Patents

Literature

101results about How to "Fully compatible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

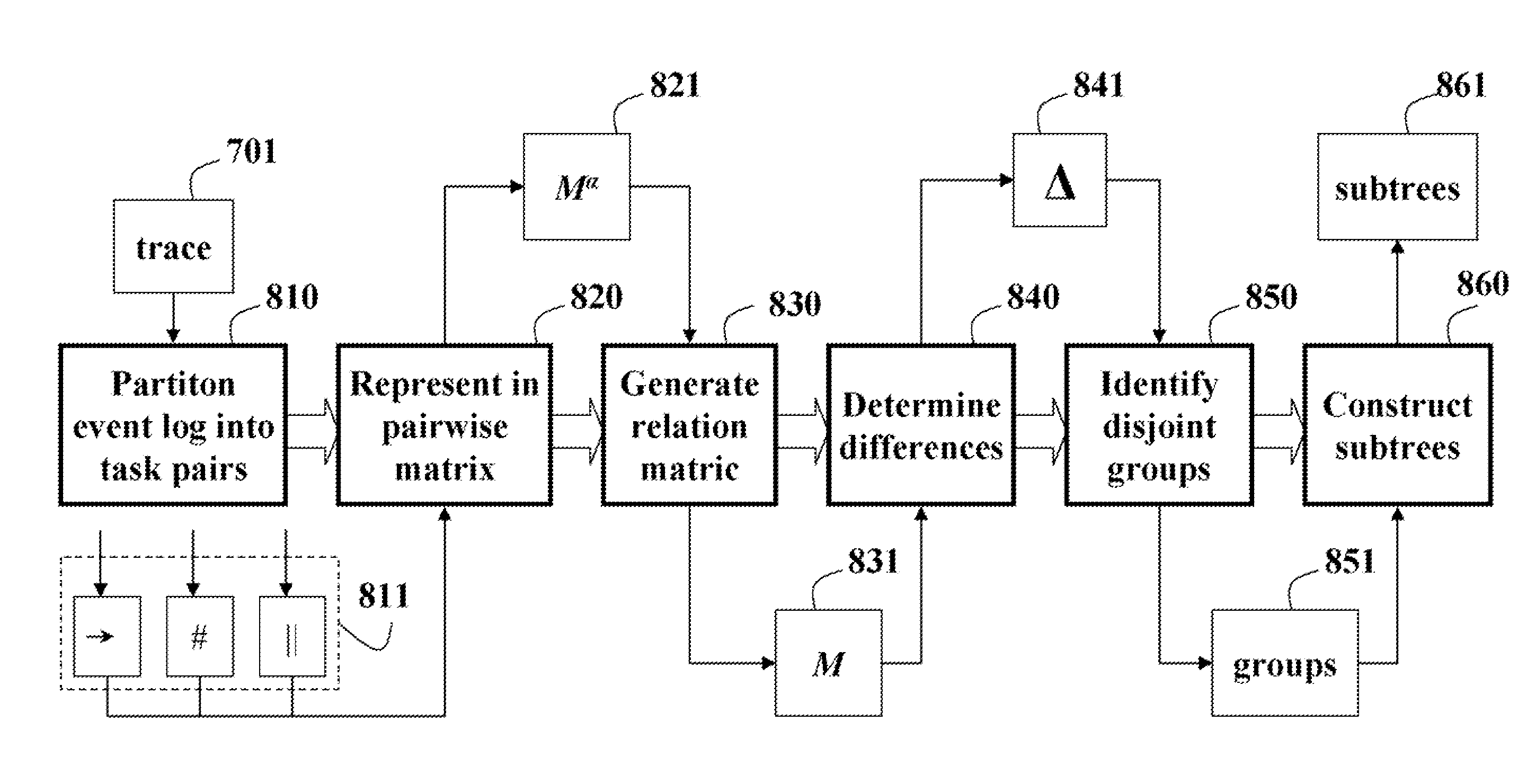

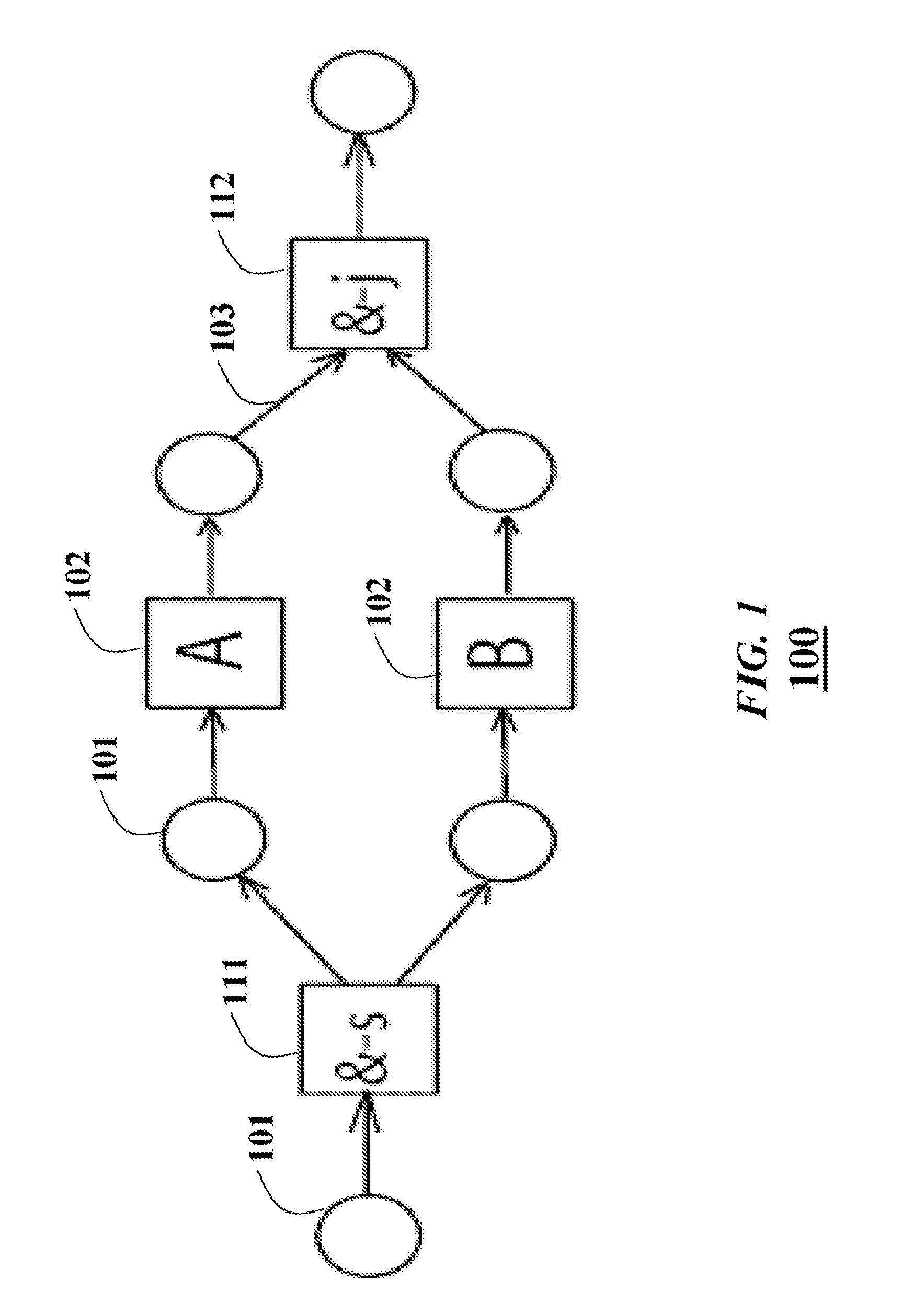

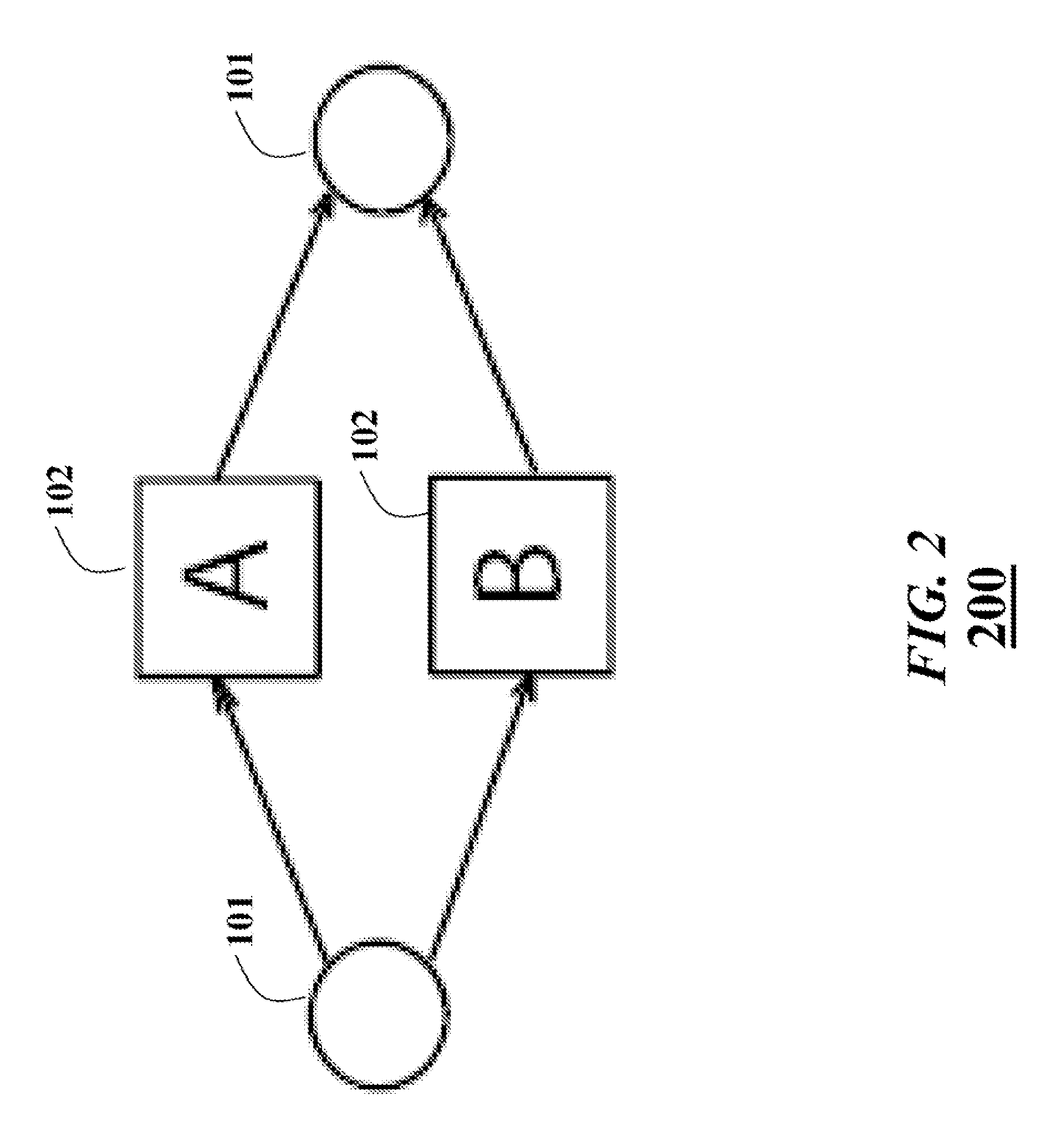

Method for Constructing Business Process Models from Task Execution Traces

InactiveUS20090094074A1Convenient MiningFully compatibleReliability/availability analysisResourcesTheoretical computer scienceBusiness process modeling

A business process is modeled by determining, for each possible pair of tasks in a trace of executions of N tasks corresponding to a business process, whether the tasks in each pair have an identical relation condition with every other task in the trace. A pair of tasks is identified as child task nodes of an associated parent relation node if the identical relation condition is true. A renderable workflow tree is constructed from all identified child task of the associated corresponding parent relation, nodes.

Owner:MITSUBISHI ELECTRIC RES LAB INC

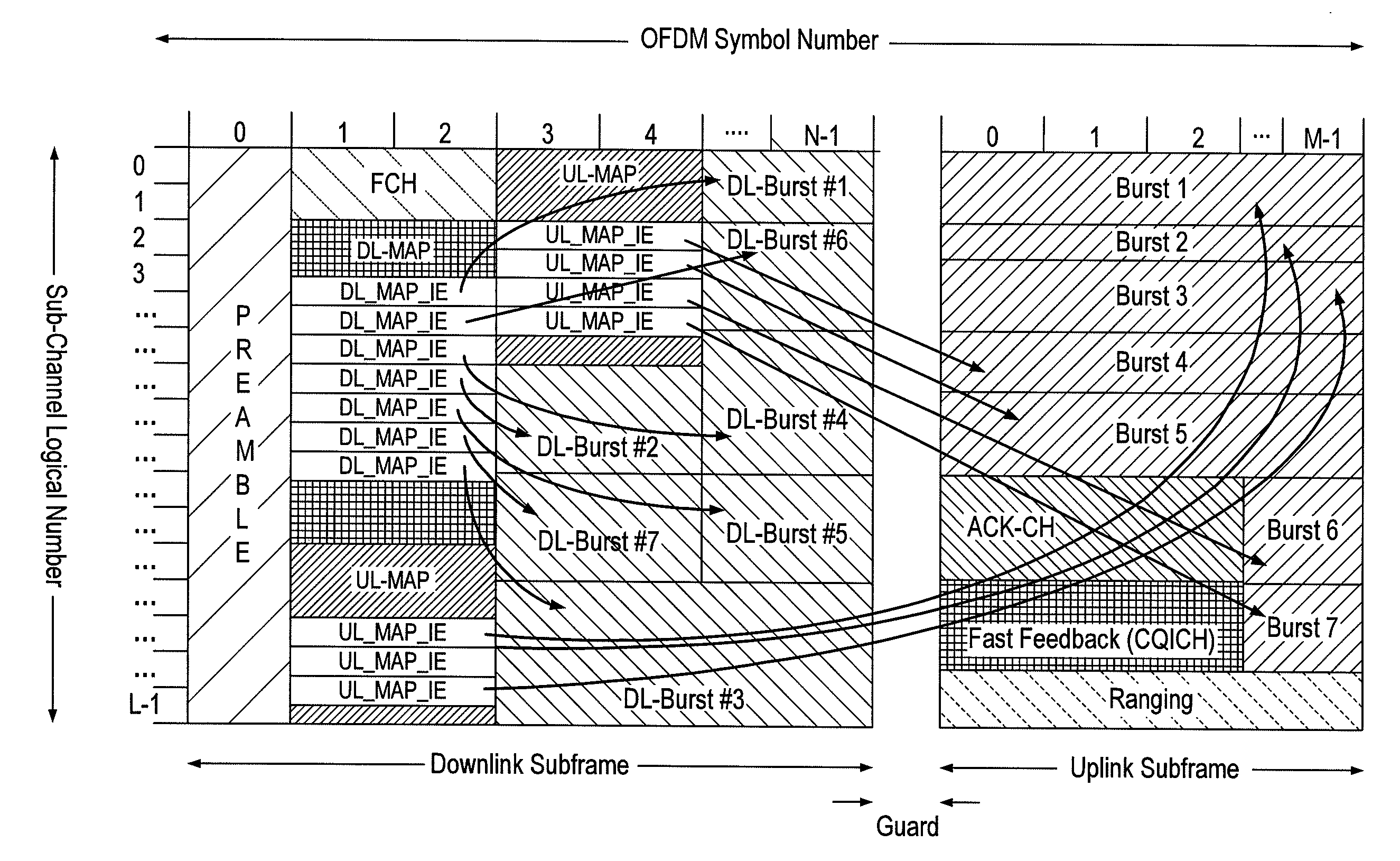

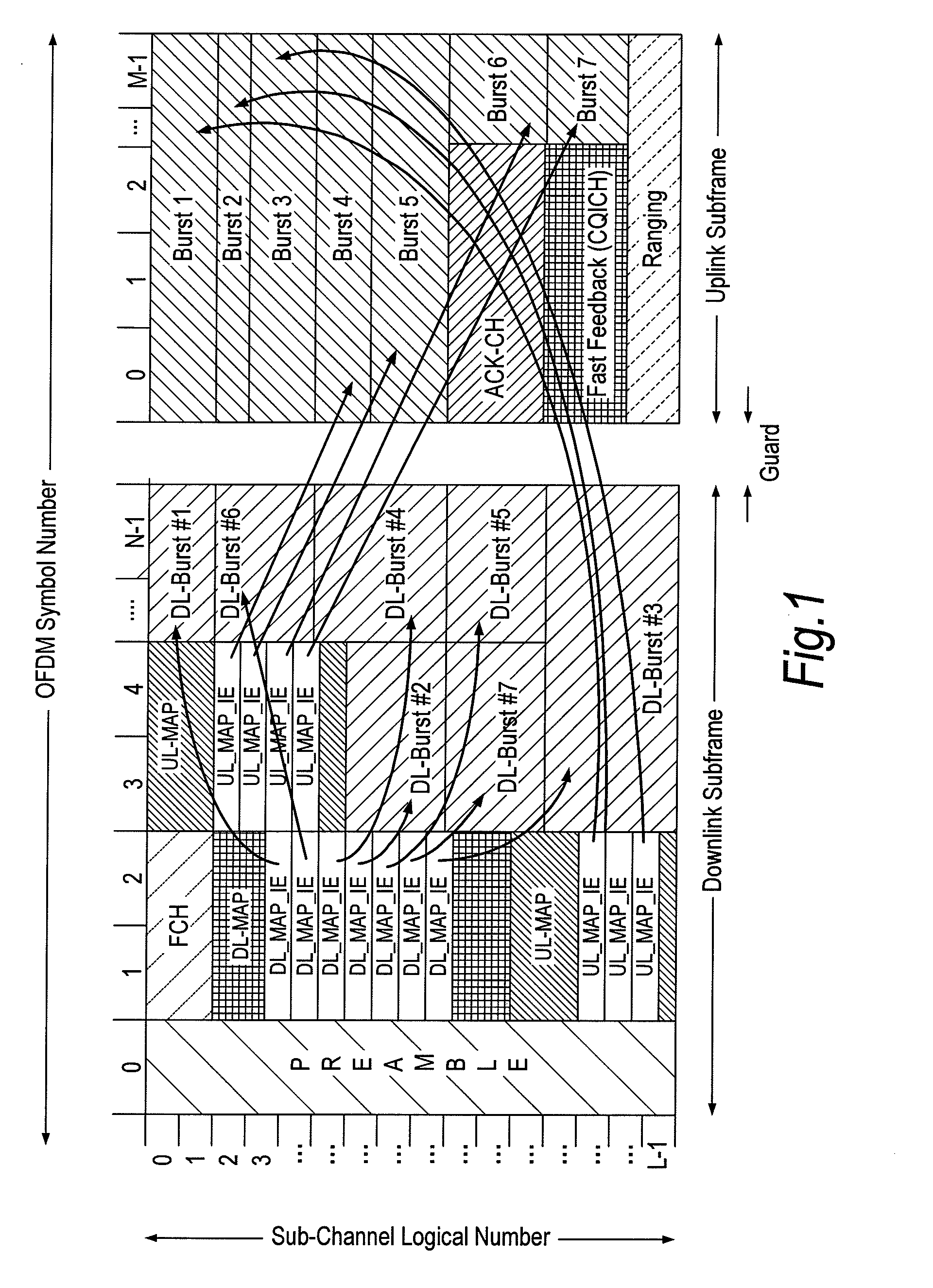

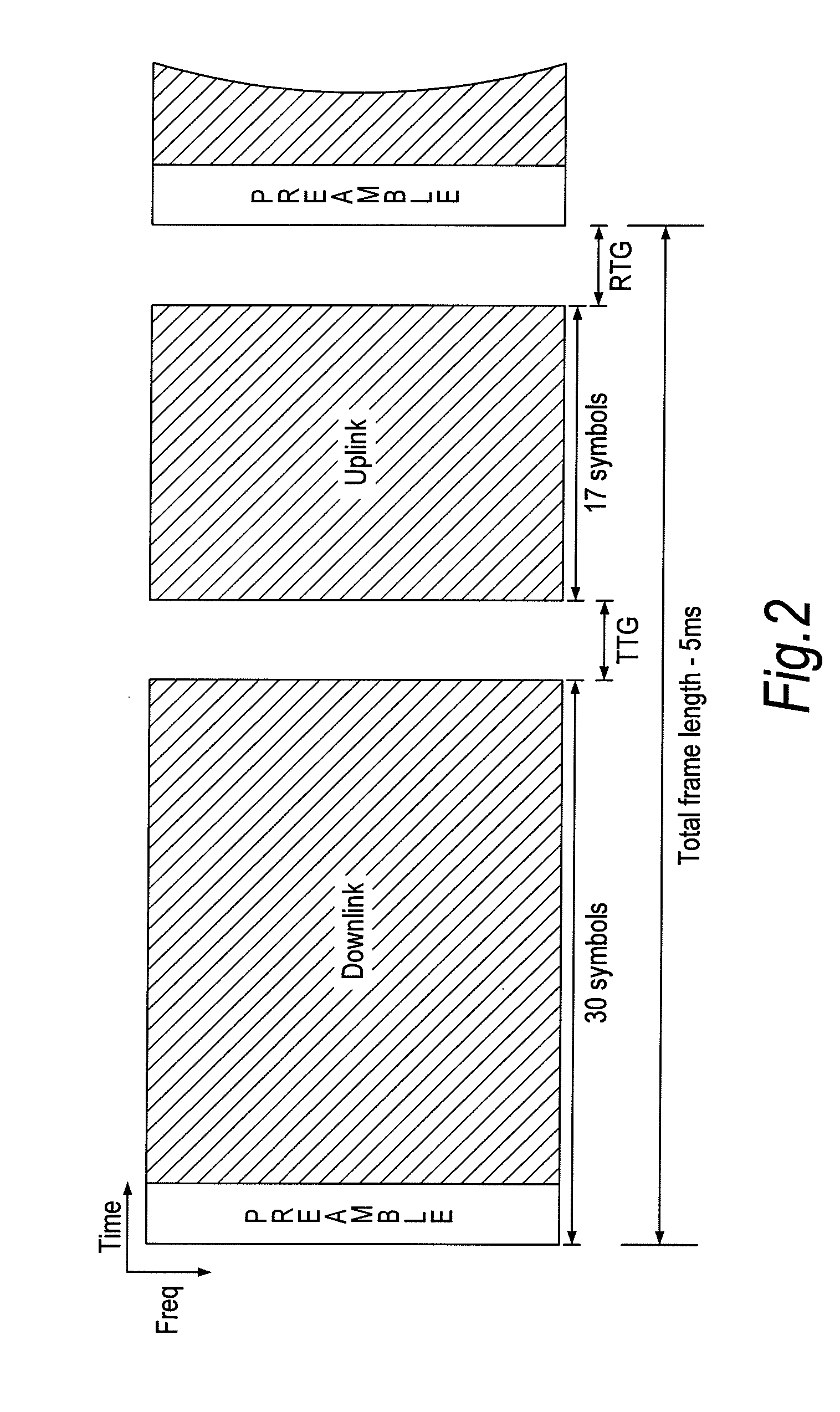

Frame structure for a wireless communication system

ActiveUS20090257366A1Improve latencyFully compatibleTime-division multiplexSecret communicationCommunications systemFeature set

A frame format used in a wireless communication system, more particularly an OFDMA TDD wireless communication system, of the kind comprising a base station and a plurality of fixed or mobile subscriber stations, the base station maintaining connections with each of the subscriber stations by performing wireless communication in units of frames having said frame format, and within each frame, allocating resources for data transmission and signalling.Each frame has a plurality of downlink subframes and a plurality of uplink subframes including, in time order, a first downlink subframe, a first uplink subframe, a final downlink subframe and a final uplink subframe. One or more further downlink subframe / uplink subframe pairs may be interposed between the first and final subframes as desired, and the configuration can be changed dynamically.The frame structure is capable of adapting to a system that is evolving from supporting predominantly legacy terminals to one which will be supporting an increasing number of enhanced terminals. The coexistence of both legacy and enhanced terminals within the proposed frame structure will have minimal impact of the performance of legacy subscriber stations. Depending on the required number of either legacy or enhanced terminals that need to be supported, the base station has the ability to define a frame configuration where the number of subframes per frame is configured based on the feature set of the operational subscriber stations and the mobility requirements of enhanced subscriber stations such that the frame structure at all times retains sufficient features to support the attachment of legacy stations that do not support the enhanced features.

