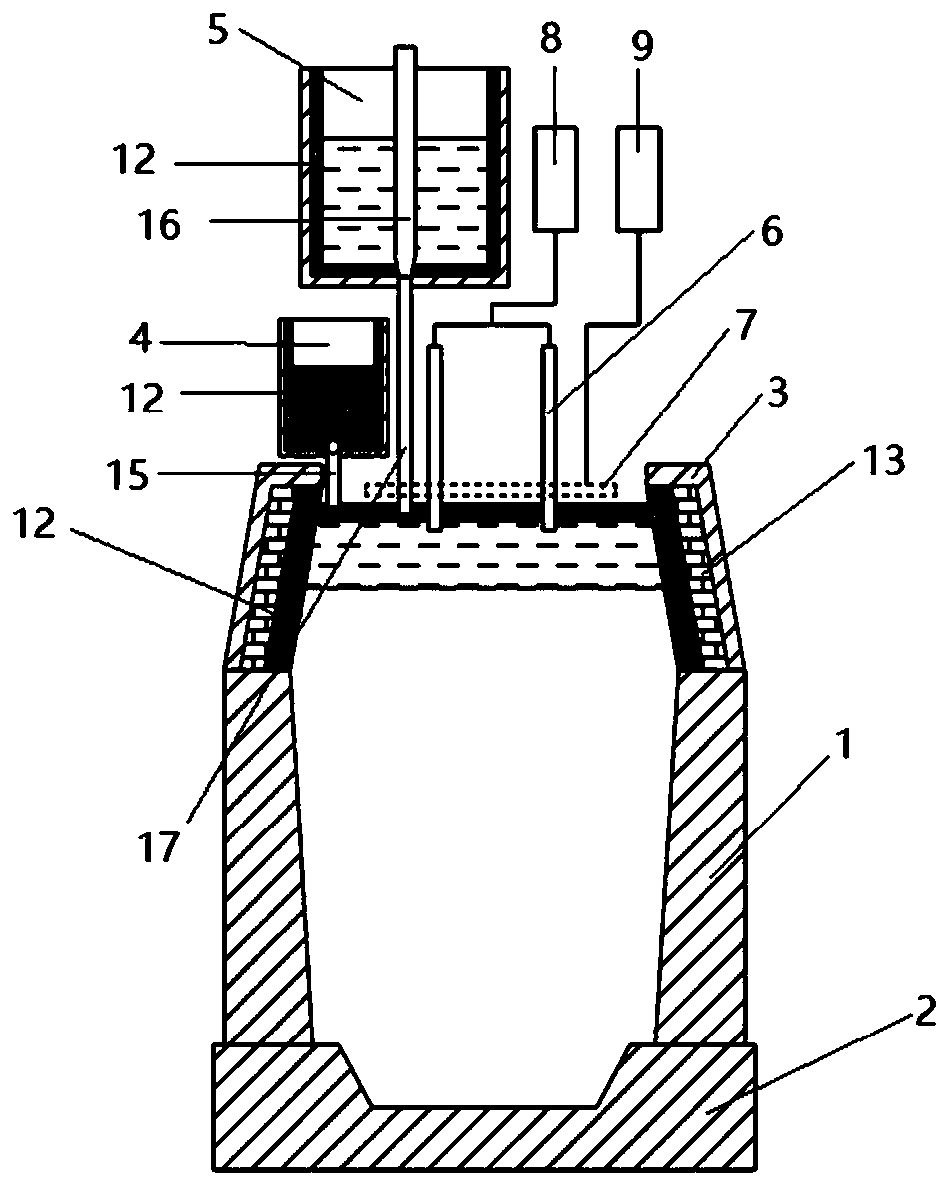

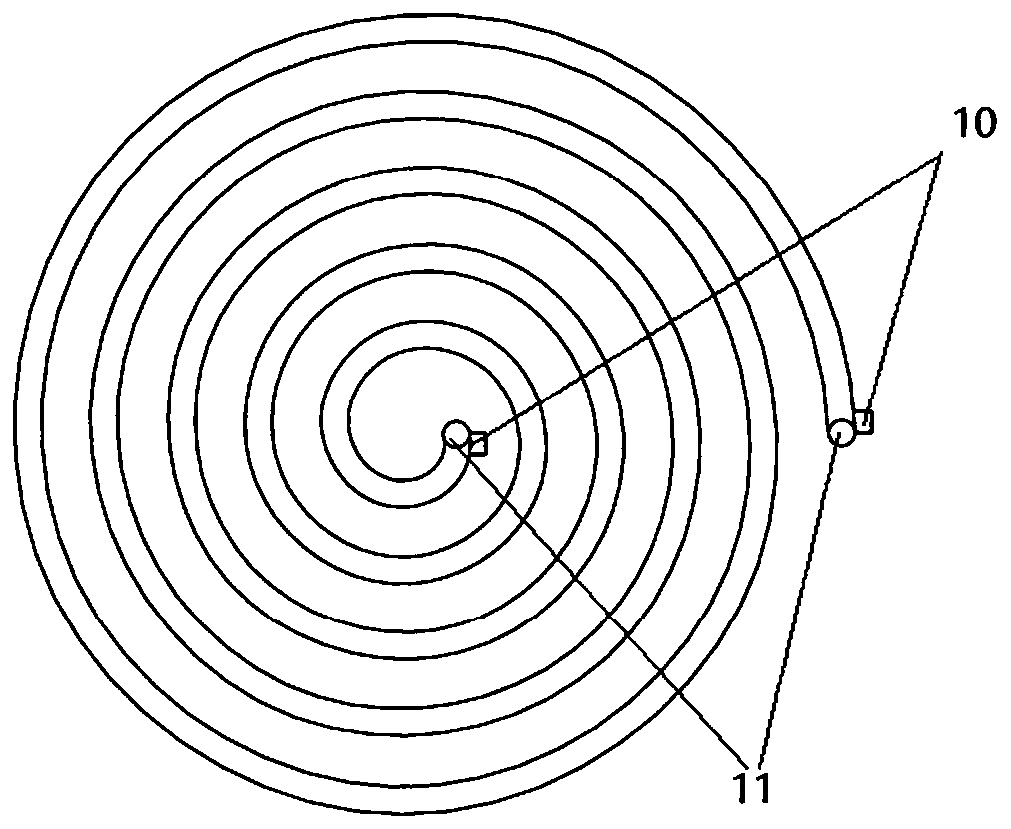

Method used

Image

Examples

Embodiment 1

[0022] In this example, 5 tons of low-alloy steel Q345 steel ingots are prepared, and the composition is shown in Table 1 below.

[0023] Table 1 Composition of Grade A Q345 Low Alloy Steel

[0024]

[0025] The preparation method of this low-alloy steel Q345 steel ingot comprises the steps:

[0026] (1) Prepare 4 portions of molten steel successively according to the design, with a superheat of 25°C: the first portion is 2 tons, and the carbon content is 0.1% higher (relative to the composition in Table 1, the same below); the second portion is 1 ton, Among them, the carbon content is 0.02% higher; the third 1 ton, the carbon content is 0.08% lower; the fourth 1 ton, the carbon content is 0.14% lower;

[0027] (2) Heating to 1400°C through the heating layer of the riser, adding mold slag at a speed of 0.005t / min, the thickness of the slag is 5-10cm, and after immersing the tapping hole for 2-3cm, add the first molten steel to the into the tundish, and inject molten steel...

Embodiment 2

[0032] This example prepares 20 tons of low-alloy steel Q345 steel ingots, and component is identical with embodiment 1, and its method step is as follows:

[0033] (1) Prepare 6 parts of molten steel according to the design, with a superheat of 15°C: the first part is 5 tons, and the carbon content is 0.05% higher; the second part is 3 tons, and the carbon content is 0.02% higher; the third part is 3 tons. tons, of which the carbon content is normal; the fourth 3 tons, of which the carbon content is 0.04% lower; the fifth 3 tons, of which the carbon content is 0.06% lower;

