Patents

Literature

50results about How to "Solve the problem of uneven mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

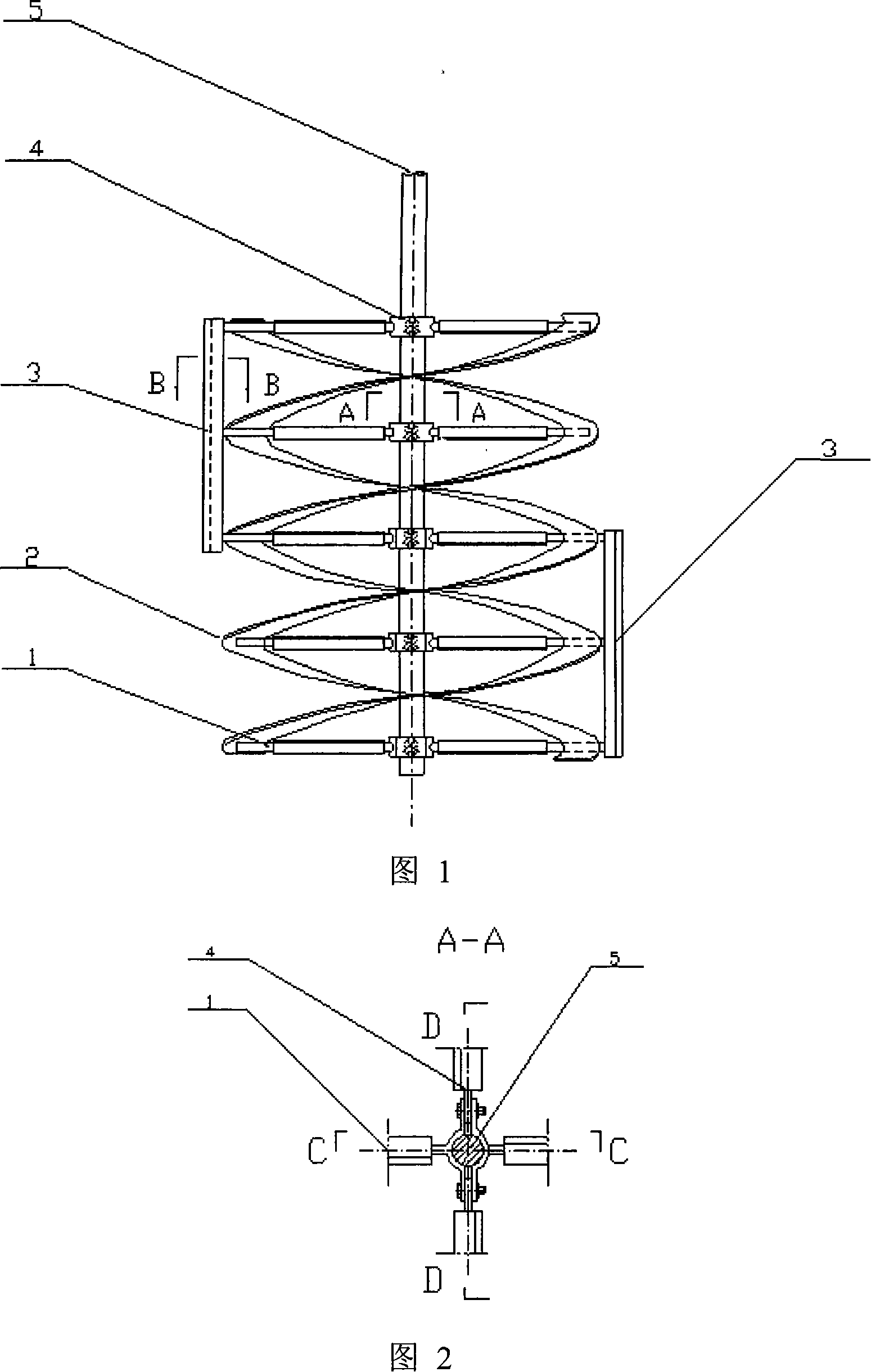

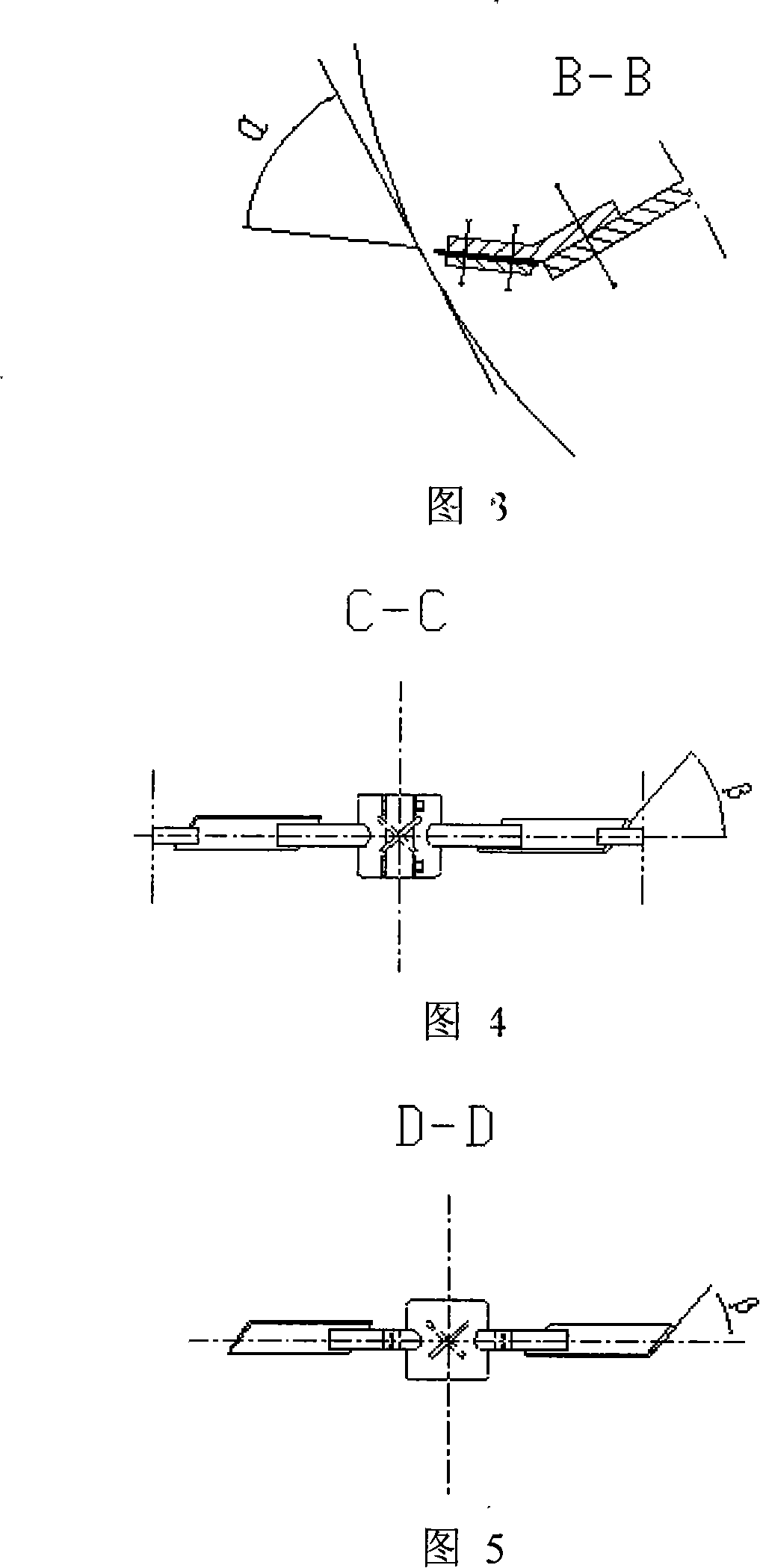

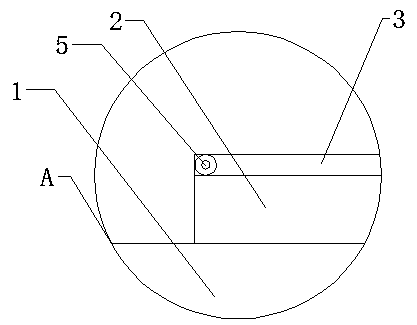

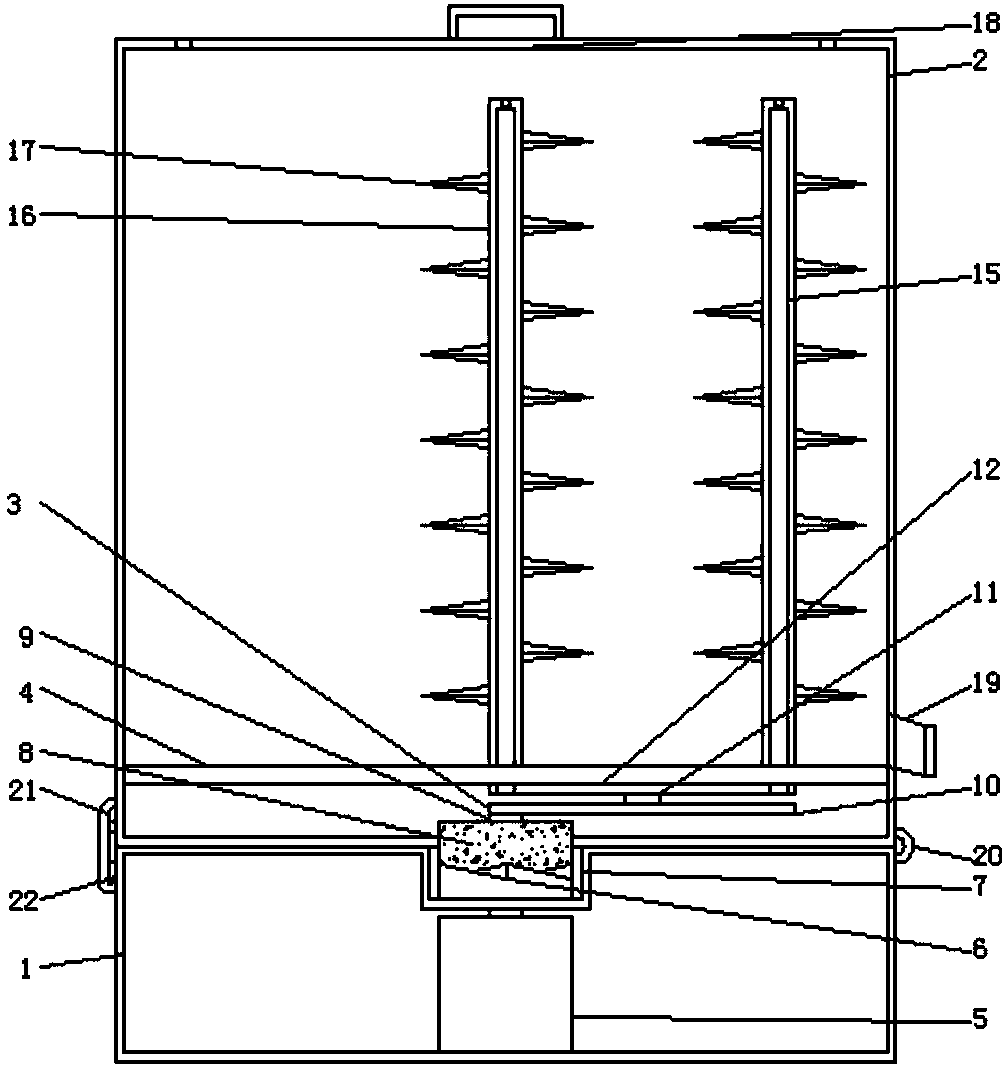

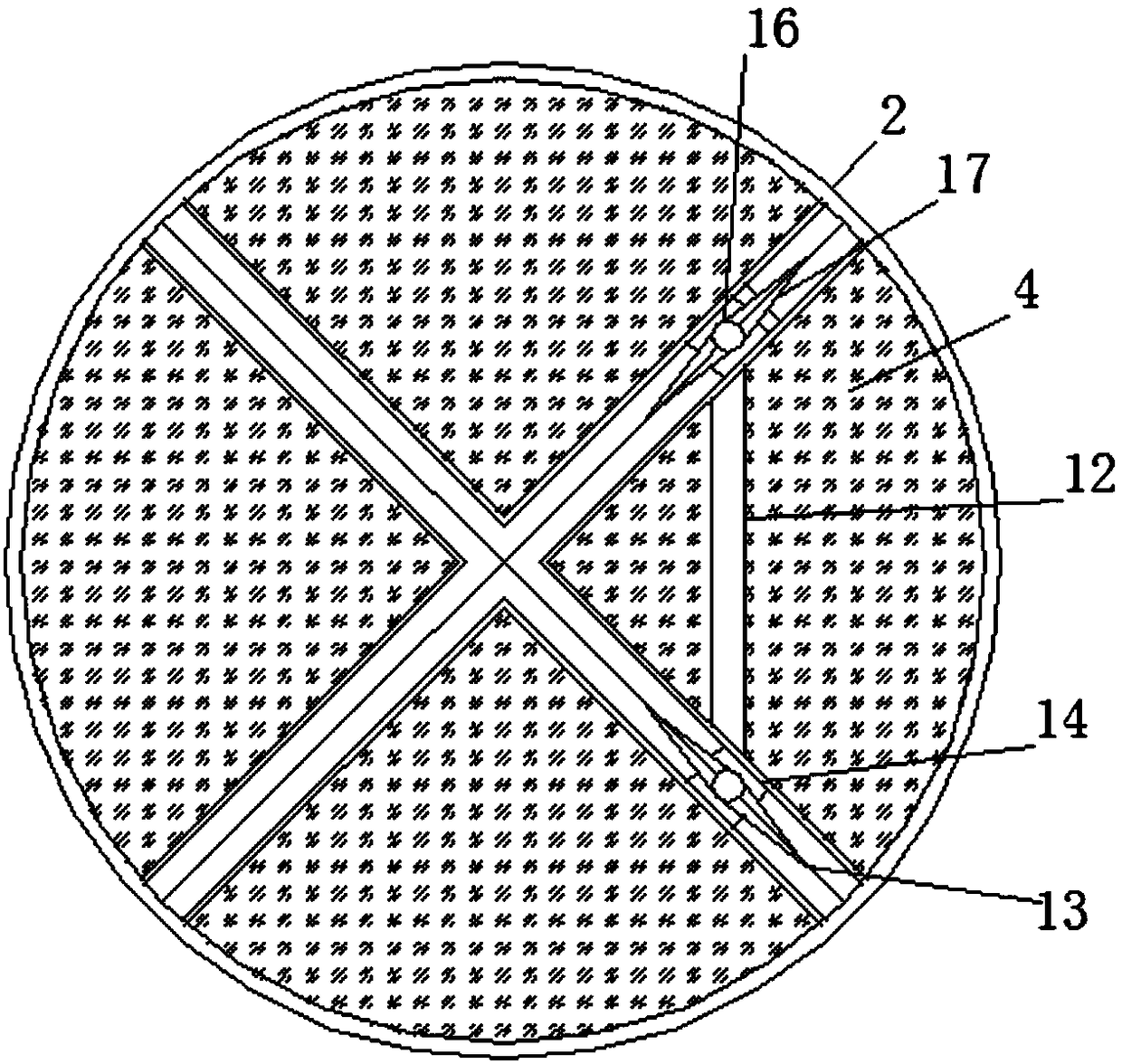

Double helical ribbon multi-layer oar blade scraping cutter type stirrer

InactiveCN101234309AAvoid liquid-liquid separationUniform temperatureRotary stirring mixersTransportation and packagingIncomplete mixingMaterial system

A double helical ribbon stirrer with multiple layers of blade scrapers comprises a stirring shaft (5), helical ribbons (2), support blades (1), separate blades (4) and a soft scraper (3). The support blades (1) and the separate blades (4) are layered and arranged on the stirring shaft (5), and the support blade and the separate blade of each layer are arranged on the stirring shaft (5) symmetrically, and the support blade (1) and the separate blade (4) keep a dip beta of 10 degrees to 45 degrees with the radical level section, and smaller dip can reduce the loss of useful work effectively. The helical ribbons (2) are connected with the stirring shaft (5) through the support blades (1) which have the functions of connecting ribs and strengthening ribs, thus causing reasonable structure design of the whole stirrer. The soft scraper (3) is divided into two sections which are fixed on the top of the helical ribbons (2) symmetrically, and an angle alpha between the soft scraper (3) and a still wall is 20 degrees to 60 degrees. The soft scraper (3) can scrape sticky material on the stirring still wall in time, thus solving the problem of incomplete mixing on the surface of the still wall and avoiding the damage to the still wall. The stirrer of the invention provides a material system that can adapt to different viscosities, in particular to the material system which has large viscosity variation range in a short time.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