Owner:FUJITSU LTD

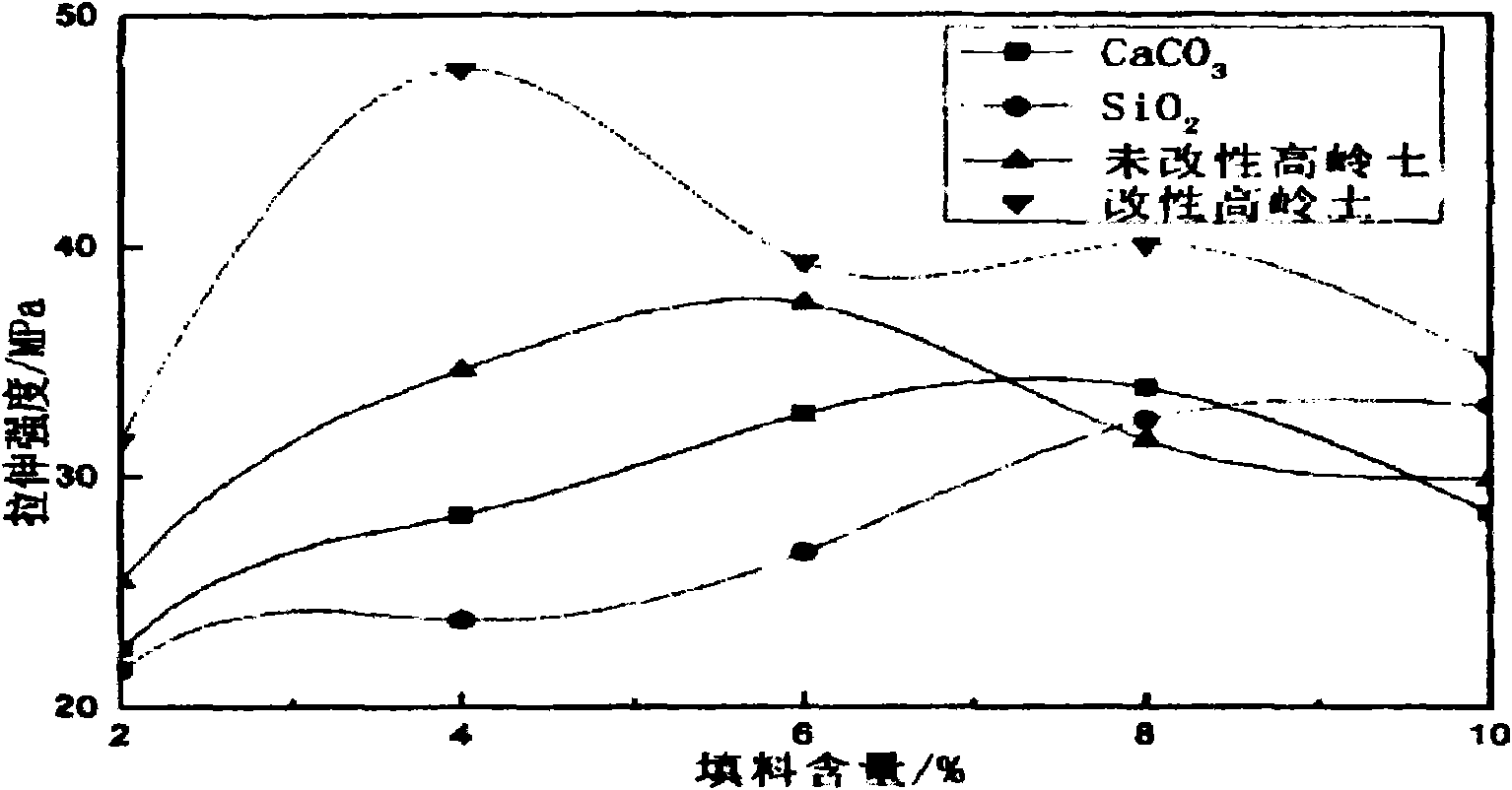

Preparation process, product and application of new plastic

ActiveCN101982495AImprove thermal stabilityImprove toughnessInsulated cablesInsulated conductorsTemperature controlHigh resistance

The invention provides a process for preparing a new plastic, which comprises the following steps: (1) preparing raw materials; (2) weighing and proportioning the raw materials; (3) mixing PVC powder, stabilizers, packing, plasticizers and other additives, then carrying out high-speed kneading on the obtained mixture, and preplasticizing the mixture so as to obtain a pre-plasticized mixture; (4) mixing the pre-plasticized mixture with TPU particles, carrying out banbury mixing on the obtained mixture under the condition of gradient temperature control so as to obtain colloidal products; (5) carrying out double-screw granulation on the obtained colloidal products; and (6) carrying out sorting, dehydration and packing on the granular products obtained in step 5 so as to obtain the new plastic. The process is simple, the conditions of the process are easy to control, and the process is suitable for large-scale production. The invention also provides a new plastic, which has the characteristics of high resistance to wear and scrape, high elasticity, easy recovery, high flame retardance, ultraviolet resistance, freezing damage (caused by low temperature in the north) resistance, environmental protection, soft handfeel and stick resistance, and the like; and the new plastic can be applicable to wire and cable compound.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

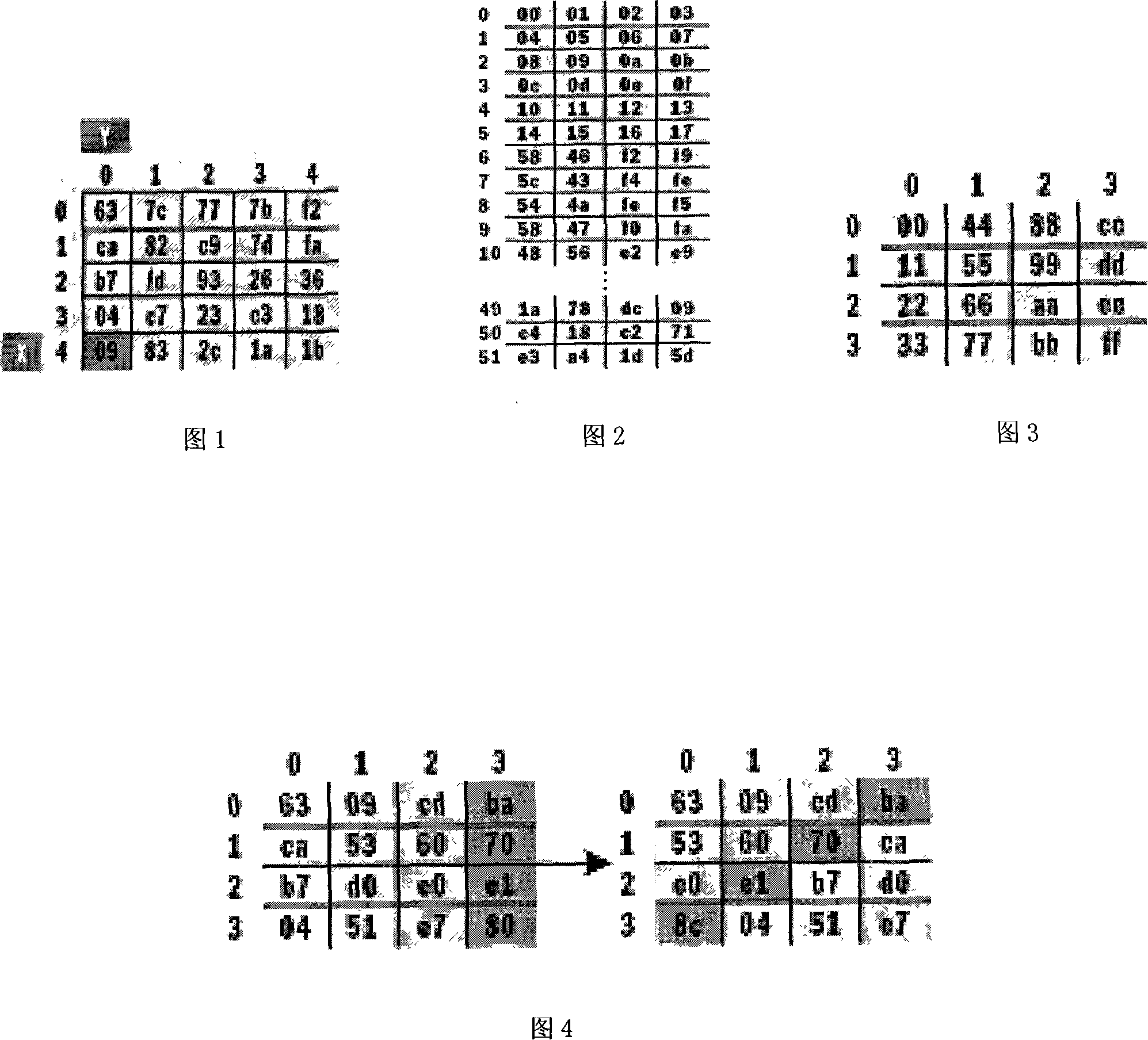

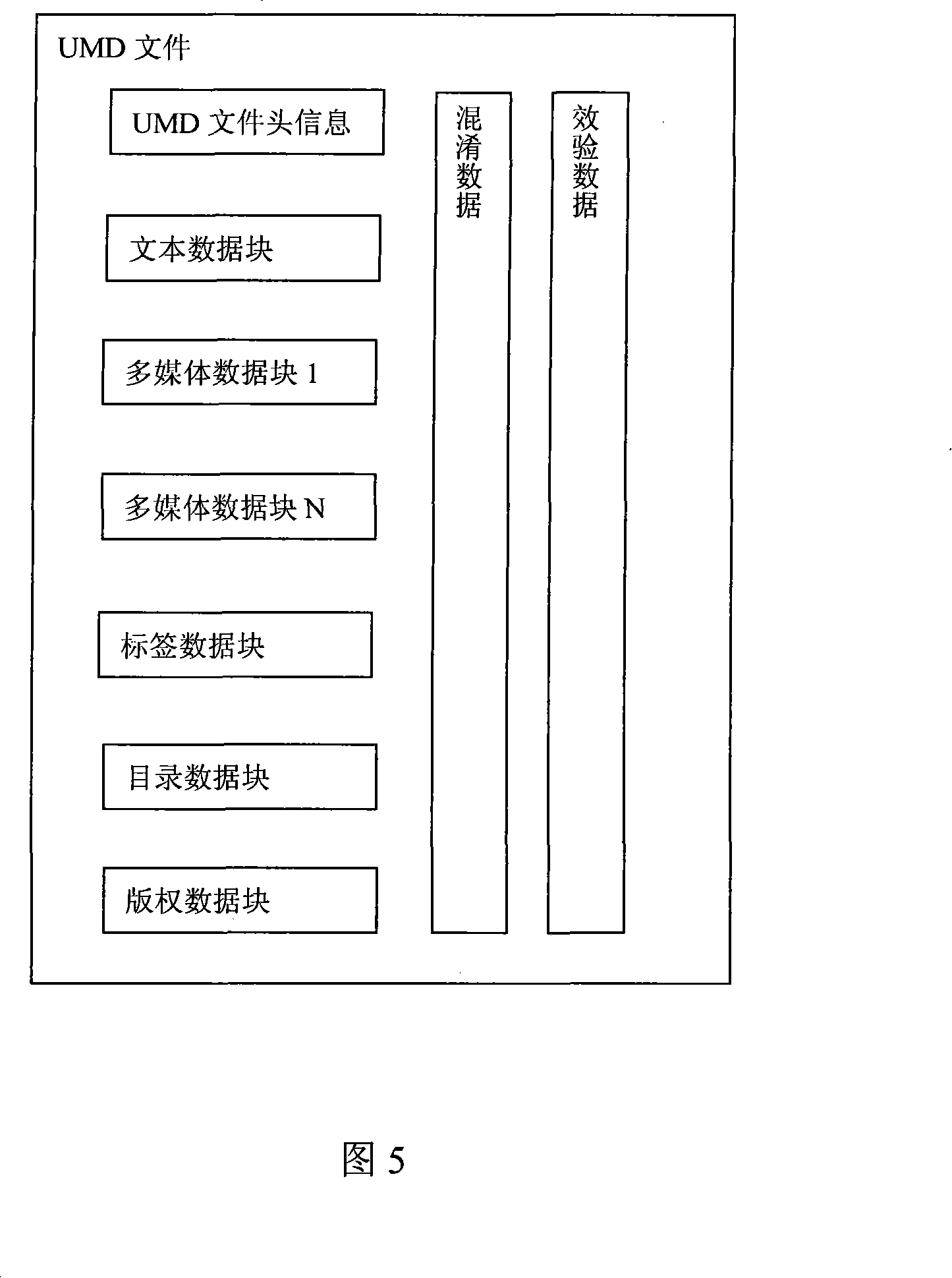

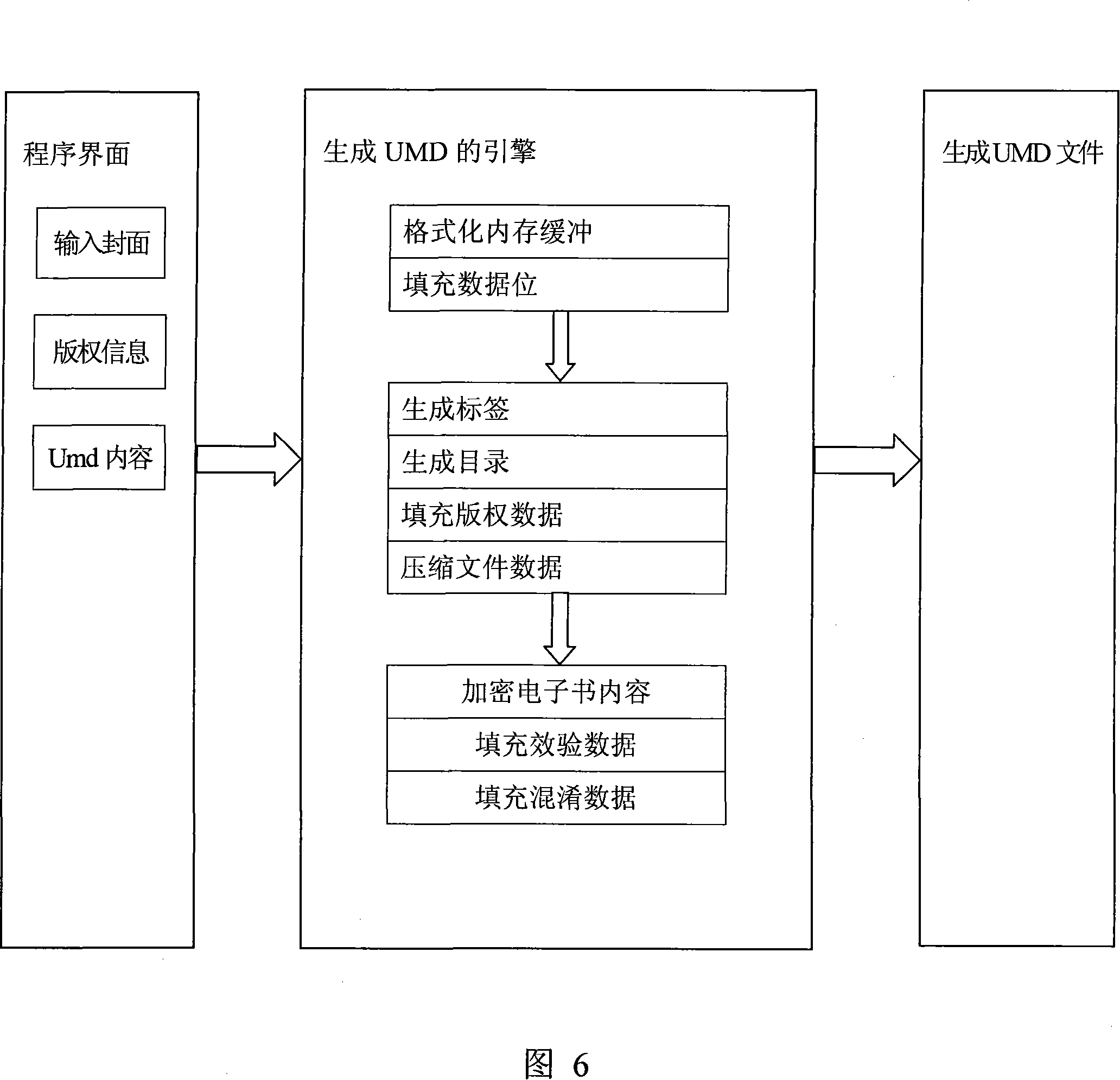

Mobile terminal apparatus electronic file memory structure and management techniques

InactiveCN101183374AEasy to receiveIncrease salesProgram/content distribution protectionSpecial data processing applicationsExtensibilityOriginal data

The invention discloses an electronic file storage structure of mobile terminal equipment and a management method, belonging to a field for wireless mode management file of mobile terminal equipment. Currently file managing and storing mode of computers are not suitable for mobile terminal equipment and not compatible. So the invention adopts a series of software and hardware technology, converts through material format, fills memory area block, fills data bits, produces catalogue and label, fills copyright data, compresses file data and encrypts electronic content before encrypted target file UMD file comprising original data, index structure and copyright information compression is finally generated; the file is copied to the mobile terminal and edit interface is arranged at terminal of users. The invention has the advantages of simple structure, less operative steps, high compatibility, flexibility, safety and expansibility.

Owner:三亚红树林投资合伙企业(有限合伙)

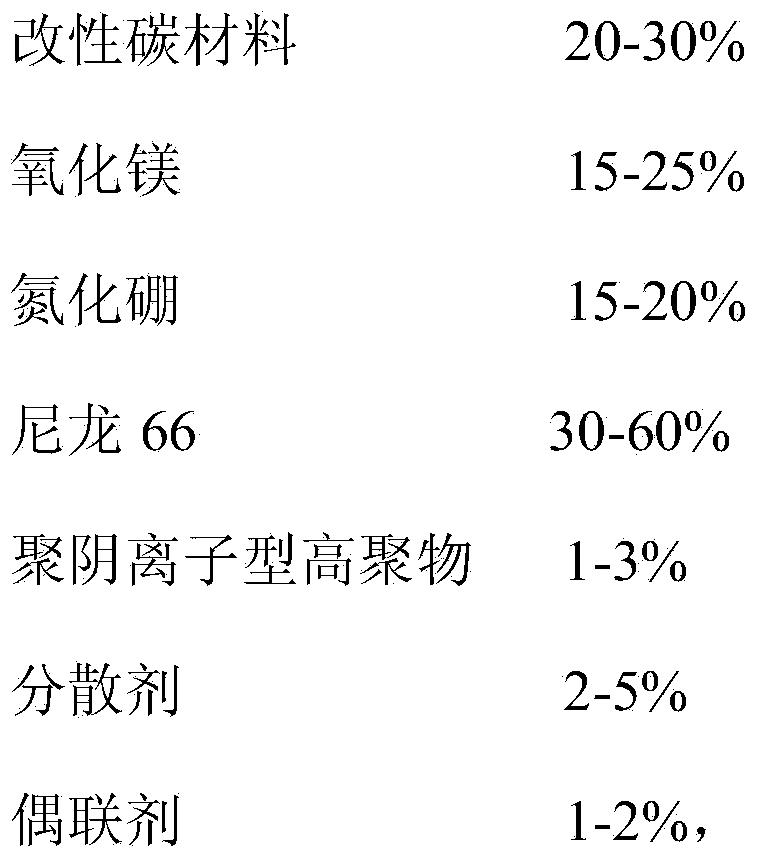

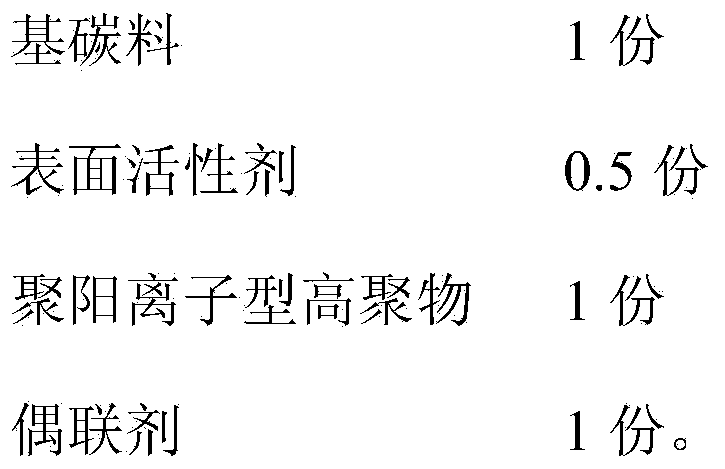

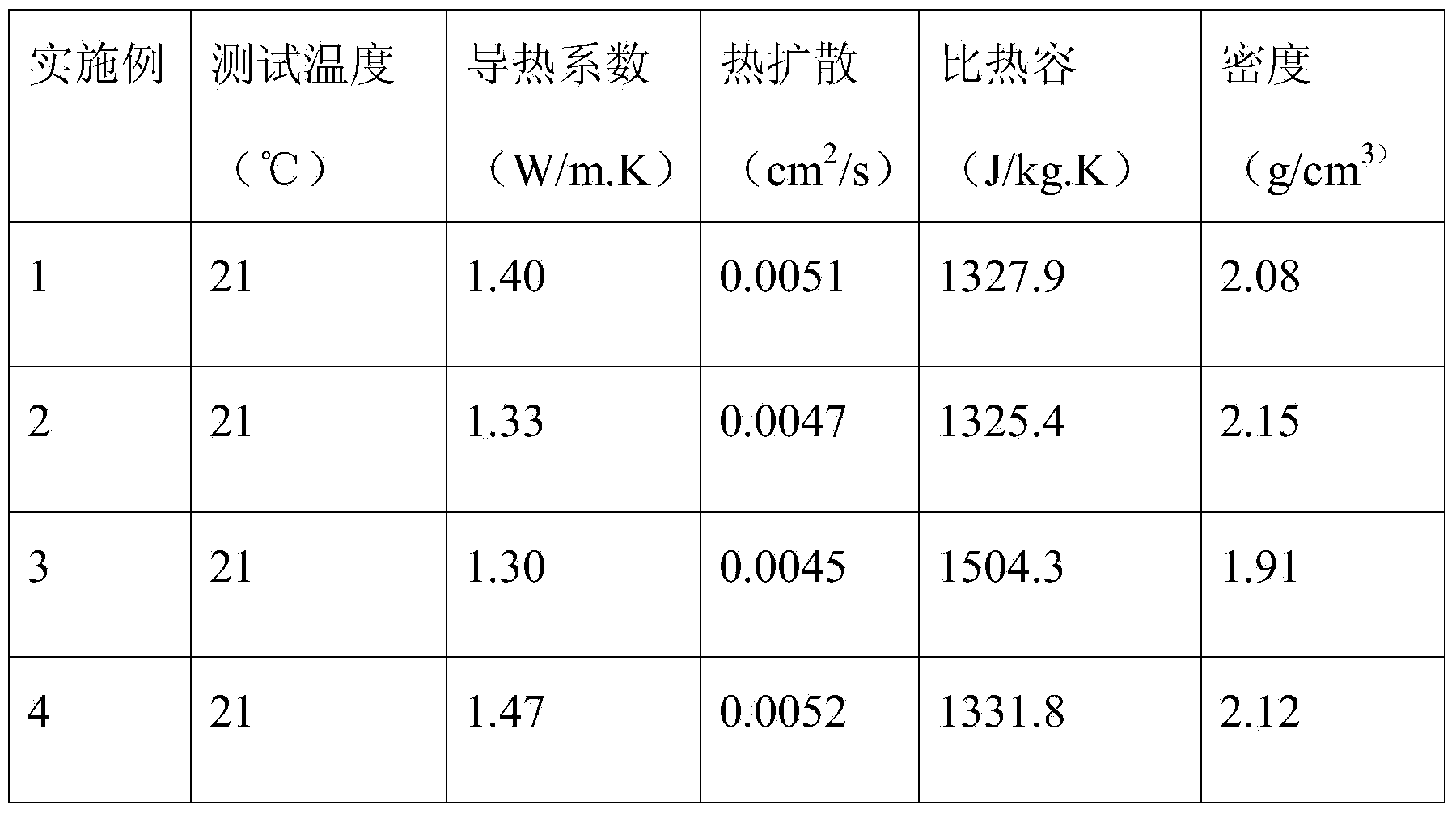

Thermal conductive plastic applying modified carbon material, and preparation method thereof

The invention discloses thermal conductive plastic applying a modified carbon material, and a preparation method thereof. The thermal conductive plastic comprises the following components in percentage by mass: the modified carbon material, magnesium oxide, boron nitride, nylon 66, a polyanionic type high polymer, a dispersing agent, and a couplant, wherein the modified carbon material comprises the following components in parts by weight: a base carbon material, a surfactant, a polycationic type high polymer, and a couplant; the modified carbon material is prepared by the steps of: mixing water, the base carbon material, sodium chloride, the surfactant and the couplant according to a proportion and then performing ultrasonic treatment, slowly adding the polycationic type high polymer during the ultrasonic process, continuously performing ultrasonic treatment and then stirring for 20-24h, filtering and drying. According to the thermal conductive plastic applying the modified carbon material, and the preparation method thereof, the problem that the materials inside the plastic are mixed unevenly can be effectively solved, and the compatibility of the carbon material can be improved greatly; the dispersity of the whole material mixture can be enhanced, and plugging is difficult in the extrusion process; the synthetic technology is simple, and the conditions of high temperature, a strongly corrosive environment and the like are not required.