[0034](2) Open the heating riser and heat to 1400°C, add mold slag at a speed of 0.1t / min until the thickness of the molten slag is 8-12cm, immerse the tapping hole for 3-4cm, then add the first part of molten steel to the middle In the ladle, the molten steel is injected into the ingot mold along the molten steel pipe through the tundish stopper at a speed of 1t / min. At the same time, the tapping hole ri...

Embodiment 3

[0039] This example prepares 200 tons of low-alloy steel Q345 steel ingots, and component is identical with embodiment 1, and its method step is as follows:

[0040] (1) Prepare 8 portions of molten steel successively according to the design, with a superheat of 10°C: the first portion is 25 tons, and the carbon content is 0.1% higher; the second portion is 15 tons, and the carbon content is 0.08% higher; the third portion is 15 tons. 15 tons, of which the carbon content is 0.06% higher; the fourth 15 tons, of which the carbon content is 0.04% higher; the fifth 15 tons, of which the carbon content is 0.02% higher; the sixth 15 tons, of which the carbon content is normal; Seventh portion of 15 tons, of which the carbon content is low by 0.01%; eighth portion of 15 tons, of which carbon content is low by 0.02%; ninth portion of 15 tons, of which carbon content is low by 0.03%; tenth portion of 15 tons, of which carbon content 0.04% lower; 15 tons of the eleventh portion, of whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com