Patents

Literature

64results about How to "Reduce stress cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

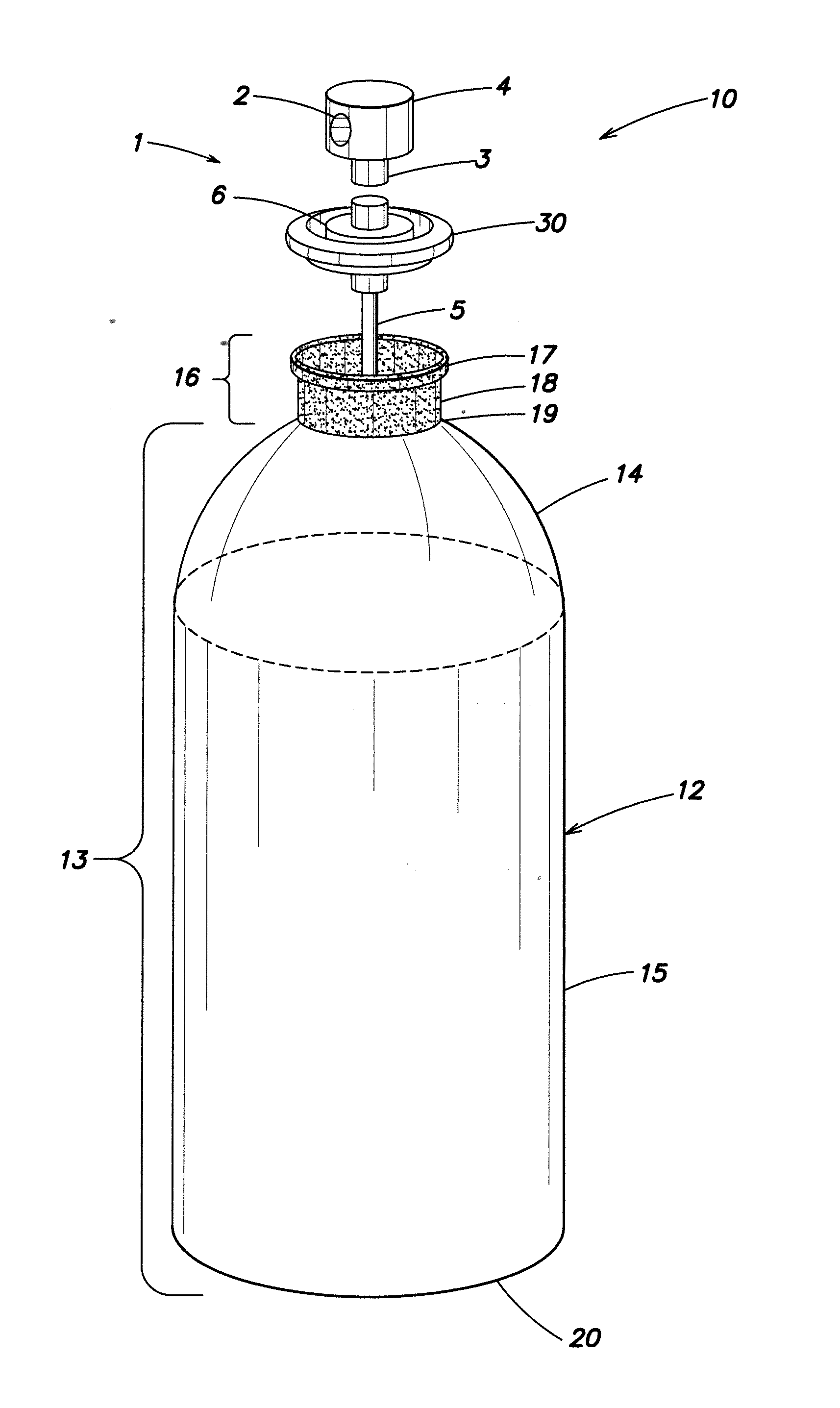

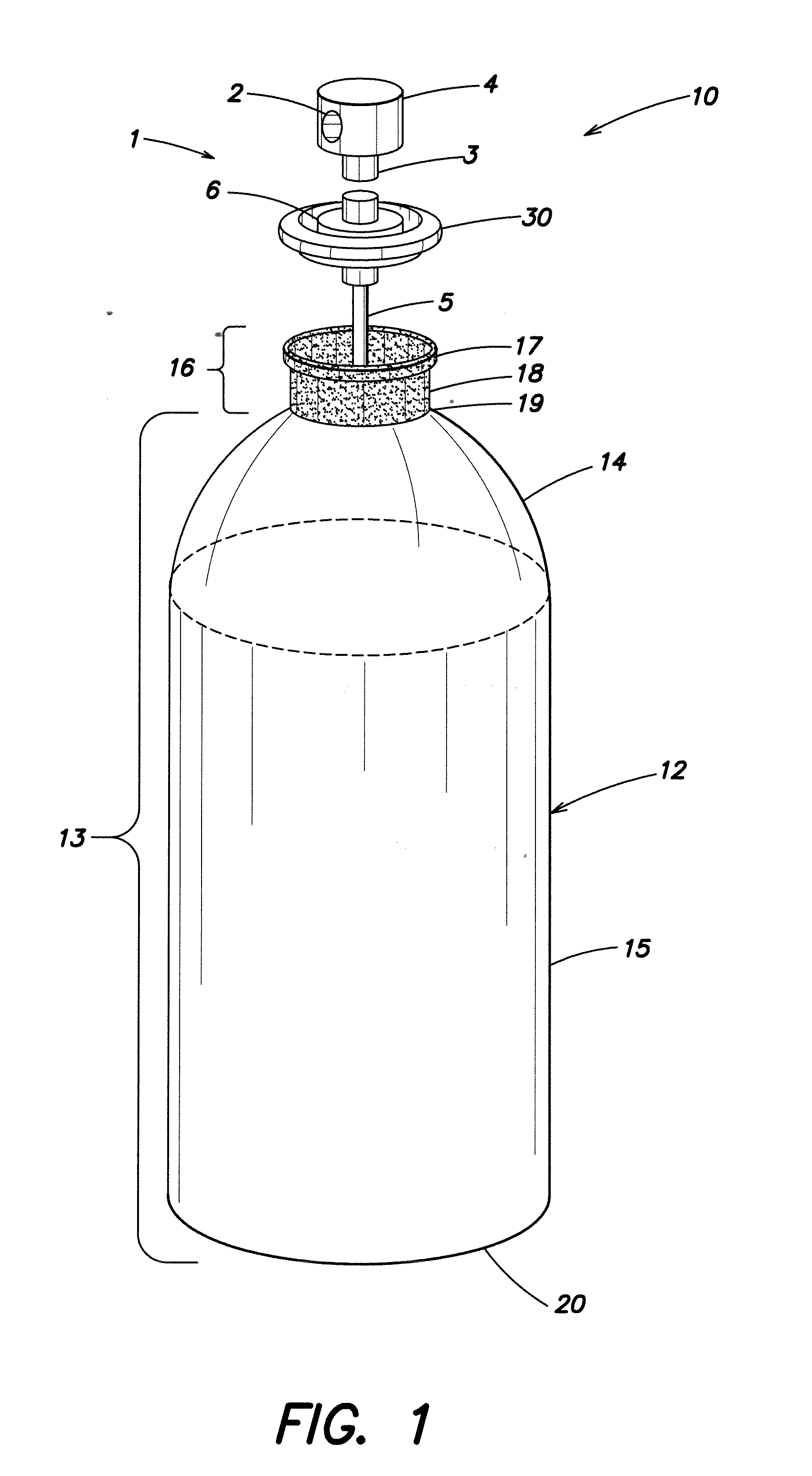

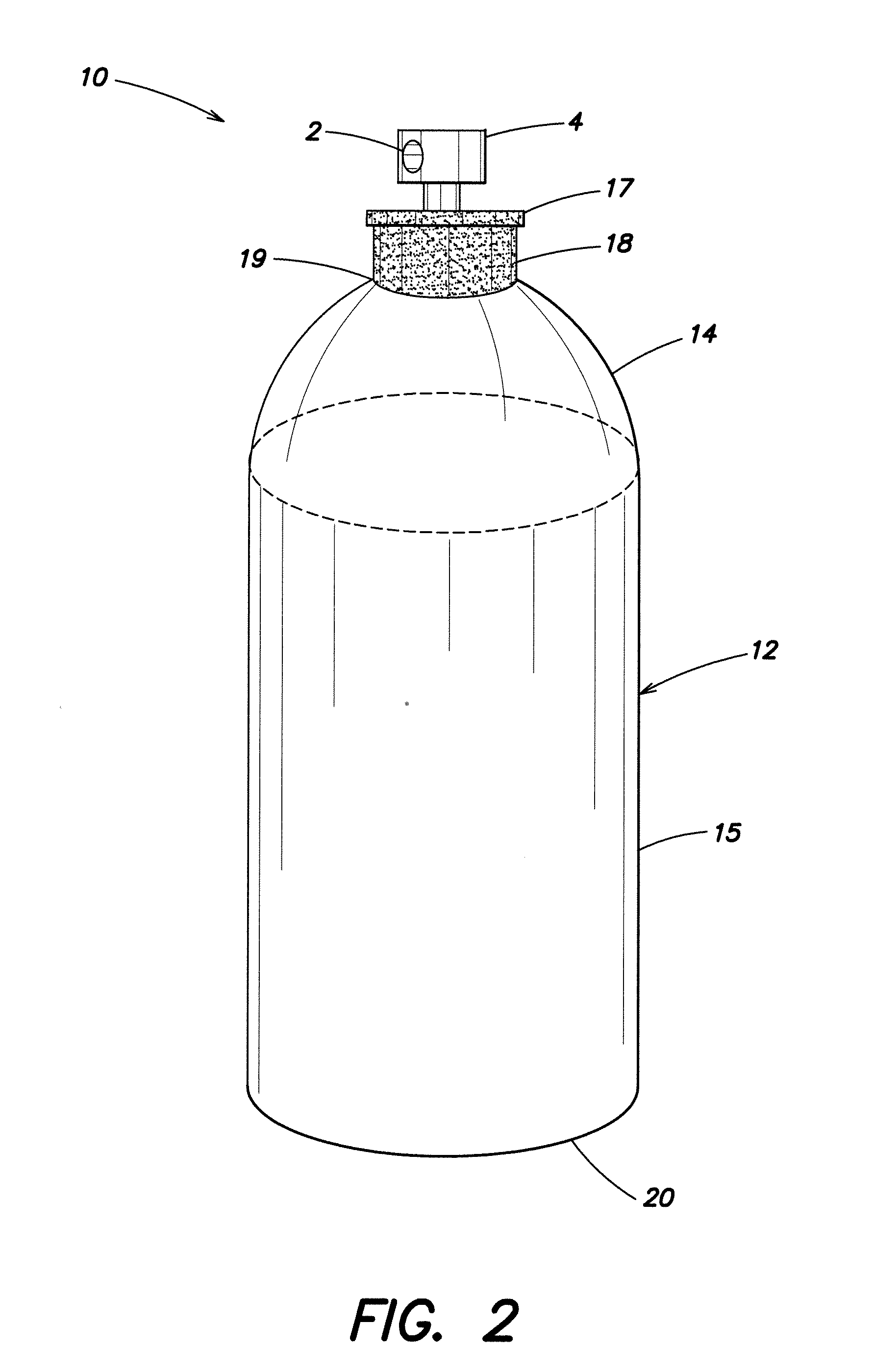

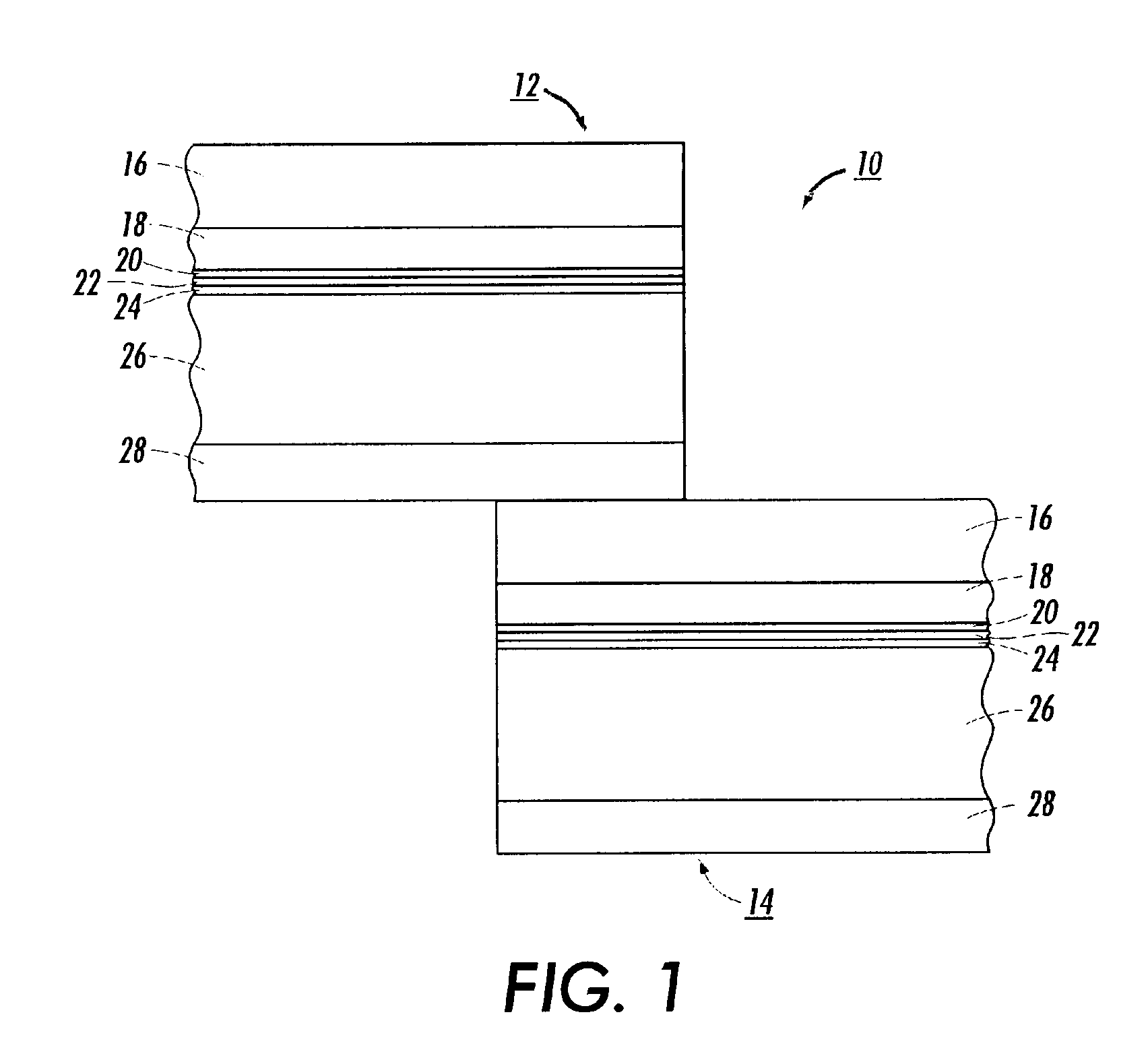

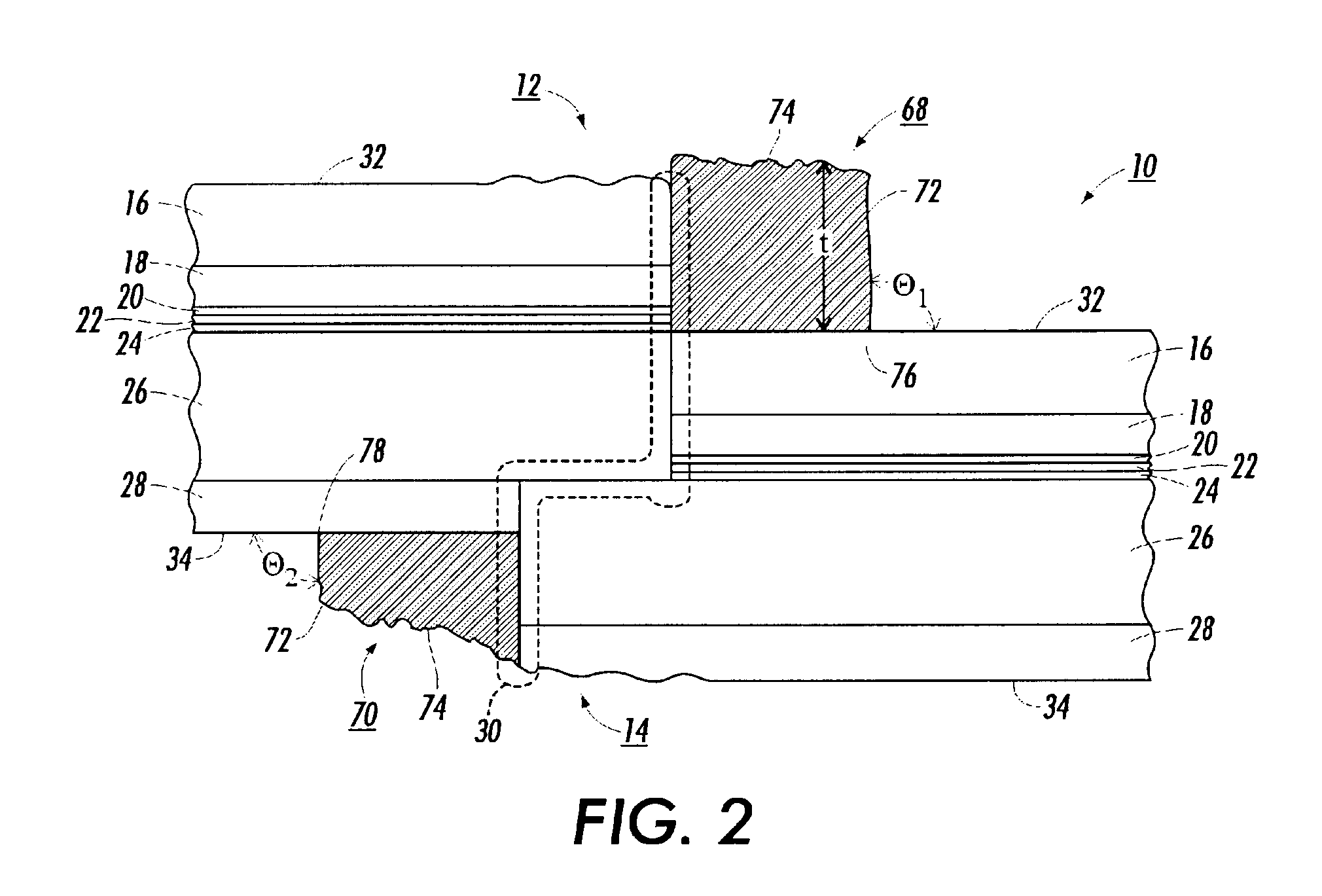

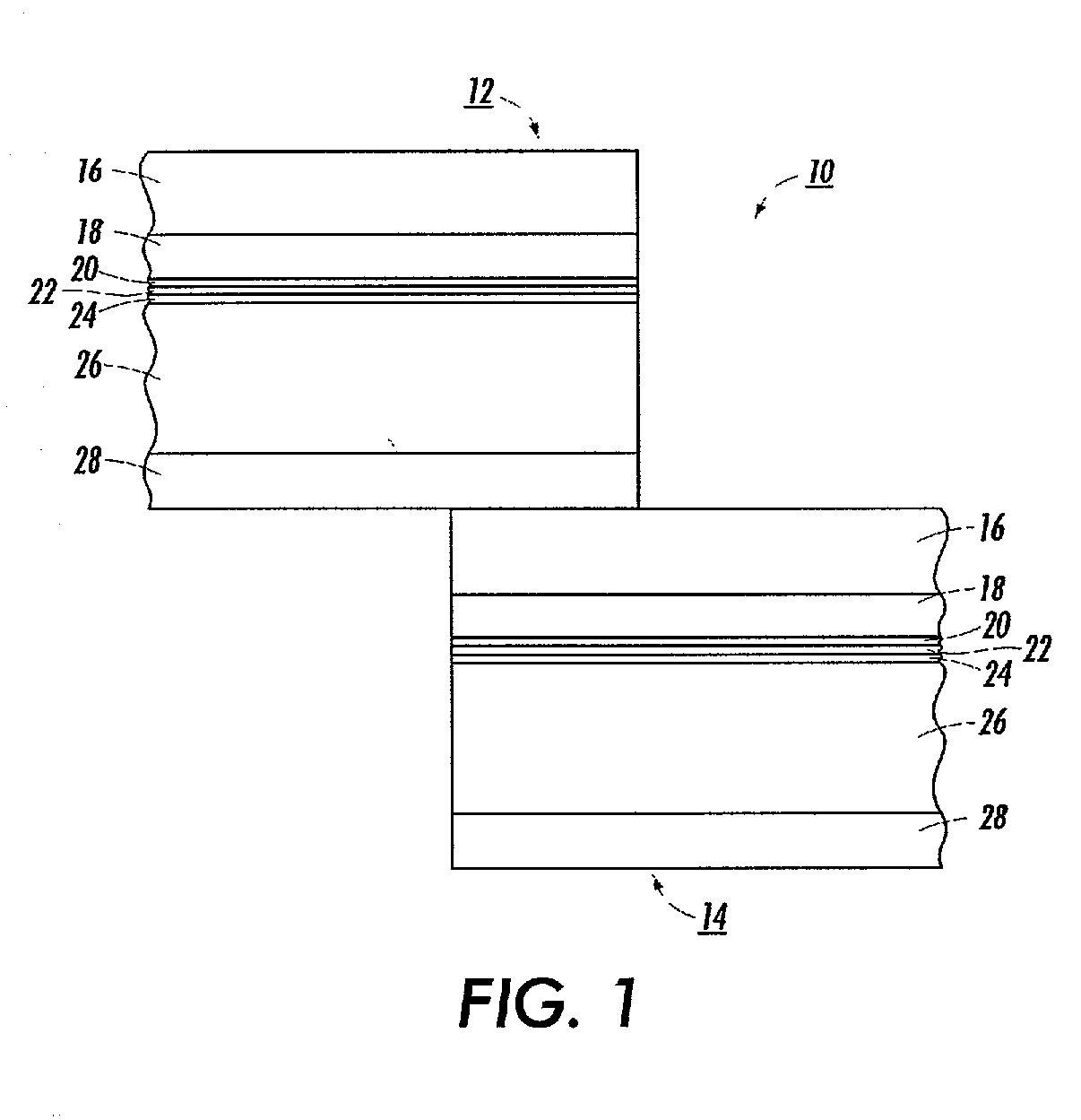

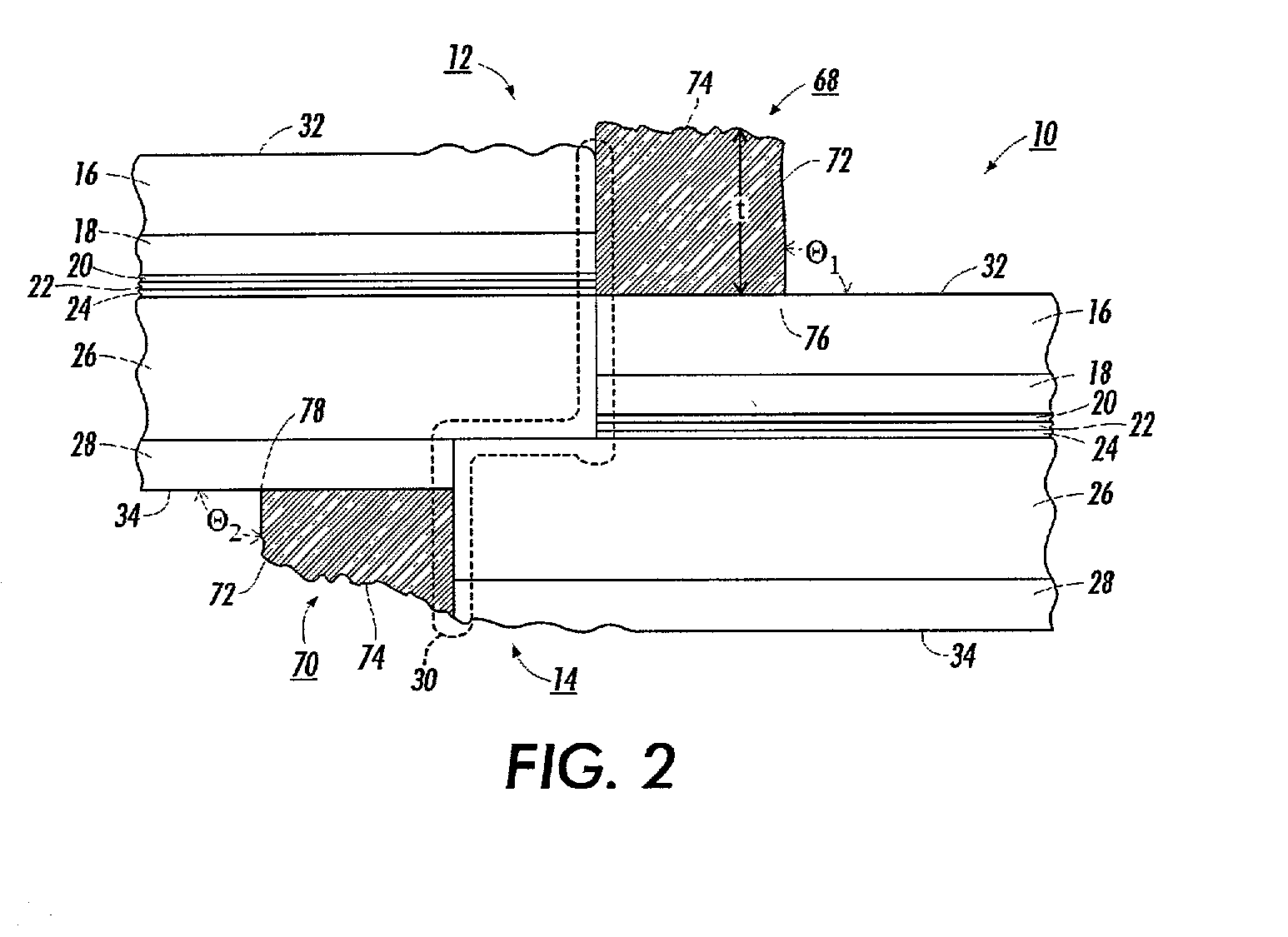

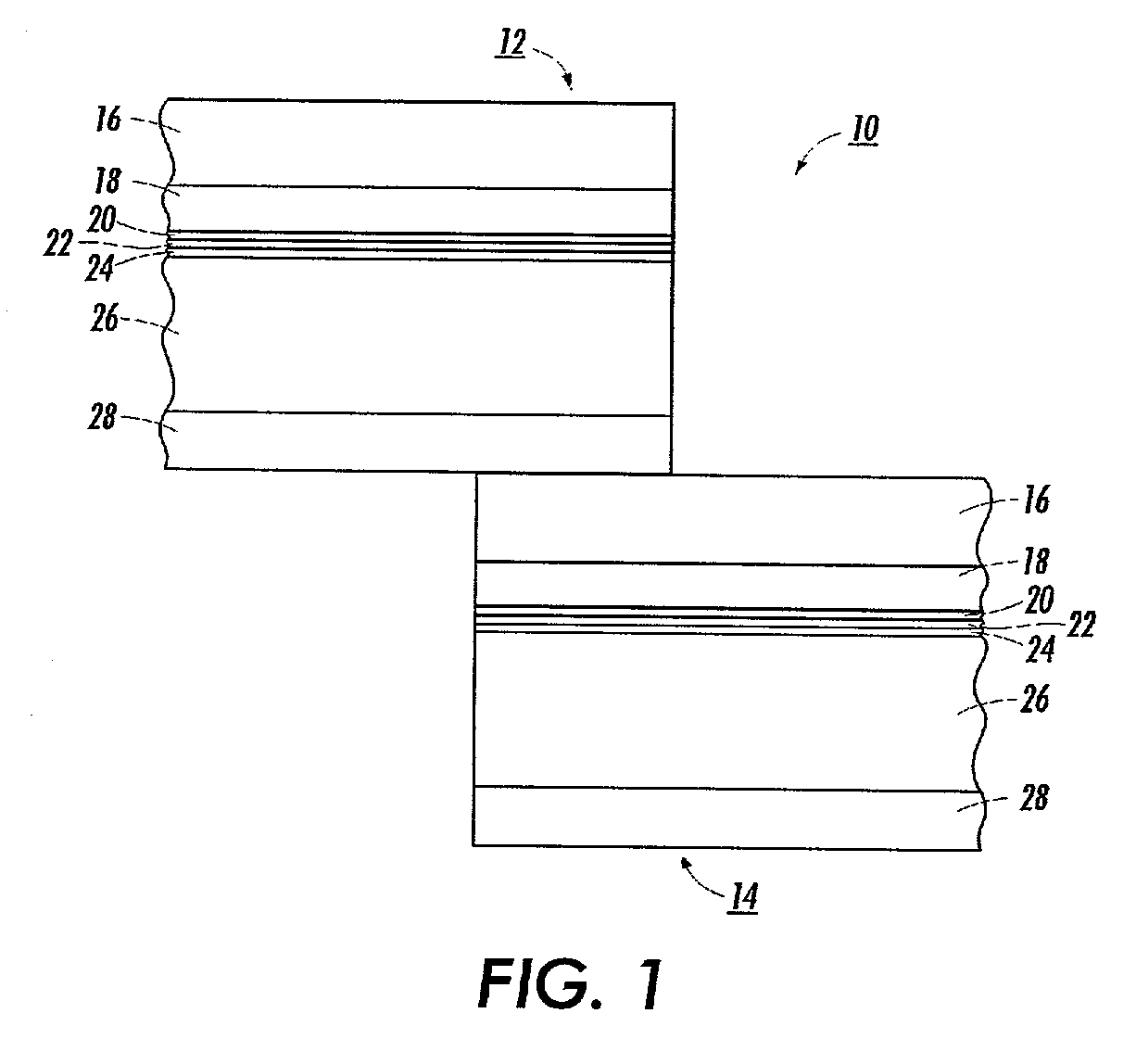

Plastic aerosol container and method of manufacture