Owner:ZHONGSHAN YONGWEI NEW MATERIAL CO LTD

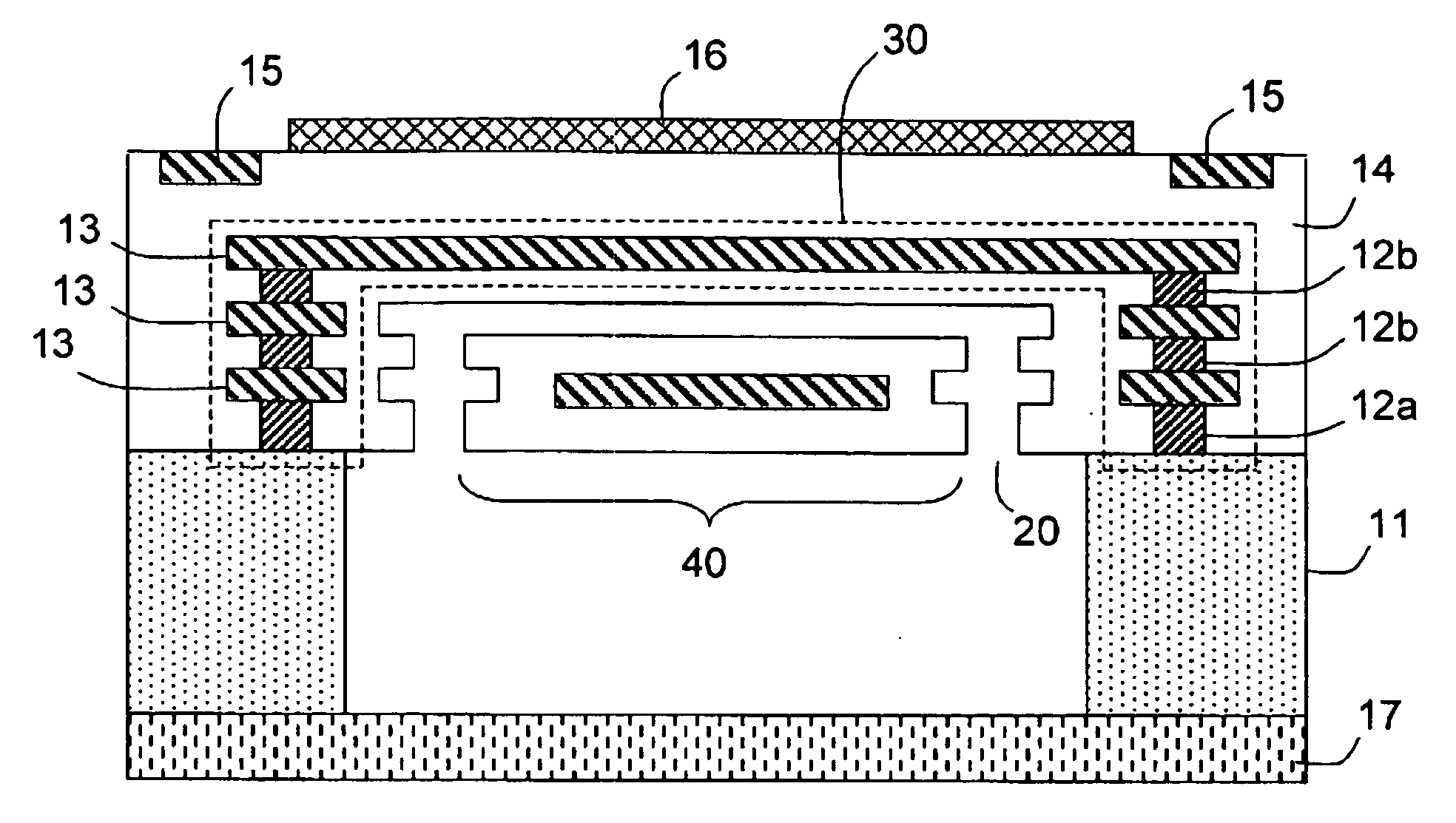

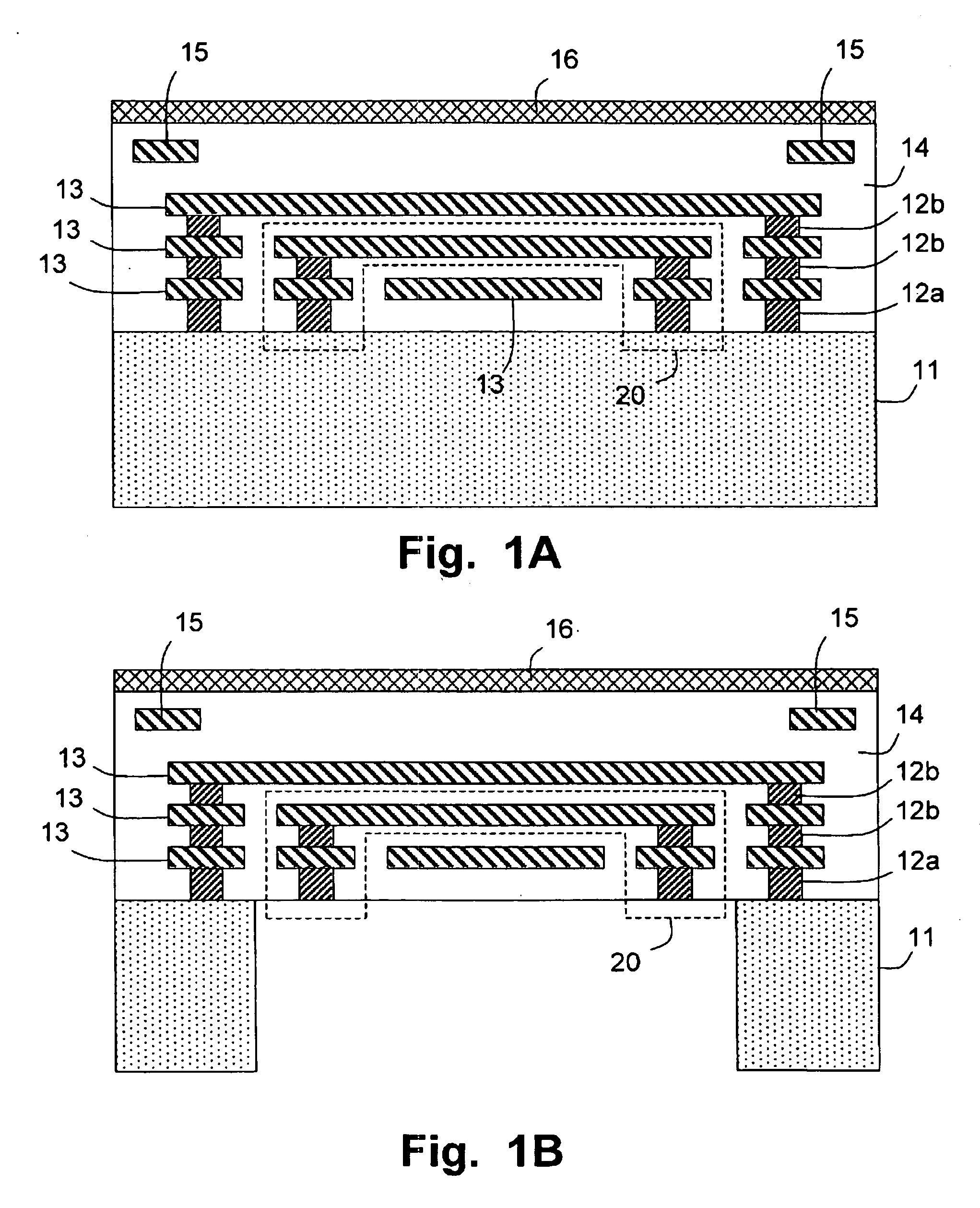

Micro-electro-mechanical-system sensor and method for making same

ActiveUS20100213557A1Fully compatibleAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingEngineeringMems sensors

The present invention discloses an MEMS sensor and a method for making the MEMS sensor. The MEMS sensor according to the present invention comprises: a substrate including an opening; a suspended structure located above the opening; and an upper structure, a portion of which is at least partially separated from a portion of the suspended structure; wherein the suspended structure and the upper structure are separated from each other by a step including metal etch.