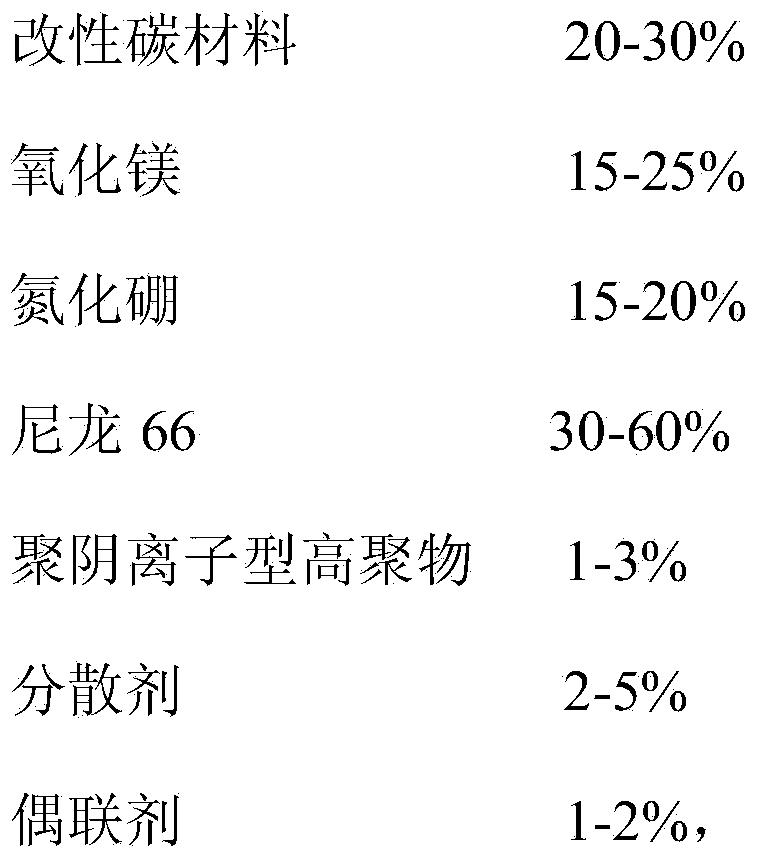

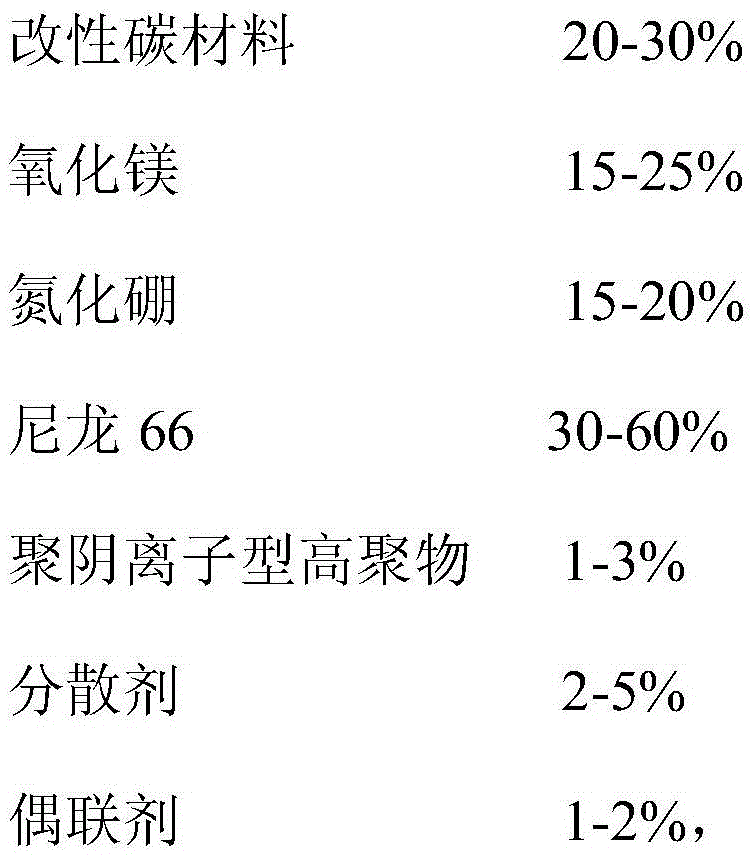

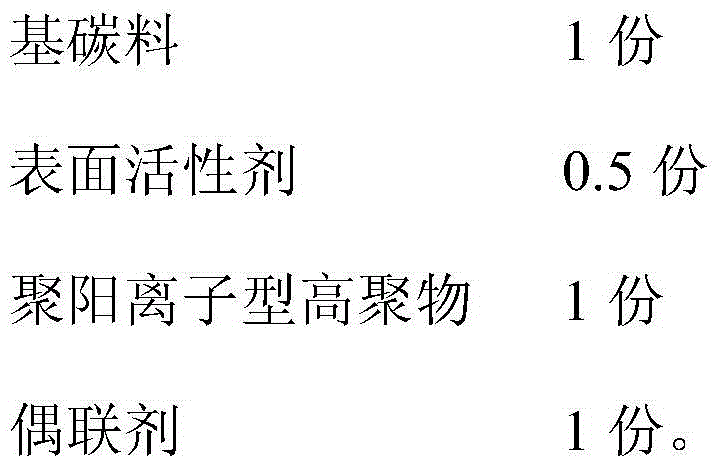

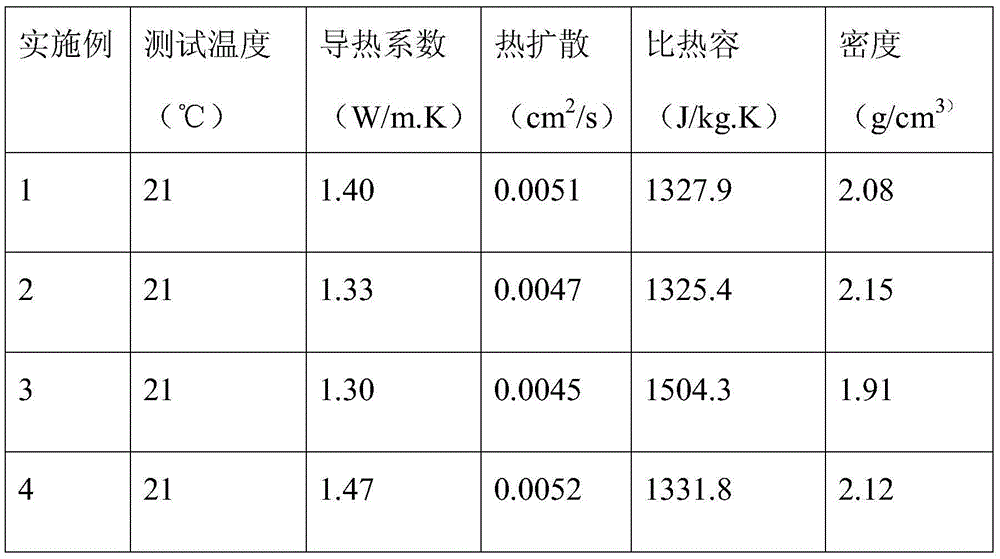

Thermal conductive plastic applying modified carbon material, and preparation method thereof

The invention discloses thermal conductive plastic applying a modified carbon material, and a preparation method thereof. The thermal conductive plastic comprises the following components in percentage by mass: the modified carbon material, magnesium oxide, boron nitride, nylon 66, a polyanionic type high polymer, a dispersing agent, and a couplant, wherein the modified carbon material comprises the following components in parts by weight: a base carbon material, a surfactant, a polycationic type high polymer, and a couplant; the modified carbon material is prepared by the steps of: mixing water, the base carbon material, sodium chloride, the surfactant and the couplant according to a proportion and then performing ultrasonic treatment, slowly adding the polycationic type high polymer during the ultrasonic process, continuously performing ultrasonic treatment and then stirring for 20-24h, filtering and drying. According to the thermal conductive plastic applying the modified carbon material, and the preparation method thereof, the problem that the materials inside the plastic are mixed unevenly can be effectively solved, and the compatibility of the carbon material can be improved greatly; the dispersity of the whole material mixture can be enhanced, and plugging is difficult in the extrusion process; the synthetic technology is simple, and the conditions of high temperature, a strongly corrosive environment and the like are not required.

Owner:ZHONGSHAN YONGWEI NEW MATERIAL CO LTD

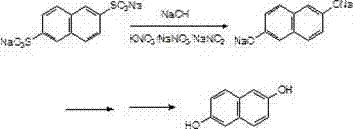

Synthetic method of 2,6 dihydroxy naphthlene

ActiveCN104844425ALow viscosityWell mixedOrganic chemistryOrganic compound preparationDecomposition problemSolvent

The invention discloses a synthetic method of 2,6 dihydroxy naphthalene, which comprises the following steps: placing 2,6 dihydroxy naphthalene in an alkali fusion pan, then a mixture of solid sodium hydroxide and nitrate is placed, Slowly heating to 150-170 DEG C, stirring, continuously heating to 320 DEG C, insulating for fusing alkali for 2.5-3.5 hours at 310-330 DEG C, then cooling to 200 DEG C, slowly dropping 450g of water for diluting, using a tri(octyl-decyl)amine solution for extracting 2,6-dihydroxy naphthalene, then acidifying the extracted 2, 6-dihydroxy naphthalene by sulfuric acid, and filtering and refining filter cake by an ethanol water mixed solvent to obtain 2,6-dihydroxy naphthalene. According to the synthetic method of 2,6-dihydroxy naphthalene, the used inorganic solvent is a mixture of potassium nitrate, sodium nitrite and sodium nitrate. According to the invention, viscosity of an alkali fusion material is low, fluidity is good, material can be uniformly mixed, and alkali fusion effect is good. In addition, under high temperature condition for alkali fusion, no decomposition problem of oxidation organic matter is generated, and no difficult separating problem is generated for the mixture.

Owner:柏盛新材料(甘肃)有限公司

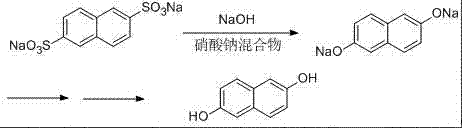

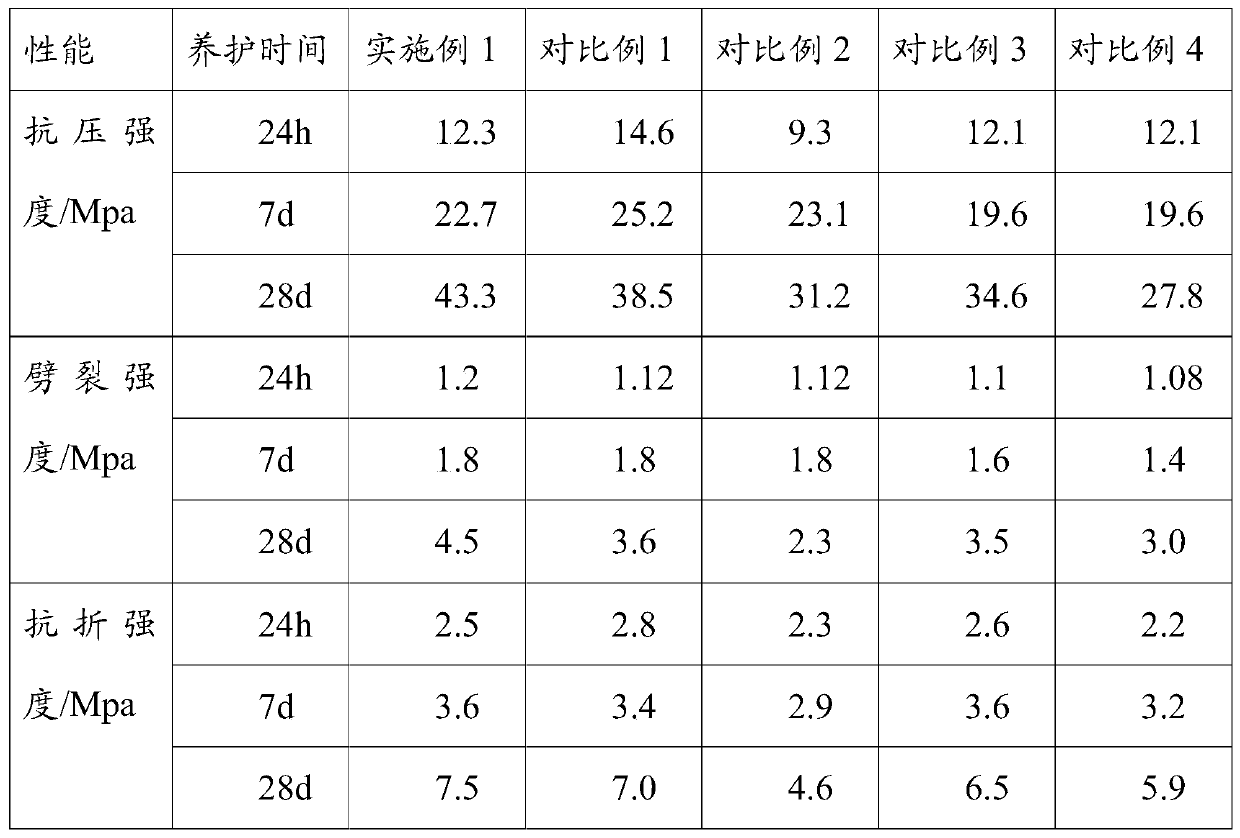

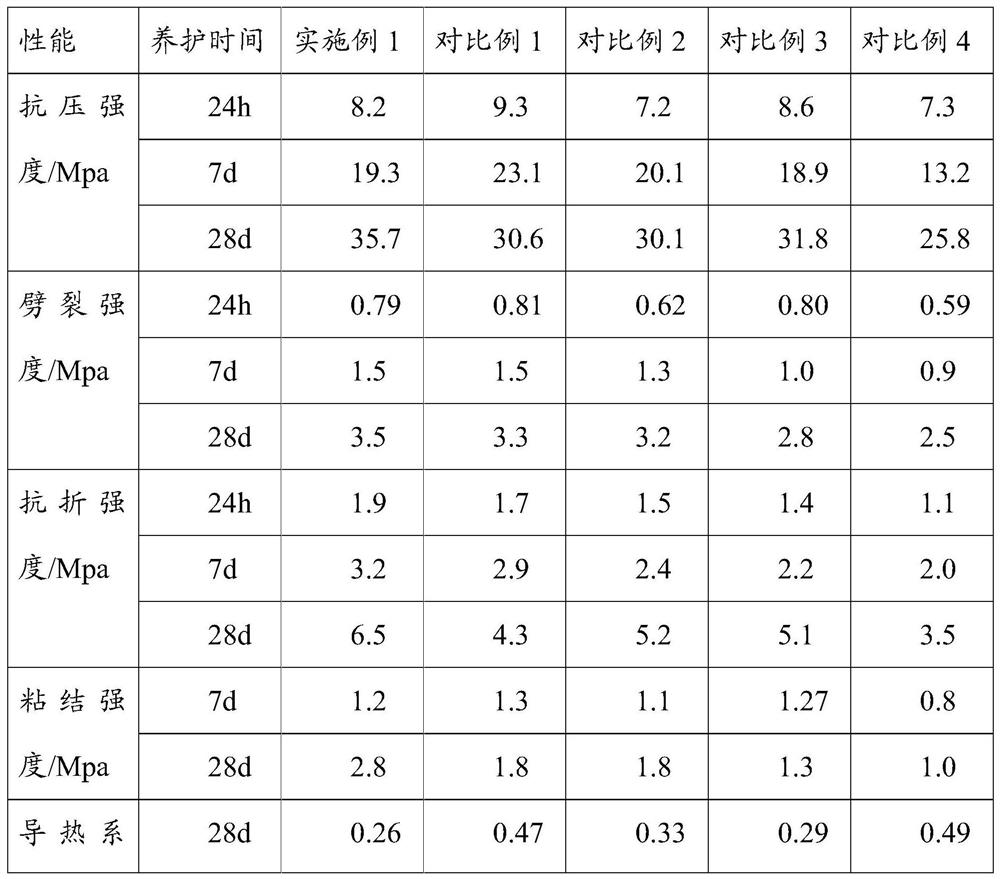

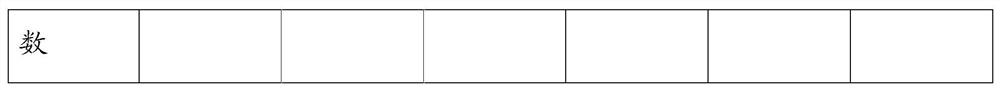

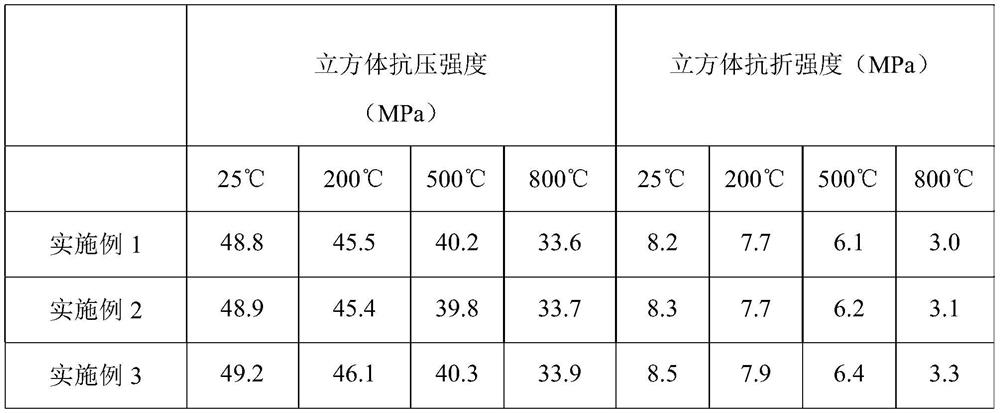

High strength sprayed concrete for high ground temperature tunnels and preparation method thereof

The invention discloses a high strength sprayed concrete for high ground temperature tunnels and a preparation method thereof. The concrete comprises following raw materials: cement, fly ash, slag powder, sand, coarse aggregate, glass beads, PVA fibers, steel fibers, modified rubber, a water reducer, a setting accelerator, and water. Low melting point water-soluble PVA fibers are adopted, after concrete reaches the melting point of the PVA fibers, fibers are melted, tunnels are formed, thus water steam in the concrete can be conveniently dissipated through the tunnels, the steam pressure in the concrete is reduced, the risk of bursting is reduced, at the same time, the melted water-soluble PVA fibers can largely enhance the inner cohesive force of concrete, and the cracking of a cement face is avoided. Through the cooperation of all raw materials, the prepared concrete has the characteristics of low heat conductivity coefficient, good anti-permeability, high interfacial bond strength,and little long-term strength loss. The long-term strength of concrete after spraying is largely improved. The cracking of high ground temperature concrete is avoided.

Owner:CHANGAN UNIV

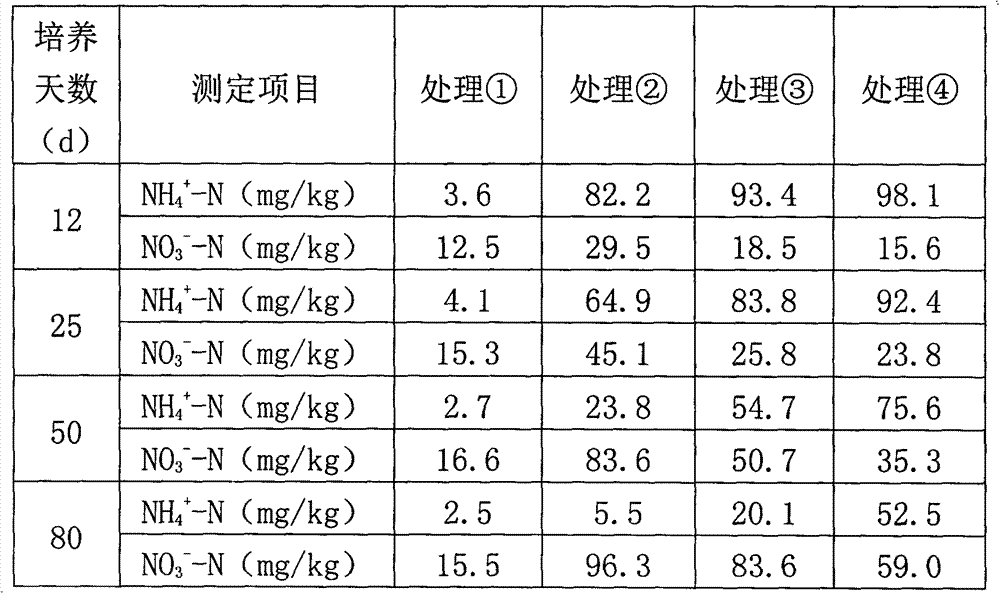

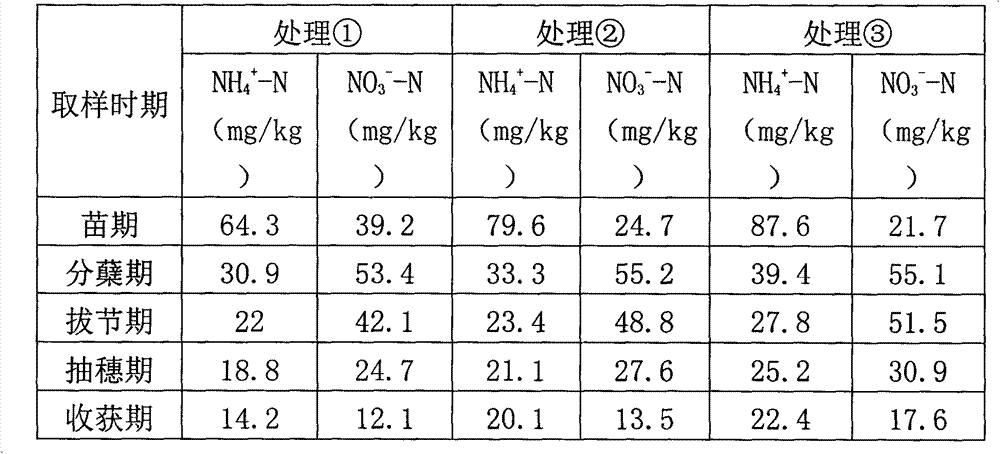

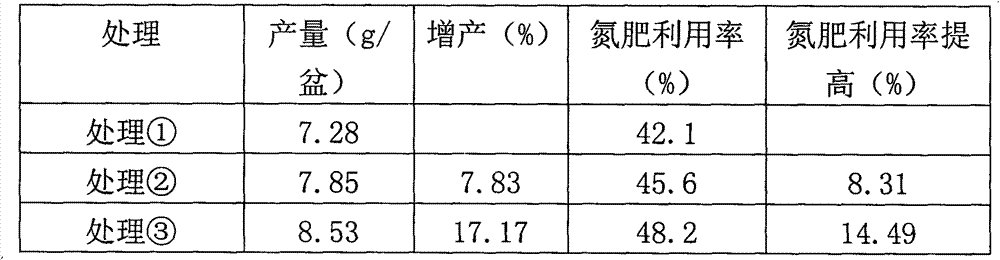

Non-metallic mineral long-acting nitrogenous fertilizer nitrification inhibitor and preparation method thereof

InactiveCN103193555ATight adsorptionEnhanced inhibitory effectAgriculture gas emission reductionFertilizer mixturesNitrification inhibitorsAqueous solution

The invention discloses a non-metallic mineral long-acting nitrogenous fertilizer nitrification inhibitor and a preparation method thereof. The preparation method is characterized by comprising the following steps: introducing 1-50 parts of the nitrification inhibitor into 100 parts of 25-100 DEG C water so as to make a solution; adding 25-75 parts of nitrification inhibitor solution into every 100 parts of non-metallic mineral powder; and sufficiently stirring and drying so as to obtain the nitrification inhibitor; or a binder accounting for 1-5% of the total weight of the non-metallic mineral and the nitrification inhibitor solution is added, sufficiently stirred, palletized and dried; or a mixture of the non-metallic mineral and the nitrification inhibitor solution or a screened powder product covers the outer surface of the fertilizer. The product is prepared by utilizing the excellent abruption property of the non-metallic mineral, the process is simple, the cost is low, the slow-release effect is better, and the inhibition effect on the activity of soil enzyme is longer; and meanwhile the non-metallic mineral can further provide various beneficial elements to the soil, so that the physicochemical properties of the soil are improved.