ActiveUS20130037580A1Reduce weightReduce areaBottlesSynthetic resin layered productsEngineeringMechanical engineering

Plastic aerosol container having a thermally crystallized neck finish configured to receive an aerosol valve assembly and an expanded strain oriented aerosol container body integral with the neck finish. A junction between the thermally crystallized neck finish and the strain oriented container body defines a pull point at which strain orientation begins.

Owner:GRAHAM PACKAGING CO LP

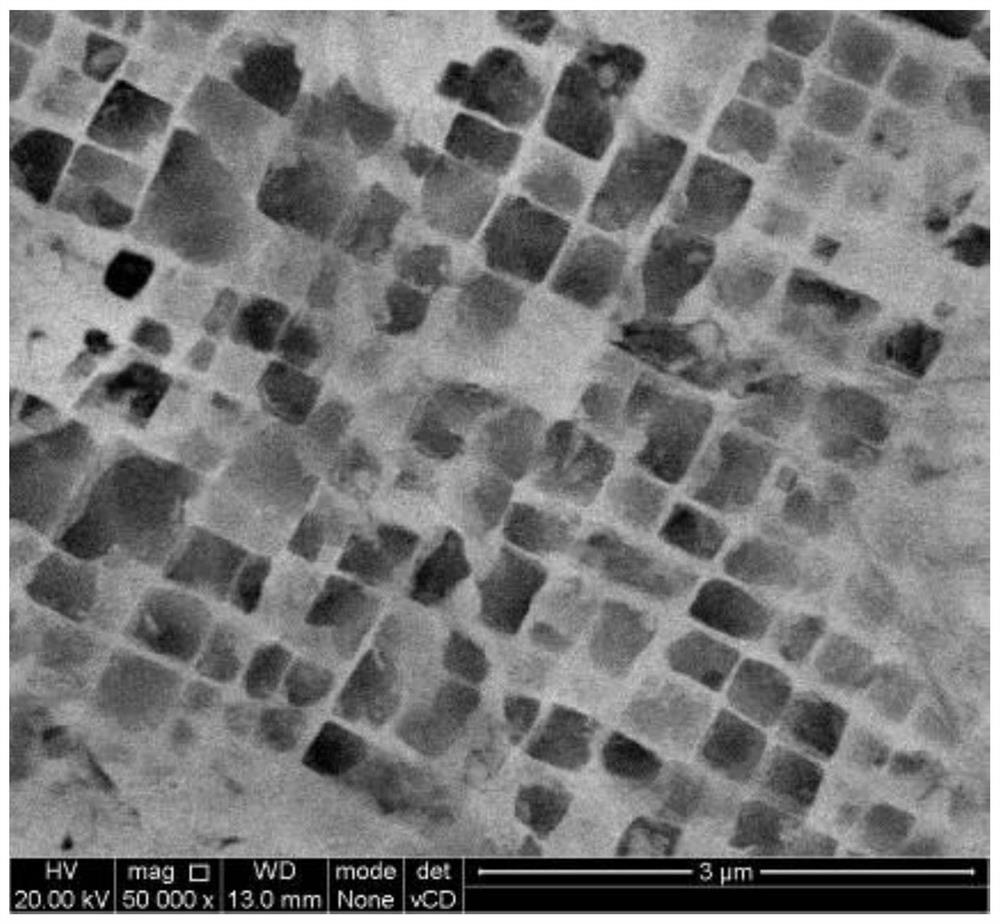

Nanocarbon reinforced low-carbon magnesia carbon brick and preparation method thereof

The invention belongs to the technical field of refractory materials and particularly relates to a nanocarbon reinforced low-carbon magnesia carbon brick and a preparation method of the nanocarbon reinforced low-carbon magnesia carbon brick. The nanocarbon content of the nanocarbon reinforced low-carbon magnesia carbon brick is 2-4%, and is 50% of the carbon content of the current mainstream magnesia carbon brick. The sintering performance, the antioxygenic property and the thermal shock performance of the magnesia carbon brick are not reduced and are even better than those of the existing magnesia carbon brick. The required total carbon is reduced by a half, the material cost is reduced, and the service life of the magnesia carbon brick is also prolonged; and in addition, the preparationcost is low, the process is simple, and the magnesia carbon brick is suitable of industrial application and large-scale promotion.