Owner:PIXART IMAGING INC

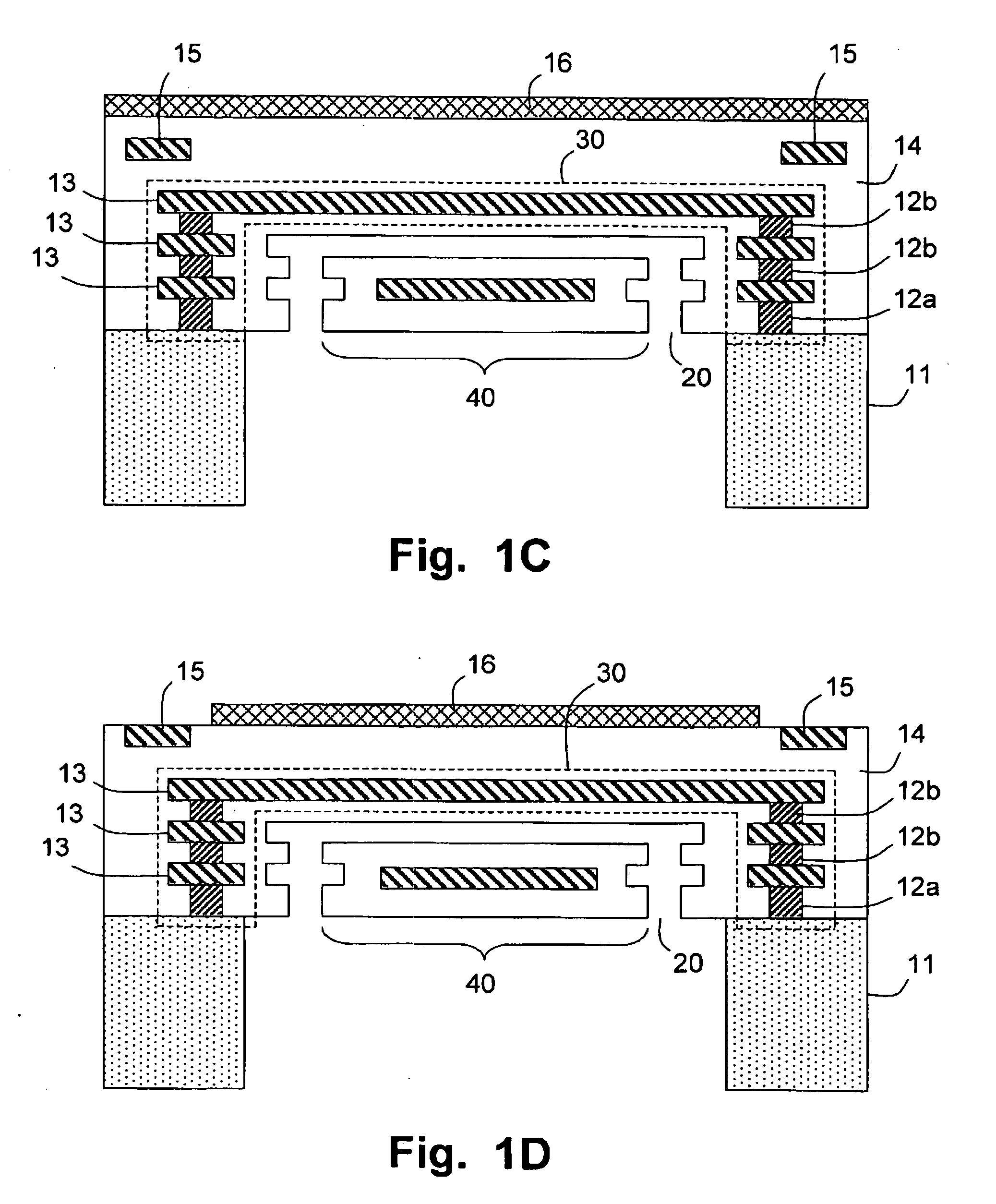

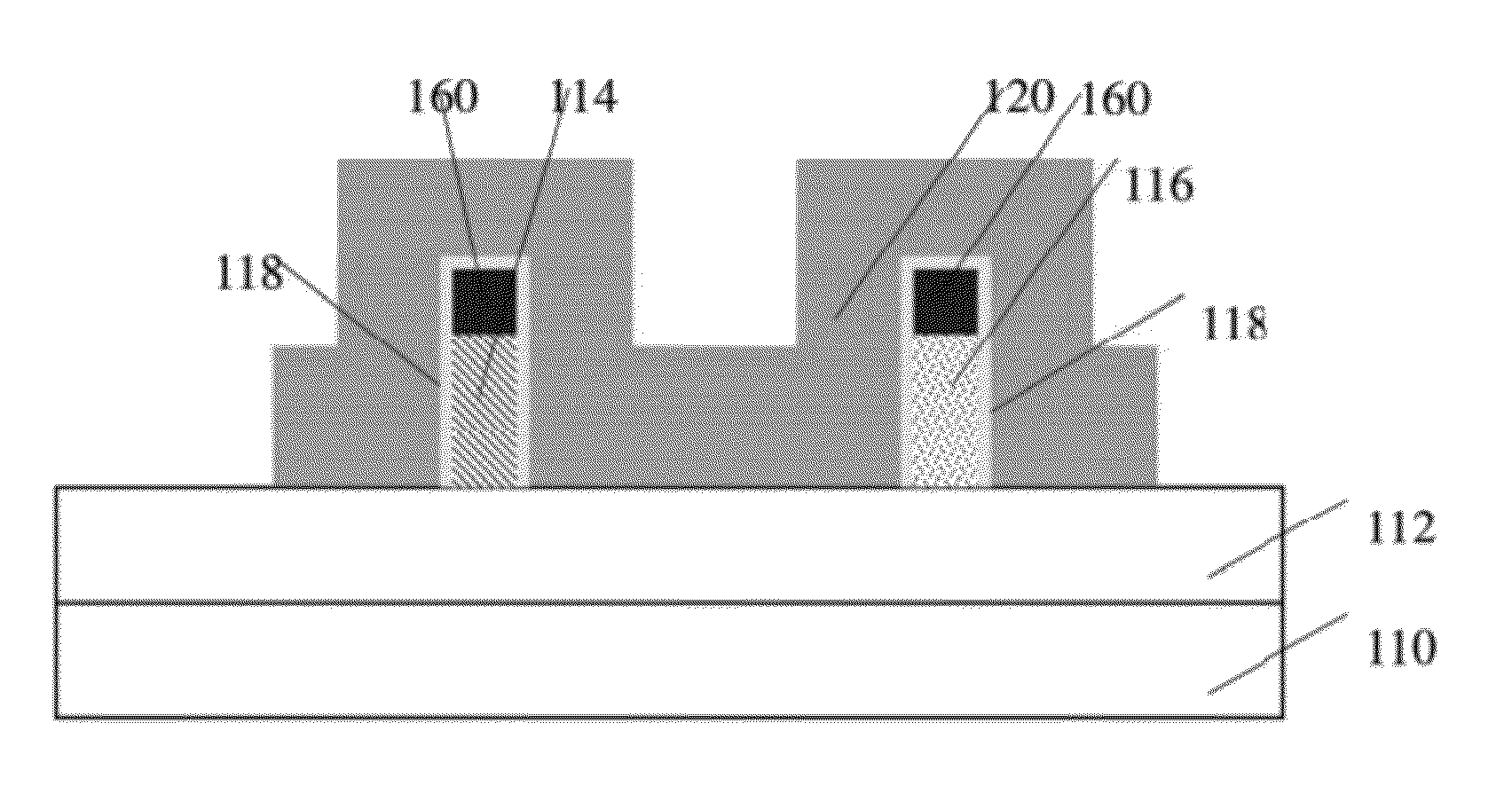

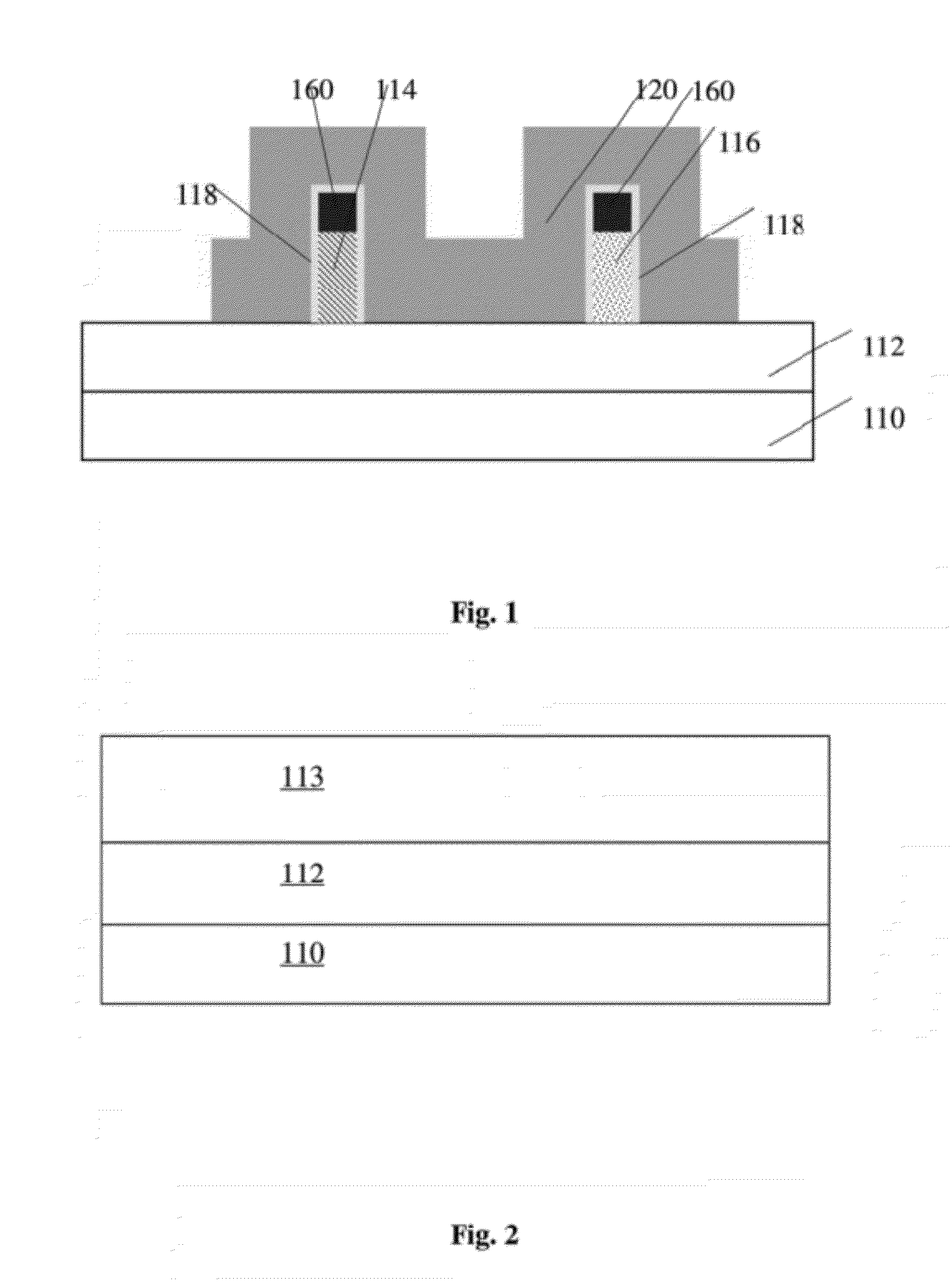

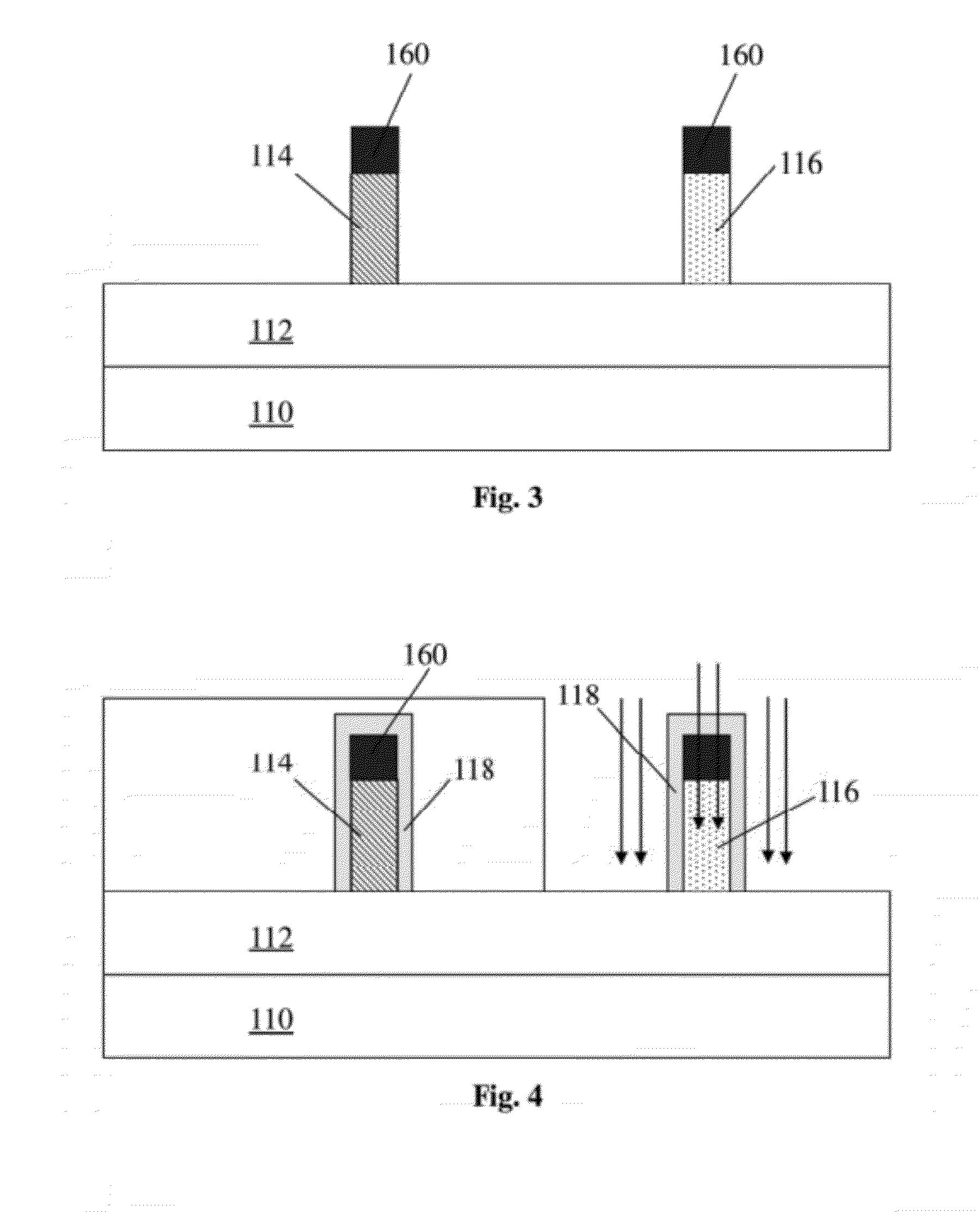

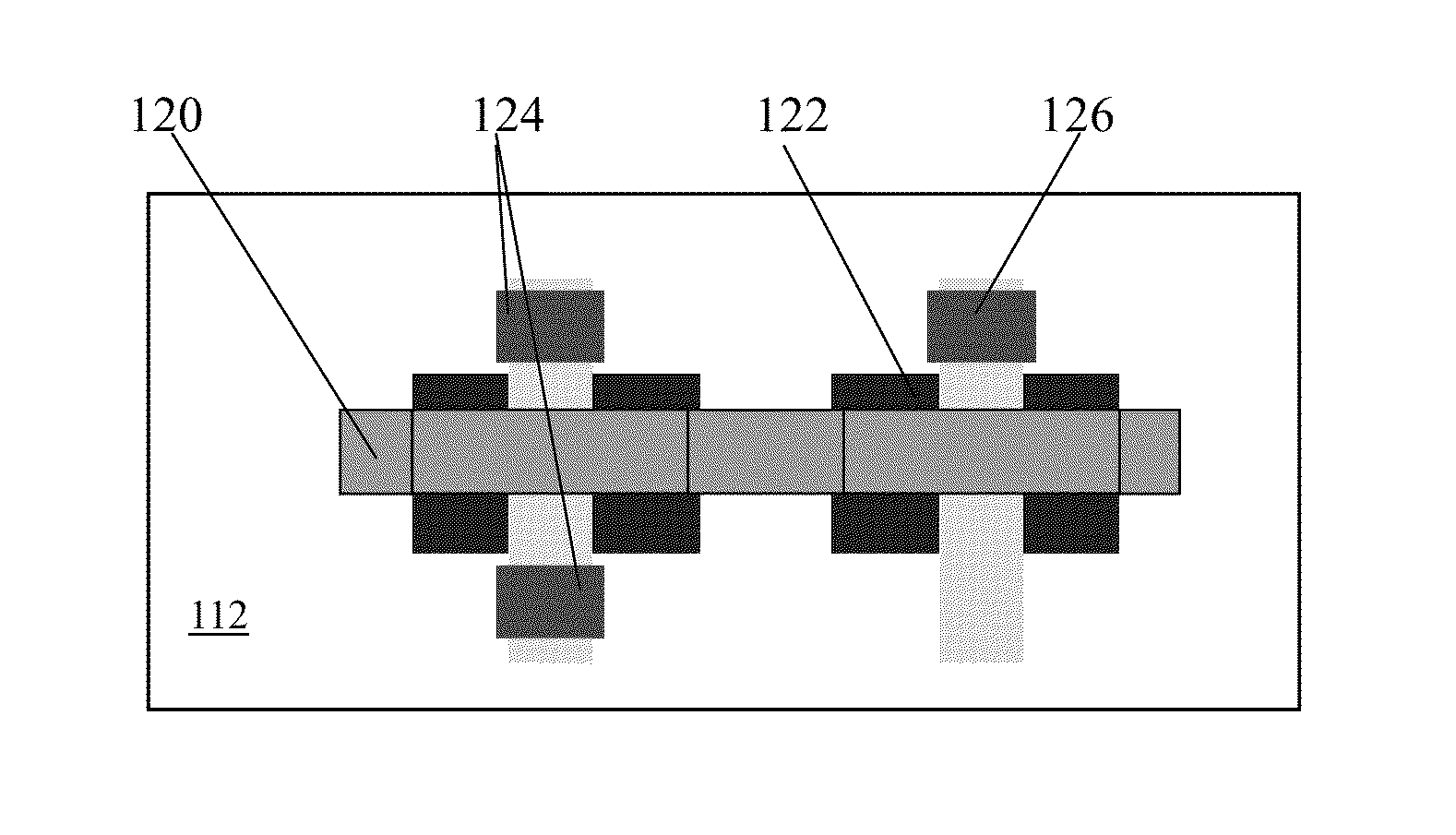

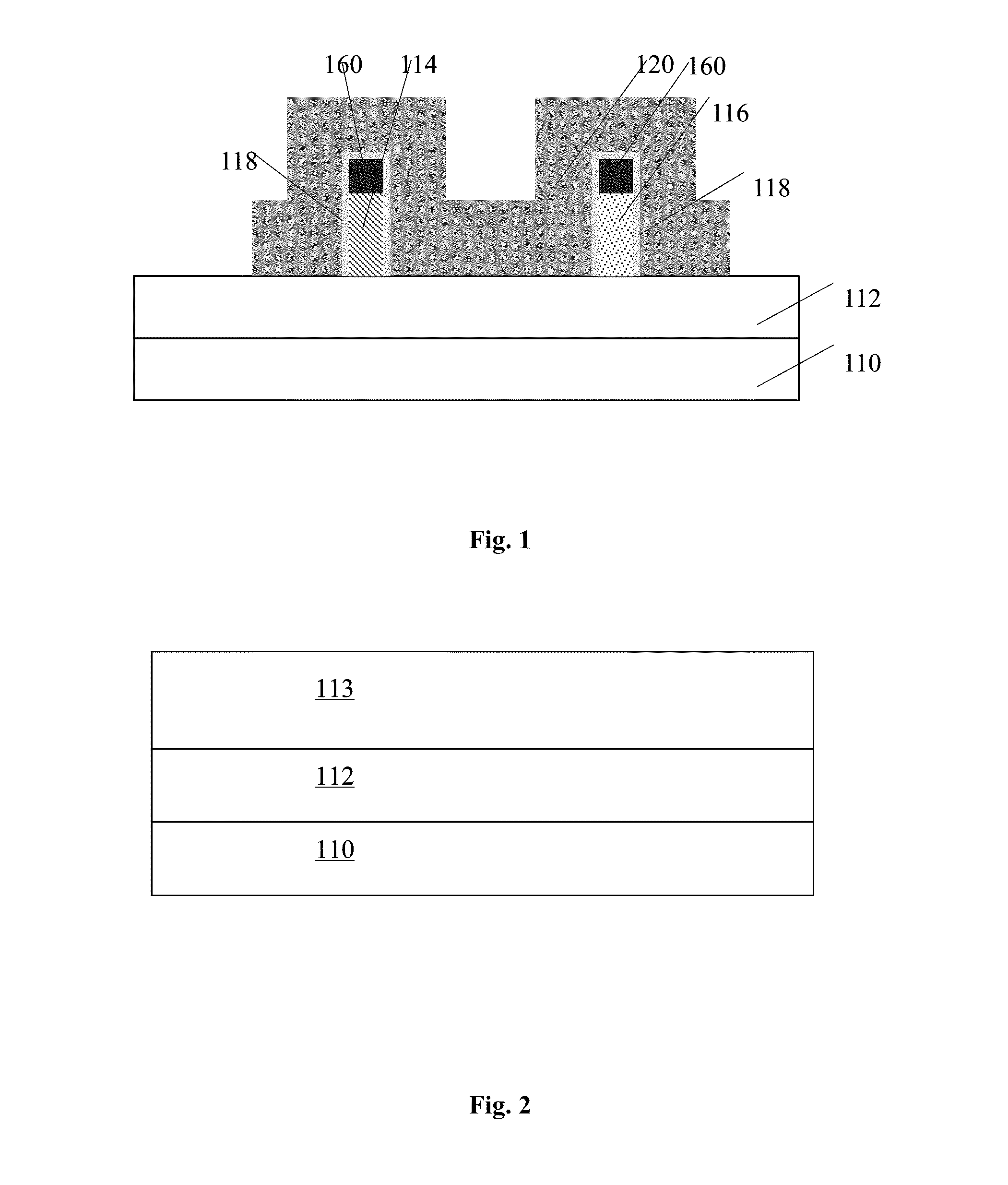

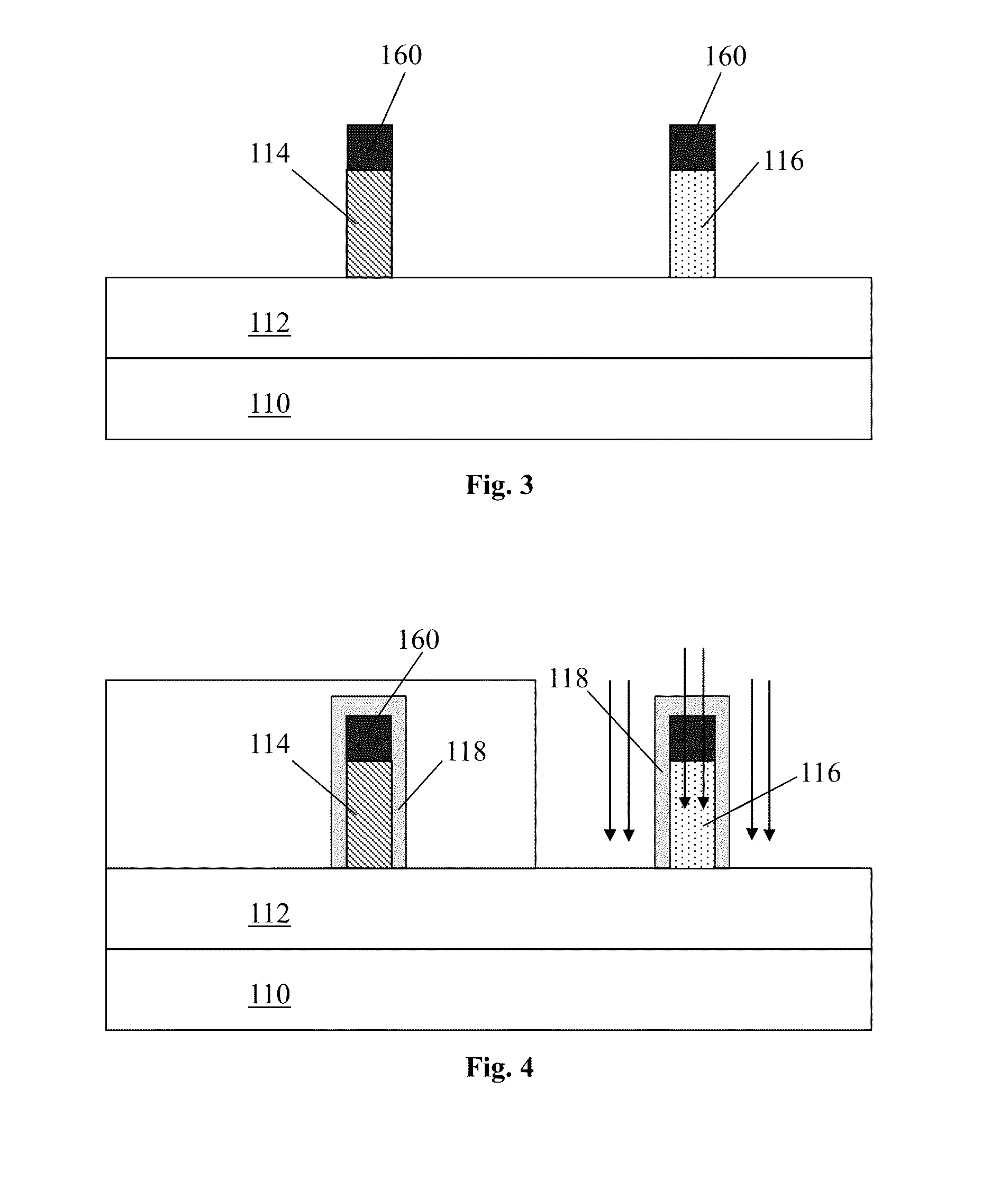

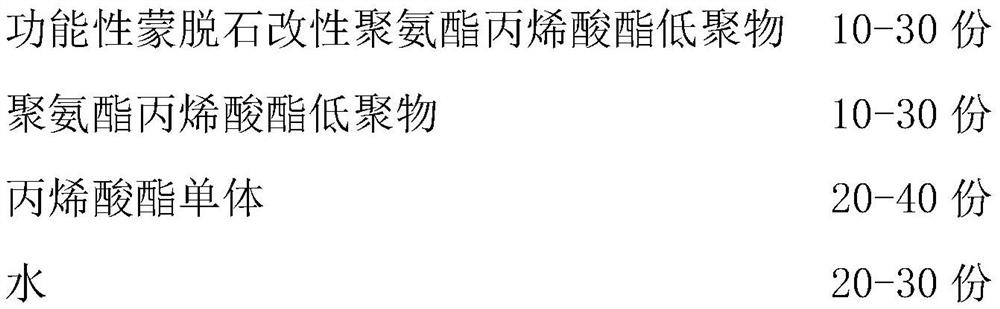

Flash memory device and method for manufacturing the same

ActiveUS20120112261A1Reduce manufacturing costComplete compatibilityTransistorSolid-state devicesGate dielectricEngineering

The present invention provides a FinFET flash memory device and the method for manufacturing the same. The flash memory device is on an insulating layer, comprising: a first fin and a second fin, wherein the second fin is a control gate of the device; a gate dielectric layer, at side walls and top of the first fin and the second fin; source / drain regions, inside the first fin at both sides of a floating gate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

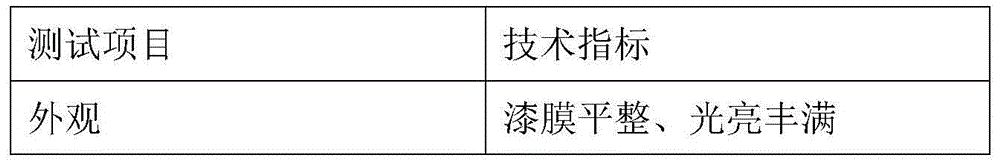

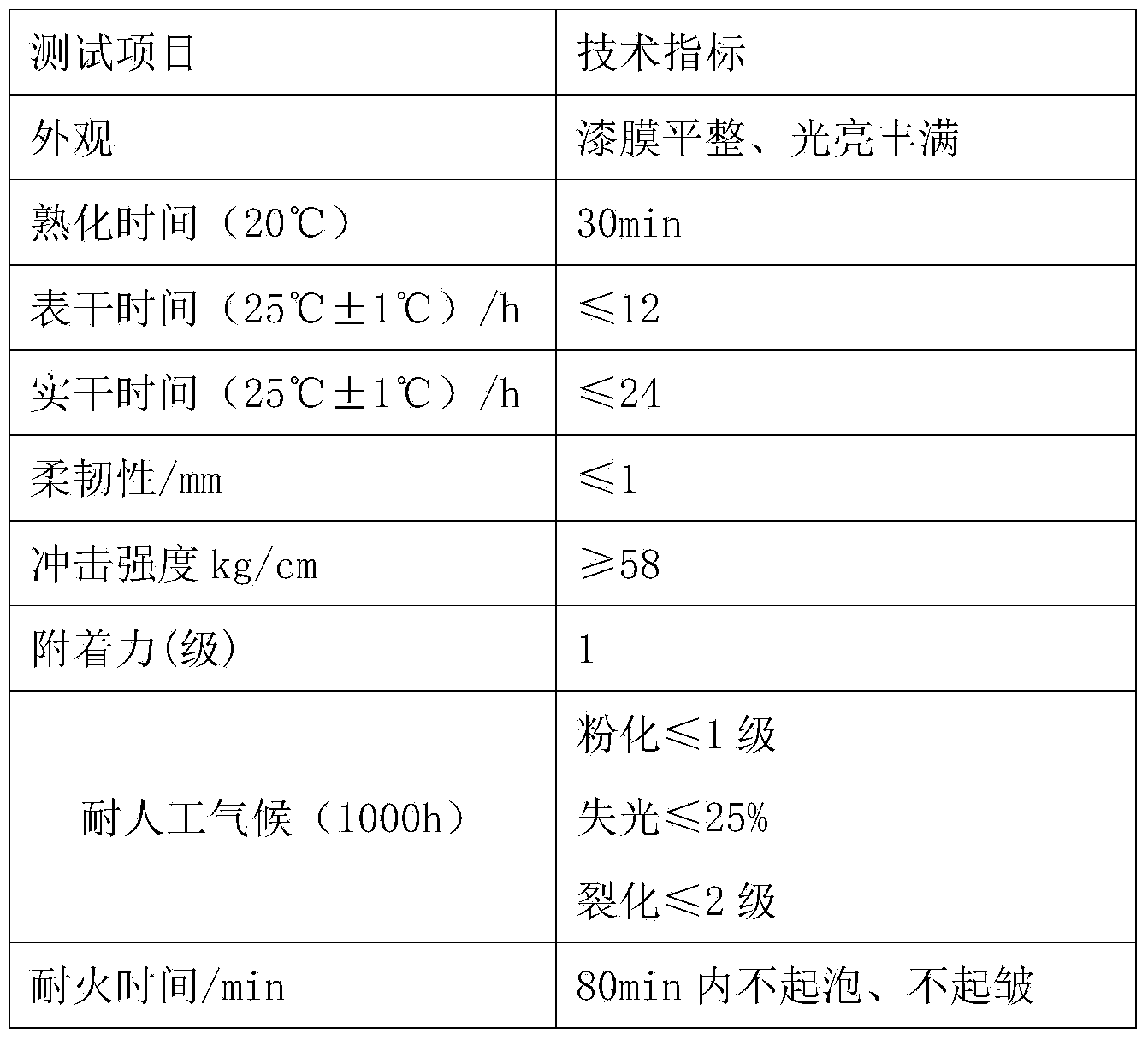

Ultraviolet-aging-resistant antirust epoxy finish paint and preparation method thereof

InactiveCN104356862AImprove UV aging resistanceUniform and stable performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyUltraviolet

The invention relates to an antirust paint, particularly an ultraviolet-aging-resistant antirust epoxy finish paint and a preparation method thereof. The paint is prepared from the following raw materials in parts by weight: 40-50 parts of epoxy resin, 22-28 parts of polyamide resin, 3-4 parts of ferrocene, 1-3 parts of castor oil polyethenoxy ether, 2-3 parts of polyoxy alkylidene diamine, 1-2 parts of dihydroxy methylbutyric acid, 8-10 parts of nano titanium dioxide, 4-6 parts of hydrogenated rosin, 20-25 parts of butyl acetate, 12-15 parts of n-butanol, 18-25 parts of antirust pigment and 2-3 parts of assistant. The paint raw materials contain the modified ferrocene and nano titanium dioxide powder, so that the combining capacity with the resin slurry can be enhanced, and the ultraviolet aging resistance of the epoxy resin is greatly improved. The raw materials of the epoxy finish paint are combined more sufficiently; the epoxy finish paint has excellent mechanical properties after being completely cured; and the epoxy finish paint has higher outdoor service performance and higher durability, and is suitable to be used as a matched finish paint for various high-performance special-type antirust primers, epoxy zinc-rich paints and epoxy micaceous iron antirust paints.

Owner:合肥宏图彩印有限公司

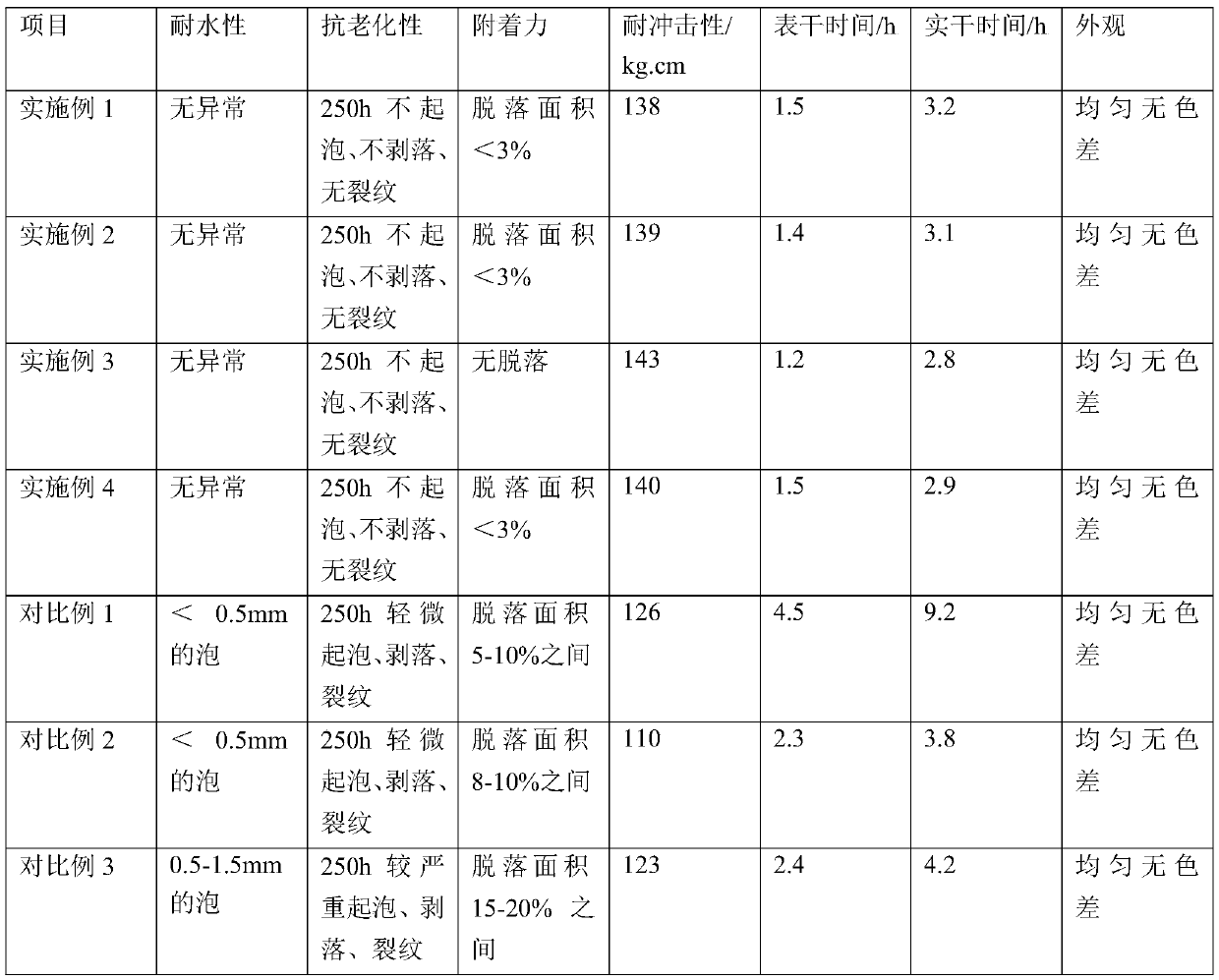

Thermal insulation coating with high adhesive force and impact resistance

ActiveCN104312335AGood dispersionEasy to spreadConjugated diene hydrocarbon coatingsAcrylic resinThermal insulation

The invention discloses a thermal insulation coating with high adhesive force and impact resistance. The thermal insulation coating is prepared from the following raw materials in parts by weight: 50-55 parts of acrylic resin, 22-26 parts of nitrile rubber 2707, 18-21 parts of phenolic resin, 1.1-1.4 parts of antioxidant 4010 NA, 23-26 parts of modified graphene, 10-13 parts of talcum powder, 8-11 parts of calcined kaolin, 3-6 parts of cenosphere, 1.1-1.5 parts of silane coupling agent KH-560, 1.4-1.8 parts of a film-forming agent, 2.2-2.5 parts of a dispersant, 1.6-1.9 parts of a defoaming agent, 1-1.5 parts of a thickening agent, 1.8-2.1 parts of a wetting agent, 1.6-2 parts of a flatting agent, 0.3-0.6 part of a preservative, 0.2-0.5 part of a mould inhibitor, and 58-62 parts of a solvent. The thermal insulation coating disclosed by the invention is high in adhesive force and good in impact resistance.

Owner:广州市哲铭油墨涂料有限公司

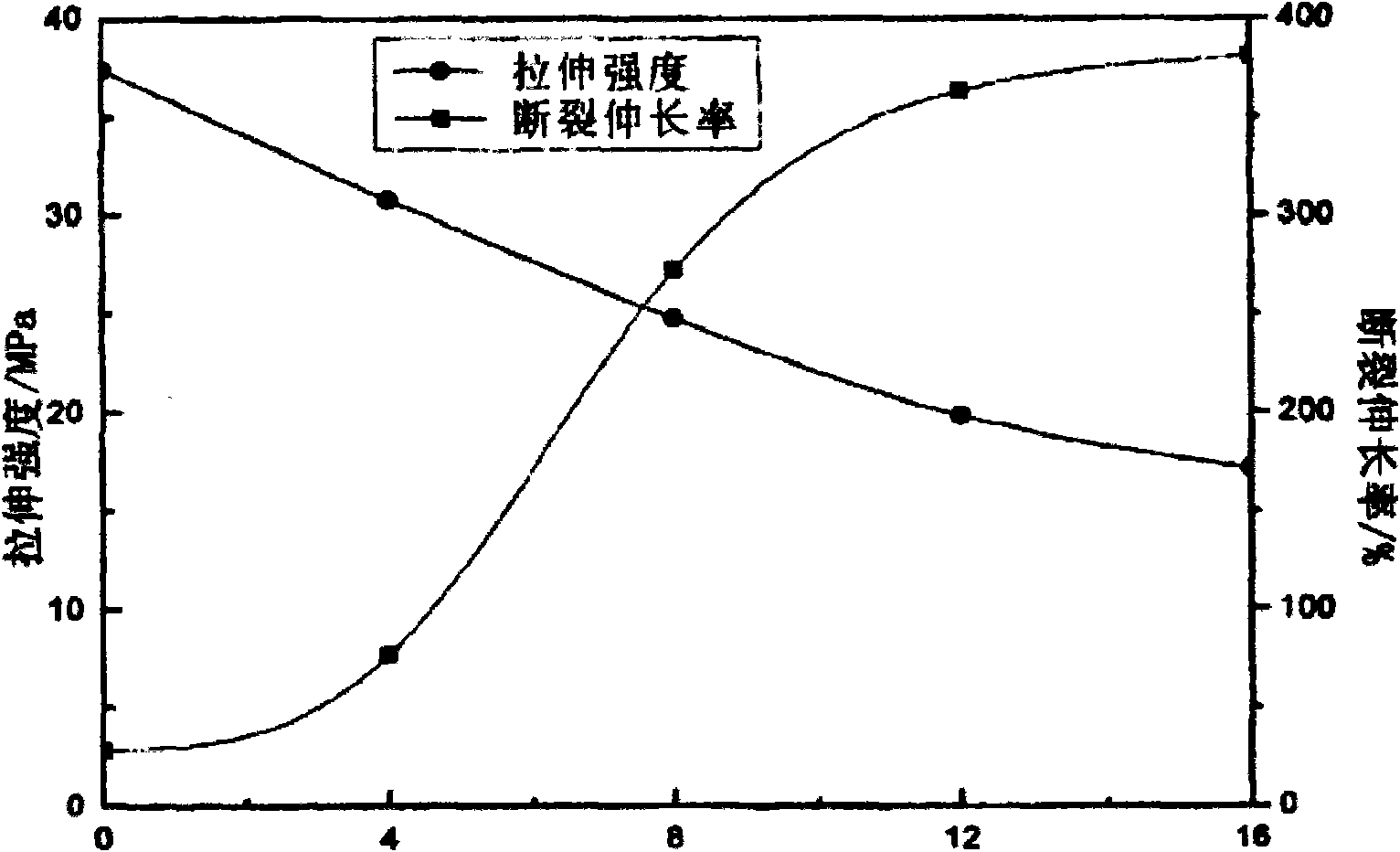

Reinforced and toughened composite material and preparation method thereof

The invention discloses a reinforced and toughened composite material and a preparation method thereof. The reinforced and toughened composite material is prepared from the following raw materials: 30to 90 weight percent of PLA, 5 to 55 weight percent of PBAT, 0.5 to 8 weight percent of nano lanthanum oxide, 0.05 to 5 weight percent of an antioxidant, 0.05 to 5 weight percent of an epoxy compoundand 0.05 to 5 weight percent of a citrate plasticizer, wherein the PLA is polylactic acid, and the PBAT is polybutylene adipate-co-terephthalate. The reinforced and toughened composite material disclosed by the invention contains the nano lanthanum oxide, the epoxy compound and the citrate plasticizer, so that the tensile strength and the elongation at break of the reinforced and toughened composite material can be greatly improved.