Owner:QIONGZHOU UNIVERSITY

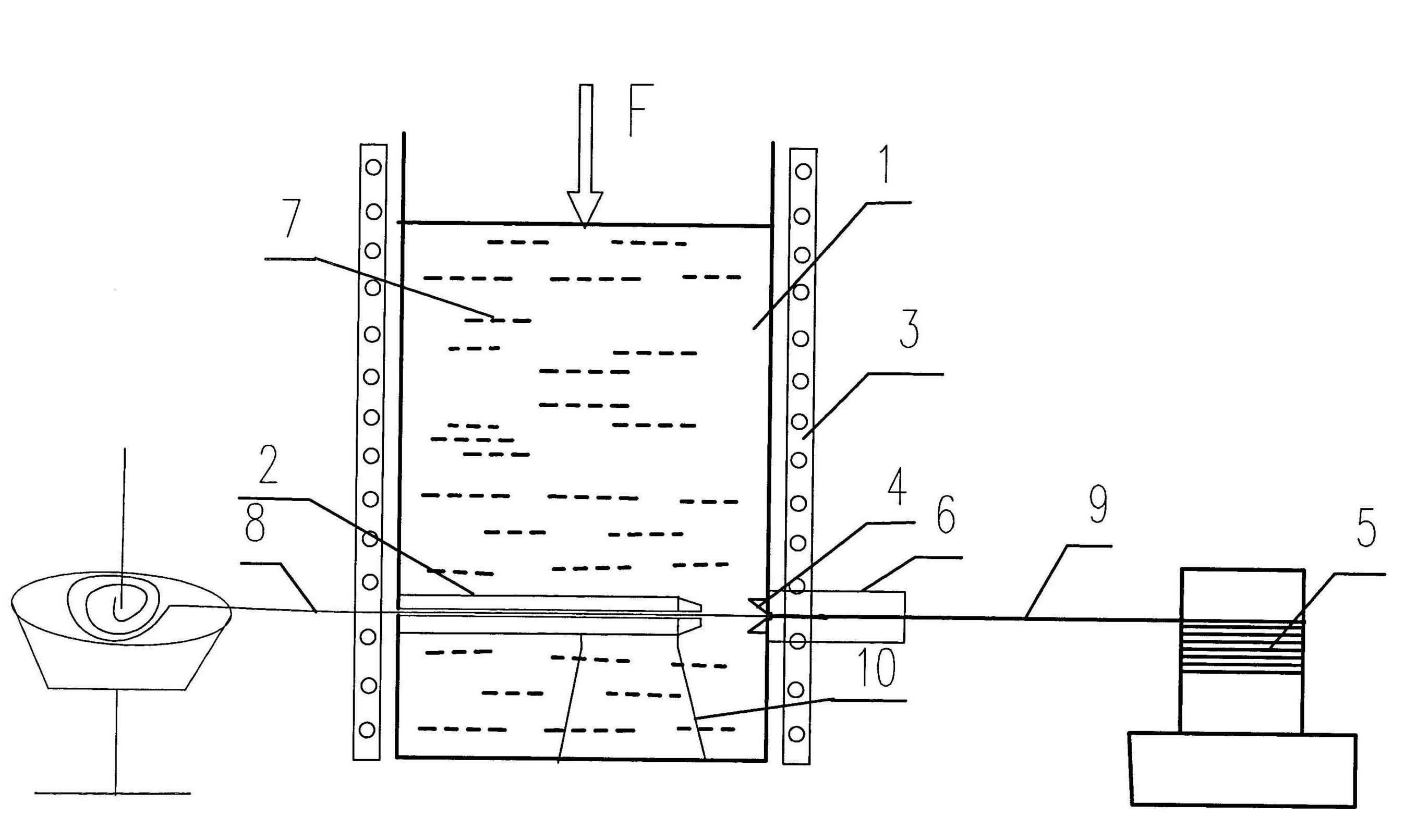

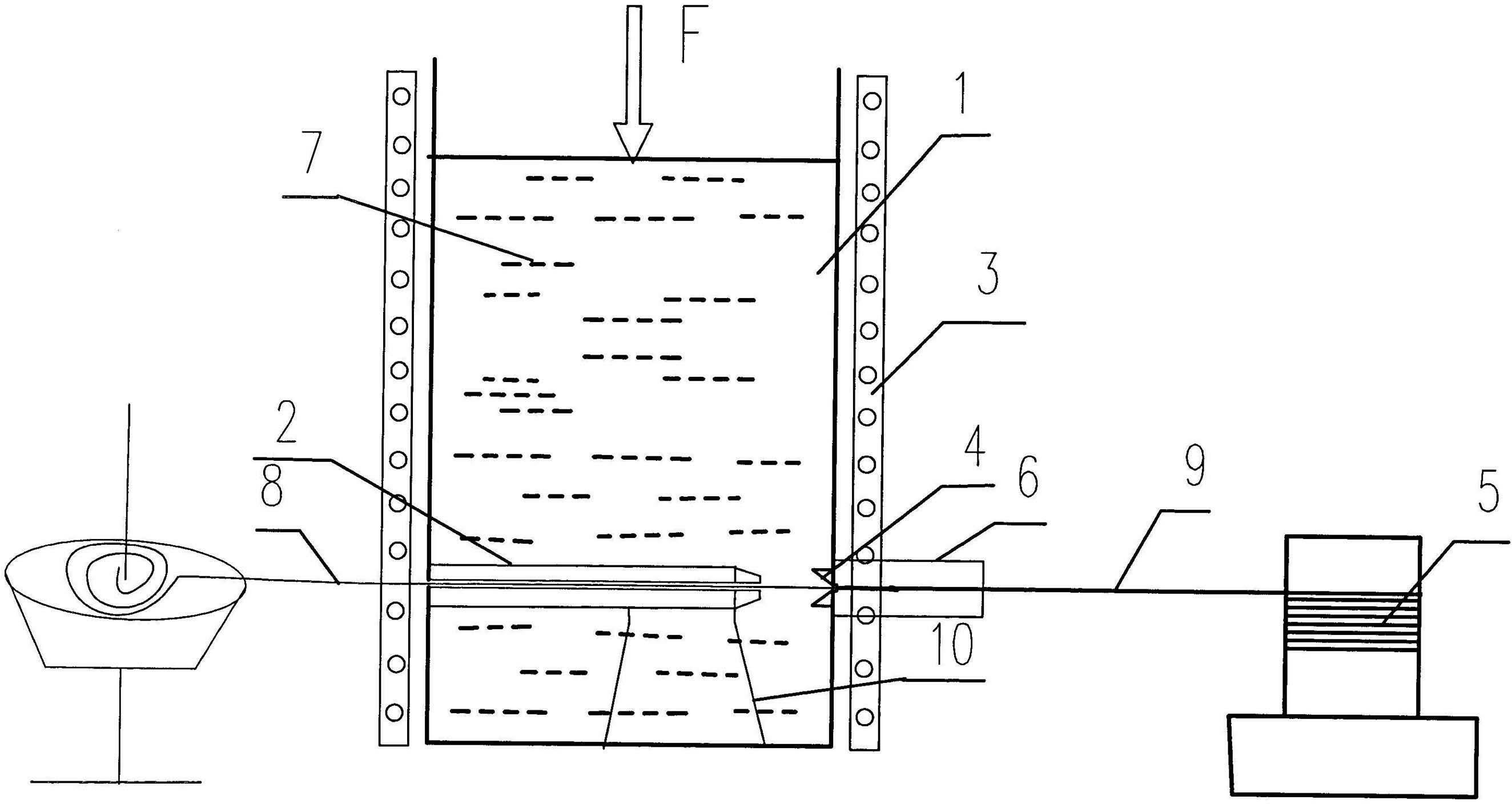

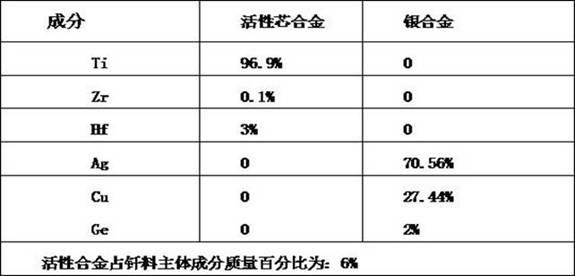

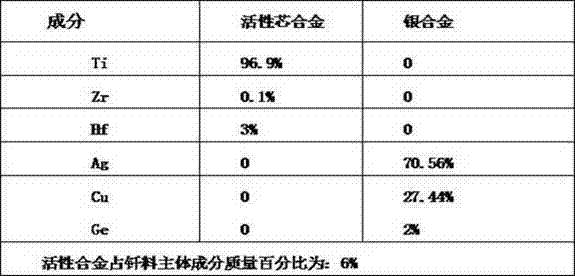

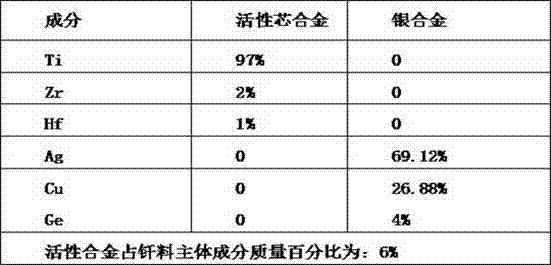

Active core silver solder for soldering ceramics and preparation method thereof

InactiveCN102319964ALow melting pointReduce hot cracksWelding/cutting media/materialsSoldering mediaElemental compositionAlloy

The invention relates to an active core silver solder for soldering ceramics and a preparation method thereof, and the active core silver solder comprises two parts, namely a core part and an outer layer, wherein the core part is composed of an active alloy containing active elements and the outer layer is composed of a silver alloy. The active core silver solder comprises the following main components by weight percent: 2-6% of the active alloy comprising three elements, namely Ti, Zr and Hf, wherein the active alloy contains 0.1-5wt% of the Zr, 0-3wt% of the Hr and the balance of the Ti; and 94-98% of the silver alloy comprising the elements of Ag, Cu and Ge, wherein the silver alloy contains 66-72wt% of the Ag, 26-27.9wt% of the Cu and 0.1-8wt% of the Ge. The threadlike active core silver solder can be directly obtained by adopting a method of wrapping an active core at the interior by extrusion through semi-molten metal. Compared with the characteristic of low melting point of thesolder of domestic like products, the preparation process is high in production efficiency and a new way is opened for manufacturing the solder which is difficult to machine and form due to brittle intermetallic compounding.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

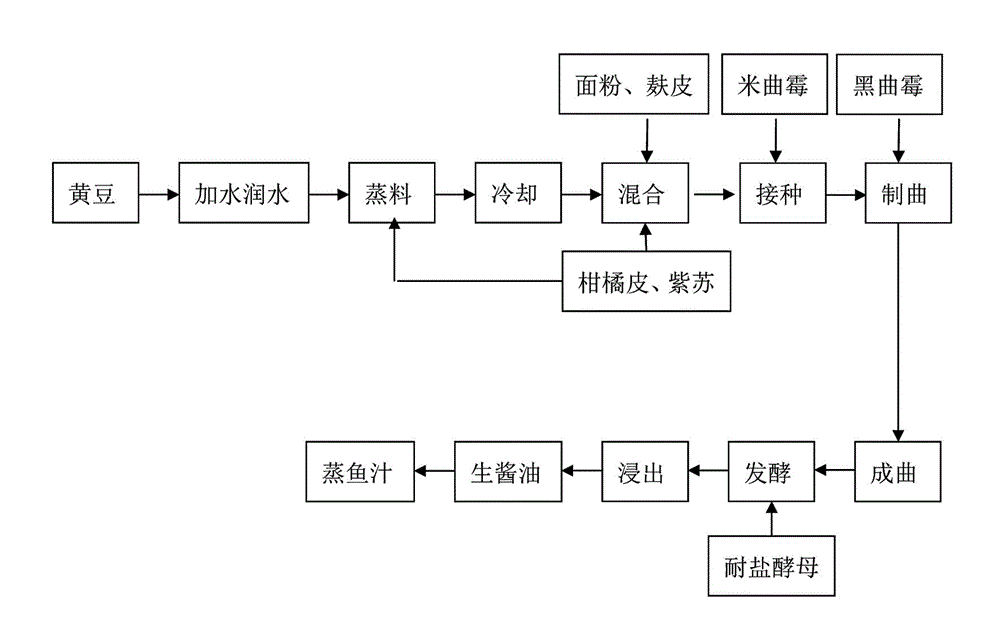

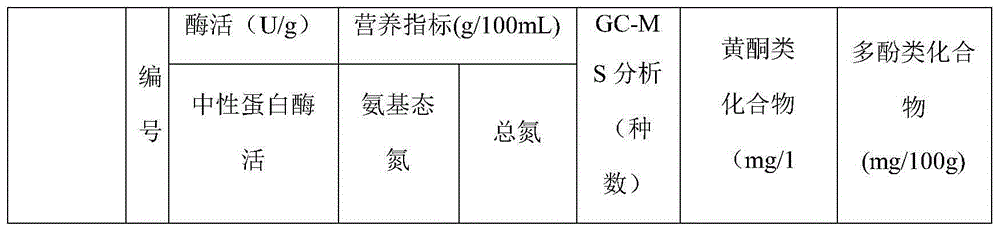

Citrus steamed fish sauce and preparation method thereof

ActiveCN104783128AIncrease aromaIncrease vitalityYeast food ingredientsFood ingredient functionsSaccharomyces rouxiiEnzyme system

The invention discloses citrus steamed fish sauce and a preparation method thereof, and belongs to the technical field of food fermentation engineering. According to the citrus steamed fish sauce disclosed by the invention, the technology that soybeans, flour, bran, citrus peels and purple perilla are used as starter propagation raw materials and aspergillus oryzae 3.042 and aspergillus niger 3.350 cooperate for starter propagation is adopted, at the middle stage of fermenting soy sauce mash, saccharomyces rouxii is added, and at the later stage, torulopsis bombicola is added. The aspergillus niger has higher cellulose activity, lipase activity and pectinase activity, and can achieve the enzyme system complementary effect with the aspergillus oryzae 3.042. The activity of the cellulase, the activity of the lipase and the activity of the pectinase obtained at the stage of starter propagation are higher, the cellulase, the lipase and the pectinase are used for decomposing the citrus peels and the purple perilla and promoting the release of various active substances in the citrus skins and the purple perilla. The addition of the two kinds of salt resistant fragrance-producing yeasts at the middle stage and the later stage of fermentation can promote the formation of flavor substances of the steamed fish sauce, improve the flavor of the steamed fish sauce and increase the kinds of the flavor substances.

Owner:HUBEI TULAOHAN FLAVORING FOOD

Efficient concrete stirring device

InactiveCN108407092AIncrease exposureMix the concrete evenlyCement mixing apparatusFixed frameEngineering

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

Metal powder mixing device and method and high-throughput metal alloy preparing system

ActiveCN107570696AIncreased chance of collisionImprove mixing efficiencyAdditive manufacturing apparatusFlow mixersMetal alloyHigh flux

The invention relates to a metal powder mixing device and method and a high-throughput metal alloy preparing system. The metal powder mixing device comprises a cylinder and a metal powder carrier gaspipeline. A metal powder carrier gas inlet is further formed in the side wall of the upper end of the cylinder. The metal carrier gas pipeline is parallel to the tangential direction of the side wallof the cylinder. Metal powder and carrier gas can form carrier gas carrying metal powder after passing through the metal powder carrier gas pipeline, the formed carrier gas enters the cylinder from the metal powder carrier gas inlet at a constant speed, and annular turbulent flow is formed in the cylinder to be mixed and scattered. In the metal powder mixing method, the carrier gas carrying metalpowder enters the cylinder and forms the annular turbulent flow, and therefore the probability of metal powder colliding is improved, and the metal powder mixing efficiency is further improved. By means of the high-throughput metal alloy preparing system, metal powder mixed evenly through the metal powder mixing device can be machined, and a needed metal alloy can be more accurately obtained.