Owner:营口石元耐火材料有限公司

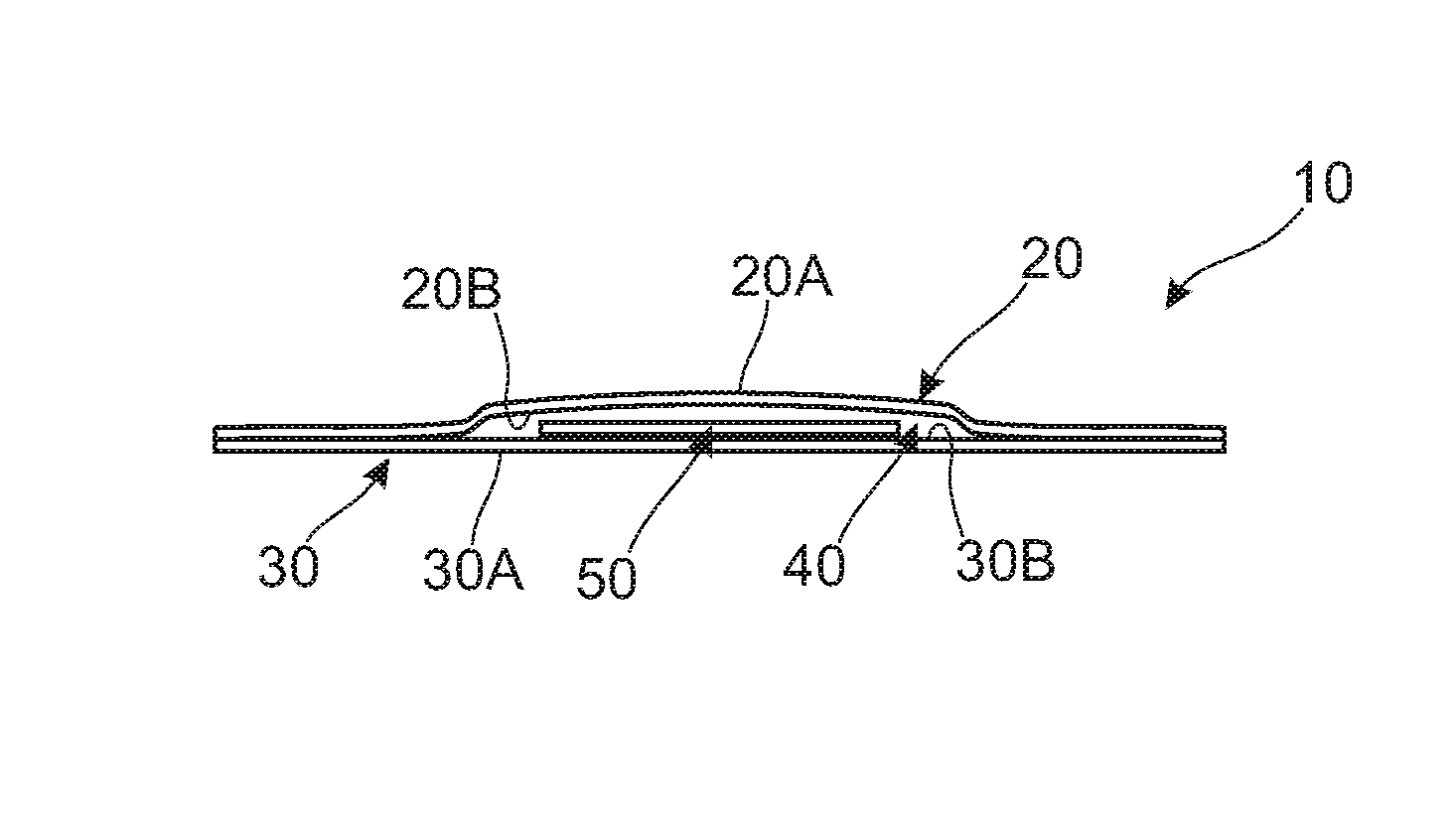

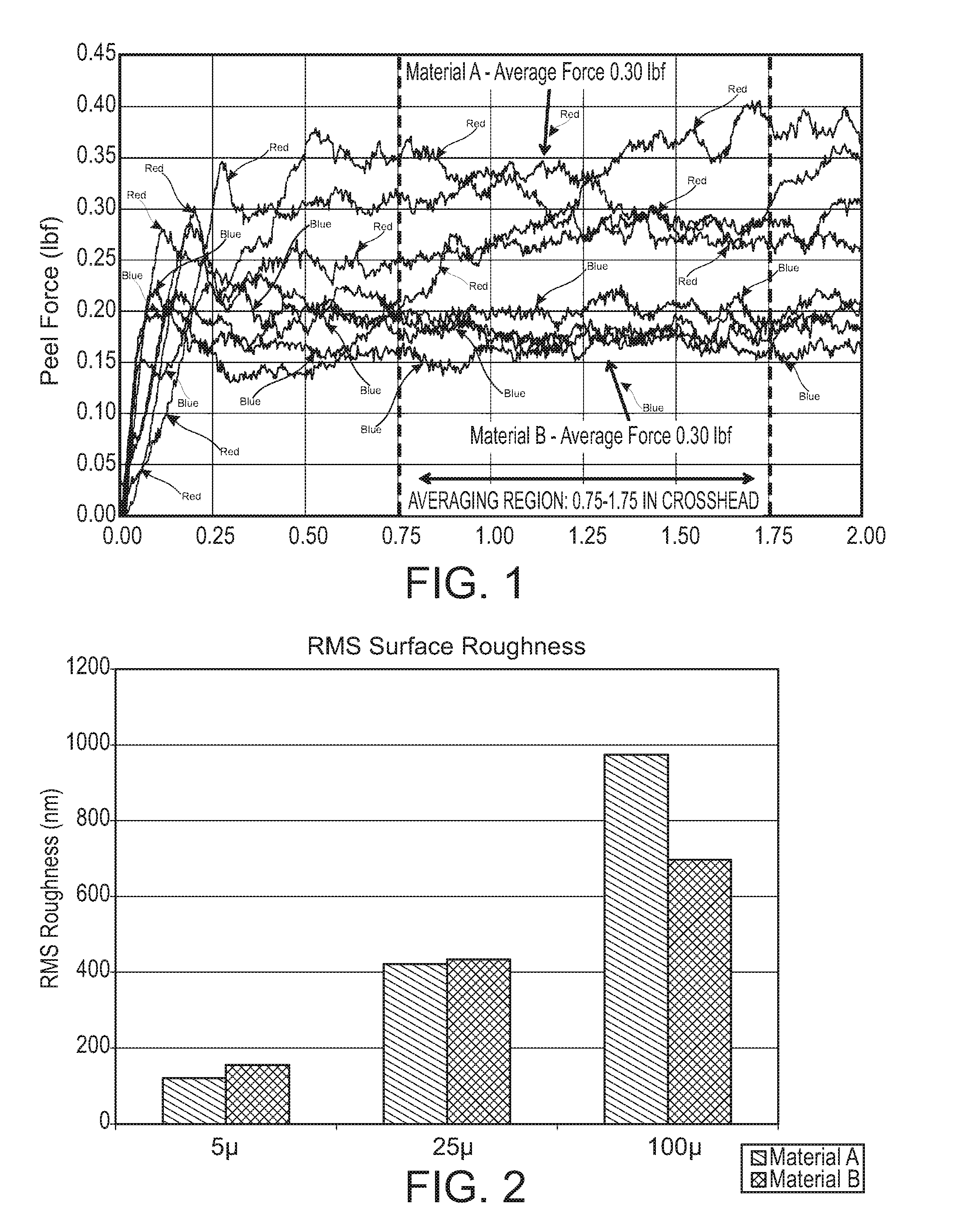

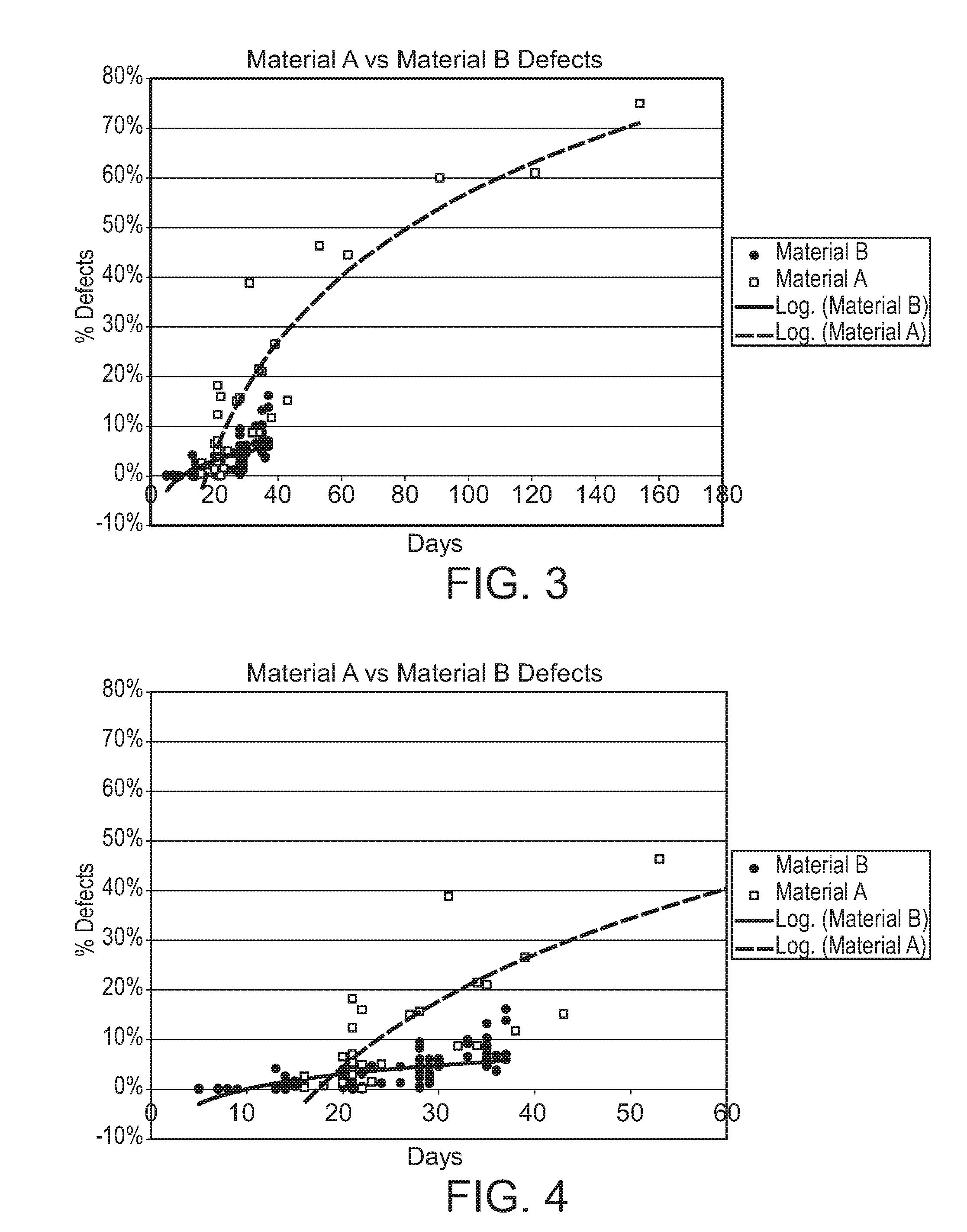

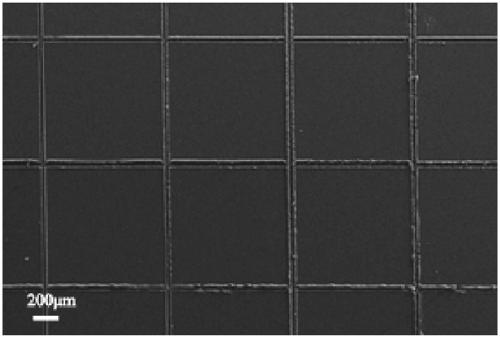

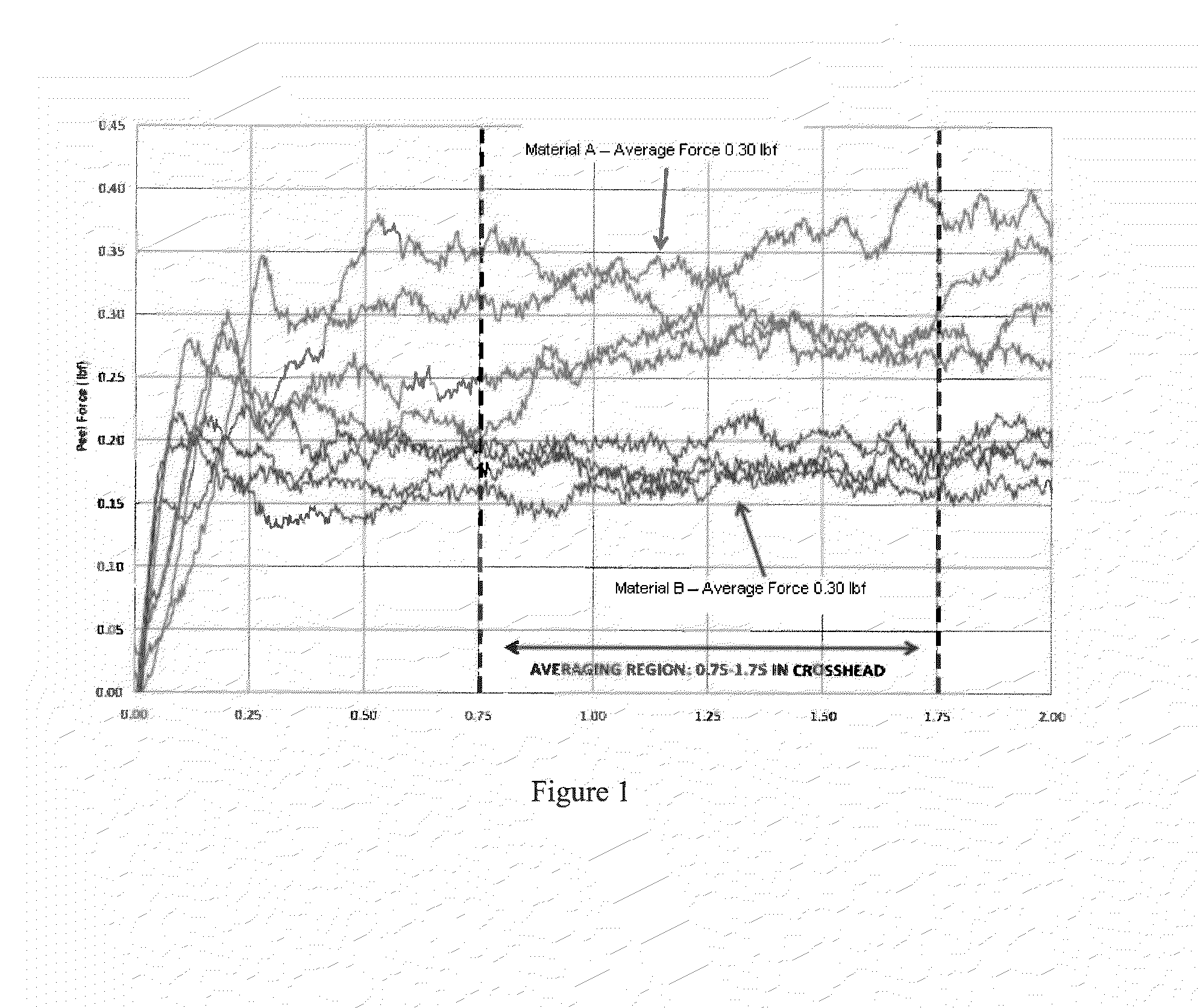