Owner:BAOTOU RES INST OF RARE EARTHS

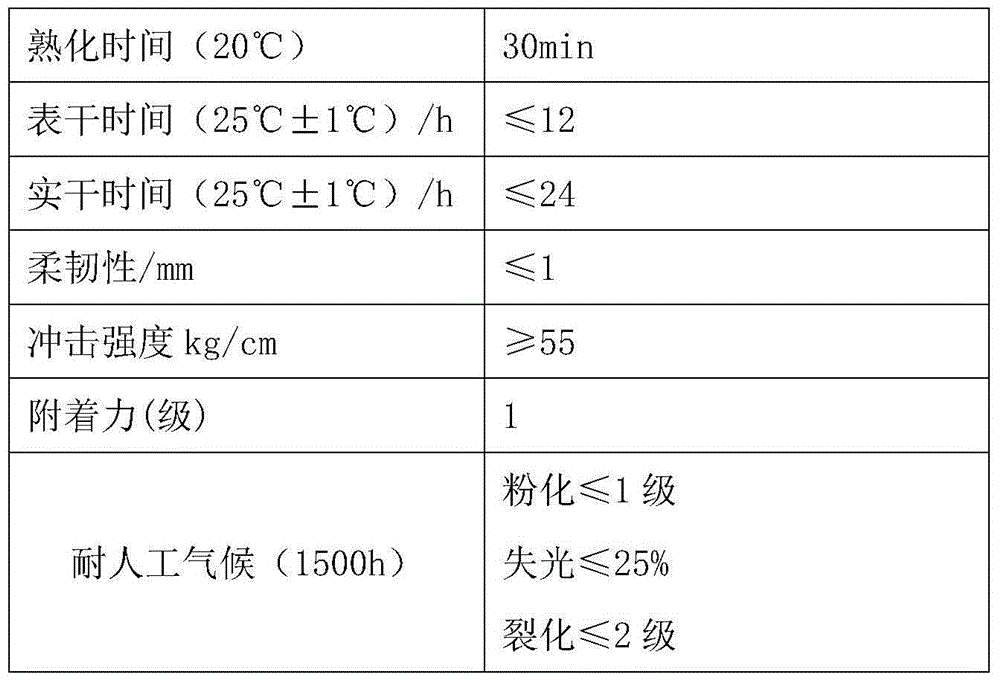

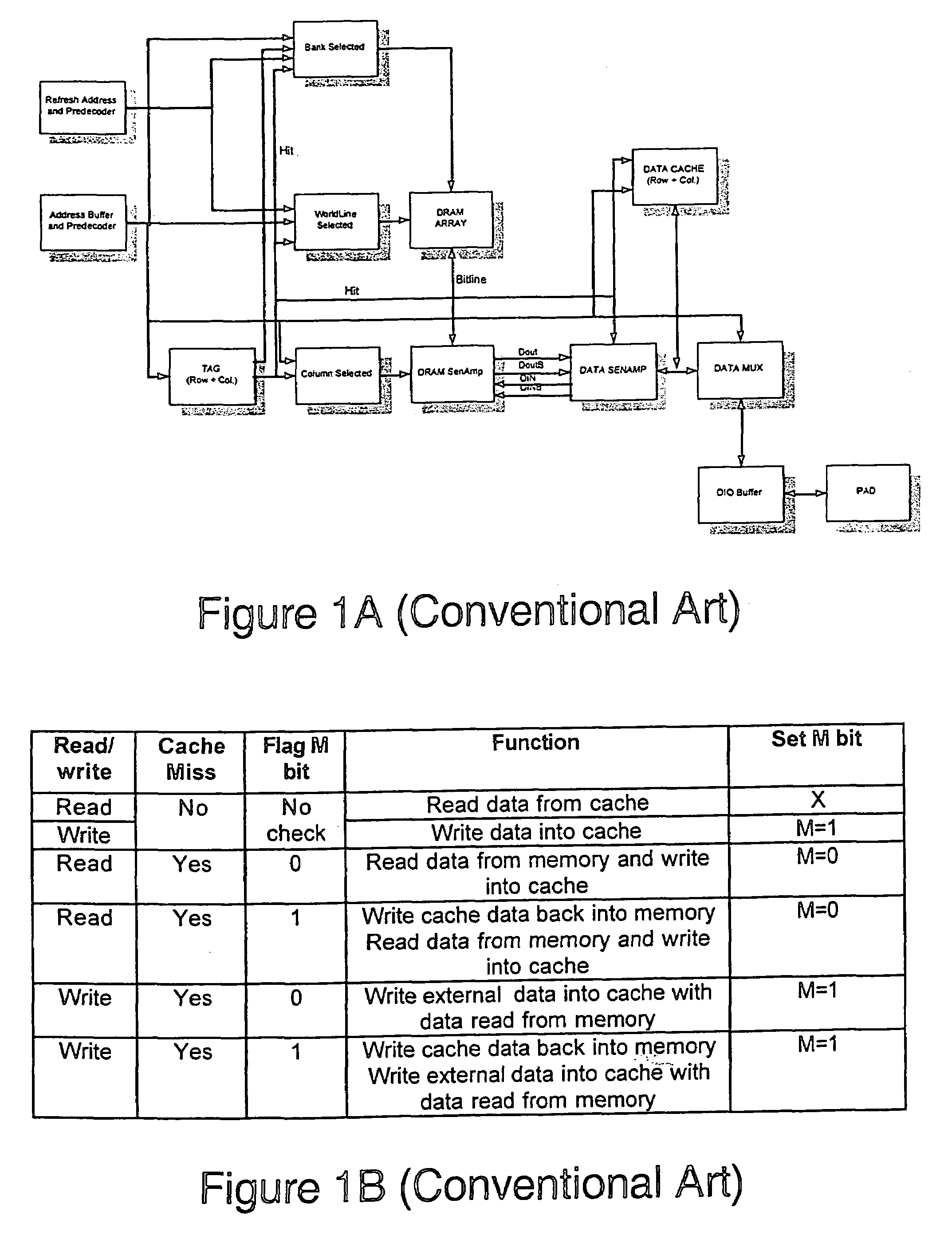

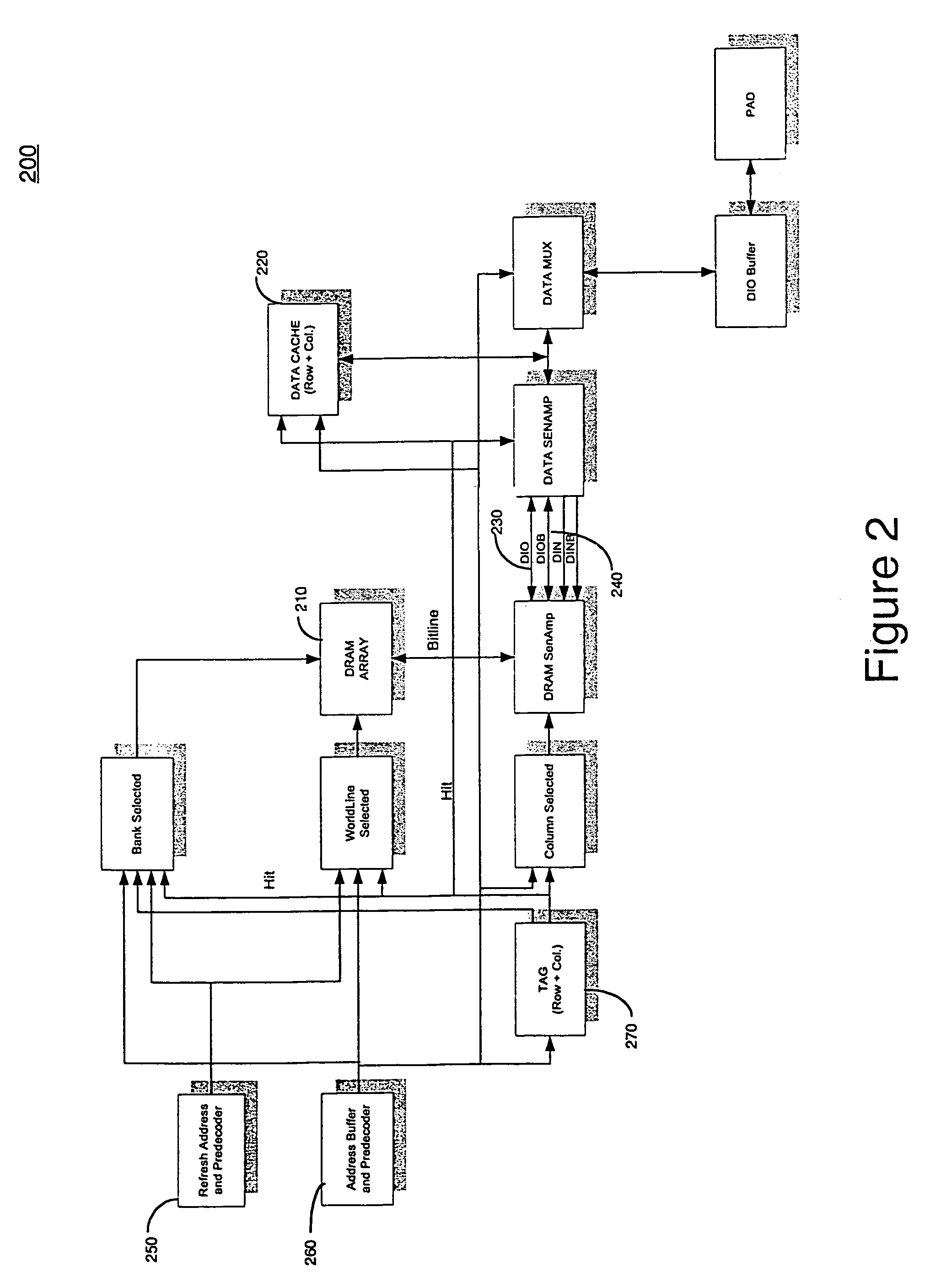

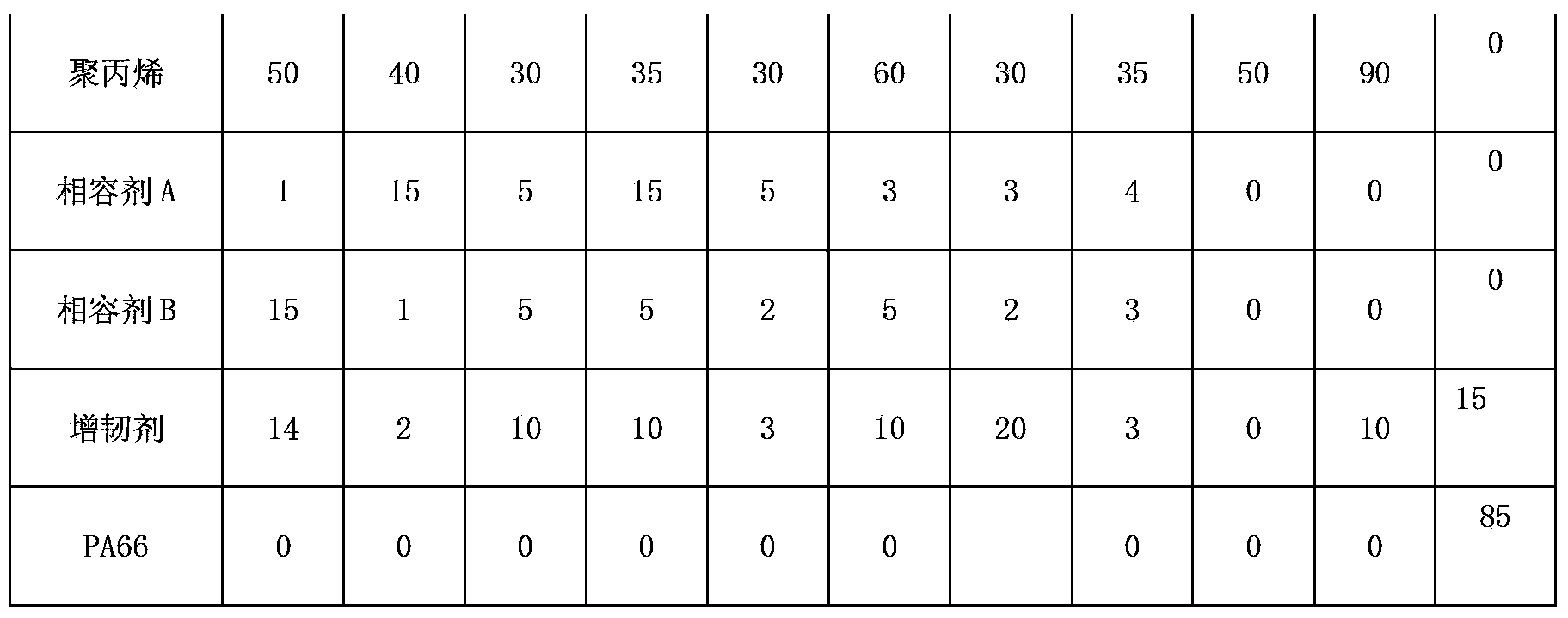

Hiding refresh in 1T-SRAM architecture

InactiveUS7146454B1Fully compatibleMemory architecture accessing/allocationMemory adressing/allocation/relocationMemory bankParallel computing

A method and device for handling the refresh requirements of a DRAM or 1-Transistor memory array such that the memory array is fully compatible with an SRAM cache under all internal and external access conditions. This includes full compatibility when sequential operations alternate between memory cells in same row and column locations within different memory banks. The device includes bi-directional buses to allow read and write operations to occur between memory banks and cache over the same bus. The refresh operations can be carried out without interference with external accesses under any conditions.

Owner:INFINEON TECH LLC

Modifier for regeneration processing of mixed waste plastic tube material and usage method thereof

The invention discloses a modifier for regeneration processing of mixed waste plastic tube materials. The modifier comprises the following components by weight: 1-6 parts of maleic anhydride, 2-6 parts of chlorinated polyethylene, 3-8 parts of an ethylene-vinyl acetate copolymer, 4-9 parts of a styrene-butadiene-styrene block copolymer and 5-9 parts of styrene. A preparation technology of the modifier is as below: adding raw materials into a high speed feed mixer for uniform mixing, discharging and cooling for standby. A usage method of the modifier for regeneration processing of mixed waste plastic tube materials comprises the following steps: (1) classifying to obtain waste plastic tube materials; (2) crushing, washing, dehydrating, drying, dehumidifying and detecting the mixed waste plastic tube materials; (3) mixing and heating the modifier with the mixed waste plastic raw materials, carrying out a grafting reaction, and cooling for standby; and (4) granulating. The invention has the advantages of simple process, convenient operation, low cost and no pollution, and can be widely used in the field of regeneration processing of waste plastic tubes.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

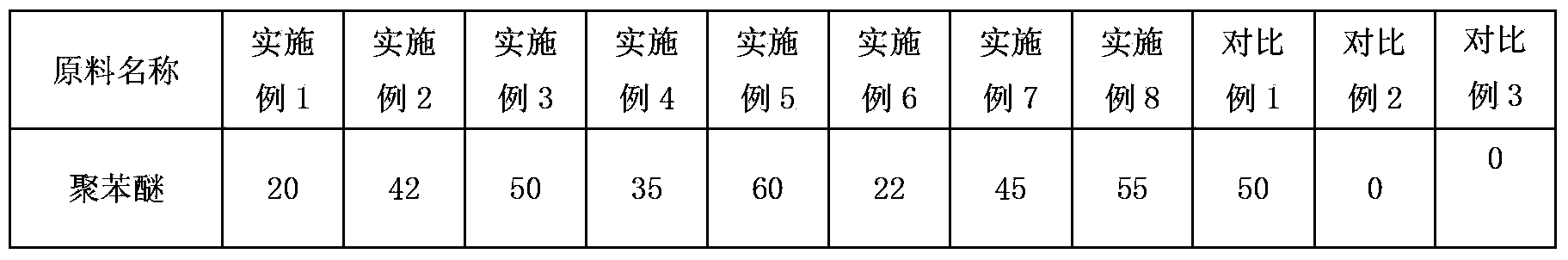

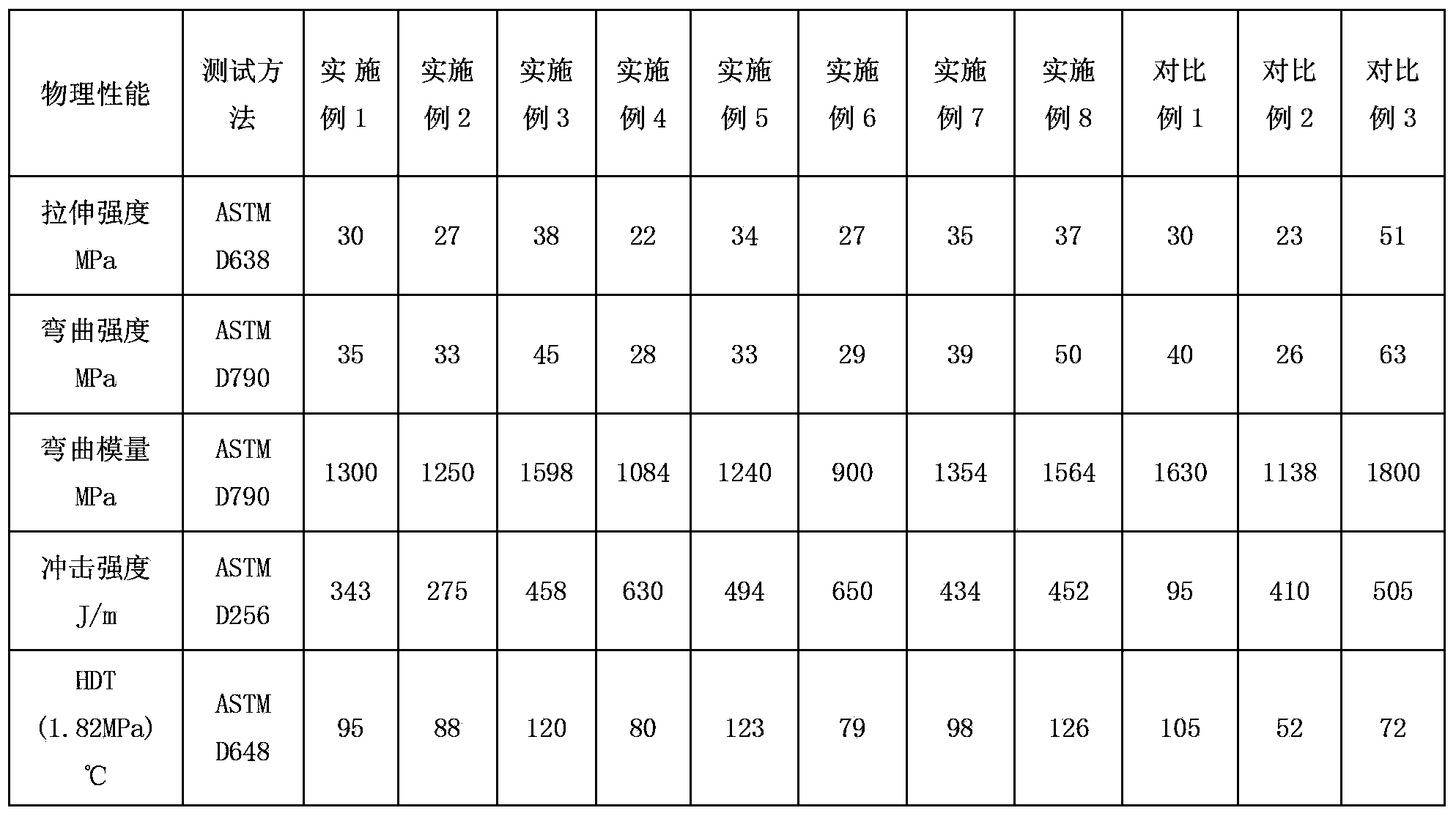

High-temperature-resistant high-impact-resistant polyphenylether/polypropylene alloy material and preparation method thereof

InactiveCN103450561AGood high and low temperature mechanical propertiesImprove heat resistanceHeat resistanceAlloy

The invention relates to a high-temperature-resistant high-impact-resistant polyphenylether / polypropylene alloy material and a preparation method thereof. The alloy is composed of the following components in percentage by mass: 20-60% of polyphenylether, 30-60% of polypropylene, 1-15% of compatilizer A, 1-15% of compatilizer B and 2-20% of toughener. The invention also relates to a preparation method of the high-impact-resistant polyphenylether / polypropylene alloy material, which comprises the following steps: proportionally mixing the raw materials in a high-speed mixer, adding into a double screw extruder by a feeder, and carrying out melt extrusion for granulation at 180-280 DEG C to obtain the high-impact-resistant polyphenylether / polypropylene alloy material. The alloy material provided by the invention has the advantages of favorable high / low-temperature mechanical properties, high heat resistance, favorable electric insulativity and the like, is easy for molding, is suitable for electronic and electrical components, electric tool housings, fluid engineering parts, automobile parts, office parts and the like, and has favorable application prospects.