Owner:向勇

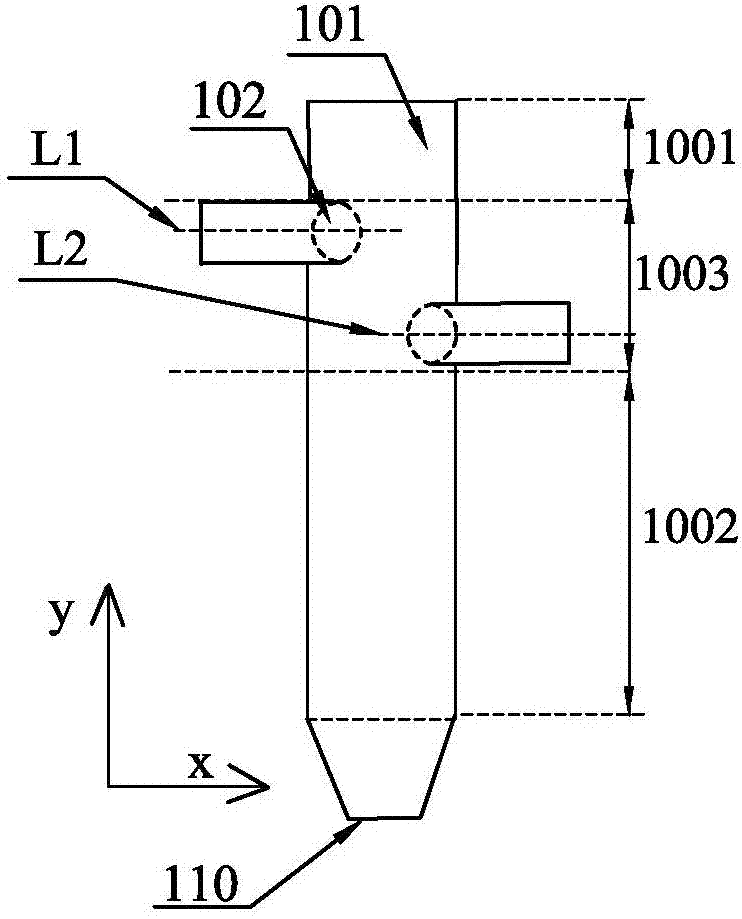

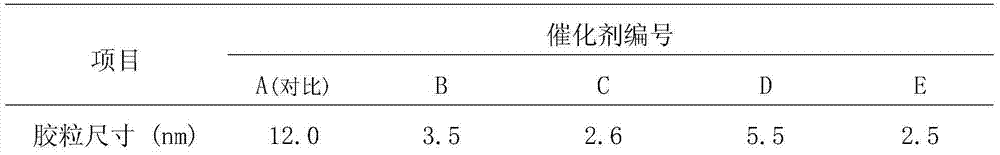

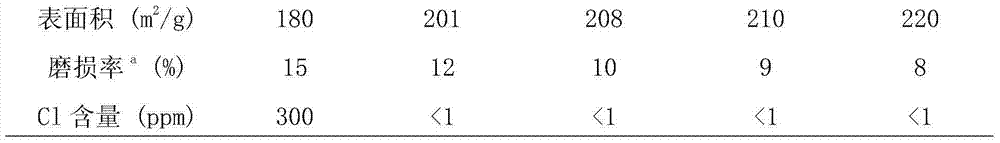

Fischer-Tropsch catalyst, as well as preparation method and application thereof

ActiveCN104707620ANovel production methodSimple processLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSilicic acidIon exchange

The invention provides a Fischer-Tropsch catalyst, as well as a preparation method and application thereof. A silicate solution is used as a raw material, a silicic acid solution is obtained through cation exchange treatment, and Cl and other anionic impurities in the silicic acid solution are then removed through anion exchange treatment, so as to obtain an activated silicic acid solution; the activated silicic acid solution can replace commercial silica gel to serve as a silicon source for Fischer-Tropsch catalyst preparation, so as to effectively solve the difficult problem of non-uniform mixing of iron species and SiO2, further enlarge the surface area of the catalyst, and improve the mechanical strength of the catalyst. The method is simple and convenient to operate, low in cost, and very applicable for the preparation of the commercialized Fischer-Tropsch catalyst.

Owner:SYNFUELS CHINA TECH CO LTD

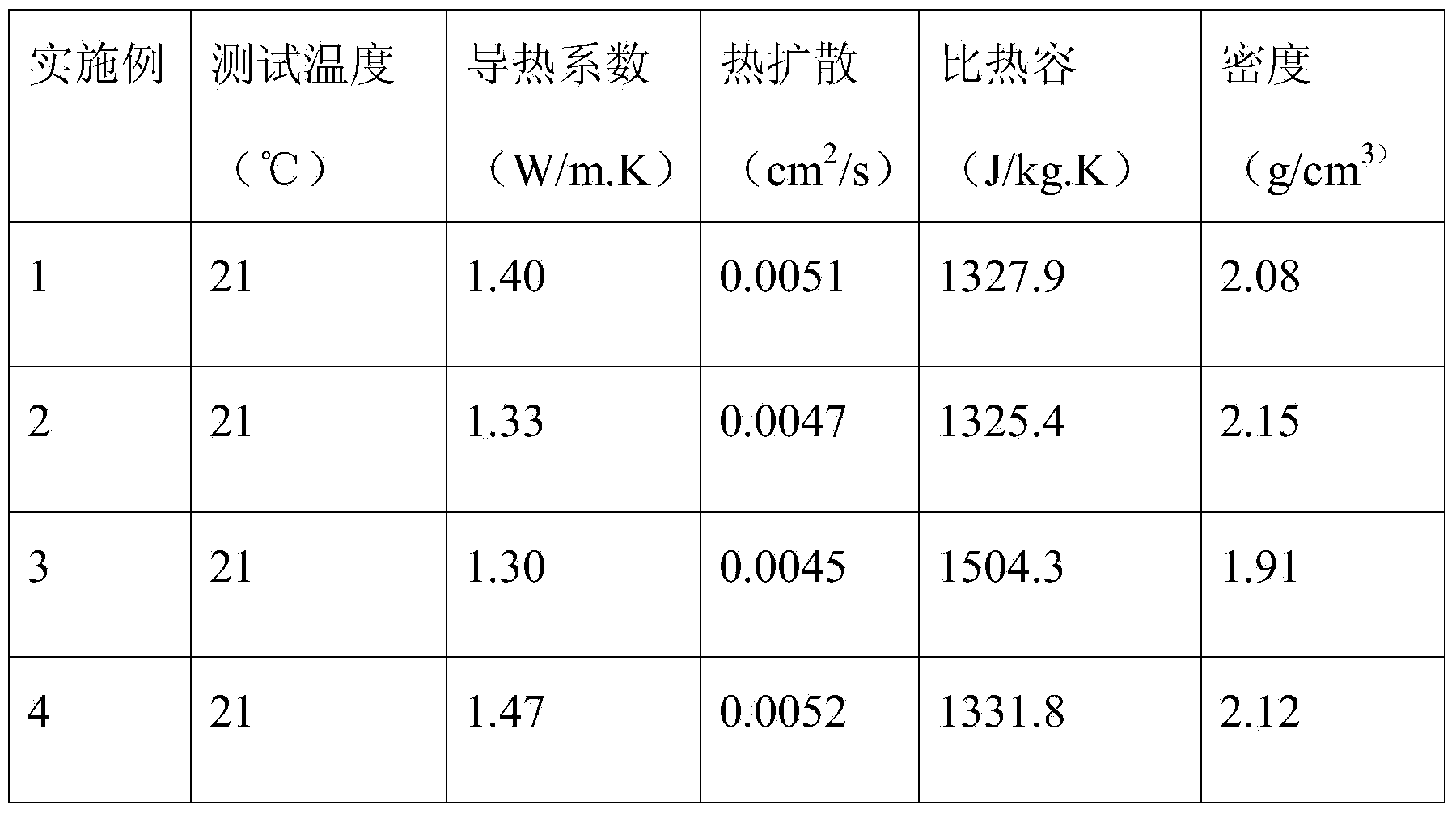

Low-density oil well cement reinforcing material and preparation method and using method thereof

PendingCN110540388AHigh compressive strengthWide variety of sourcesDrilling compositionOrganic acidCement slurry

The invention discloses a low-density oil well cement reinforcing material, and relates to the technical field of oil well cement. The low-density oil well cement reinforcing material consists of, byweight: 20-60% of a reinforced inorganic material, 5-30% of a coagulation-promoting early-strength material, 5-30% of micro-silica powder and 10-30% of granular cement, specifically, the reinforced inorganic material is one of superfine gelling material or superfine latent gelling material, and the particle size of the reinforced inorganic material is 1250 meshes to 8000 meshes; and the coagulation-promoting early-strength material comprises, by weight: 50% of organic acid salt cement early-strength agent and the mixture of 50% of organic cement early-strength agent and inorganic cement early-strength agent. The invention also discloses a preparation method and use method of the low-density oil well cement reinforcing material. The low-density oil well cement reinforcing material is capable of obviously increasing the compressive strength of low-density oil well cement when being added into a cement slurry system, wide in material source and low in cost.

Owner:德州市亿源机械化工有限公司 +1

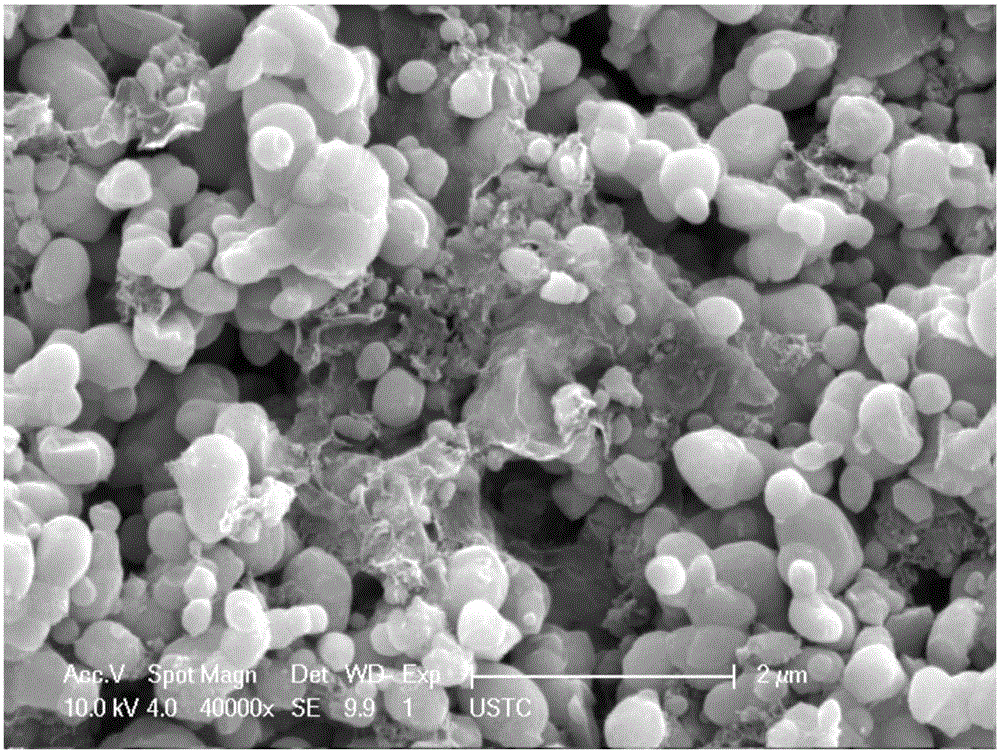

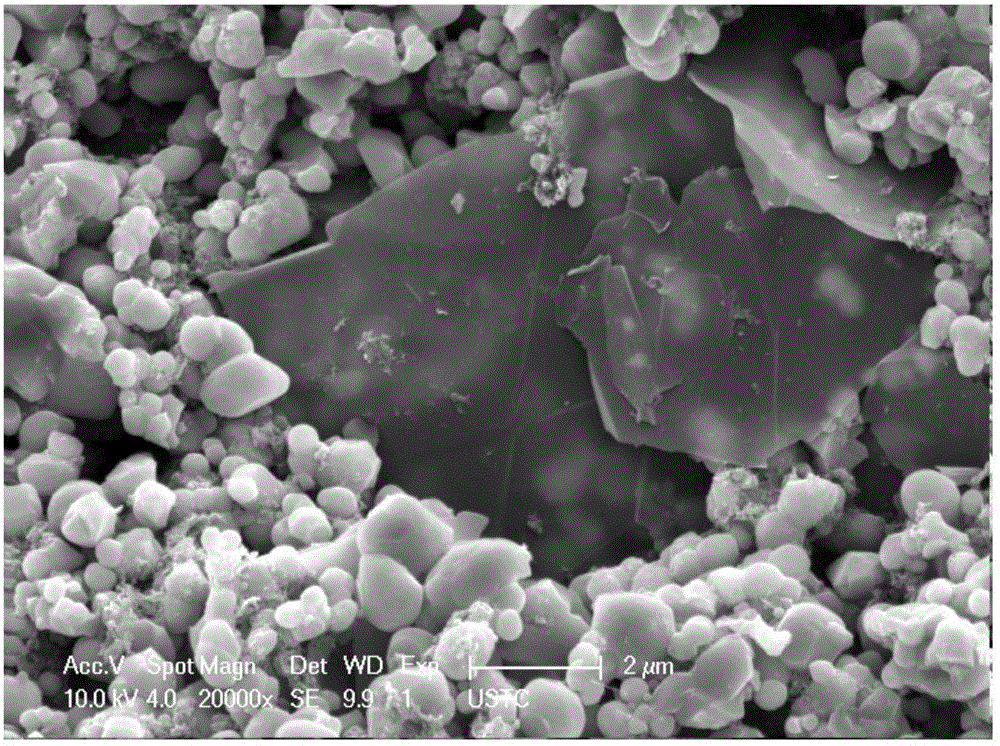

Preparation method of graphene/lithium iron phosphate composite material

InactiveCN105932255ASolve floatingSolve reunionPhosphatesCell electrodesLithium iron phosphateReducing atmosphere

The invention discloses a preparation method of a graphene / lithium iron phosphate composite material. The method comprises the following steps: adding a graphene oxide suspension liquid to a lithium iron phosphate precursor or a pre-sintered material or a sintered body; adding a little of solvent for wet ball-milling; and carrying out dry grinding treatment after ball-milling, and sintering the product in a reducing atmosphere to prepare the graphene / lithium iron phosphate composite material. The adopted graphite oxide contains a lot of oxygen-containing hydrophilic groups and is easily dispersed into the solvents of water, ethyl alcohol and the like under ultrasonic action, so that the problems of floatation, agglomeration and uneven mixing due to direct addition of graphene in a traditional lithium iron phosphate preparation method are solved; and the graphene prepared by the method is evenly dispersed among lithium iron phosphate particles, is free of accumulation and agglomeration and can form a good conductive network. The method is simple to operate; and large-scale industrial production is easy to implement.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Plastic stirring machine facilitating slurry movement

The invention discloses a plastic stirring machine facilitating slurry movement. The plastic stirring machine comprises a machine body. A discharging opening is formed in one side of the machine body. The position, located above the discharging opening, of one side of the machine body is fixedly connected with a controller. A feeding opening is formed in the top of the machine body. The top of the machine body is fixedly connected with a first motor. The output end of the first motor penetrates the machine body and extends into a stirring box arranged in the machine body. The two sides of the output end, located in the stirring box, of the first motor are fixedly connected with first connecting rods. The side, far away from the output end of the first motor, of each first connecting rod is fixedly connected with a stirring plate. Material passing holes are formed in the surface of each stirring plate. According to the plastic stirring machine facilitating slurry movement, by means of cooperation of the first motor, the stirring plates, the material passing holes and material passing grooves, slurry movement is faster; the effect of even stirring of plastic raw materials during stirring is achieved; and the problem that uneven stirring is prone to happening to an original plastic stirring machine is solved.

