HIPS composite material as well as preparation method and application thereof

A composite material and resin technology, applied in the field of HIPS composite material and its preparation, can solve the problems of no outstanding improvement in high toughness stress cracking, decreased material dimensional stability, expensive graphene components, etc., and achieve a reduction in melt viscosity. , the effect of reducing density and light density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

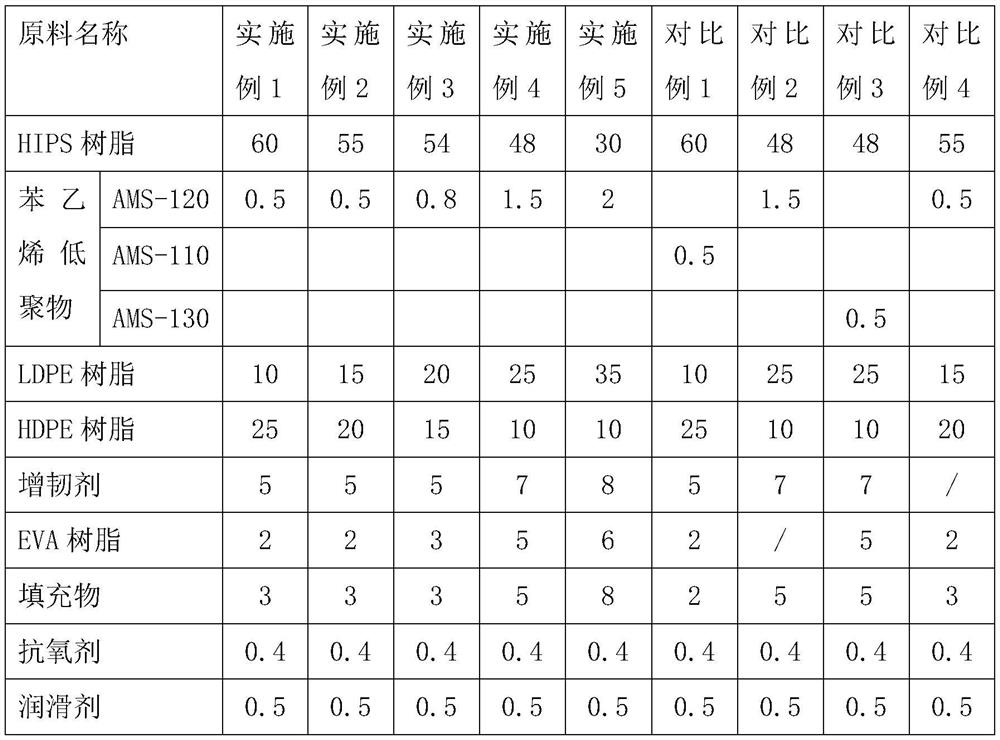

[0049] A kind of PS composite material of low density, high toughness, low stress cracking characteristics, its raw material formula is as shown in table 1, and its preparation method comprises the following steps:

[0050] The above-mentioned LDPE resin and EVA resin are frozen and pulverized, and then mixed evenly with other raw materials except the oil-extended SBS elastomer, and then fed from the main feeding port of the extruder, and the oil-extended SBS elastomer is passed through Side feeding means, side feeding into the barrel of the extruder; the raw materials are melted, extruded and granulated in the extruder to obtain PS composite materials with low density, high toughness and low stress.

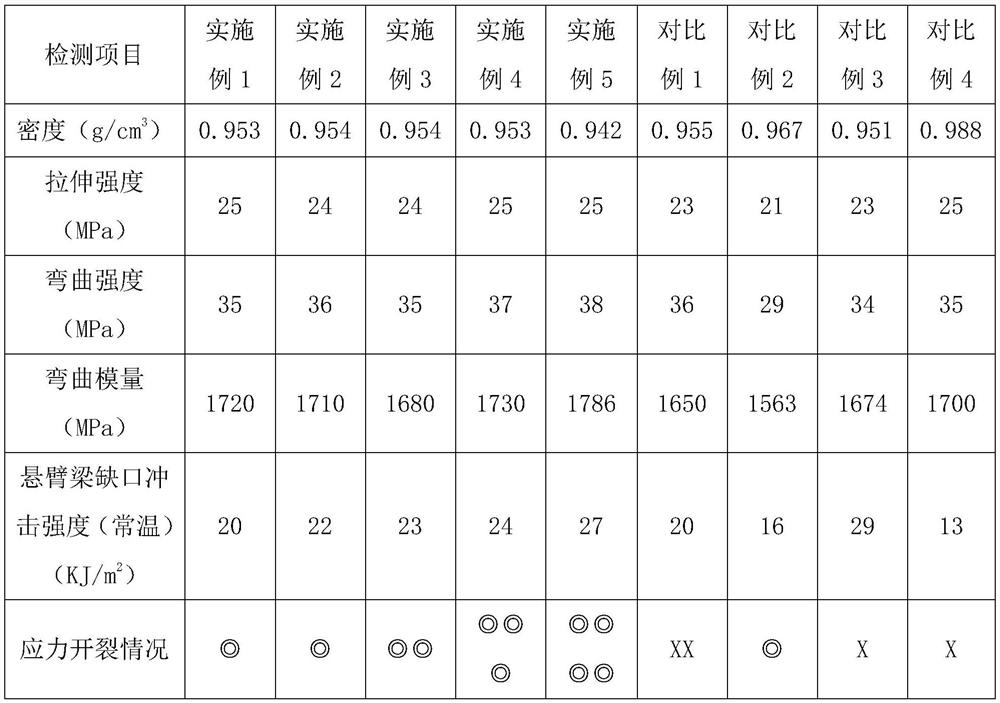

[0051] The pellets were injection molded into corresponding samples for testing, and the test results are shown in Table 2.

Embodiment 1

[0060] Embodiment 1 is compared with comparative example 1 and embodiment 4 and comparative example 3, and AMS-120 can obviously improve the stress cracking situation than AMS-110, AMS-130, and the molecular weight that shows that the present invention selects for use is that the styrene of 800-1300 is low The polymer has better overall mechanical properties and stress cracking resistance of the material. In terms of processability and fluidity, AMS-120 has better balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com