Owner:SHANGHAI SUNNY

Golf ball material and golf ball

Owner:BRIDGESTONE SPORTS

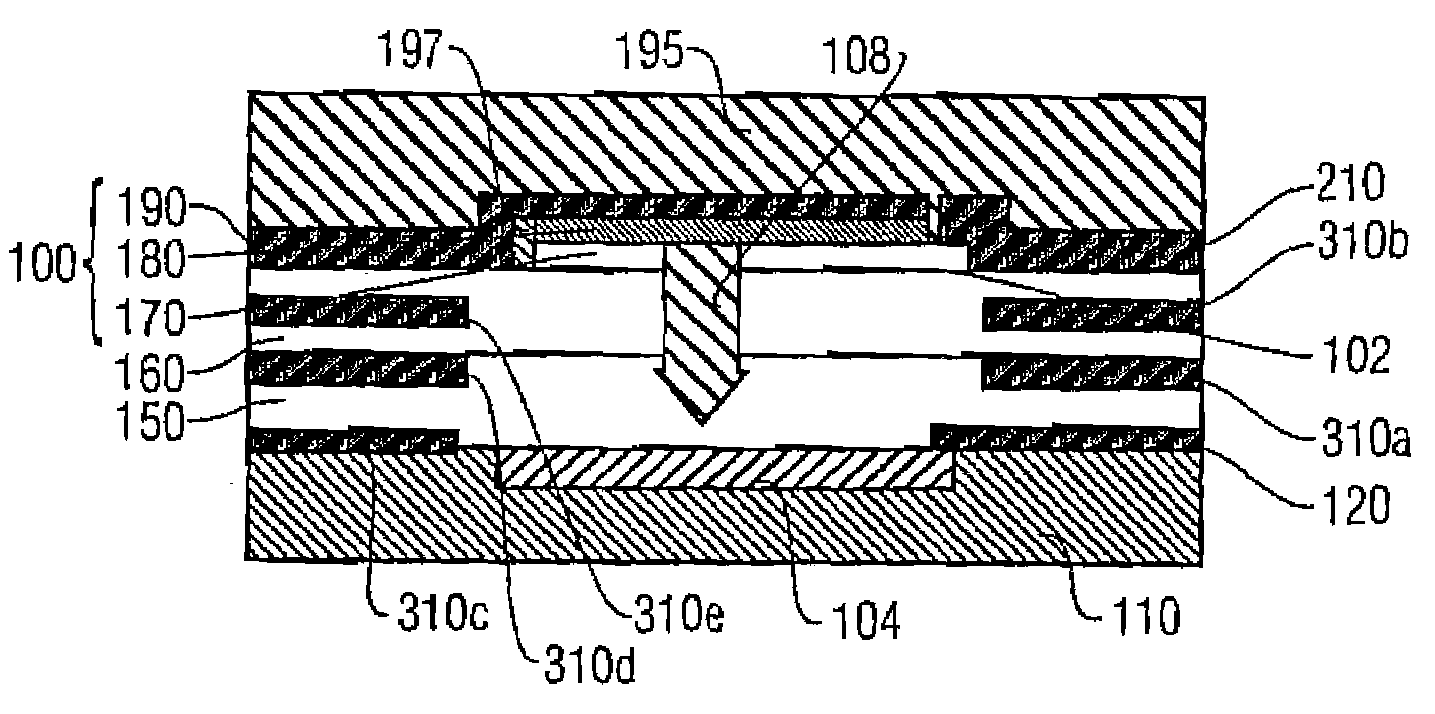

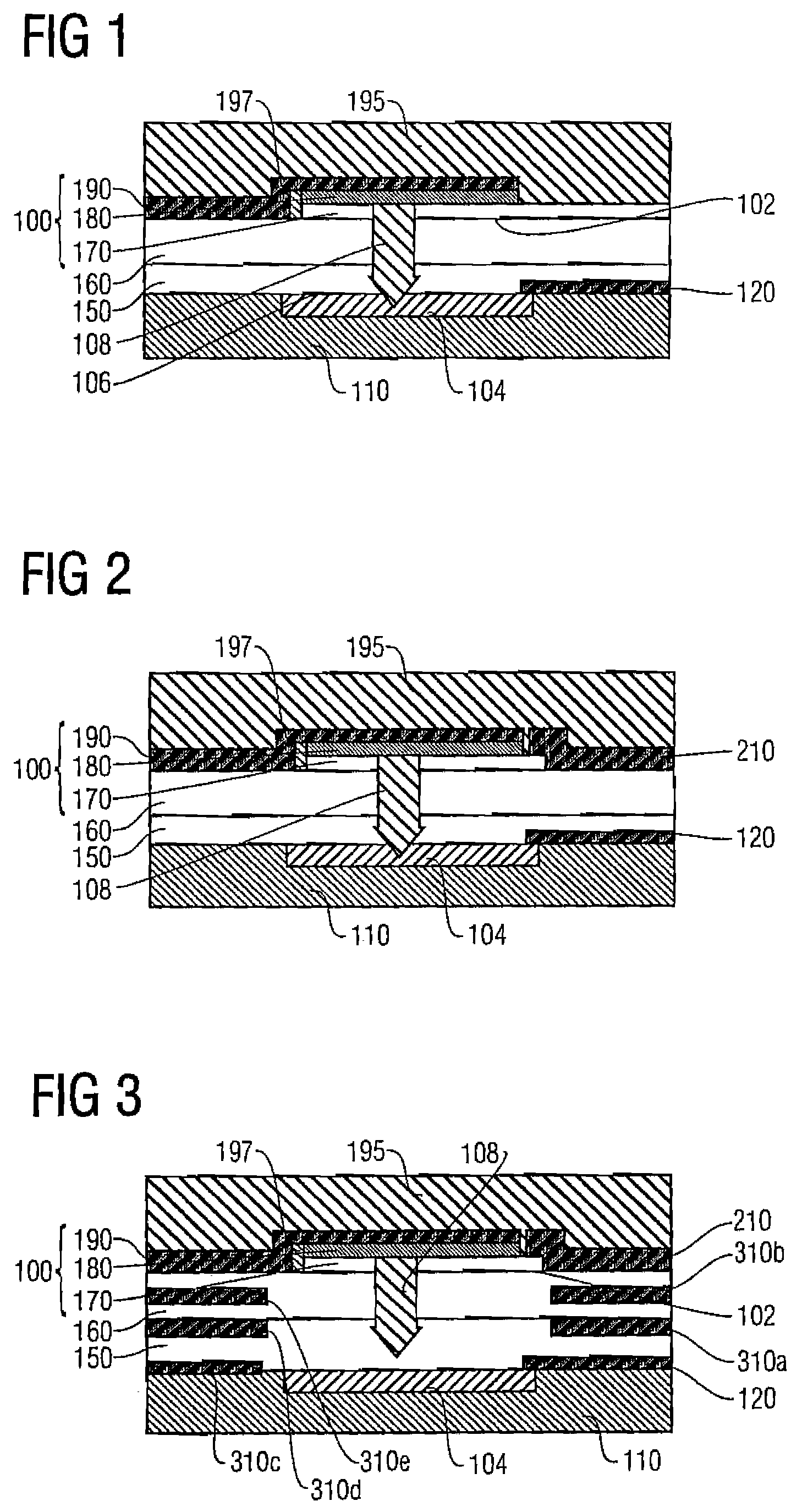

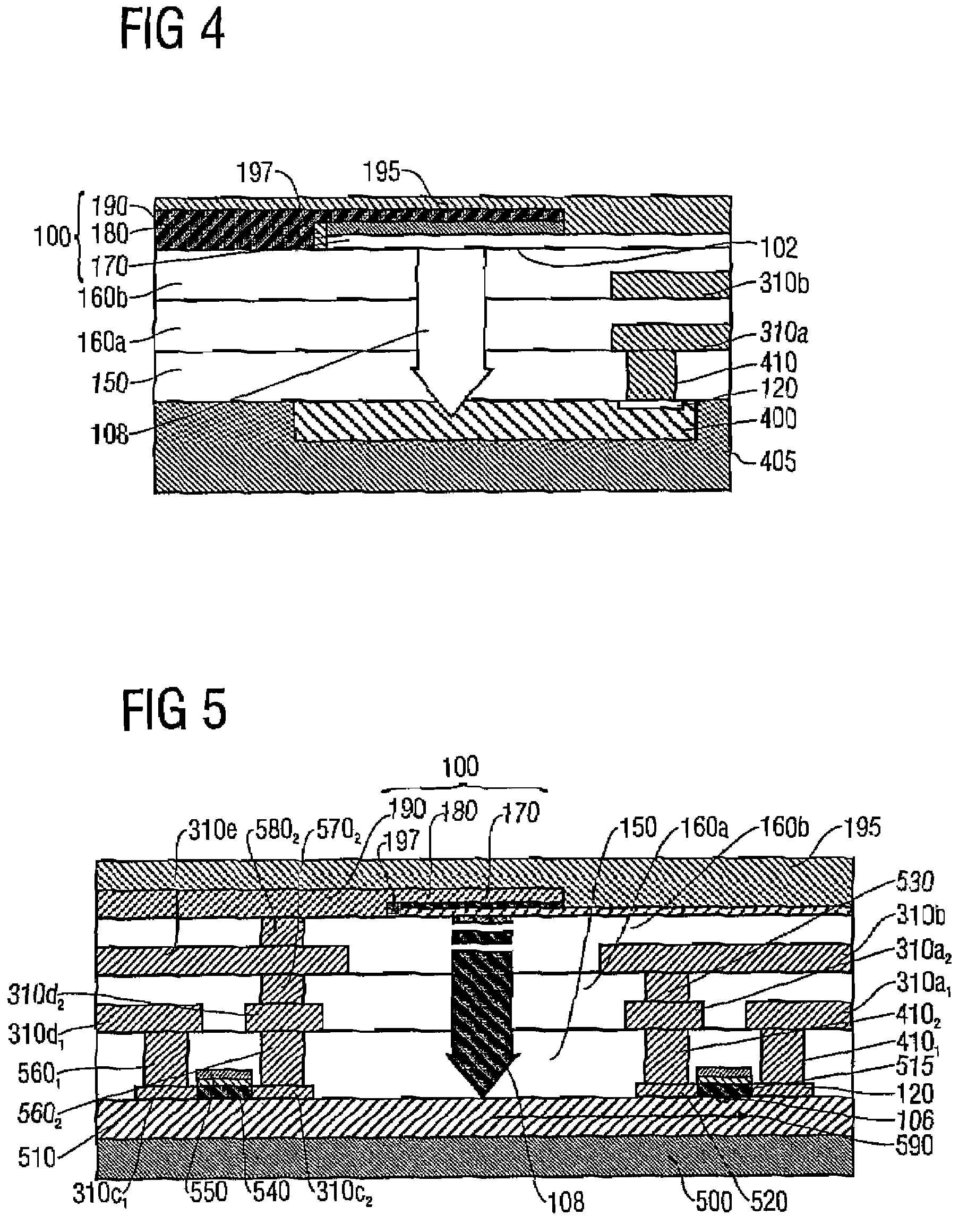

Integrated optocoupler with organic light emitter and inorganic photodetector

InactiveUS7626207B2Easy to integrateRisk of damageSolid-state devicesDiodePhotovoltaic detectorsPhotodetector

An optocoupler has an organic light emitter and an inorganic photodetector with a detector area, the detector area being optically coupled to the organic light emitter. The organic light emitter converts an electrical input signal into a light signal and the inorganic photodetector converts the light signal into an electrical output signal, the organic light emitter and the inorganic photodetector being integrated in a component and galvanically separated.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Waterproofing acid-proofing anti-collision insulating coating

InactiveCN105315820AGood dispersionEasy to spreadConjugated diene hydrocarbon coatingsMicrosphereSolvent

The invention discloses a waterproofing acid-proofing anti-collision insulating coating. The coating is prepared from the following raw materials in parts by weight: 50-55 parts of acrylic polymer emulsion, 22-26 parts of nitrile rubber 2707, 18-21 parts of phenolic resin, 1.1-1.4 parts of a thixotropic agent, 23-26 parts of modified graphene, 10-13 parts of talcum powder, 8-11 parts of calcined kaolin, 3-6 parts of hollow microspheres, 1.1-1.5 parts of a silane coupling agent KH-560, 1.4-1.8 parts of a coalescing agent, 2.2-2.5 parts of a dispersing agent, 1.6-1.9 parts of a defoaming agent, 1-1.5 parts of a thickening agent, 1.8-2.1 parts of a wetting agent, 1.6-2 parts of anti-precipitant, 0.3-0.6 part of preservative, 0.2-0.5 part of mildew preventive and 58-62 parts of solvent. The waterproofing acid-proofing anti-collision insulating coating has high adhesion and good impact resistance.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

General mask and application thereof

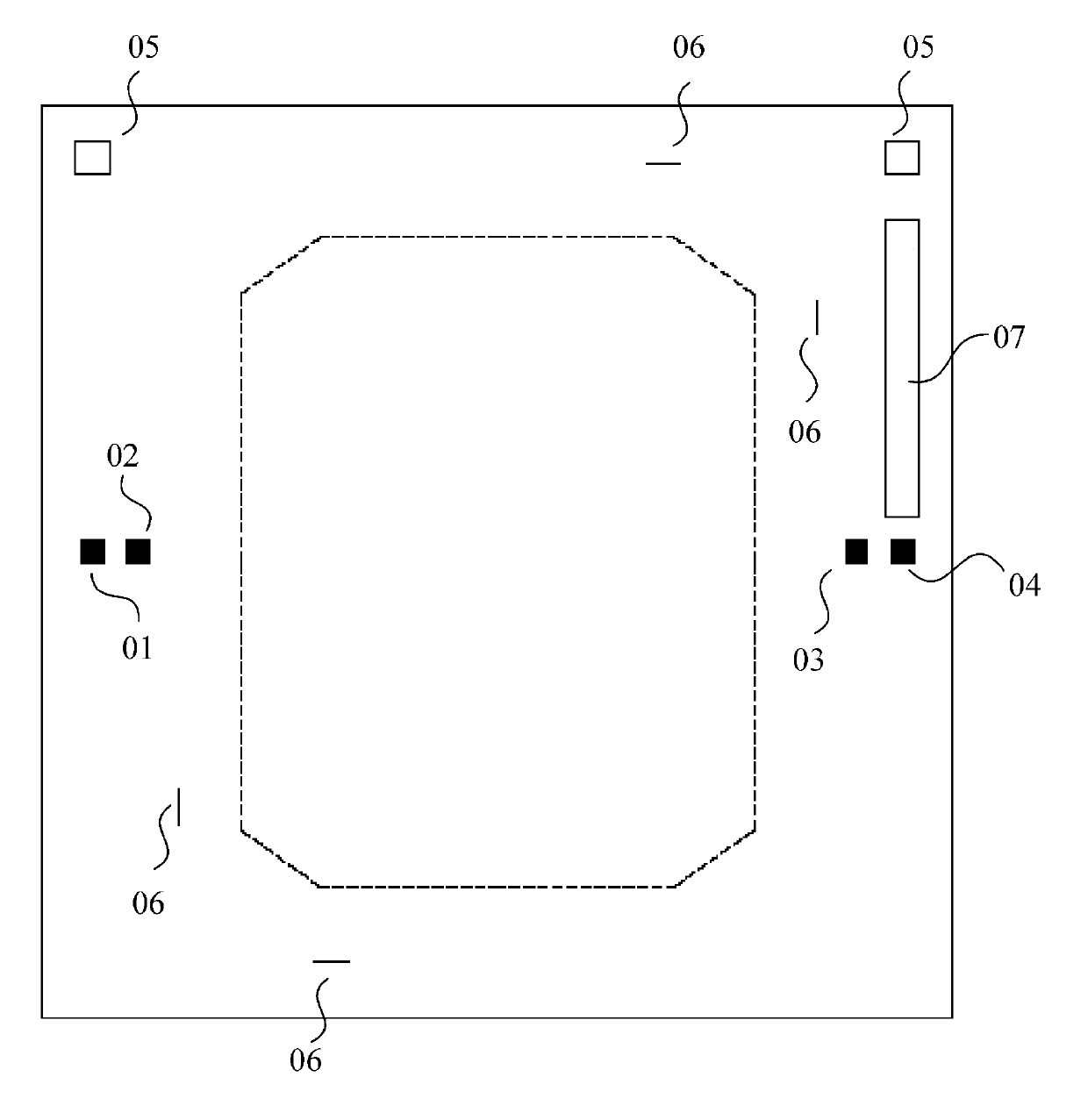

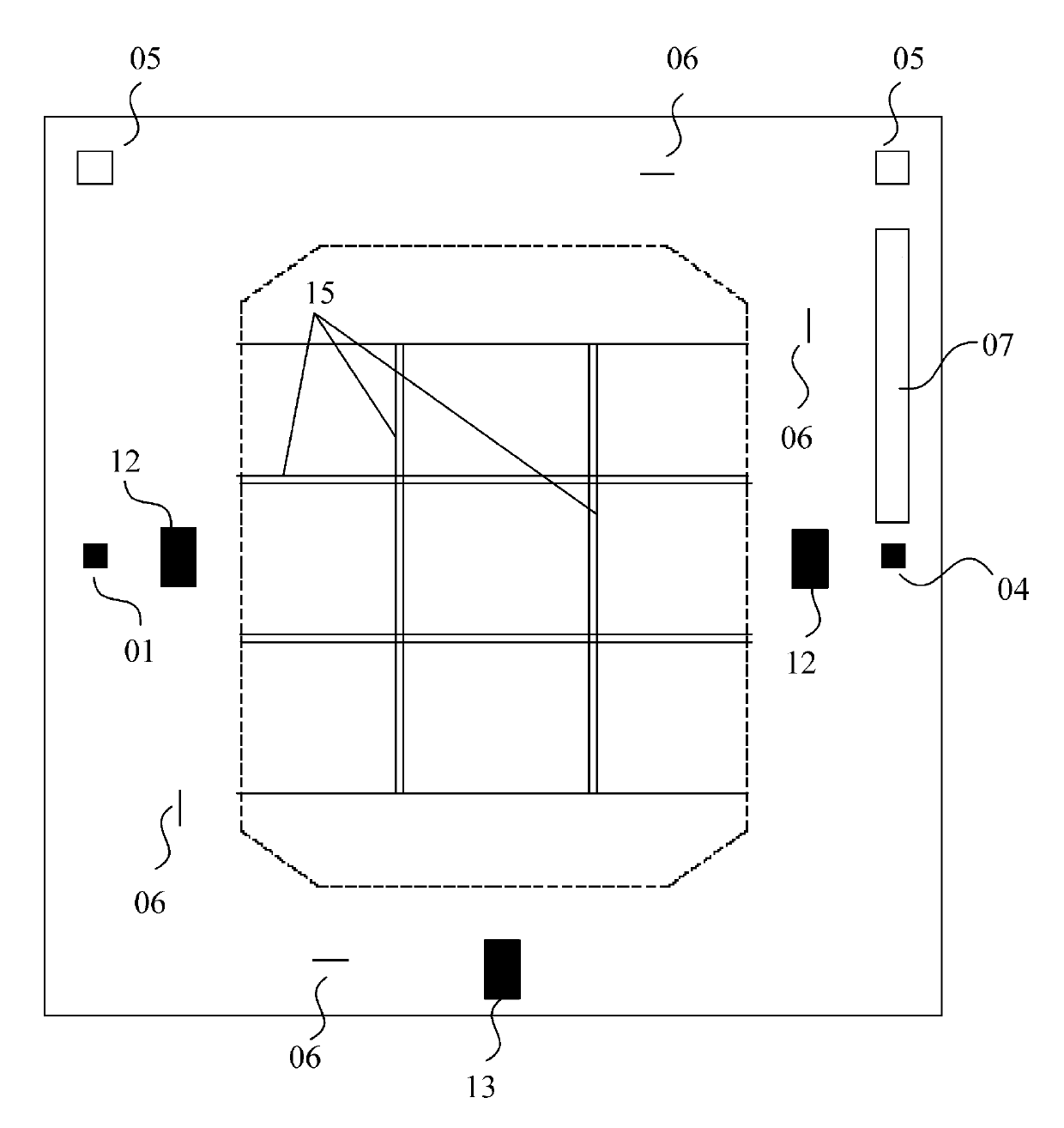

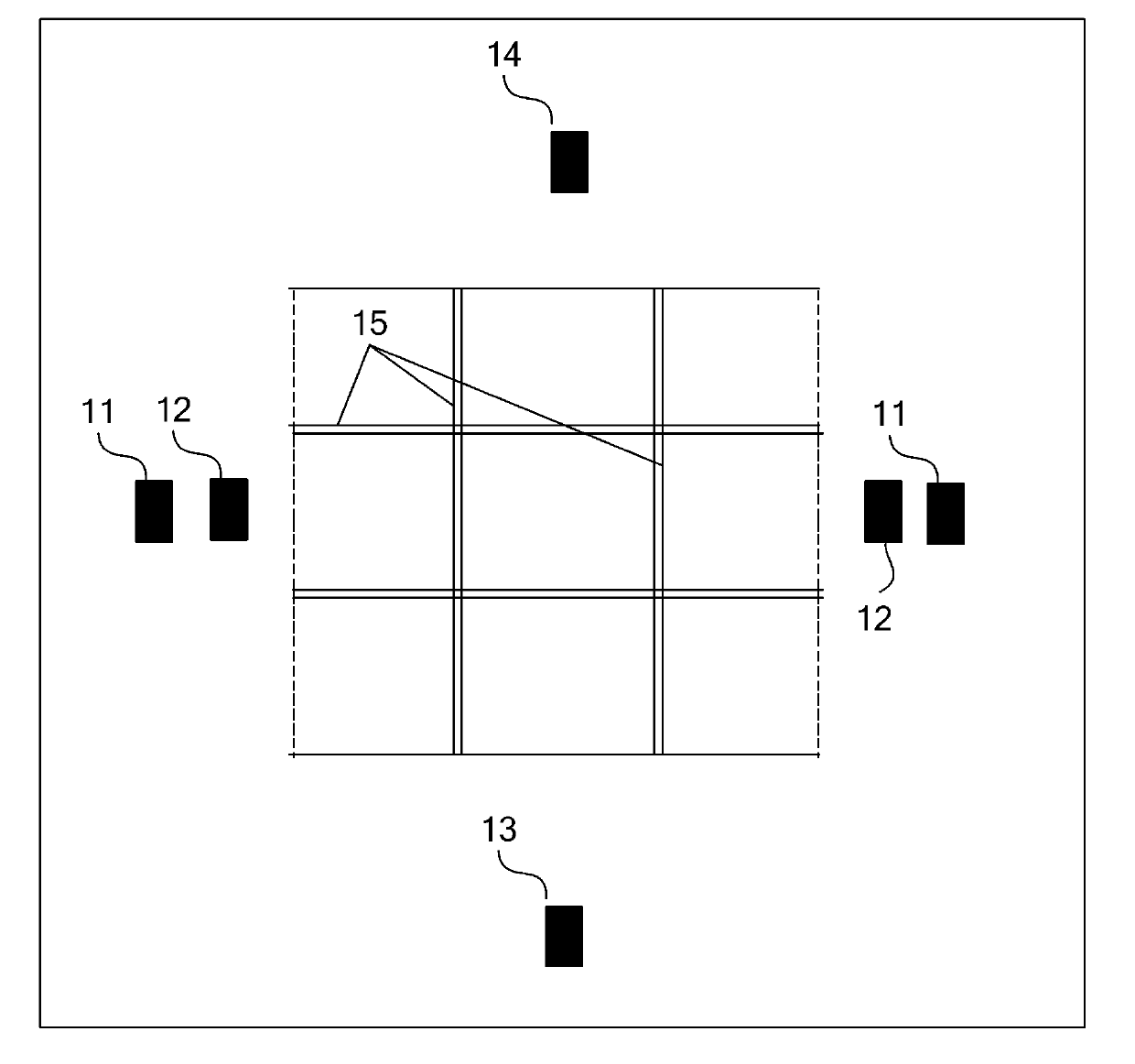

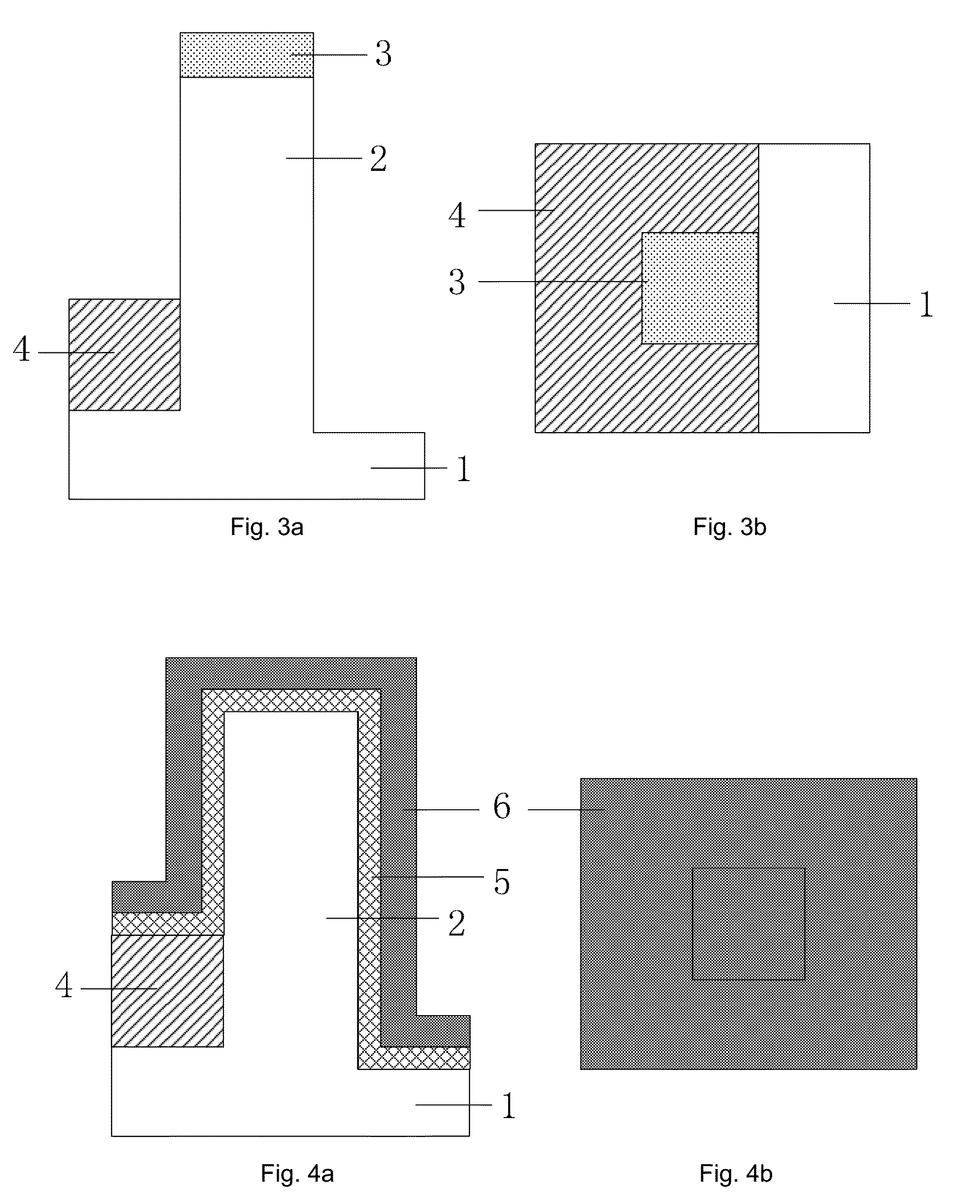

ActiveCN103376645AFully compatiblePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringElectrical and Electronics engineering

The invention discloses a general mask for the exposure operation of at least two lithography machines. The general mask comprises a plurality of first mask alignment marks and a plurality of second mask alignment marks, wherein a first mask is used for exposing a first lithography machine; a second mask is used for exposing a second lithography machine. According to the general mask, the alignment sheathing operation between an advanced semiconductor material lithography (ASML) stepped lithography machine and a NIKON stepped lithography machine can be realized.