Owner:山东森庆新材料科技有限公司

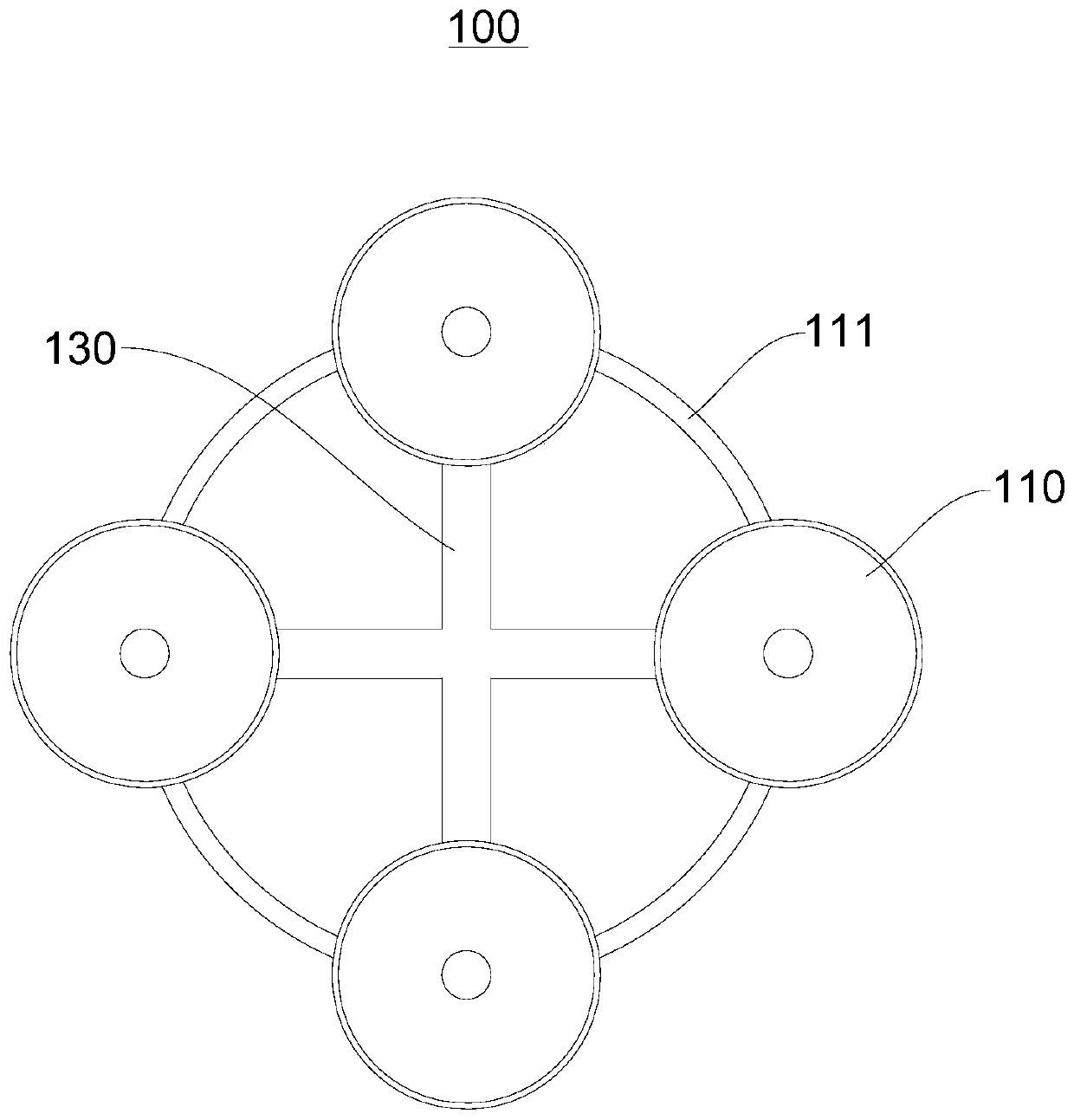

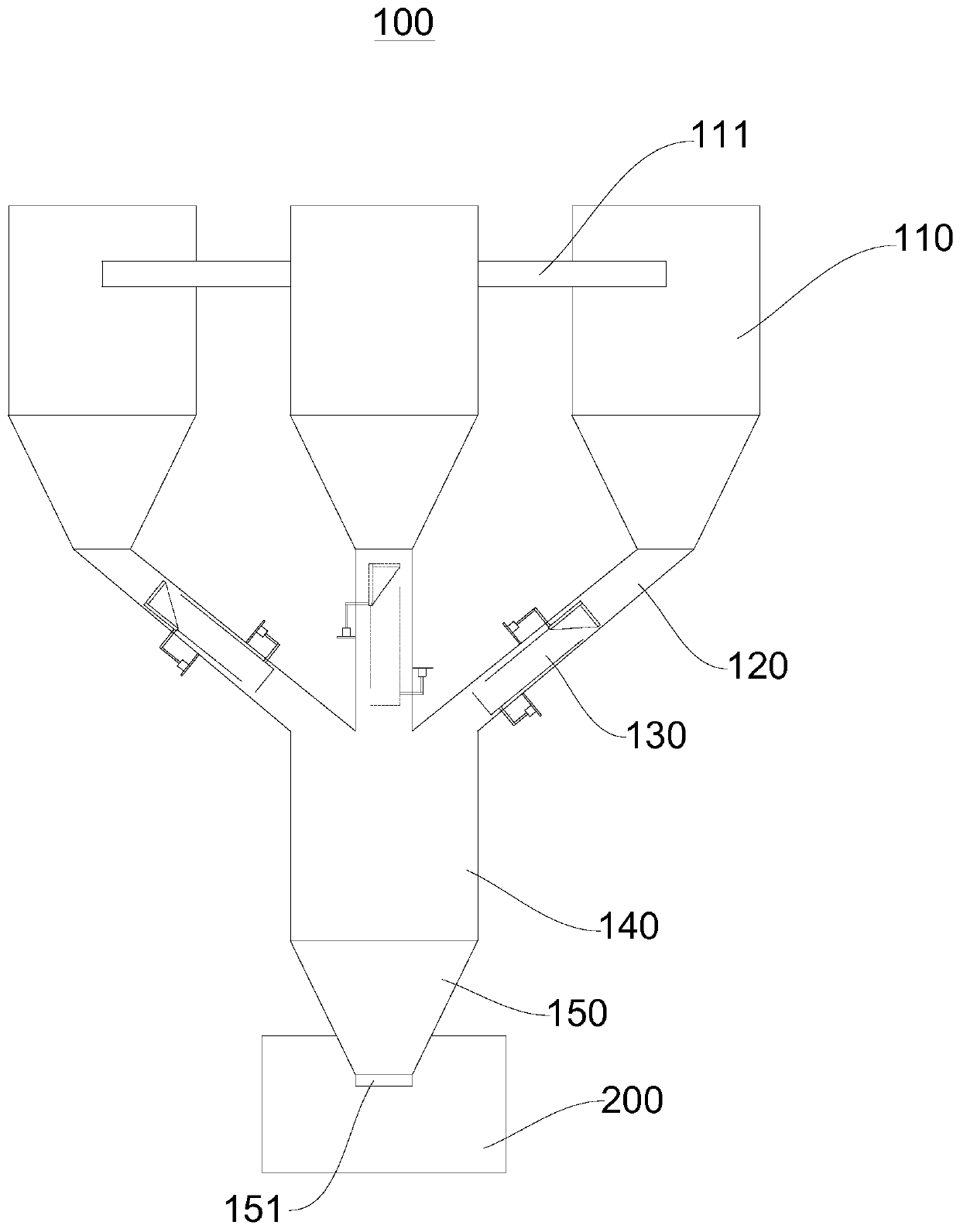

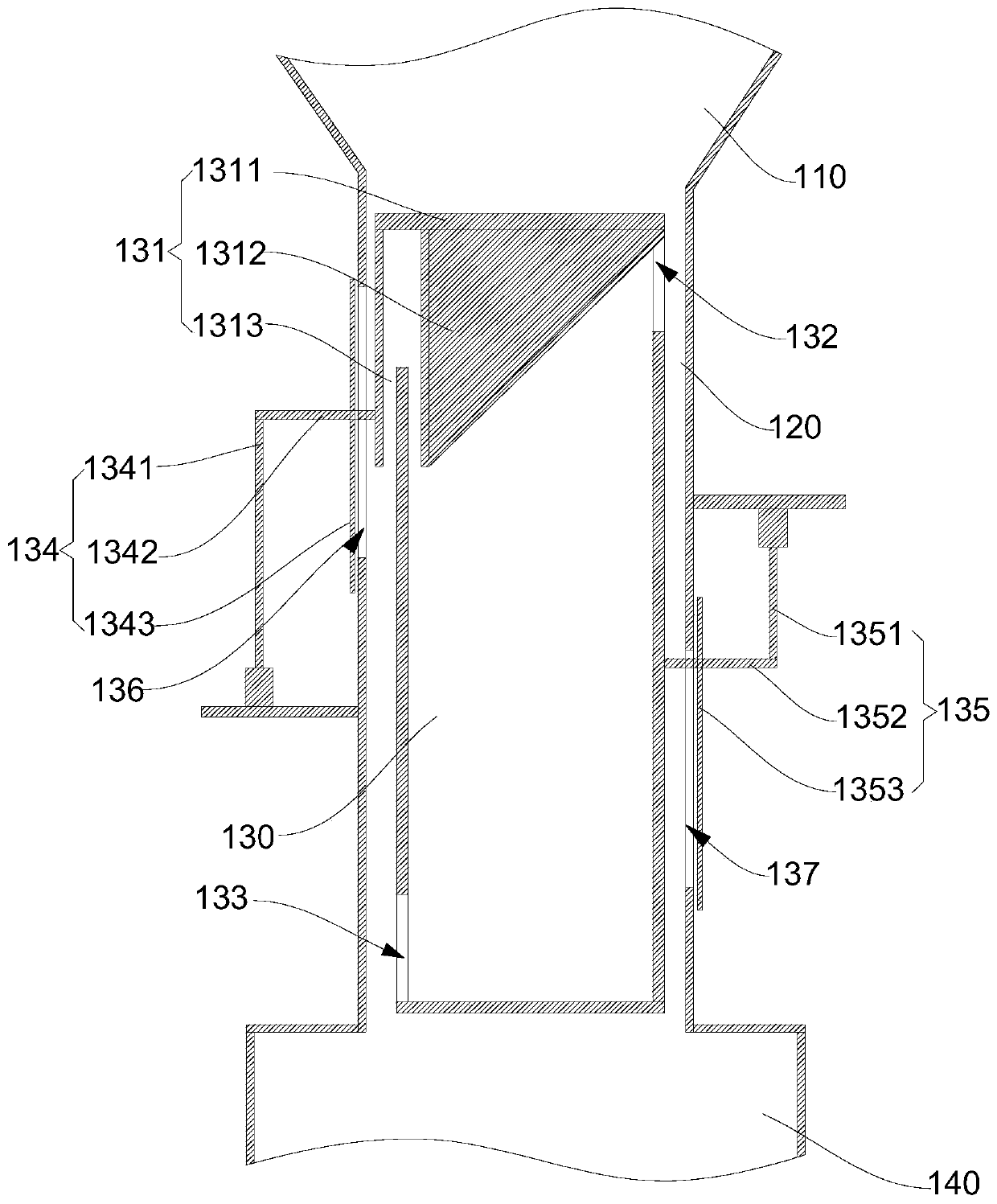

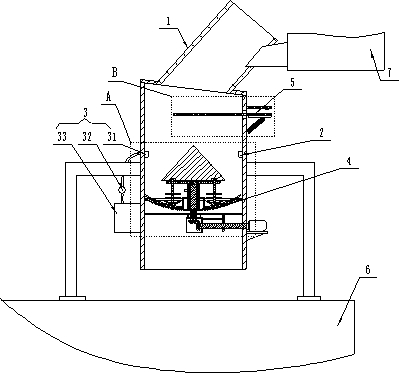

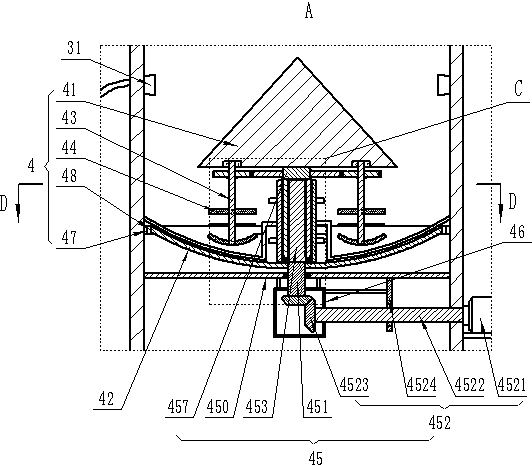

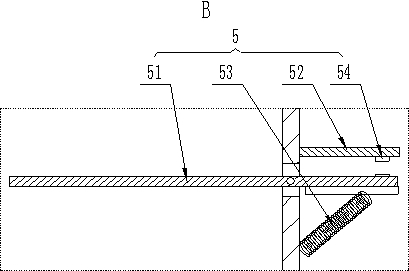

Device and method for transporting materials quantitatively and mixing and packaging integrated equipment

PendingCN111301727AReduce content differentiationGuaranteed accuracyMixer accessoriesSolid materialProcess engineeringEnvironmental geology

The invention provides a device and a method for transporting materials quantitatively and mixing and packaging integrated equipment and relates to the field of food and drug processing equipment. Thedevice comprises a feeding barrel, an unloading channel and a quantitative transportation pipeline. The unloading channel communicates to the feeding barrel, and the quantitative transportation pipeline is mounted in the unloading channel and can move in the unloading channel to feed or discharge the materials; a striker plate is arranged in the quantitative transportation pipeline, the bottom ofthe quantitative transportation pipeline is sealed, a feed inlet is formed above the upper side of the side wall of the quantitative transportation pipeline, and a discharge opening is formed below the side wall of the quantitative transportation pipeline. The device can achieve quantitative transportation by adjusting the size of the quantitative transportation pipeline randomly, and materials with different characteristics are mixed and then poured into corresponding feeding barrels, so that the problem that the materials are not mixed uniformly due to characteristic difference is solved. The content difference among the products is reduced, and the accuracy of adding mixtures is ensured. In addition, the mixing and packaging integrated equipment can process the materials quickly, so that the mixing and packaging accuracy of the materials is guaranteed, and the device is more efficient.

Owner:玛士撒拉(上海)医疗科技有限公司

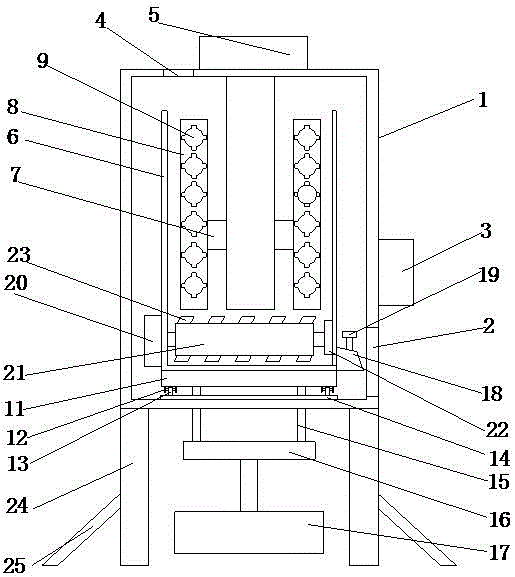

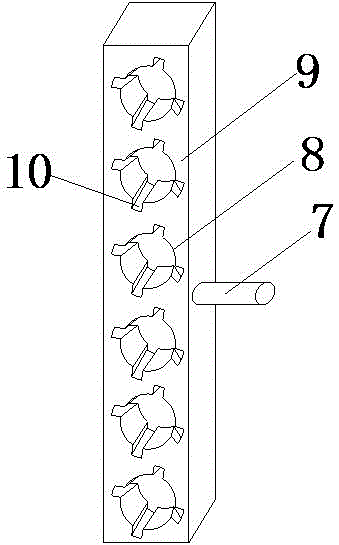

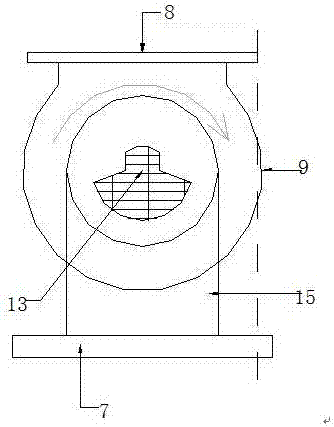

Self-rotating stirrer

InactiveCN106902682AAvoid damageExtended service lifeRotating receptacle mixersTransportation and packagingDrive shaftEngineering

The invention relates to a self-rotating stirrer. The self-rotating stirrer comprises a power part, a drive shaft, a tank body part, stirrer blades, a machine tool base, a rotating part and a moving part, wherein the power part is fixed to a supporting part, one end of the power part is connected with the drive shaft, two ends of the drive shaft are connected with the power part and the stirrer blades respectively, and the stirrer blades and part of drive shaft are located in the tank body part. The rotating part is erected on one side of the tank body part and fixed to the machine tool base, and the power part comprises a motor, a speed-reducing box, a sliding guide rail and a sliding base. The motor and the speed-reducing box are fixed to the sliding base. The sliding base is put on the sliding guide rail.

Owner:黄裕才

A kind of high-strength shotcrete for high ground temperature tunnel and its preparation method

The invention discloses a high strength sprayed concrete for high ground temperature tunnels and a preparation method thereof. The concrete comprises following raw materials: cement, fly ash, slag powder, sand, coarse aggregate, glass beads, PVA fibers, steel fibers, modified rubber, a water reducer, a setting accelerator, and water. Low melting point water-soluble PVA fibers are adopted, after concrete reaches the melting point of the PVA fibers, fibers are melted, tunnels are formed, thus water steam in the concrete can be conveniently dissipated through the tunnels, the steam pressure in the concrete is reduced, the risk of bursting is reduced, at the same time, the melted water-soluble PVA fibers can largely enhance the inner cohesive force of concrete, and the cracking of a cement face is avoided. Through the cooperation of all raw materials, the prepared concrete has the characteristics of low heat conductivity coefficient, good anti-permeability, high interfacial bond strength,and little long-term strength loss. The long-term strength of concrete after spraying is largely improved. The cracking of high ground temperature concrete is avoided.

Owner:CHANGAN UNIV

High-performance concrete suitable for high-temperature areas

The invention relates to high-performance concrete suitable for a high-temperature area. The high-performance concrete comprises the following components in parts by mass: 100-280 parts of cement; 150 to 230 parts of modified metakaolin; 150 to 260 parts of clay clinker; 80-190 parts of coal ash powder; 100 to 150 parts of sand; 50 to 100 parts of water glass; 15 to 50 parts of sodium silicate; 30 to 80 parts of asphalt; 15 to 25 parts of a functional additive; 200 to 400 parts of water; according to the invention, various mechanical properties and high temperature resistance of the concrete are improved, and the freeze-thaw resistance of the concrete is effectively improved.

Owner:JIANGSU DONGZHAO CONSTR IND INNOVATION & DEV RES INST CO LTD

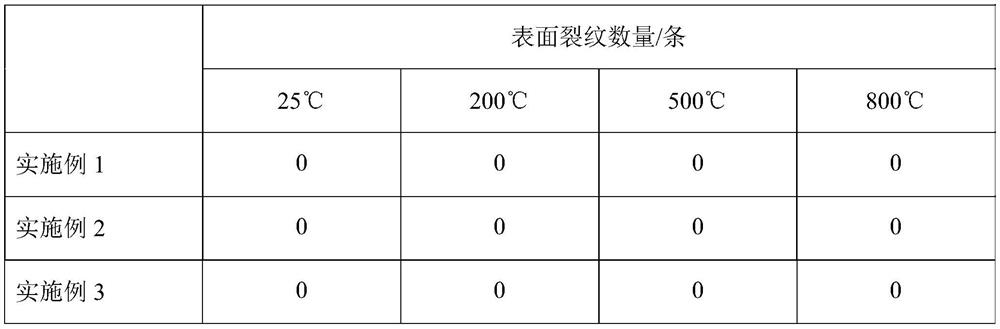

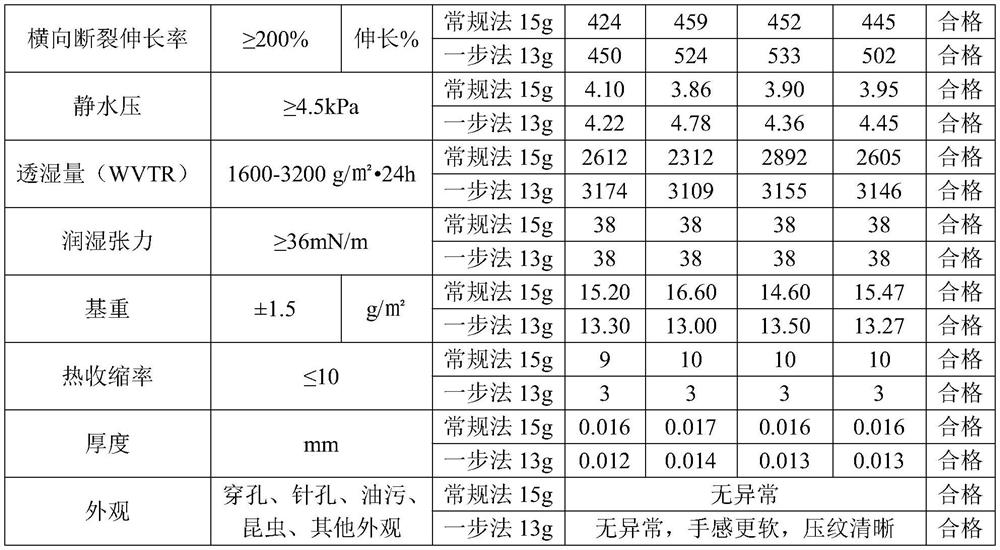

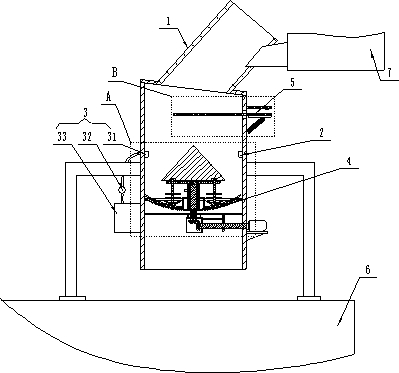

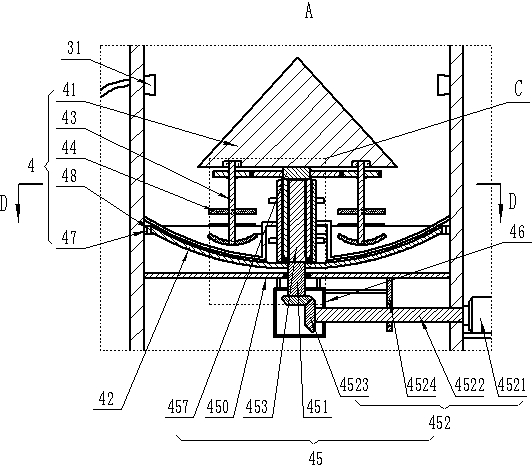

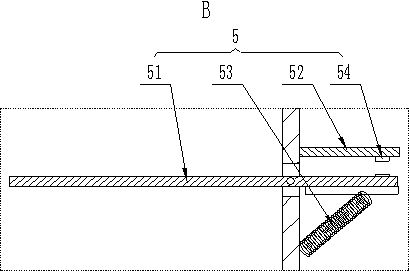

High-load low-resistance melt-blown material production device and method

InactiveCN111571985AThe process steps are simpleUnique production formulaEngineeringProcess engineering

The invention discloses a high-load low-resistance melt-blown material production device and method. The high-load low-resistance melt-blown material production device comprises a hopper, and a feeding device is movably arranged at the side end of the hopper; a mixing partition plate is arranged in a mixing machine to divide the mixing machine into a front space and a rear space, a double-layer stirring device is arranged in the front space of the mixing machine, and stirred and mixed materials enter the rear space of the mixing machine through a first discharging hole below the mixing partition plate for temporary storage. A double-screw extruder, a cooling device and a cooling device are arranged at the tail end of the mixing machine; the materials cooled by the cooling device are conveyed to a granulator through a conveying belt for granulation and screening, the materials are dried by a fan and then fed into a homogenizing and mixing tank through a rotary feeder for homogenizing processing, and finally a finished product is prepared. The process steps are optimized, integrated and intensive design and arrangement are carried out, the production formula is unique, the productionresistance is reduced, discharging is smooth, the product quality is kept excellent, and high-load low-resistance melt-blown materials can be efficiently produced with high quality.