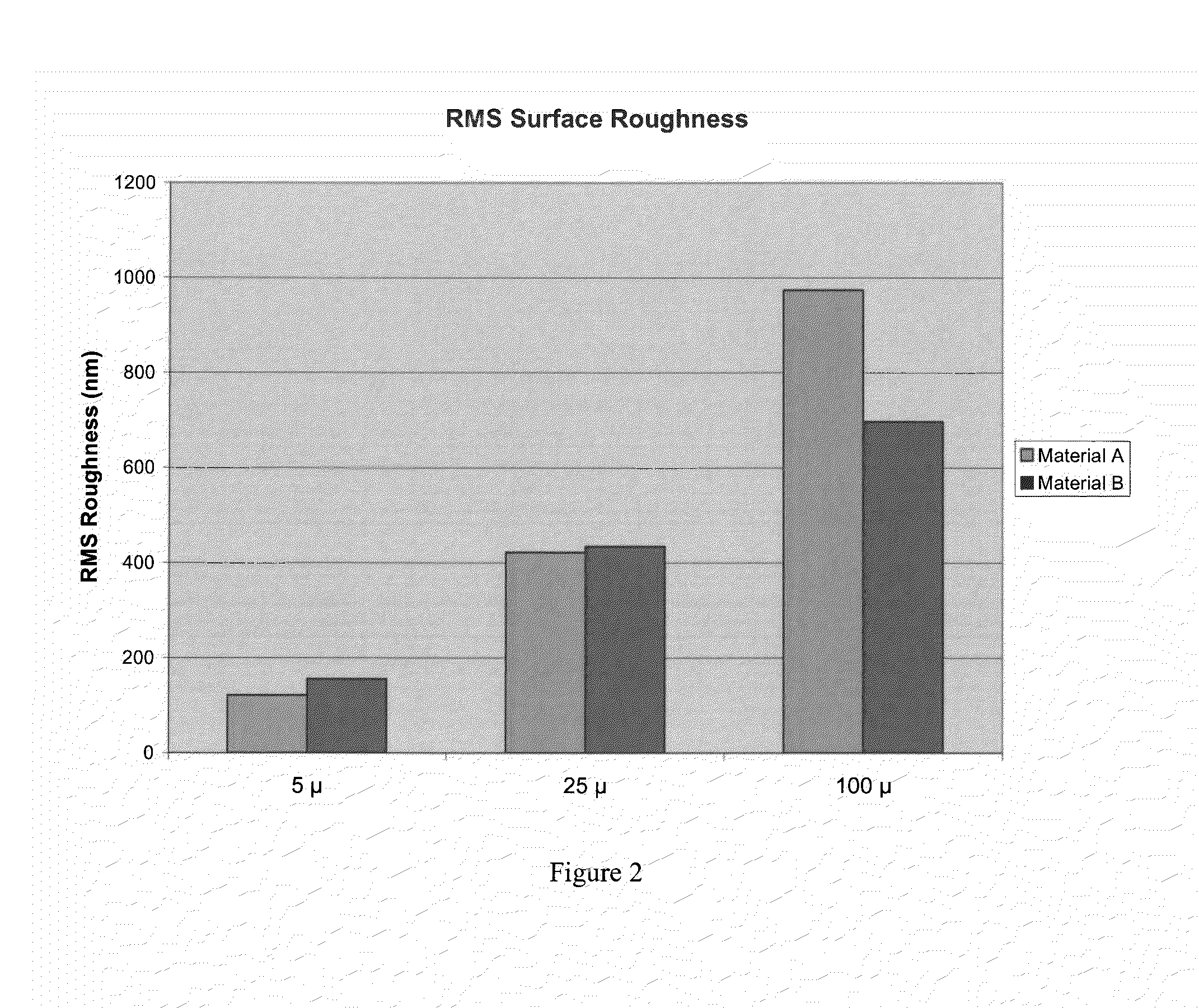

Reduction in stress cracking of films

ActiveUS9346601B2Reducing and substantially reducing stress crackingLower surface energyWrappersShock-sensitive articlesMaterials sciencePolymer

