Active core silver solder for soldering ceramics and preparation method thereof

A technology of silver solder and activity, applied in the field of active core silver solder for brazing ceramics and its preparation, can solve the problems affecting the performance of ceramic brazing joints, difficult extrusion, drawing, rolling, and affecting the application of active solder, etc. problems, to achieve the effect of increasing competitiveness, reducing hot cracks, and low extrusion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

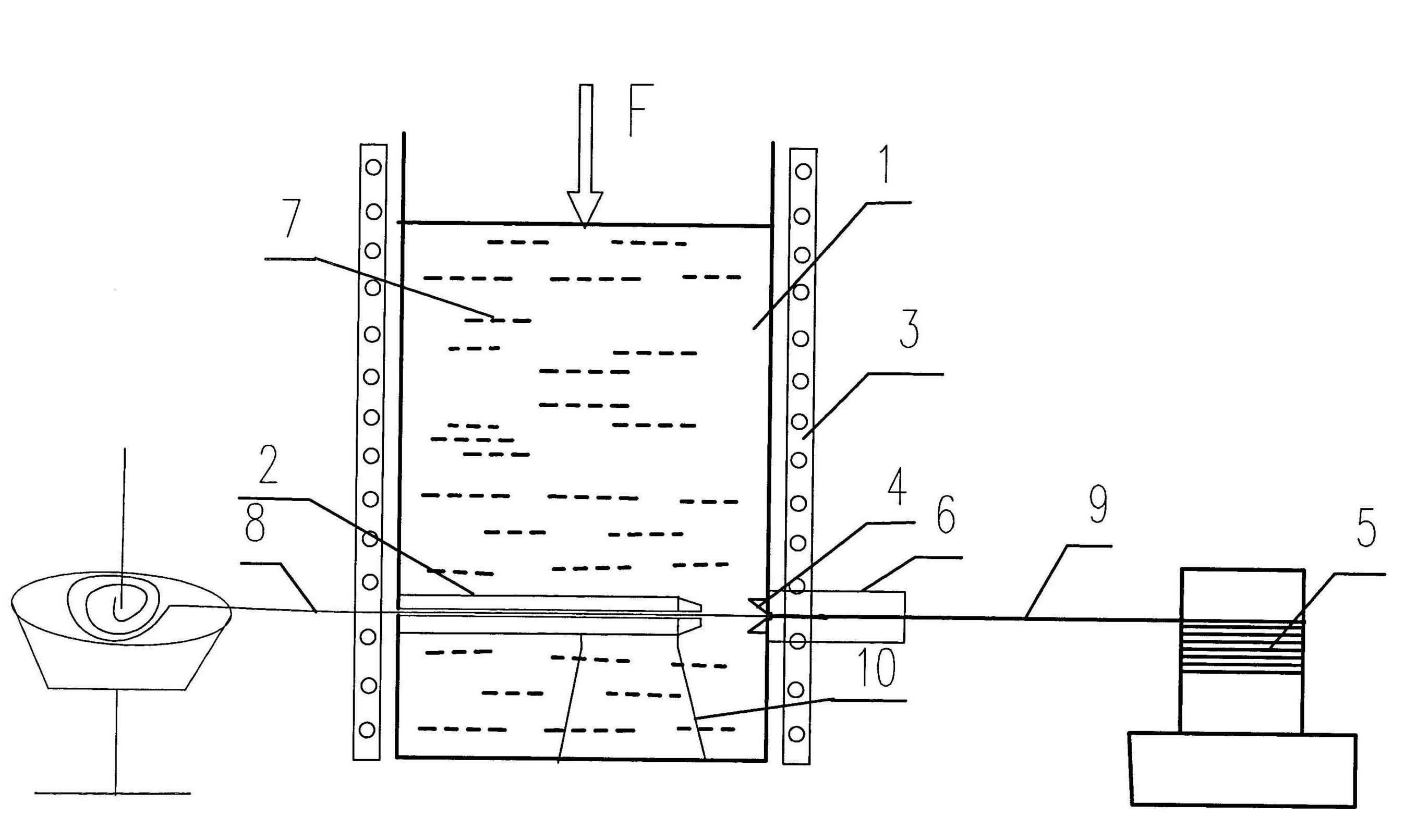

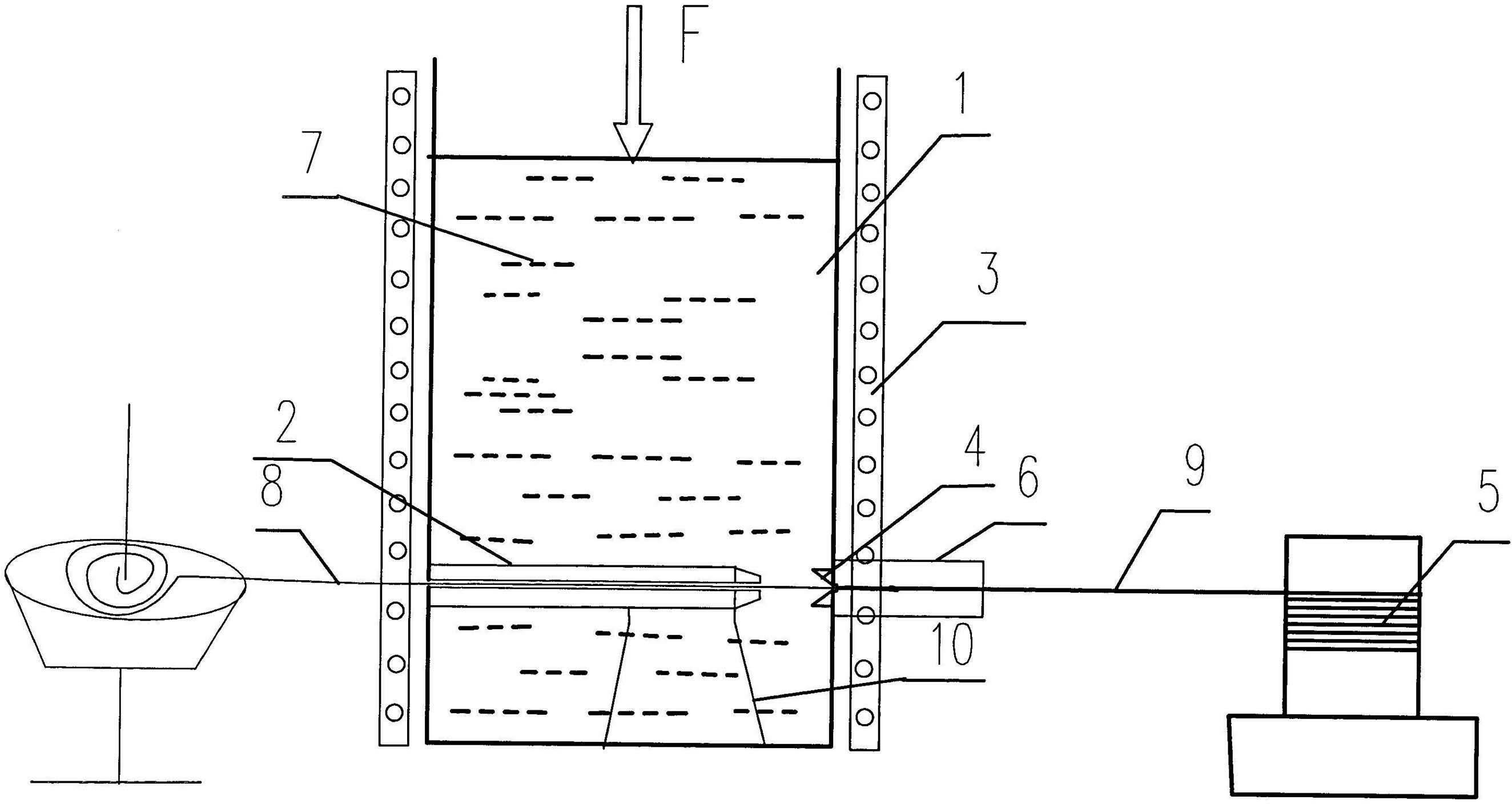

[0021] Example 1, see figure 1 :