Owner:HUNAN SHENGJIN NEW MATERIAL

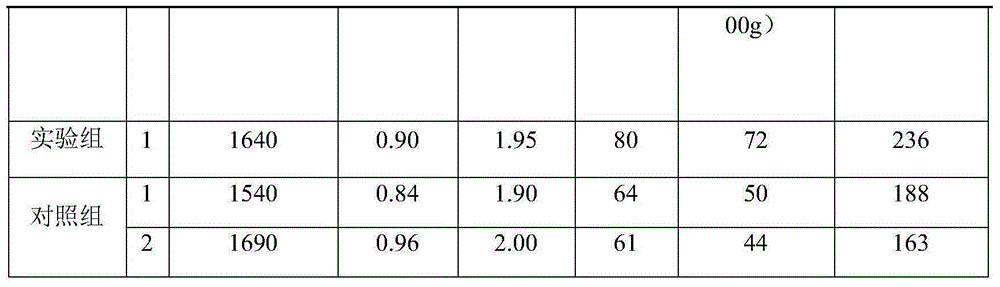

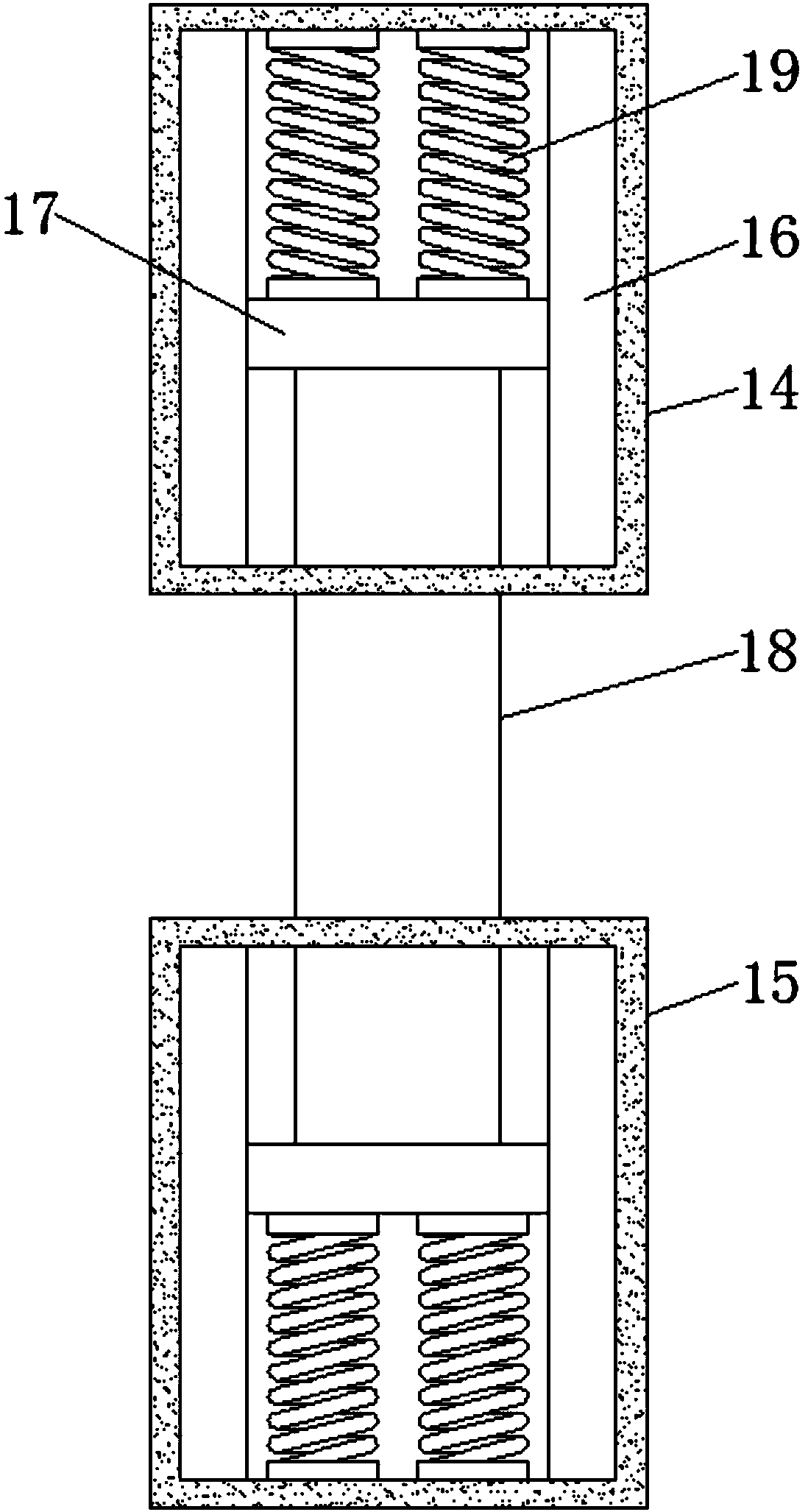

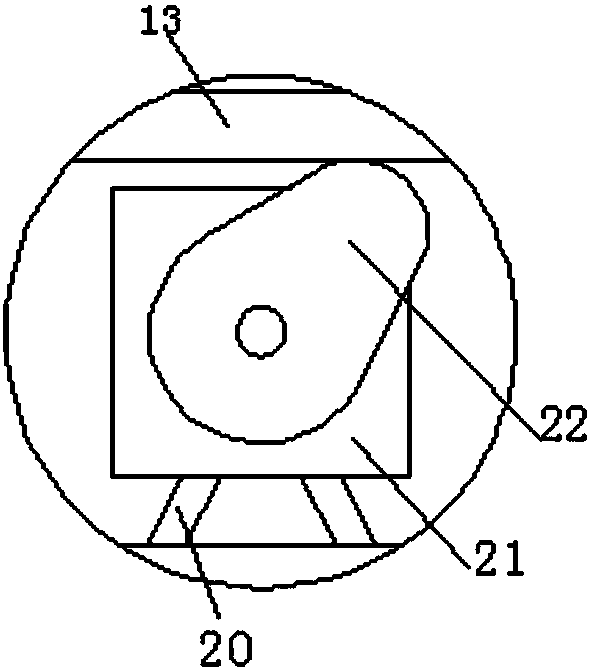

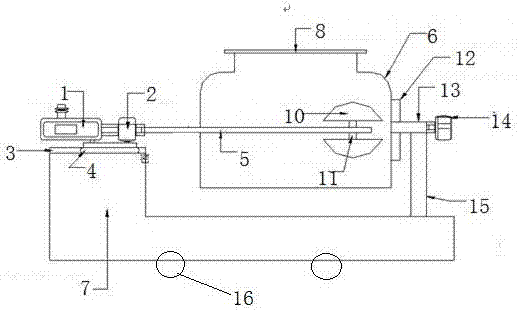

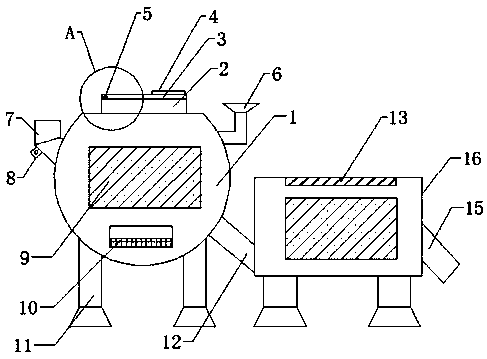

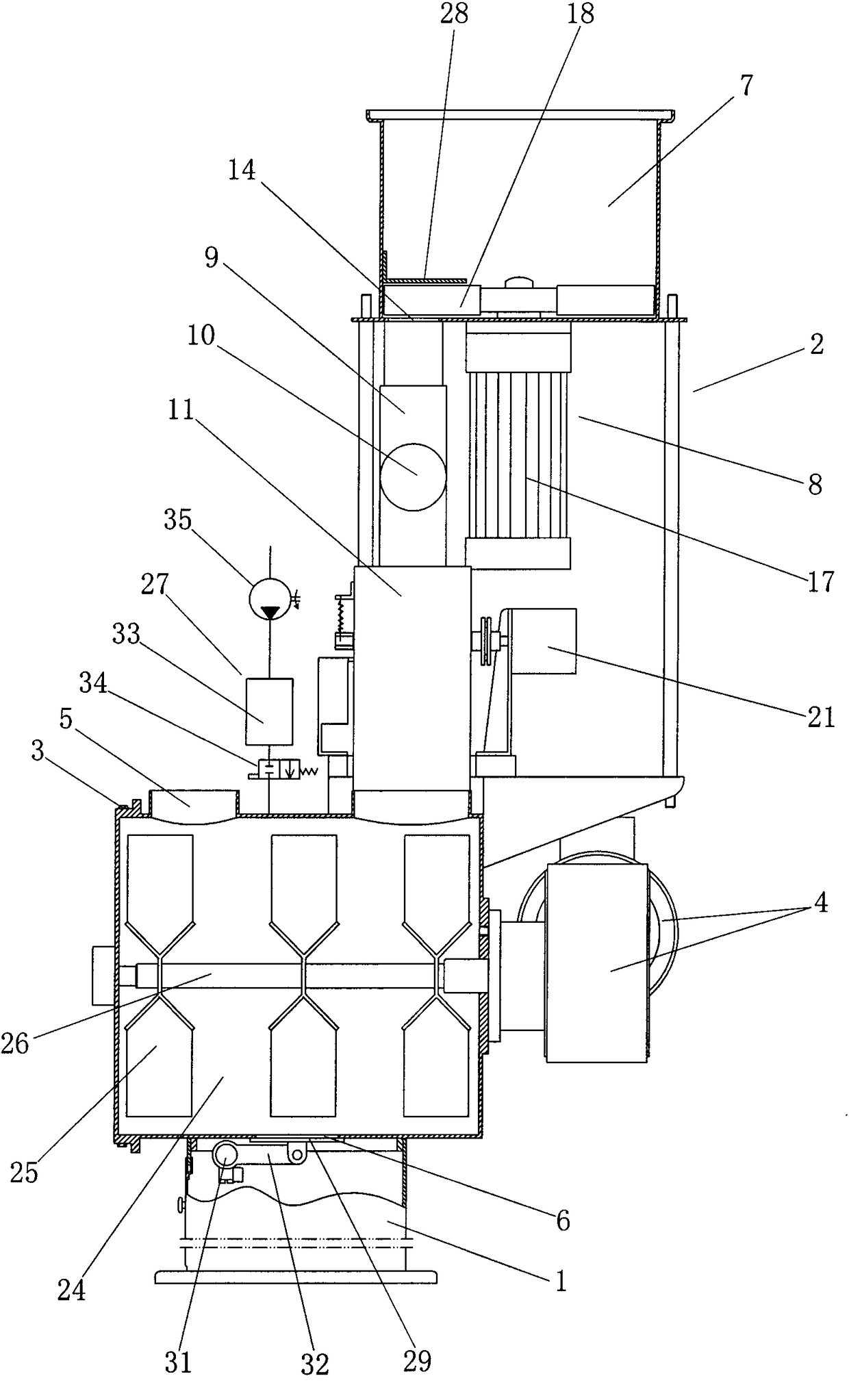

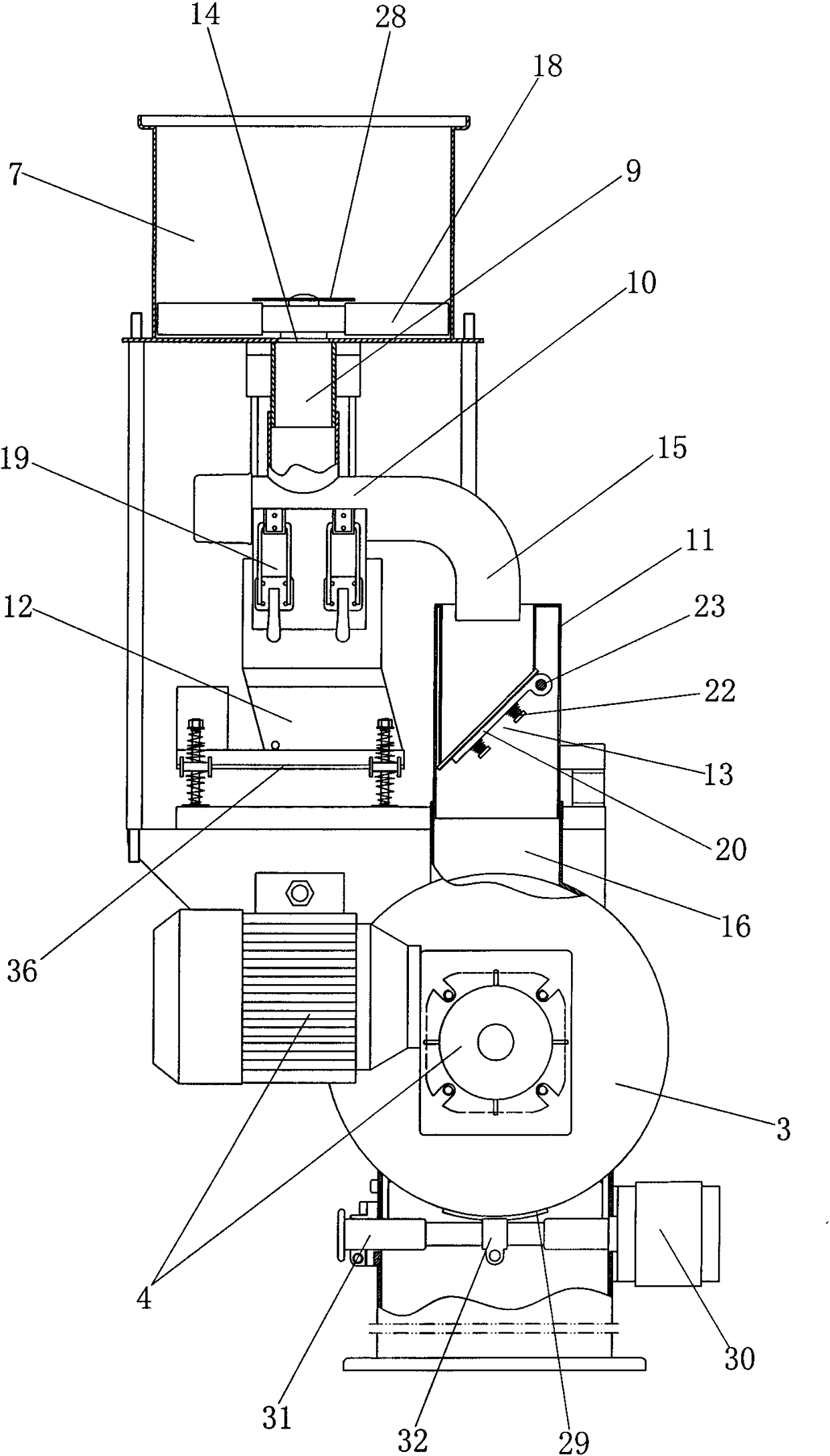

Quantitative microbial feed fermentation device

InactiveCN110343613APrevent sinkingSolve the problem of uneven mixingBioreactor/fermenter combinationsBiological substance pretreatmentsMotor driveEngineering

The invention discloses a quantitative microbial feed fermentation device. The quantitative microbial feed fermentation device comprises a device body and a fermentation tank, a feeding inlet runs through the top of the device body, a top cover is connected to one side of the top of the feeding inlet through a movable shaft, and the top of the top cover is fixedly provided with a handle. A ventilation pipe penetrates through the upper portion of one side of the device body, a quantifying tank penetrates through the other side of the device body, a quantifying device is arranged on one side ofthe quantifying groove, an operation table is arranged below the outer surface of the device body, the cross section area of a stirring rod is equal to that of the lower portion in a mixing chamber, and a plurality of bosses are fixed to the outer surface of the stirring rod. During work, a motor drives the stirring rod to rotate, materials, which sink to the bottom, on the lower portion in the mixing chamber can be stirred, and the materials are prevented from sinking to the bottom.