Owner:WUXI CHINA RESOURCES HUAJING MICROELECTRONICS

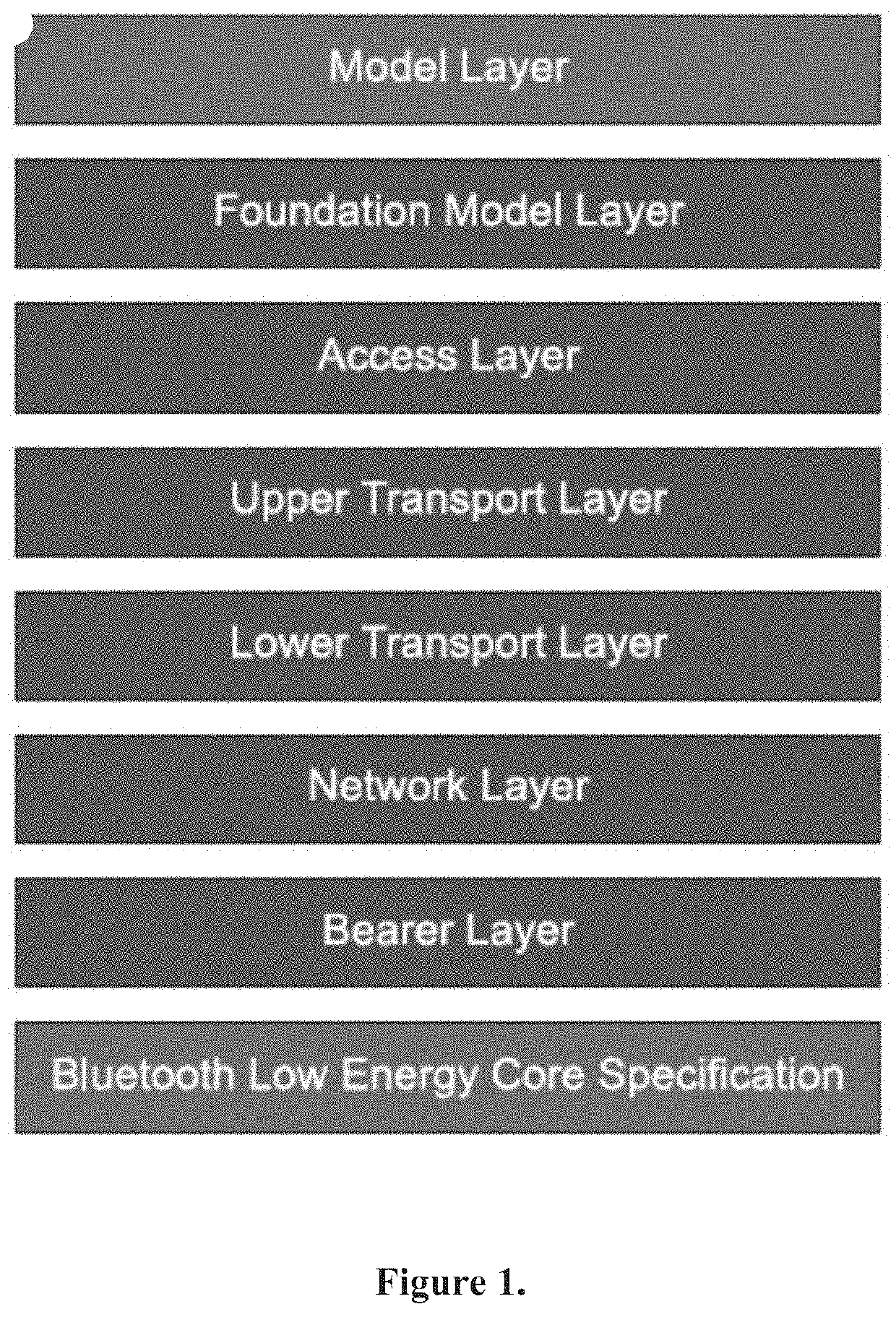

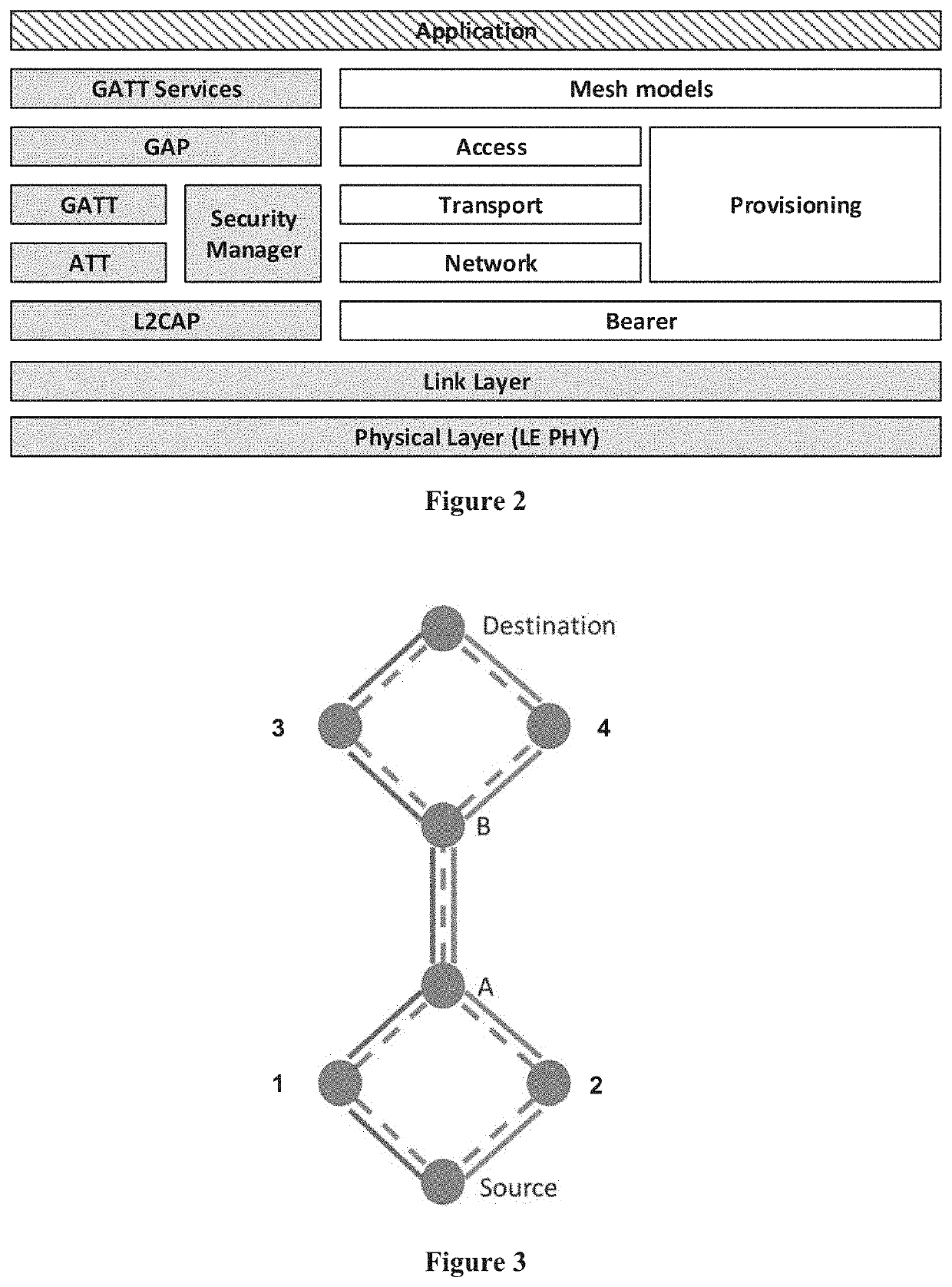

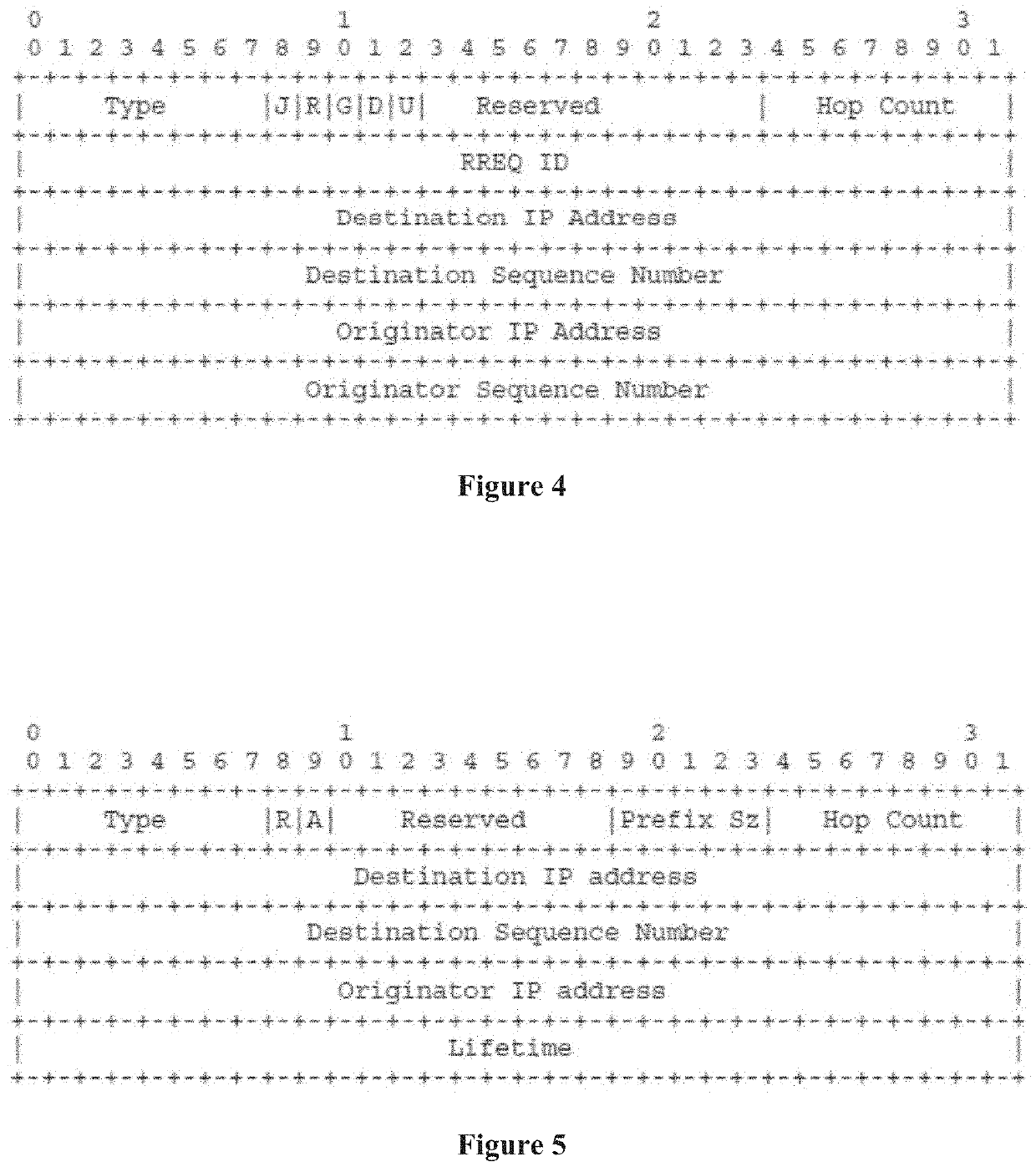

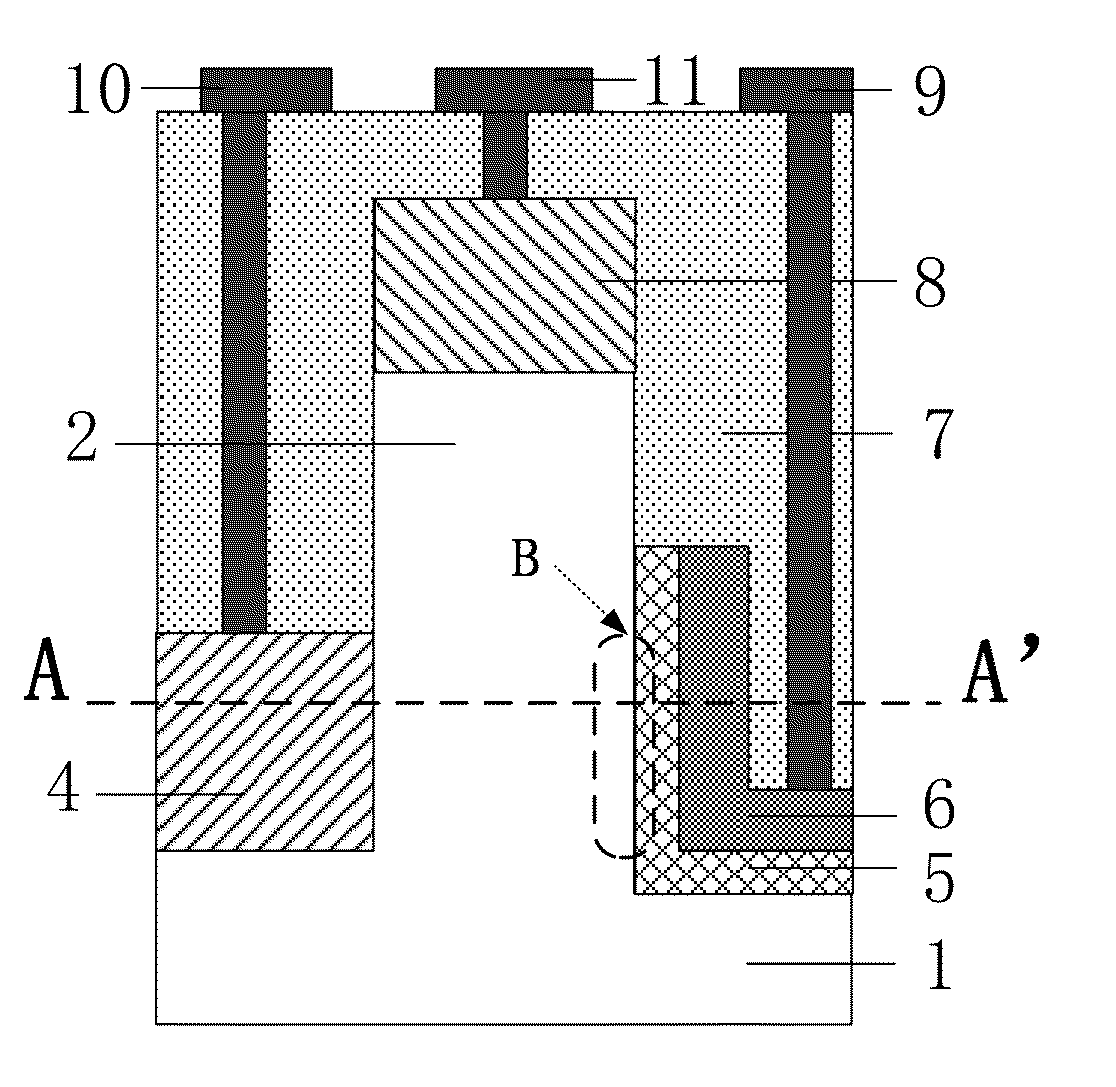

Detecting Critical Links in Bluetooth Mesh Networks

ActiveUS20200084689A1Improve reliabilityFully compatibleNetwork topologiesData switching networksComputer networkWireless mesh network

A method for identifying a critical link in a path between a source node and a destination node in a wireless mesh network, wherein said method comprises the steps of receiving, a forwarding path request, PREQ, message relating to a discovery of a path between said source node and said destination node, determining that further PREQ message relating to the discovery of said path are not received during a predetermined duration, and, triggered by said determination, setting a first critical flag in a discovery table entry associated with said path between said source node and said destination node, and forwarding said received PREQ message to one or more other nodes in said wireless mesh network

Owner:TELEFON AB LM ERICSSON (PUBL)

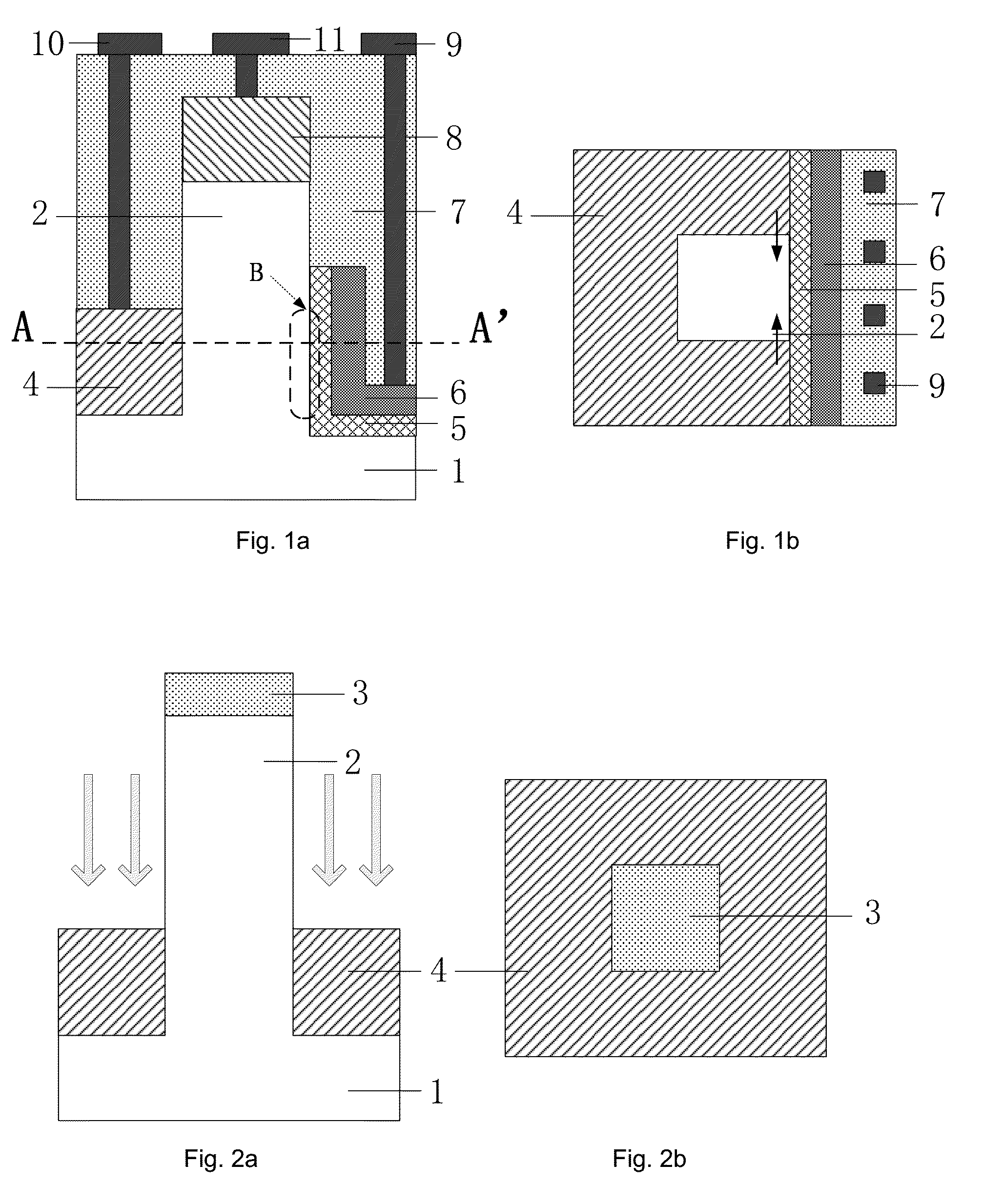

A junction-modulated tunneling field effect transistor and a fabrication method thereof

InactiveUS20160079400A1Improve featuresNarrow widthSemiconductor/solid-state device manufacturingDiodeEngineeringField-effect transistor

The present invention discloses a junction-modulated tunneling field effect transistor and a fabrication method thereof, belonging to a field of field effect transistor logic device and the circuit in connection with CMOS ultra large scale integrated circuit (ULSI). The PN junction provided by a highly-doped source region surrounding three sides of the vertical channel region of the tunneling field effect transistor can deplete effectively the channel region, so that the energy band of the surface channel under the gate is lifted, therefore the device may obtain a steeper energy band and a narrower tunneling barrier width than the conventional TFET when the band-to-band tunneling occurs, equivalently achieving the effect of a steep doping concentration gradient at the source tunneling junction, and thereby the sub-threshold characteristics are significantly improved while the turn-on current of the device is improved relative to the conventional TFET. Under the conditions that the device of the present invention is compatible with the existing CMOS process, on the one hand an ambipolar effect of the device can be inhibited effectively, while a parasitic tunneling current at a source junction corner in the small size device can be inhibited and thus can equivalently achieve an effect of a steep doping concentration gradient at the source junction.