Owner:AQUESTIVE THERAPEUTICS INC

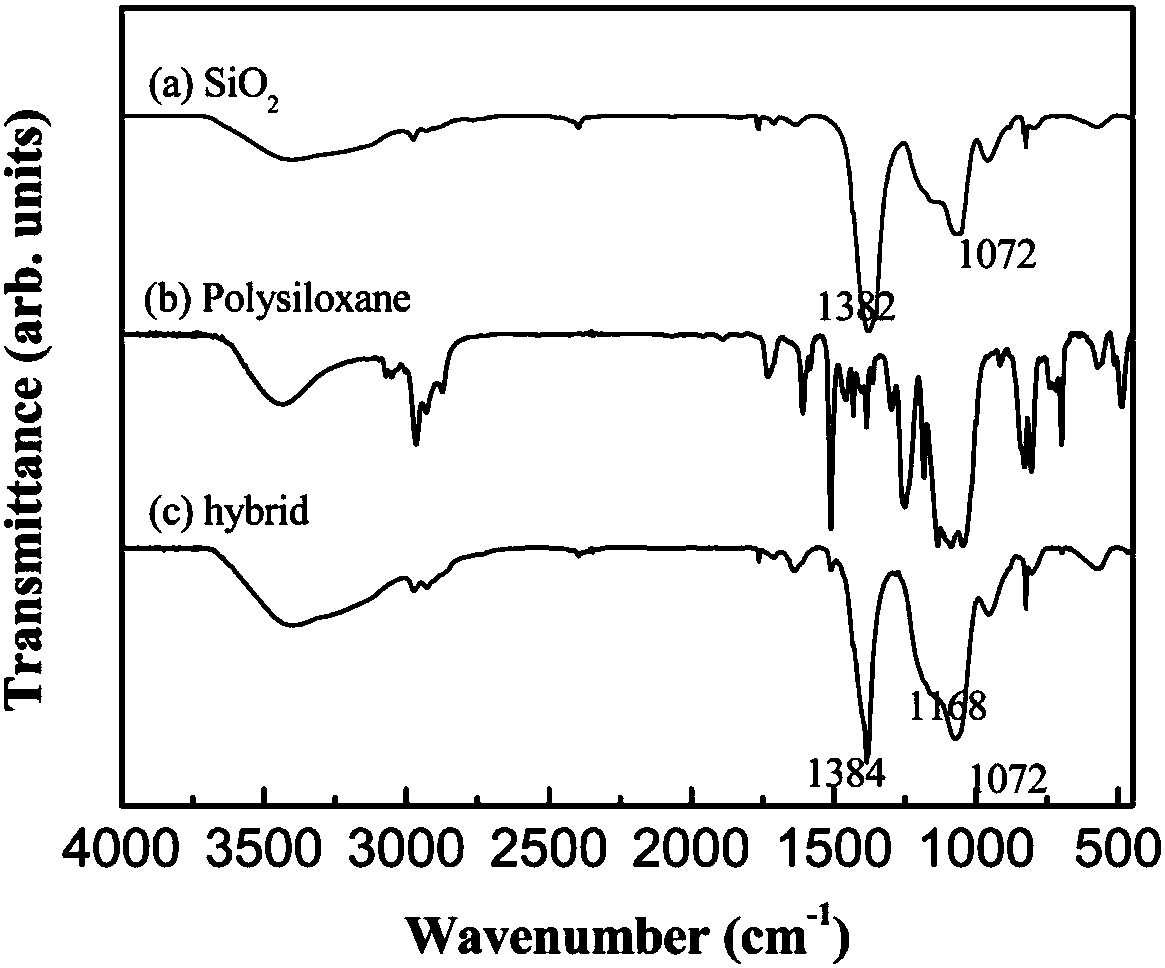

Method for preparing high inorganic component silicone-SiO2 hybrid coating by sol-gel method

InactiveCN109423076AImprove corrosion resistanceResist erosionSilicaPretreated surfacesSilicic acidMaterials science

The invention mainly relates to the field of preparation of protective coatings resistance to atomic oxygen erosion and resistance to vacuum ultraviolet radiation, and particularly relates to a methodfor preparing a high inorganic component silicone-SiO2 hybrid coating resistance to space atomic oxygen erosion and resistance to vacuum ultraviolet radiation by a sol-gel method. The sol-gel methodis adopted, silicon tetraacetate is used as a precursor of a SiO2 inorganic component, and organosilicon is used as an organic component; a high inorganic component hybrid coating is prepared on the surface of a space material by adjusting and controlling critical process parameters; and under the premise of ensuring the flexibility and transparency of the material, the coating can effectively protect the space material from erosion and destruction by high energy atomic oxygen and vacuum ultraviolet in a low-earth orbit space environment. The method achieves hybridization of organic and inorganic components at a molecular level, when the silicone-SiO2 hybrid coating is applied as the protective coating on the space material, the erosion performance resistance to atomic oxygen and resistance to vacuum ultraviolet of a matrix material can be significantly improved, and the service life of the space material is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

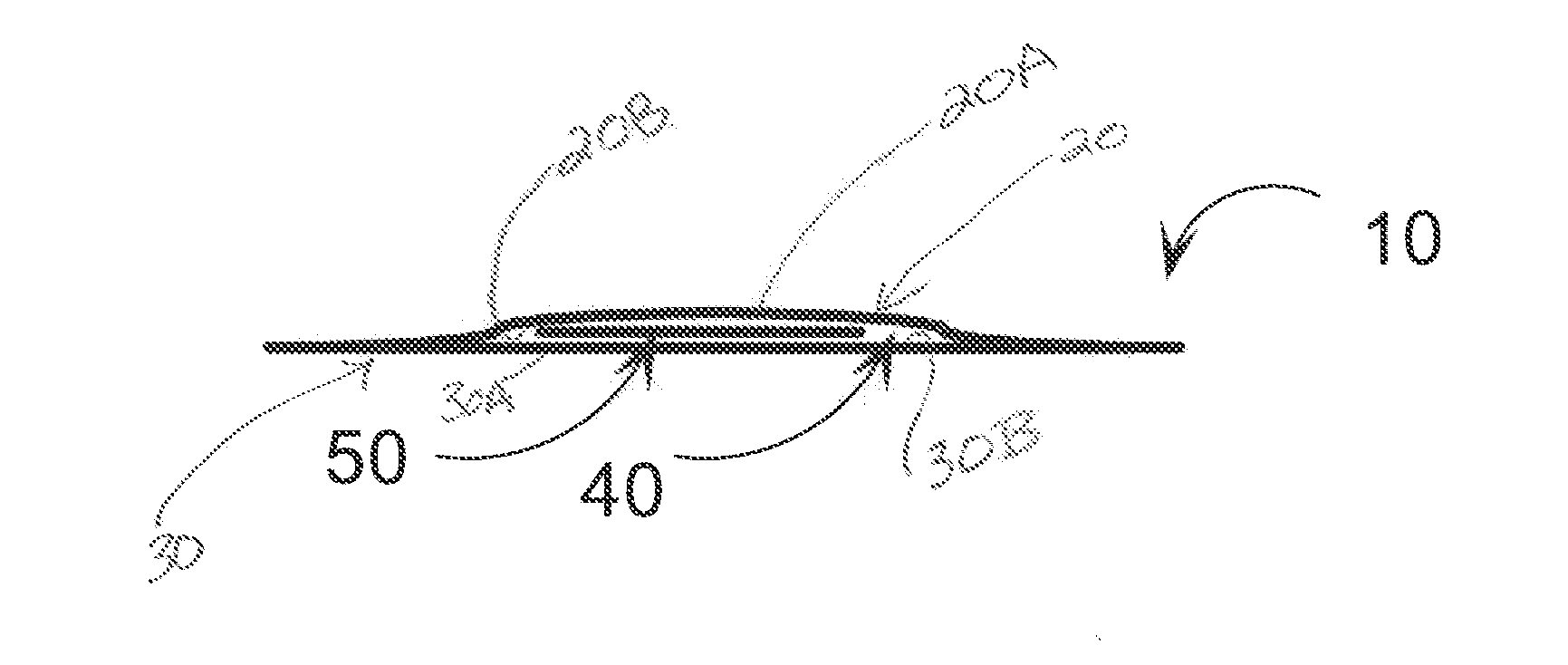

Reduction in stress cracking of films

InactiveUS20140272220A1Reducing and substantially reducing stress crackingLower surface energySynthetic resin layered productsBagsMaterials sciencePolymer

Methods and packages for storing film strips while reducing or eliminating stress cracking during storage, including use of packages having an inner surface made from polymeric materials exhibiting various physical properties and including films and pouches that are annealed.