Owner:WUHAN POLYTECHNIC UNIVERSITY

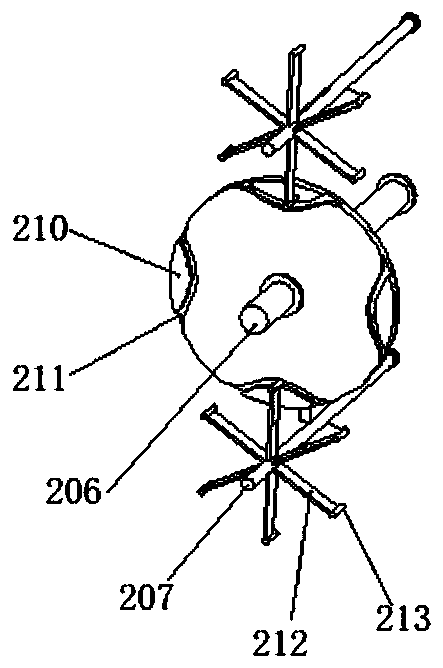

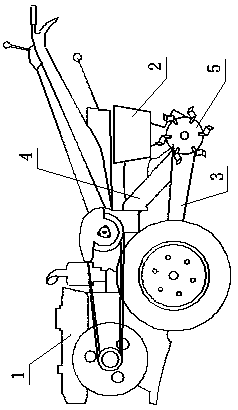

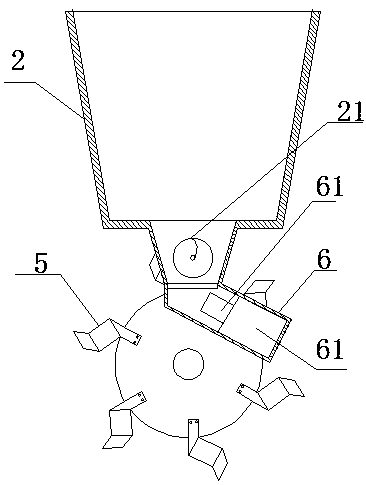

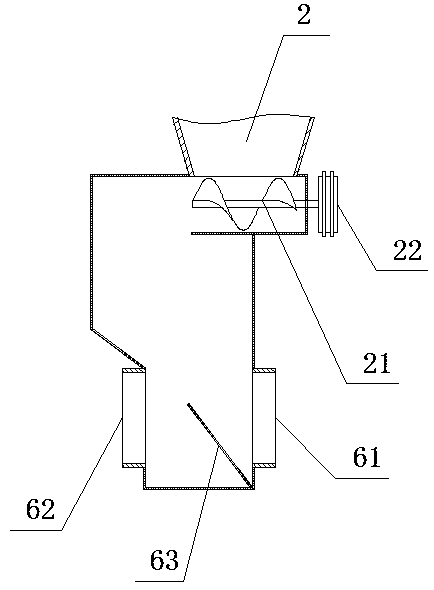

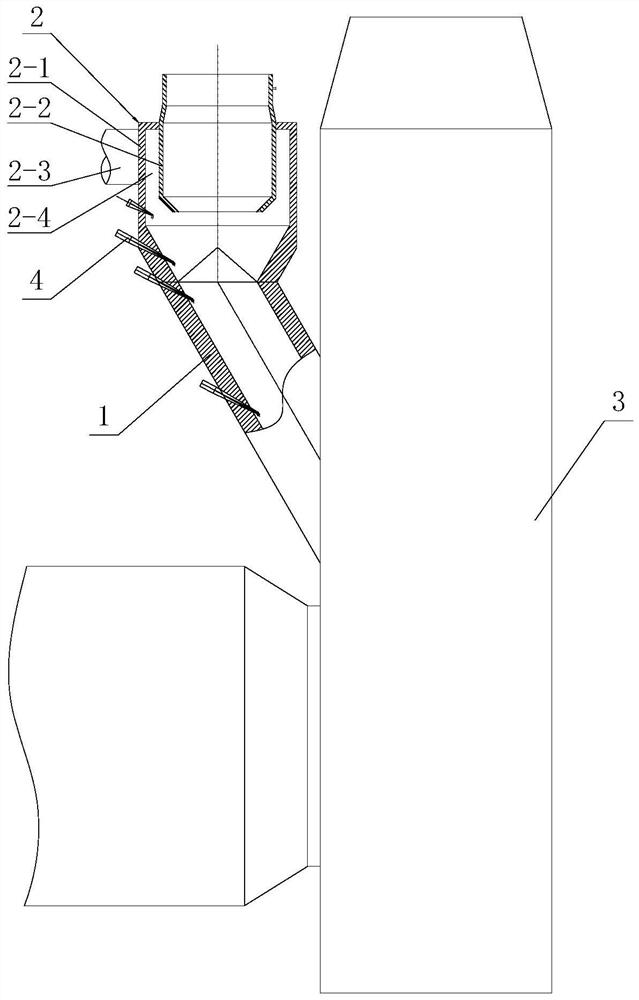

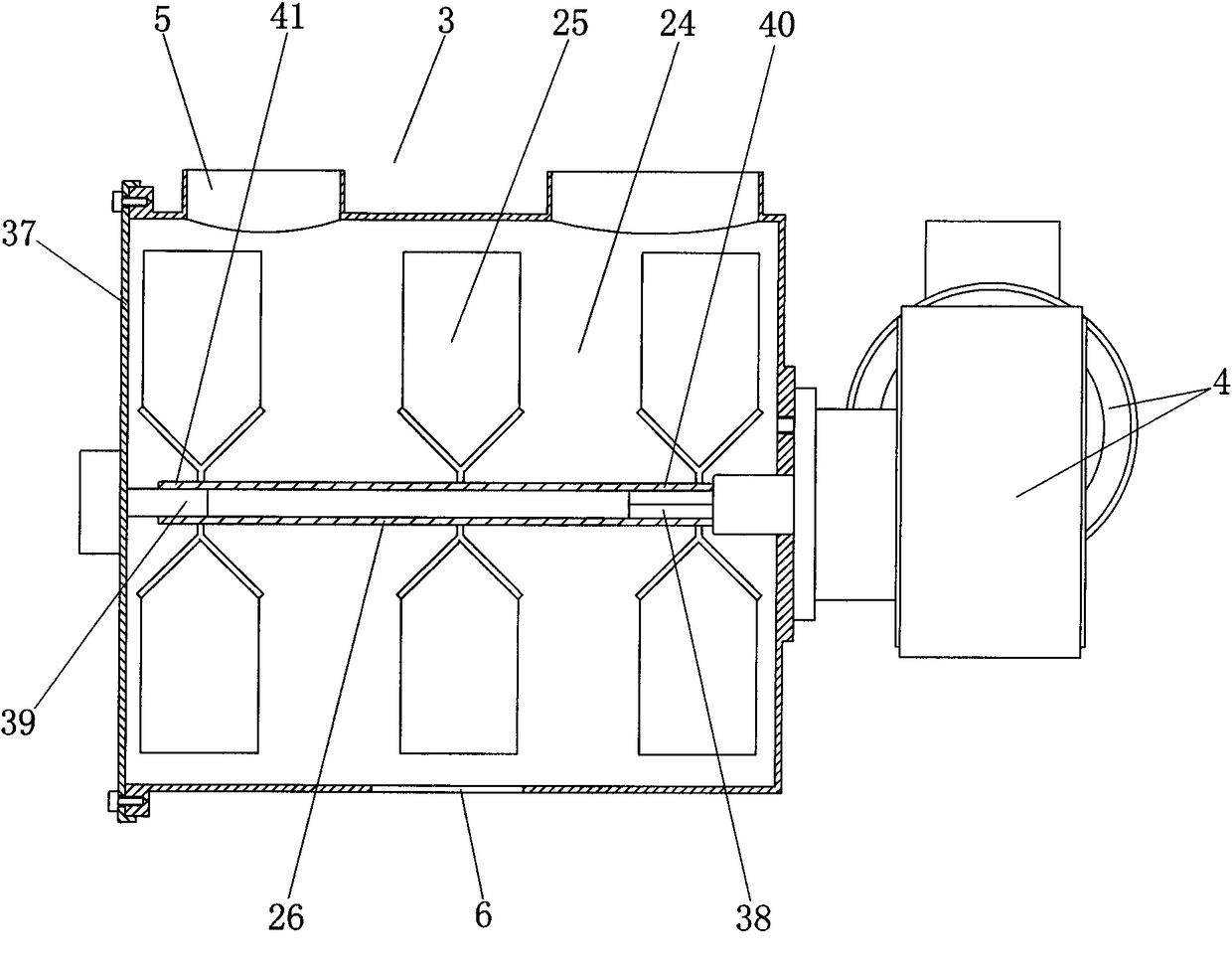

Uniform fertilizer spreading device

InactiveCN108293342ASolve the problem of uneven mixingAvoid wastingSpadesFertiliser distributersAgricultural engineeringAgricultural machinery

The invention relates to agricultural machinery, and provides a uniform fertilizer spreading device. The device comprises a rotary cutter wheel which is in power connection with a traction machine, and a support of the rotary cutter wheel is supported on and fixed to the traction machine; a fertilizer bin for containing a fertilizer is fixed to the upper portion of the support of the rotary cutterwheel, and a feeding hole of a fertilizer conveying mechanism for conveying the fertilizer is communicated with the lower portion of the fertilizer bin; a discharging opening of the fertilizer conveying mechanism is communicated with a cuboid fertilizer spreading bin which is obliquely arranged; a plurality of fertilizer spreading openings are formed in the two sides of the fertilizer spreading bin, a partition plate for separating the fertilizer to the fertilizer spreading openings is arranged in the fertilizer spreading bin, and the fertilizer spreading openings are formed above the rotarycutter wheel. The device solves the problem that in the prior art, the fertilizer and soil are not uniform in mixing, and the fertilizer is conveyed to the portion above the rotary cutter wheel and evenly separated through the fertilizer spreading device, so that the fertilizer waste is avoided, the structure is compact and simple, and the device is suitable for being matched with various tractionmachines in use.

Owner:蒙阴县红地农业科技有限公司

Bypass air release quench chamber device

InactiveCN111659243AReasonable structureFlexible layoutGas treatmentDispersed particle separationCold airThermodynamics

The invention discloses a bypass air release quench chamber device. The bypass air release quench chamber device is characterized by comprising a hot air settling chamber and a quench chamber connected with the hot air settling chamber; the hot air settling chamber is provided with a settling channel penetrating through the two ends; and the quench chamber comprises an outer cylinder, an inner cylinder and a volute, the inner cylinder is arranged on the inner side of the outer cylinder, an annular duct is formed between the inner cylinder and the outer cylinder, one end of the outer cylinder is a hot air inlet communicated with an outlet of the settling channel of the hot air settling chamber, the other end of the outer cylinder is connected with the outer wall of the inner cylinder, the end, away from the hot air inlet, of the inner cylinder is a quench chamber outlet, a cold air inlet capable of guiding air into the inner side of the outer cylinder in the tangential direction of theinner wall of the outer cylinder is formed in the outer side of the end, close to the quench chamber outlet, of the outer cylinder, and the volute is communicated with the cold air inlet. The quench chamber device is high in hot flue gas cooling speed, high in cold and hot air mixing efficiency, small in overall structure, convenient to arrange and easy to operate and maintain, coarse sedimentation discharge is reduced, and rapid enrichment of harmful ingredients is facilitated.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

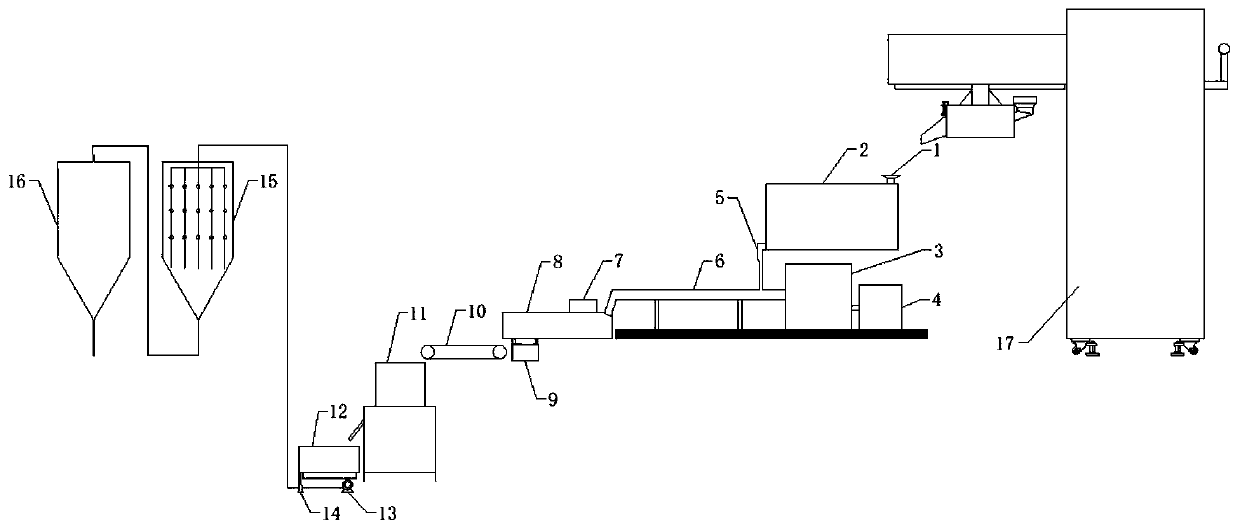

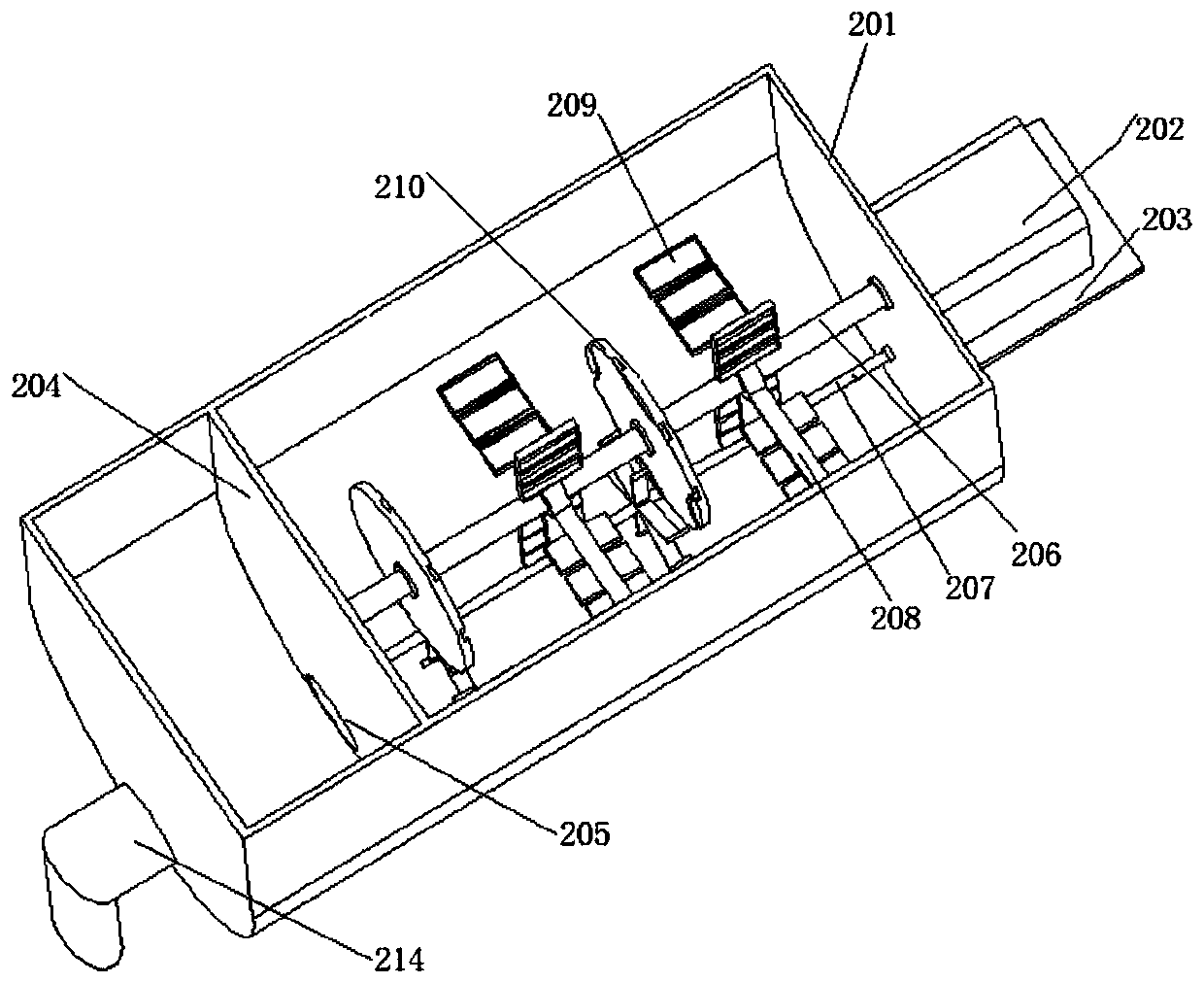

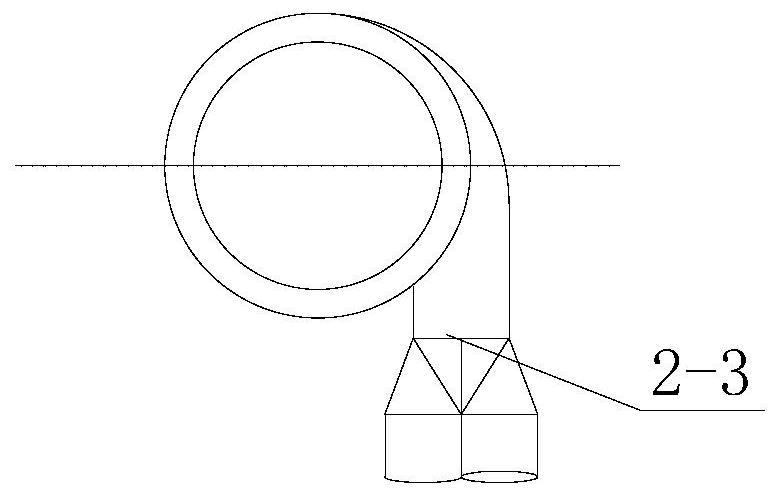

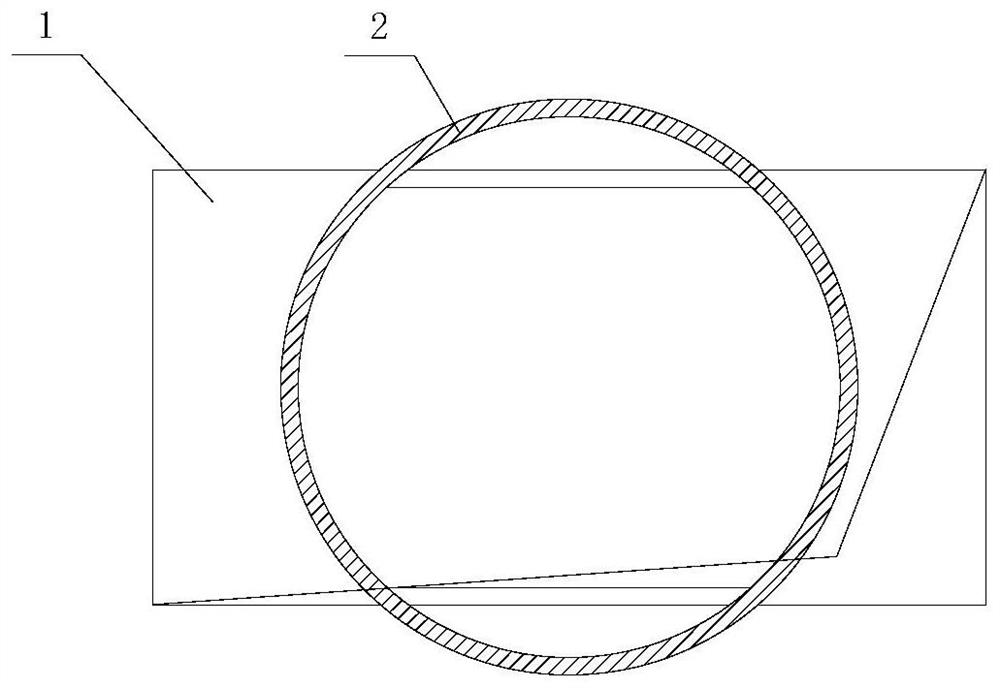

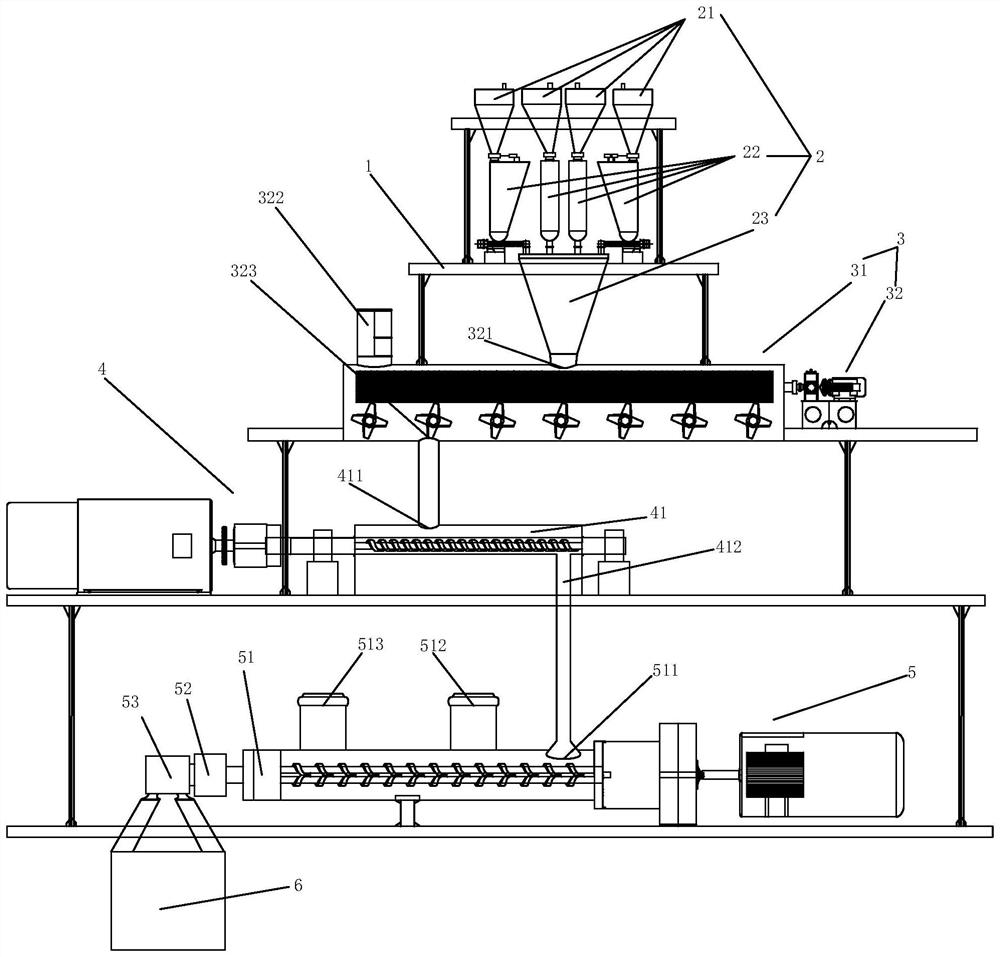

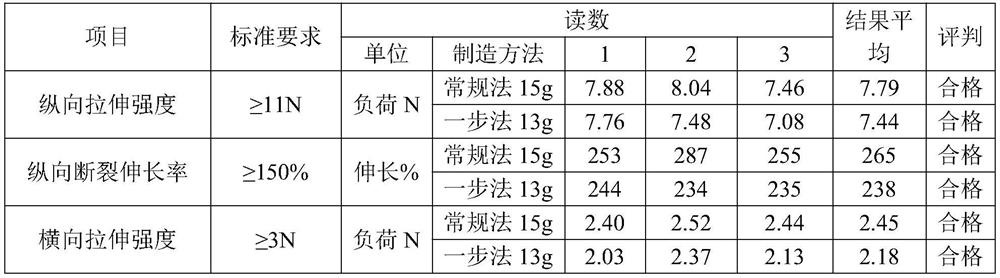

Multifunctional double-order melting method efficient production equipment and process

PendingCN114311584AReduce molecular structure changesAvoid secondary pollutionMolten stateProcess equipment

The invention provides multifunctional double-order melting method efficient production equipment and process, the equipment comprises a rack, a material storage device, a weighing device, a material collecting device, a mixing mechanism, a banburying mechanism, an extruding mechanism and a follow-up mechanism, and the process comprises the steps that materials are put into the material storage device, and after being metered by the weighing device, the materials are fed into the extruding mechanism; materials are fed into the mixing mechanism through the material collecting device to be primarily stirred and mixed, the evenly-mixed mixture is internally mixed and plasticized, then enters the extrusion mechanism in a semi-molten state, is heated and stirred in the extrusion mechanism and then is extruded in a molten state to be subjected to follow-up requirements such as tape casting or granulation, and the materials are formed through one-time machining. And compared with traditional equipment, material molecular structure changes caused by secondary or multiple heating plasticization of the material are reduced, and secondary pollution of the material is more effectively avoided.