Owner:PEKING UNIV

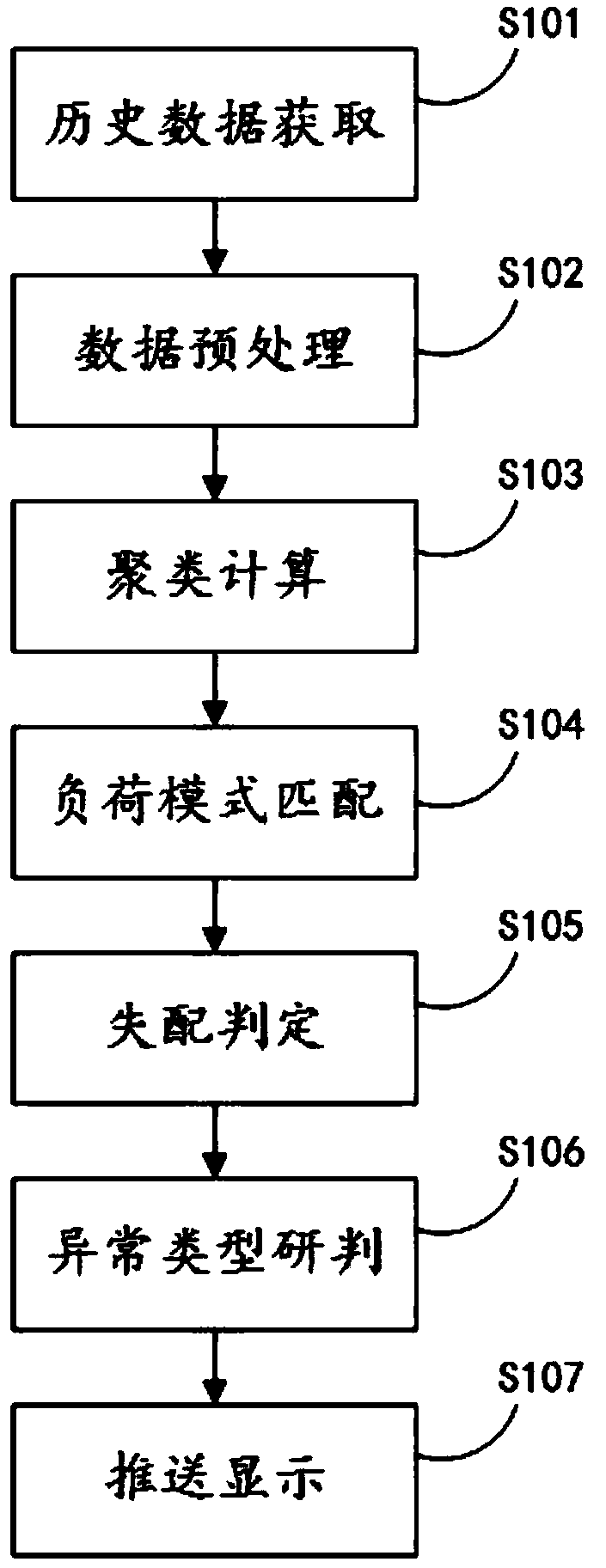

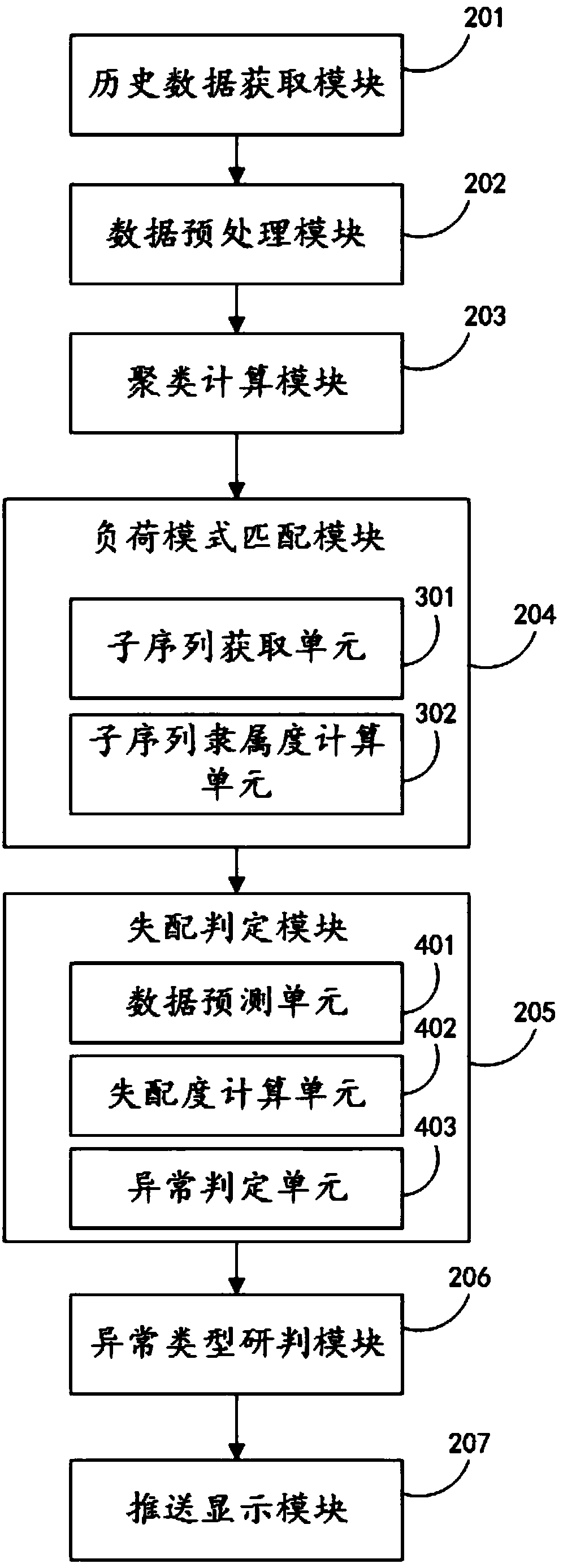

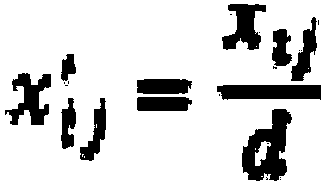

Historical data analysis-based abnormality monitoring method and system of power distribution network

ActiveCN107611940AImprove accuracyStrong reliabilityEmergency protective circuit arrangementsInformation technology support systemData analysisDistribution networks

The invention provides a historical data analysis-based abnormality monitoring method and system of a power distribution network. The method comprises the steps of acquiring historical current data ofa 10KV main line where a power distribution line is located, standardizing the historical current data by taking circuit current limit number as a reference, clustering the historical current data according to a circuit load mode, performing load mode matching on current load data, calculating mismatching degree, judging whether a mismatching degree judgment circuit is abnormal or not, and further determining, pushing and displaying a circuit abnormality type. The method is high in data accuracy and high in reliability and is easy to read and process, so that the constraint that existing power distribution network equipment cannot be used for supporting fault monitoring is got rid of; and moreover, the method is small in data volume, fast in calculation speed and low in calculation equipment requirement, and is easy to promote and implement, existing equipment and data of a power supply enterprise can be fully compatible, and the construction cost is low.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Modifier for regenerating and processing hybrid waste plastic injection part materials and usage method

InactiveCN103665728AImproved recycling performanceImprove toughnessGraft reactionChlorinated polyethylene

The invention discloses a modifier for regenerating and processing hybrid waste plastic injection part materials, wherein the modifier contains the following components by weight: 1-7 parts of maleic anhydride, 2-7 parts of chlorinated polyethylene, 3-9 parts of ethane-vinyl acetate copolymer, 4-10 parts of styrene-butadiene-styrene segmented copolymer, and 5-10 parts of styrene; and a preparation process of the modifier comprises: uniformly mixing the raw materials of the modifier into a high speed mixer, discharging and cooling for standby application. A usage method of the modifier for regenerating and processing hybrid waste plastic injection part materials has the following steps of: (1) classifying the obtained hybrid waste plastic injection part materials; (2) crushing, washing, dehydrating, drying, dehumidifying and detecting the hybrid waste plastic injection part materials; (3) uniformly mixing the modifier for regenerating and processing hybrid waste plastic injection part materials and the hybrid waste material raw materials, heating to generate grafting reaction, and cooling for standby application; and (4) granulating. The modifier has characteristics of simple technology, convenient operation, low cost and no pollution, and can be widely used in a generating and processing field of waste plastic injection parts.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

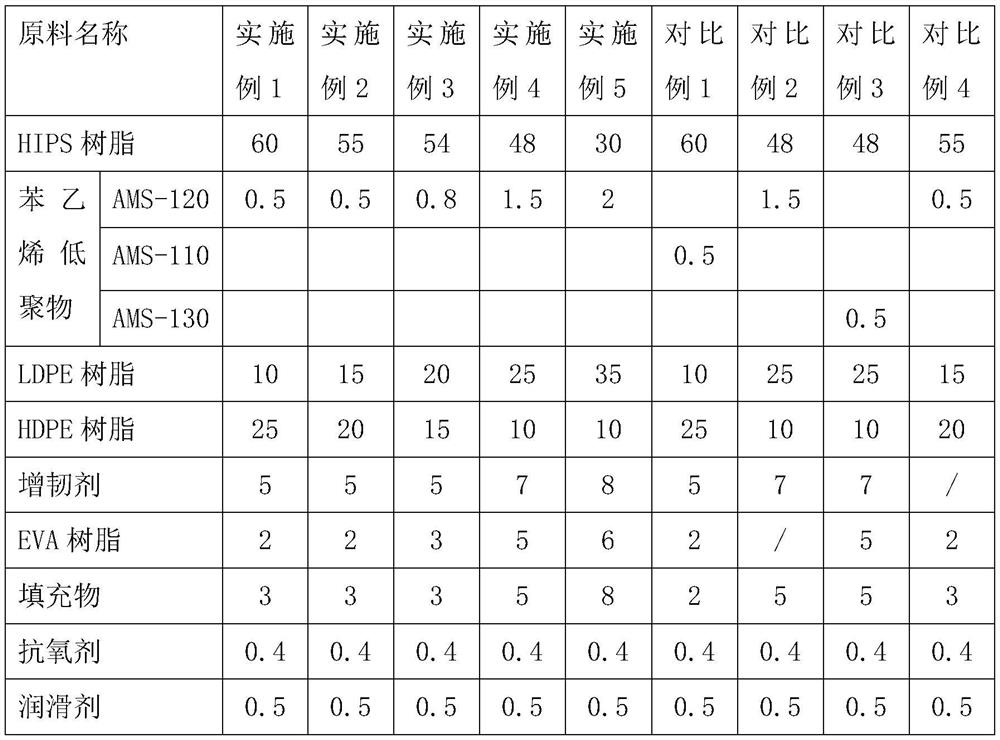

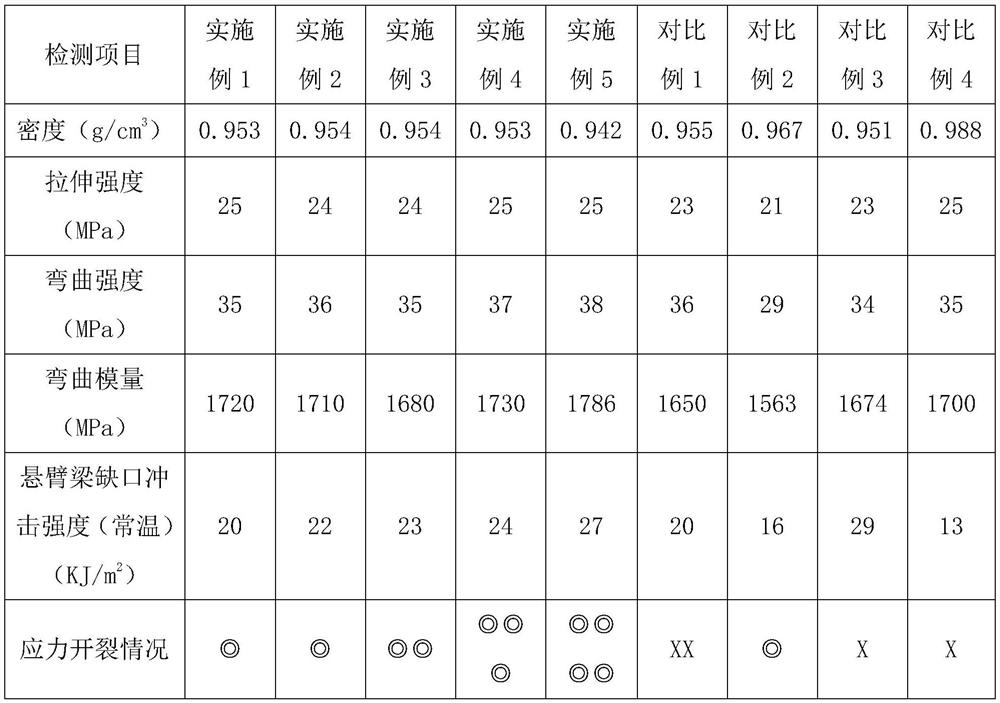

HIPS composite material as well as preparation method and application thereof

The invention provides an HIPS composite material as well as a preparation method and application thereof. The composite material comprises the following components in parts by mass: 30-60 parts of HIPS resin, 0.5-2 part of a styrene oligomer, 10-35 parts of a HDPE resin, 10-35 parts of an LDPE resin, 2-10 parts of an EVA resin, 2-10 parts of a filler, 5-10 parts of a toughening agent, and 0.5-1.5parts of a processing aid. The PS composite material provided by the invention has the characteristics of low density, high toughness and low stress cracking.

Owner:TIANJIN KINGFA NEW MATERIAL

Wear-resisting, heat-resisting and acid-alkali resistant modified rubber sealing element

InactiveCN106432935AImprove wear resistance, acid and alkali resistanceImproved wear resistance, acid and alkali resistanceLow-density polyethylenePolymer science

The invention discloses a wear-resisting, heat-resisting and acid-alkali resistant modified rubber sealing element which comprises modified sulfonated polyethylene rubber, butadiene styrene rubber, diphenyl phosphoryl chloride, hydrobromic acid tripolycyanamide, sulfur, barium sulfate, low-density polyethylene, polystyrene, asbestos fibers, talcum powder, trioctyl trimellitate, dioctyl phthalate, phenolic resin, accelerants DM, accelerants M, lead oxide, magnesium oxide, stearic acid, vaseline, anti-aging agents NBC, auxiliaries and diphenyl ketone. The wear-resisting, heat-resisting and acid-alkali resistant modified rubber sealing element has excellent wear resistance, heat resistance and acid-alkali resistance.

Owner:安徽亚兰密封件股份有限公司

High-efficiency anti-rusting epoxy finishing paint loaded with silicon dioxide nano spheres and preparation method of high-efficiency anti-rusting epoxy finishing paint

InactiveCN104293111AGood dispersionIncrease light aging resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyOmega

The invention relates to anti-rusting paint, and in particular relates to high-efficiency anti-rusting epoxy finishing paint loaded with silicon dioxide nano spheres and a preparation method of the high-efficiency anti-rusting epoxy finishing paint. The paint is prepared from the following raw materials in parts by weight: 40-50 parts of epoxy resin, 26-32 parts of polyamide resin, 4-6 parts of poly omega-caprolactone diol, 3-4 parts of silicon dioxide nano spheres, 1-2 pars of nano copper oxide, 3-5 parts of fischer tropsch, 1-2 parts of polyphosphazene, 6-8 parts of dimethoxymethane, 1-2 parts of a silane coupling agent, 15-18 parts of magnesium silicate, 18-22 parts of n-butyl acetate, 18-22 parts of anti-rusting pigment and 2-3 parts of an additive. According to the paint, the modified silicon dioxide nano spheres and nano copper oxide are loaded on epoxy resinite, so that the hardness and the toughness of a paint membrane are improved, in addition, by adopting the preparation method of the paint, the raw materials are relatively sufficiently combined, and the paint is excellent in mechanical property after being completely cured, is durable and long-lasting when being compared with conventional epoxy anti-rusting finishing paint and is applicable to various high-performance special anti-rusting primers, epoxy zinc-rich paint and matting finishing paint of epoxy micaceous iron rust preventing paint.

Owner:合肥宏图彩印有限公司

Silicon carbide/molybdenum disulfide composite ceramic and preparation method thereof

The invention discloses a silicon carbide / molybdenum disulfide composite ceramic and a preparation method thereof. The silicon carbide / molybdenum disulfide composite ceramic contains silicon carbide, graphite, molybdenum disulfide, water soluble resin, a plasticizer and a demolding agent, wherein the water soluble resin is selected from one or more of polyvinyl alcohol, polyethylene oxide, poly(N-vinyl pyrrolidone) and polyurethane, and the particle size of silicon carbide is 1-5 [mu]m. The silicon carbide / molybdenum disulfide composite ceramic has excellent wear resistance, heat resistance and mechanical properties, besides, the preparation method is simple in steps, and the raw materials are easy to obtain.

Owner:ANHUI DONGXUN SEALING TECH

Environment-friendly coating for exterior wall and preparation method thereof

InactiveCN110845953AExtended service lifeImprove adhesionCellulose coatingsAnti-corrosive paintsFiberPolymer science

The invention belongs to the technical field of environment-friendly coatings and relates to an environment-friendly coating for an exterior wall and a preparation method thereof. The environment-friendly coating for the exterior wall comprises the following raw materials in parts by weight: 40 to 50 parts of an acrylic emulsion, 20-30 parts of polyether polyol, 20-30 parts of a filler, 10-20 parts of carboxymethyl betaine, 5-10 parts of isocyanate, 5-10 parts of ceramic fibers, 5-10 parts of nanometer silicon dioxide, 5-8 parts of a surfactant, 3-6 parts of a plasticizer, 1-3 parts of a drying agent, 1-2 parts of an anti-aging agent and 0.5-1 part of an anti-ultraviolet agent, wherein the anti-aging agent is prepared from zirconium oxide, nanometer titanium dioxide and modified graphene according to a mass ratio of (10-5): (4-8): 1. The environment-friendly coating is non-toxic, odorless, green and safe, has good elasticity, flexibility, waterproofness, aging resistance, abrasion resistance and ultraviolet resistance, short curing time, good hardness and long service life, can be directly painted, and is convenient to operate and applicable to exterior walls.

Owner:青川源泰建材科技有限公司

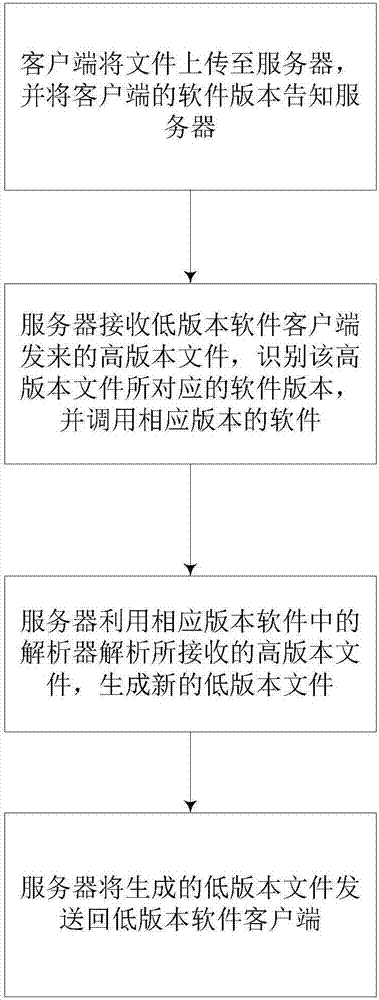

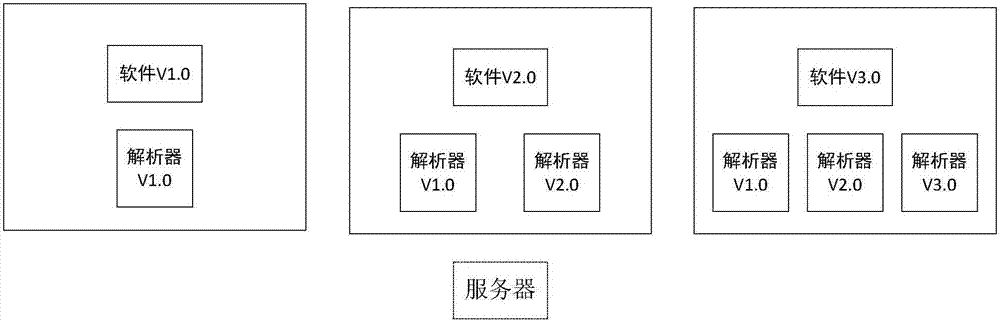

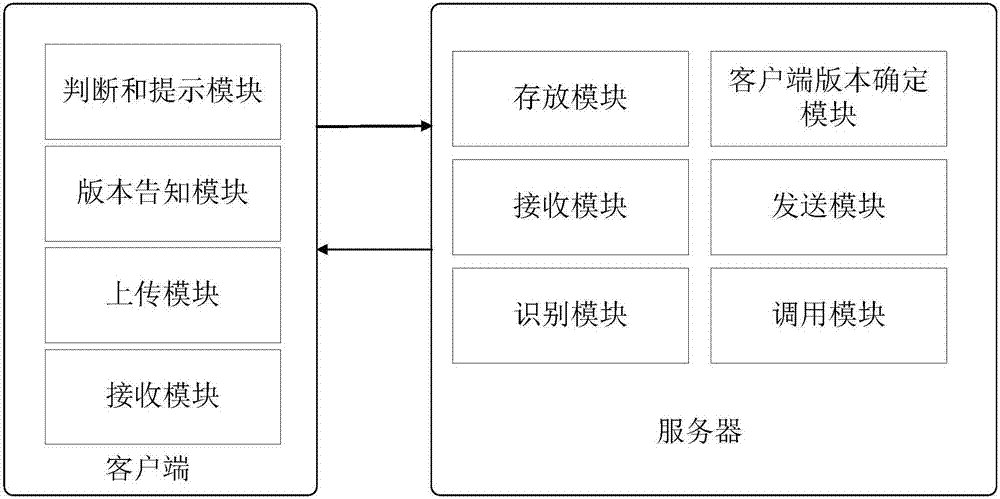

Method of enabling low-version software to be compatible with high-version software, client side and server

ActiveCN106874004AFully compatibleVersion controlSpecific program execution arrangementsSoftware engineeringClient-side

The invention relates to a method of enabling low-version software to be compatible with high-version software. The method includes the steps that a server receives a high-version file sent by a low-version software client side, recognizes the software version corresponding to the high-version file and calls the software of the corresponding version; the server uses an analyzer in the software of the corresponding version for analyzing the received high-version file so as to generate a new low-version file; the server sends the generated low-version file back to the low-version software client side. The invention requests to protect the corresponding client side, the server and a system. By means of the scheme, software of different versions can be compatible, and particularly the low-version software can be compatible with the high-version software.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

Flash memory device and method for manufacturing the same

The present invention provides a FinFET flash memory device and the method for manufacturing the same. The flash memory device is on an insulating layer, comprising: a first fin and a second fin, wherein the second fin is a control gate of the device; a gate dielectric layer, at side walls and top of the first fin and the second fin; source / drain regions, inside the first fin at both sides of a floating gate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

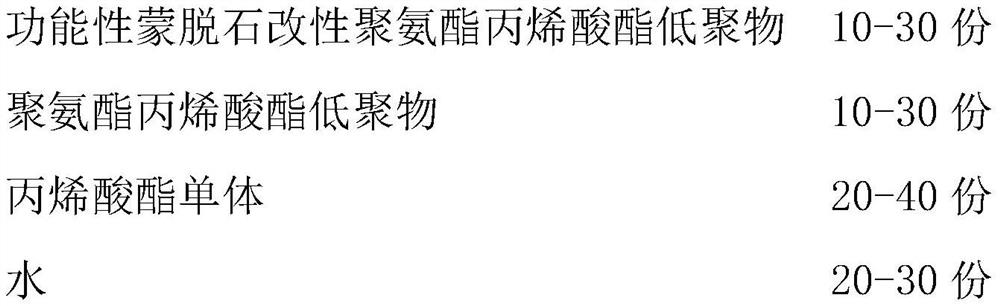

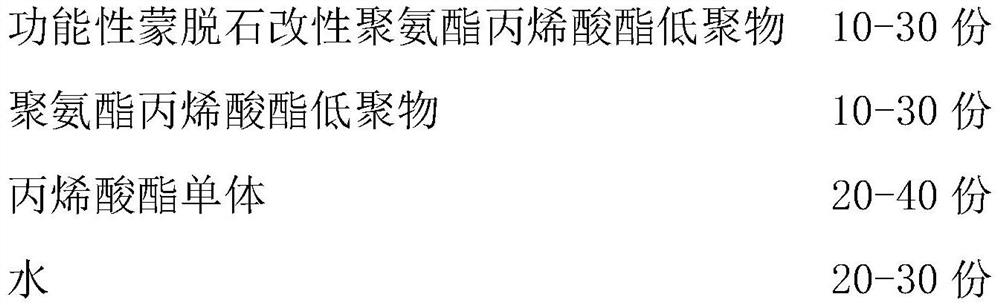

Environment-friendly high-solid-content waterborne polyurethane acrylate composite emulsion as well as preparation method and application thereof

ActiveCN114045107AAdjust the degree of polarityFully compatibleNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention provides an environment-friendly high-solid-content waterborne polyurethane acrylate composite emulsion as well as a preparation method and application thereof. The environment-friendly high-solid-content waterborne polyurethane acrylate composite emulsion comprises functional layered silicate, and the functional layered silicate is layered silicate modified by an anionic surfactant, a cationic surfactant and a hydroxyl-rich water-soluble polymer in a composite intercalation manner. The preparation method comprises the following steps of: (1) mixing: well mixing a functional montmorillonite modified polyurethane acrylate oligomer, a polyurethane acrylate oligomer, an acrylate monomer and water, heating, stirring in a stirrer, and naturally cooling to room temperature to obtain a component A; (2) well stirring a photoinitiator, a flatting agent and water at normal temperature to obtain a component B; and (3) mixing the component A and the component B, stirring well at normal temperature, standing for defoaming, and storing in a dark place to obtain the environment-friendly high-solid-content waterborne polyurethane acrylate composite emulsion. The environment-friendly high-solid-content waterborne polyurethane acrylate composite emulsion can be used for adhesives or coatings.

Owner:NANXIONG RISING CHEM IND

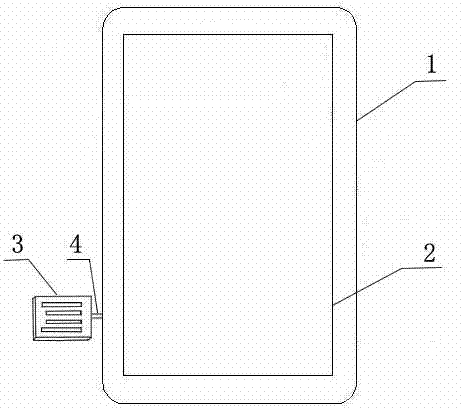

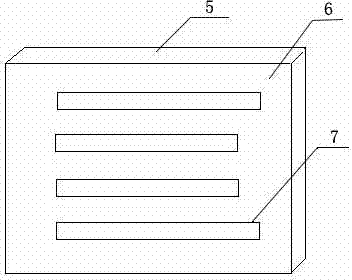

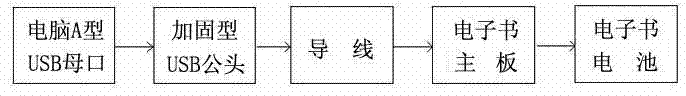

Novel communication digital product

The invention discloses a novel communication digital product and relates to digital communication products such as mobile phones and electronic books. The novel communication digital product comprises a shell of the communication digital product, a USB (universal serial bus) plug, a mainboard and a battery, and is characterized in that the USB plug is a reinforced USB plug capable of being directly plugged into an A-type USB socket and is connected with the mainboard of the communication digital product by a conducting wire. The reinforced USB plug is arranged inside the shell of the product or a groove of the shell of the product at ordinary times, and can be pushed out by modes such as a manual mode, an electric mode, a flat-pushing mode, a rotating mode and a bending mode, so that the novel communication digital product can be directly connected with a computer, a laptop, a mobile power source and the like, convenient charging and data transmission can be realized, further, stability, bearing capacity and strength of a USB interface are improved due to the fact that the shell is thickened and reinforced, and problems that a common USB interface is loosened and damaged due to long-term usage are solved. The invention is particularly applicable to relevant products with built-in ultra-thin USB plugs.

Owner:倪晓旺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com