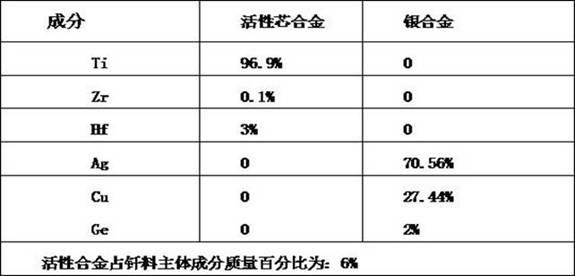

[0022] A Preparation of active alloy wire: Prepare 0.099kg of Ti and 0.001kg of Zr; through smelting, casting, rolling, swaging, and drawing, a TiZr active alloy wire (8) with a diameter of ψ=1mm is formed. Put it into the wire feeding mechanism (2), and fix one end on the wire winding frame (5).

[0023] Turn on the heating device on the extrusion barrel (1) to make the extrusion temperature reach 725±2°C, and turn on the cooling device (6) at the extrusion nozzle.

[0024] Replace the extrusion nozzle (4) on the extrusion barrel with an extrusion nozzle with a diameter of Ф3mm at the wire outlet.

[0025] B Prepare 1.134kg of Ag, 0.447kg of Cu, and 0.137kg of Ge, smelt them into a semi-molten silver alloy (7), pour them into the extrusion cylinder (1) at a temperature of 725°C, and keep it warm for 2 minutes.

[0026] C extrudes the semi-molten silver alloy (7) with an extrusion force of 900kN, and at the same time starts the winding fra...

Embodiment 2

[0029] Example 2, see figure 1 :

[0030] A Preparation of active alloy wire: prepare 0.098kg of Ti and 0.002kg of Zr; obtain TiZr active alloy wire (8) with ψ=1.2mm after melting, casting, rolling, swaging and drawing. Put it into the wire feeding mechanism (2), and fix one end on the wire winding frame (5).

[0031] Turn on the heating device on the extrusion barrel (1) to make the extrusion temperature reach 750±2°C, and turn on the cooling device (6) at the extrusion nozzle.

[0032] Replace the extrusion nozzle (4) on the extrusion cylinder with an extrusion nozzle with a diameter of Ф3.5mm at the wire outlet.

[0033] B prepares 1.179kg of Ag, 0.458kg of Cu, and 0.017kg of Ge, melts them into a semi-molten silver alloy (7), pours them into the extruding cylinder (1) at a temperature of 750°C, and keeps it warm for 2 minutes.

[0034] C extrudes the semi-molten silver alloy (7) with an extrusion force of 700kN, and at the same time starts the winding frame (5), pulls t...

Embodiment 3

[0038] Example 3, see figure 1 :

[0039] A Preparation of active alloy wire: prepare 0.0969kg of Ti, 0.0001kg of Zr, and 0.003kg of Hf; obtain TiZrHf active alloy wire (8) with ψ=1mm after melting, casting, rolling, swaging and drawing. Put it into the wire feeding mechanism (2), and fix one end on the wire winding frame (5).

[0040] Turn on the heating device on the extrusion barrel (1) to make the extrusion temperature reach 755±2°C, and turn on the cooling device (6) at the extrusion nozzle.

[0041] Replace the extrusion nozzle (4) on the extrusion barrel with an extrusion nozzle with a diameter of Ф3mm at the wire outlet.

[0042] B prepares 1.105kg of Ag, 0.430kg of Cu, and 0.031kg of Ge, melts them into a semi-molten silver alloy (7), pours them into the extrusion barrel (1) at a temperature of 755°C, and keeps it warm for 2 minutes.

[0043] C extrudes the semi-molten silver alloy (7) with an extrusion force of 900kN, and at the same time starts the winding frame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com