Owner:山东庆昕机械科技有限公司

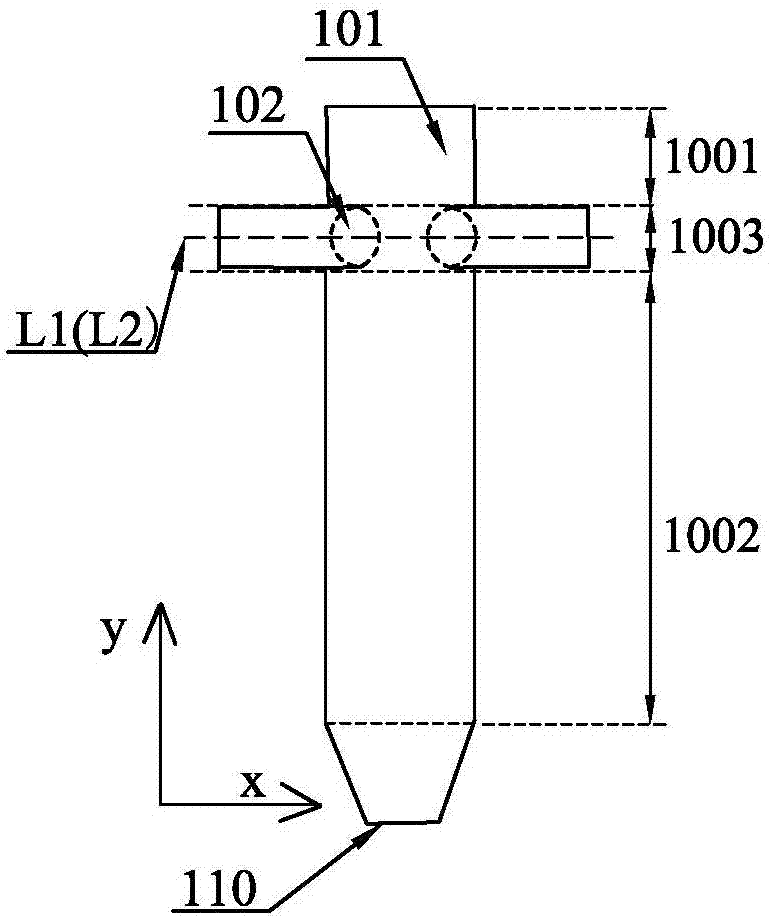

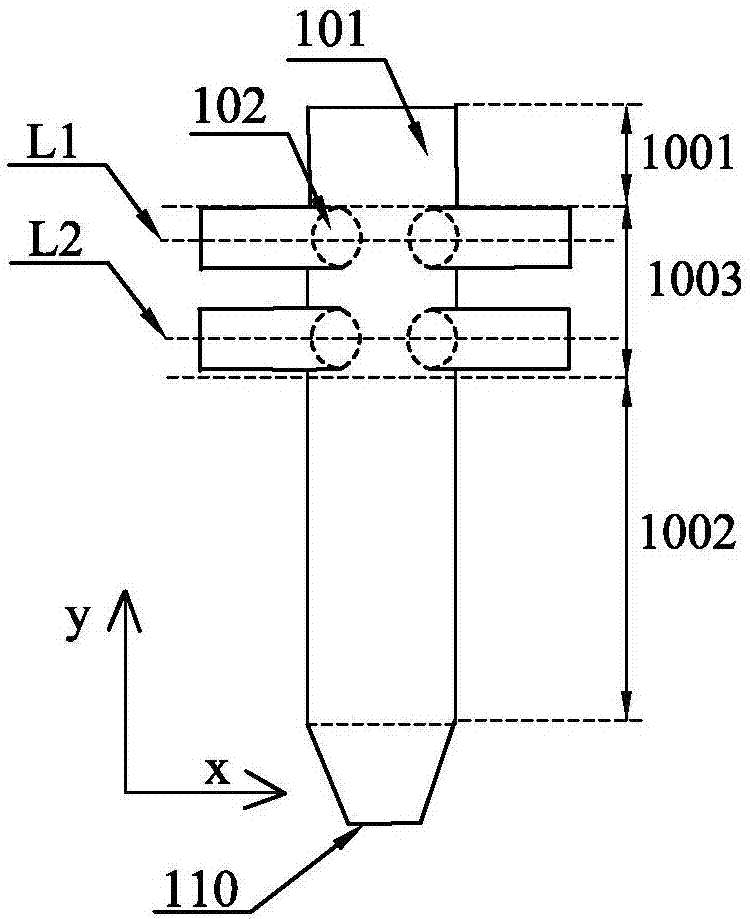

A sludge treatment system for drilling engineering mud circulation

ActiveCN114605048BImprove convenienceImprove the mixing effectWaste water treatment from quariesSludge treatmentSludgeProcess engineering

The invention discloses a sludge treatment system for drilling engineering mud circulation, which includes a vibrating screen and a sedimentation tank, and an inclined confluence pipe and a vertical integrated mixing pipe are arranged between the sludge outlet of the vibrating screen and the sedimentation tank. The integrated mixing pipe is equipped with a spraying device that can spray the agent through the sludge and a mixing mechanism that can evenly mix the sludge and the agent. By setting the converging pipe and the comprehensive mixing pipe, and setting up the spraying device, when the sludge is transported to the sedimentation tank, the agent can be sprayed and added simultaneously, and the mixing mechanism is further set up, which also makes the sludge and the agent mix. It is further mixed evenly under the mixing of the mixing mechanism. Compared with the current direct installation of a stirring device in the sedimentation tank, the volume of the equipment is reduced, the equipment consumables are saved, and the mixing has no dead ends, which improves the mixing effect and achieves environmental protection and green. Exploration purpose.

Owner:SHANDONG PROVINCIAL COAL GEOLOGICAL PLANNING EXPLORATION & RES INST

Livestock feed stirring device

InactiveCN108125265ASolve the problem of uneven mixingEffective crushing mixingFeeding-stuffElectric machineryEngineering

The invention discloses a livestock feed stirring device. The device comprises a base, a stirring barrel and a stirring device, wherein the stirring barrel is movably connected with the top of the base, and a transverse plate is connected with the interior of the stirring barrel; the stirring device is arranged in a cavity formed by the transverse plate and the stirring barrel, a motor is arrangedin the base, and the motor is fixedly connected with a rotating base through a rotating shaft; the rotating base is connected with a connecting base which protrudes out of the bottom of the stirringbarrel; the stirring device comprises a rotating head, a connecting head, a sliding rod, a sliding block, a rotating rod, a sliding groove, a connecting block, a connecting column, a stirring column and a stirring knife. The livestock feed stirring device can solve the problem that in the prior art, when a feed stirring device is used for stirring large materials, the materials cannot be crushed easily and accordingly feed cannot be uniformly mixed, and the feed can be effectively crushed and stirred; the device is simple in structure, convenient to use, convenient to operate, high in safety and convenient to maintain, and parts are convenient to replace.

Owner:安徽省义华农牧科技有限公司

A method for preparing niobium-tungsten binary composite carbide nanopowder

ActiveCN107128921BSolve the problem of uneven mixingHigh purityMaterial nanotechnologyOxy/sulfo carbidesReduction treatmentTungstate

The invention discloses a method for preparing niobium-tungsten binary complex carbide nano powder. The method comprises the following steps: S1, putting tungstate into a fluorine-niobium acid solution, further adding a surfactant till the pH value is 9-12, leaving to stand, aging, and filtering; S2, collecting niobium-tungsten precursor precipitate, and washing; S3, drying washed precipitate, and grinding and screening so as to obtain niobium-tungsten precursor complex powder; S4, performing reduction treatment on the niobium-tungsten precursor complex powder so as to obtain niobium oxide-tungsten complex powder; S5, selecting actual carbon addition coefficients; S6, adding carbon, and uniformly mixing with raw material powder; S7, putting uniformly mixed powder in a graphite boat or a ceramic boat loosely, performing carbonization treatment, and cooling and discharging from a furnace after treatment is completed; and S8, grinding and screening the discharged niobium-tungsten complex carbide, thereby obtaining the niobium-tungsten binary complex carbide powder. By adopting the method, mixing of niobium-tungsten binary complex carbide of a molecular grade is achieved, and the niobium-tungsten binary complex carbide powder is not only fine in granule, but also very high in chemical uniformity and purity.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

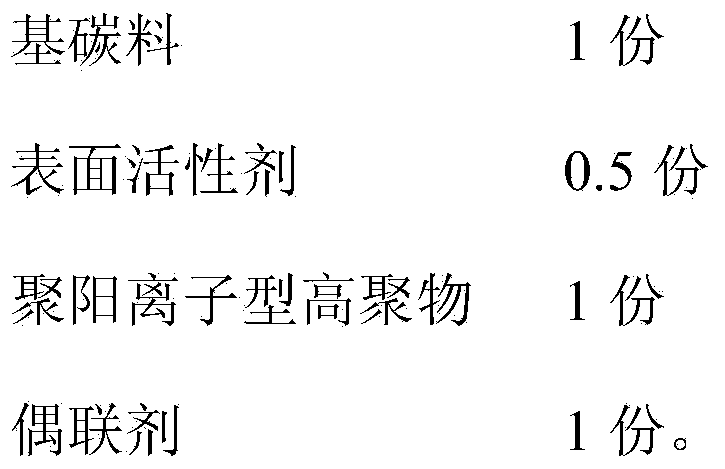

A kind of thermally conductive plastic using modified carbon material and preparation method thereof

The invention discloses thermal conductive plastic applying a modified carbon material, and a preparation method thereof. The thermal conductive plastic comprises the following components in percentage by mass: the modified carbon material, magnesium oxide, boron nitride, nylon 66, a polyanionic type high polymer, a dispersing agent, and a couplant, wherein the modified carbon material comprises the following components in parts by weight: a base carbon material, a surfactant, a polycationic type high polymer, and a couplant; the modified carbon material is prepared by the steps of: mixing water, the base carbon material, sodium chloride, the surfactant and the couplant according to a proportion and then performing ultrasonic treatment, slowly adding the polycationic type high polymer during the ultrasonic process, continuously performing ultrasonic treatment and then stirring for 20-24h, filtering and drying. According to the thermal conductive plastic applying the modified carbon material, and the preparation method thereof, the problem that the materials inside the plastic are mixed unevenly can be effectively solved, and the compatibility of the carbon material can be improved greatly; the dispersity of the whole material mixture can be enhanced, and plugging is difficult in the extrusion process; the synthetic technology is simple, and the conditions of high temperature, a strongly corrosive environment and the like are not required.

Owner:ZHONGSHAN YONGWEI NEW MATERIAL CO LTD

Sludge treatment system for slurry circulation in drilling engineering

ActiveCN114605048AImprove convenienceSolve the problem of uneven mixingWaste water treatment from quariesSludge treatmentSludgeProcess engineering

The invention discloses a sludge treatment system for slurry circulation in drilling engineering, which comprises a vibrating screen and a settling pond, and an obliquely arranged converging pipe and a vertically arranged comprehensive mixing pipe are sequentially arranged between a sludge outlet of the vibrating screen and the settling pond; the comprehensive mixing pipe is provided with a spraying device capable of spraying a medicament to the sludge and a uniform mixing mechanism capable of uniformly mixing the sludge and the medicament, and the spraying device and the uniform mixing mechanism are jointly controlled by a switch capable of automatically starting and stopping according to the falling condition of the sludge; the confluence pipe, the comprehensive mixing pipe and the spraying device are arranged, chemicals can be synchronously sprayed and added while sludge is conveyed to the sedimentation tank, the uniform mixing mechanism is further arranged, the sludge and the chemicals are further uniformly mixed under the mixing of the uniform mixing mechanism, and compared with the existing mode that a stirring device is directly additionally arranged in the sedimentation tank, the equipment size is reduced, and the equipment cost is reduced. Equipment consumables are saved, no dead angle exists in mixing, the mixing effect is improved, and the purposes of environmental protection and green exploration are achieved.

Owner:SHANDONG PROVINCIAL COAL GEOLOGICAL PLANNING EXPLORATION & RES INST

Preparation method of lithium iron phosphate cathode material

ActiveCN105206835BSolve the problem of high energy consumptionSolve the problem of uneven mixingCell electrodesSecondary cellsPepsin inhibitorRaw material

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

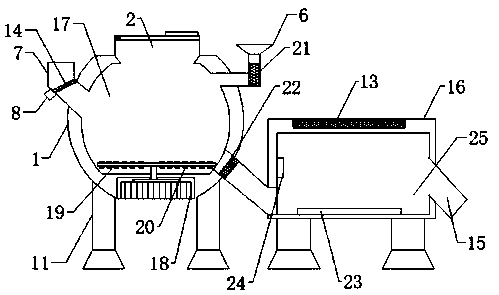

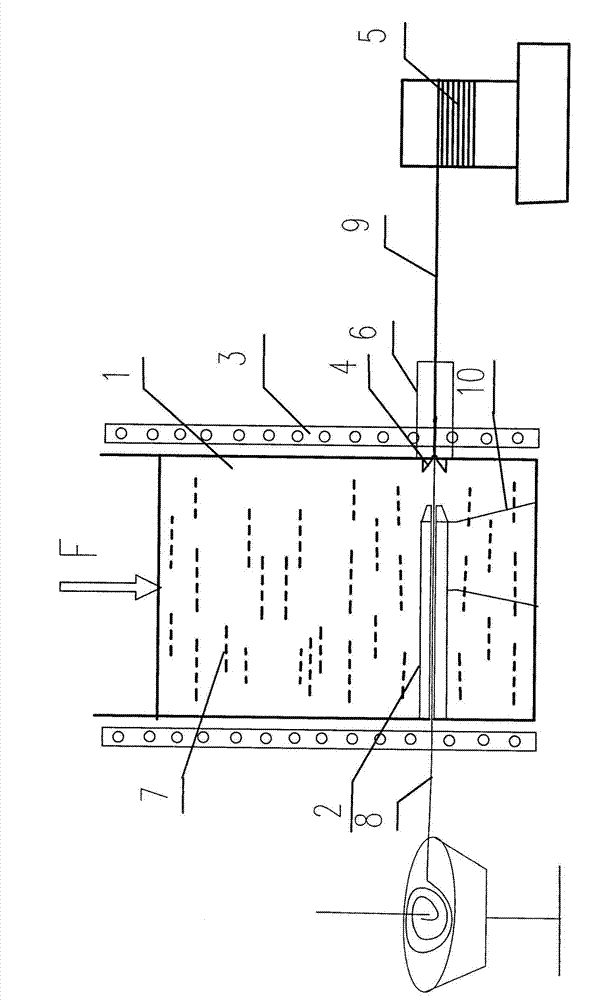

Metering, stirring and mixing device for industrial powder and granules

PendingCN108704517AStable deliveryAvoid easy to accumulate in the bending part of the pipelineRotary stirring mixersTransportation and packagingImpellerEngineering

The invention relates to a metering, stirring and mixing device for industrial powder and granules which solves the problems that the structure is complex, the volume is huge, the power is easily accumulated and cannot be uniformly mixed, and the like in the prior art. The device is characterized by comprising a stander, a powder blanking device, a stirring mixer and a stirring power machine, wherein the powder blanking device comprises a storage container, a discharging device, a first vertical conveying pipe, a horizontal conveying pipe, a second vertical conveying pipe, a vibrator and a blanking controller, the storage container, the first vertical conveying pipe, the horizontal conveying pipe, the second vertical conveying pipe, a vibrator and the stirring mixer are sequentially connected; the discharging device comprises a stirring driver and stirring impellers; the vibrator is connected with the horizontal conveying pipe; the blanking controller comprises a blanking door, a blanking driver and a weight sensor, the blanking door is matched to s blanking hole of the second vertical conveying pipe, and the weight sensor is mounted on the blanking door; and the stirring mixer comprises a horizontal cylinder container and stirring impellers and is further provided with a liquid adder.

Owner:广东信一科技有限公司

Active core silver solder for soldering ceramics and preparation method thereof

InactiveCN102319964BOvercome the shortcomings of single formSolve the problem of uneven mixingWelding/cutting media/materialsSoldering mediaElemental compositionAlloy

The invention relates to an active core silver solder for soldering ceramics and a preparation method thereof, and the active core silver solder comprises two parts, namely a core part and an outer layer, wherein the core part is composed of an active alloy containing active elements and the outer layer is composed of a silver alloy. The active core silver solder comprises the following main components by weight percent: 2-6% of the active alloy comprising three elements, namely Ti, Zr and Hf, wherein the active alloy contains 0.1-5wt% of the Zr, 0-3wt% of the Hr and the balance of the Ti; and 94-98% of the silver alloy comprising the elements of Ag, Cu and Ge, wherein the silver alloy contains 66-72wt% of the Ag, 26-27.9wt% of the Cu and 0.1-8wt% of the Ge. The threadlike active core silver solder can be directly obtained by adopting a method of wrapping an active core at the interior by extrusion through semi-molten metal. Compared with the characteristic of low melting point of thesolder of domestic like products, the preparation process is high in production efficiency and a new way is opened for manufacturing the solder which is difficult to machine and form due to brittle intermetallic compounding.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com