Owner:AQUESTIVE THERAPEUTICS INC

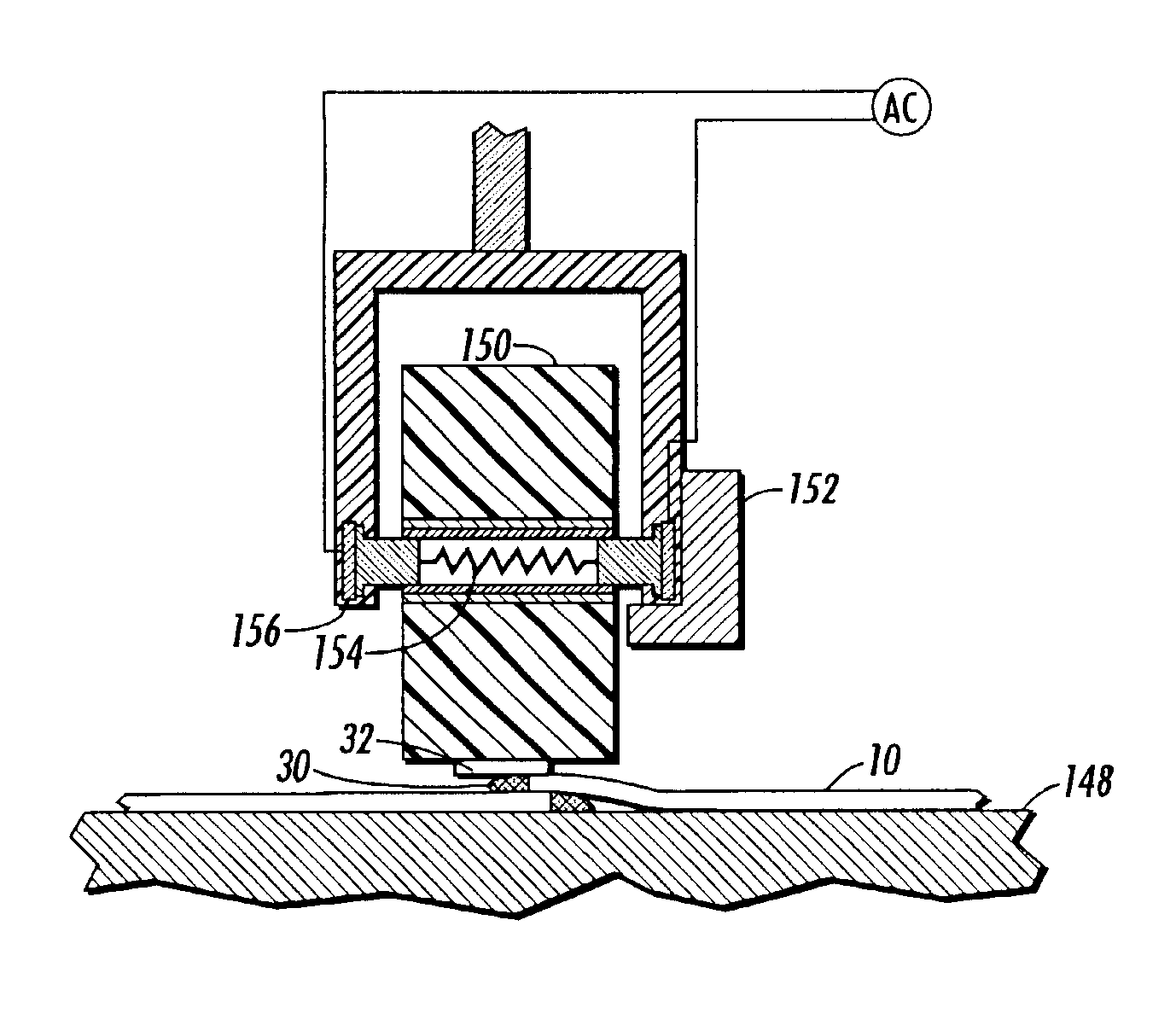

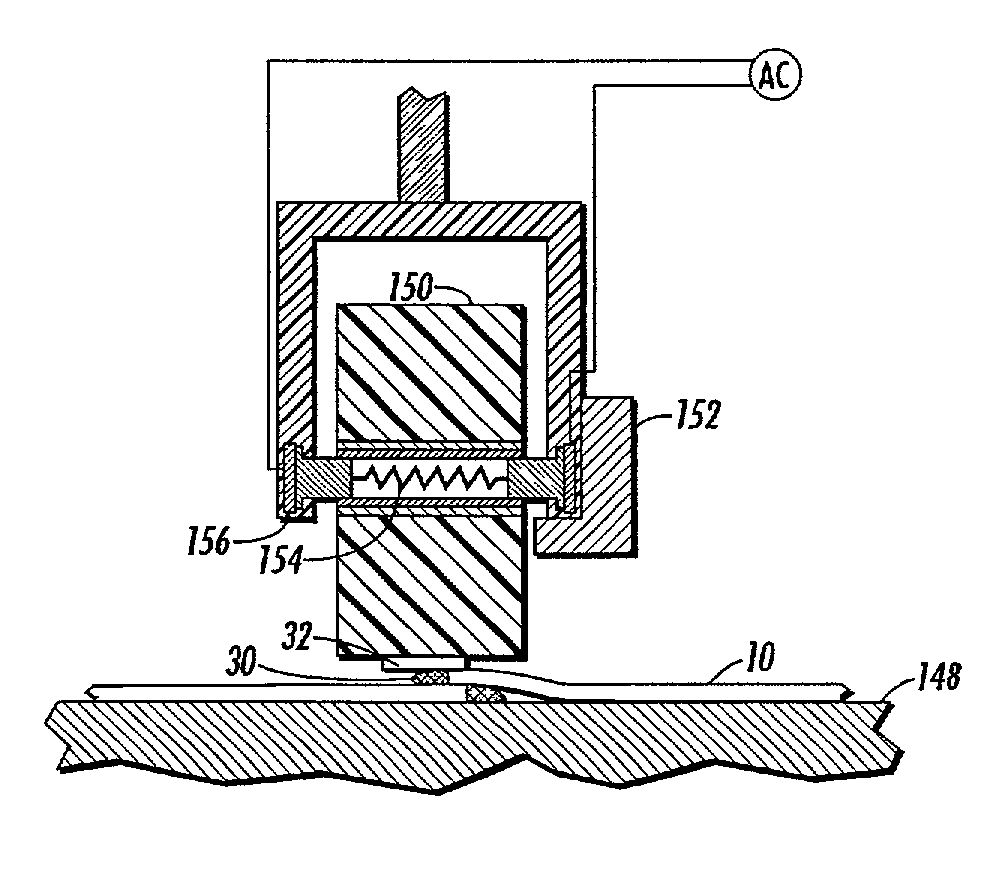

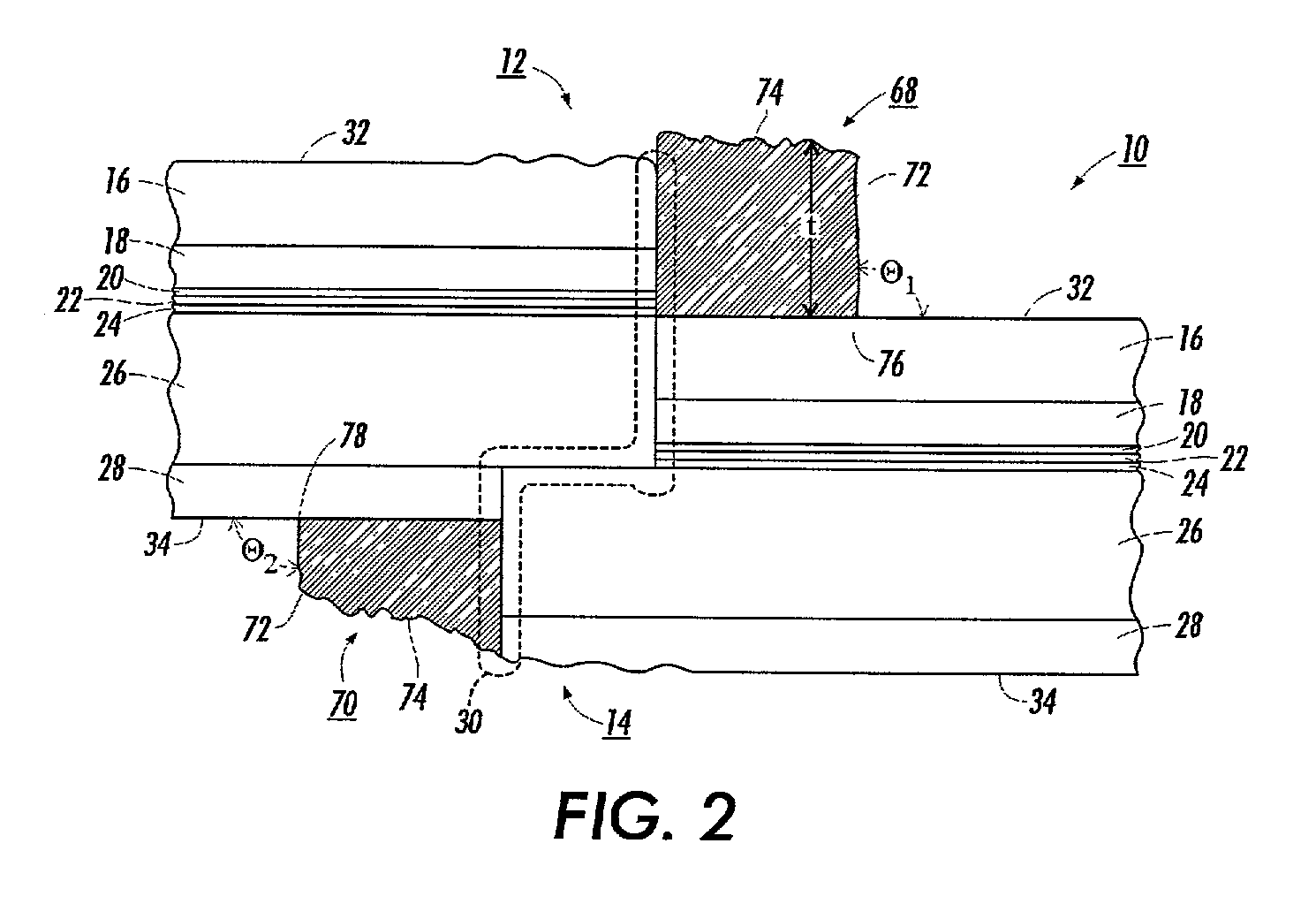

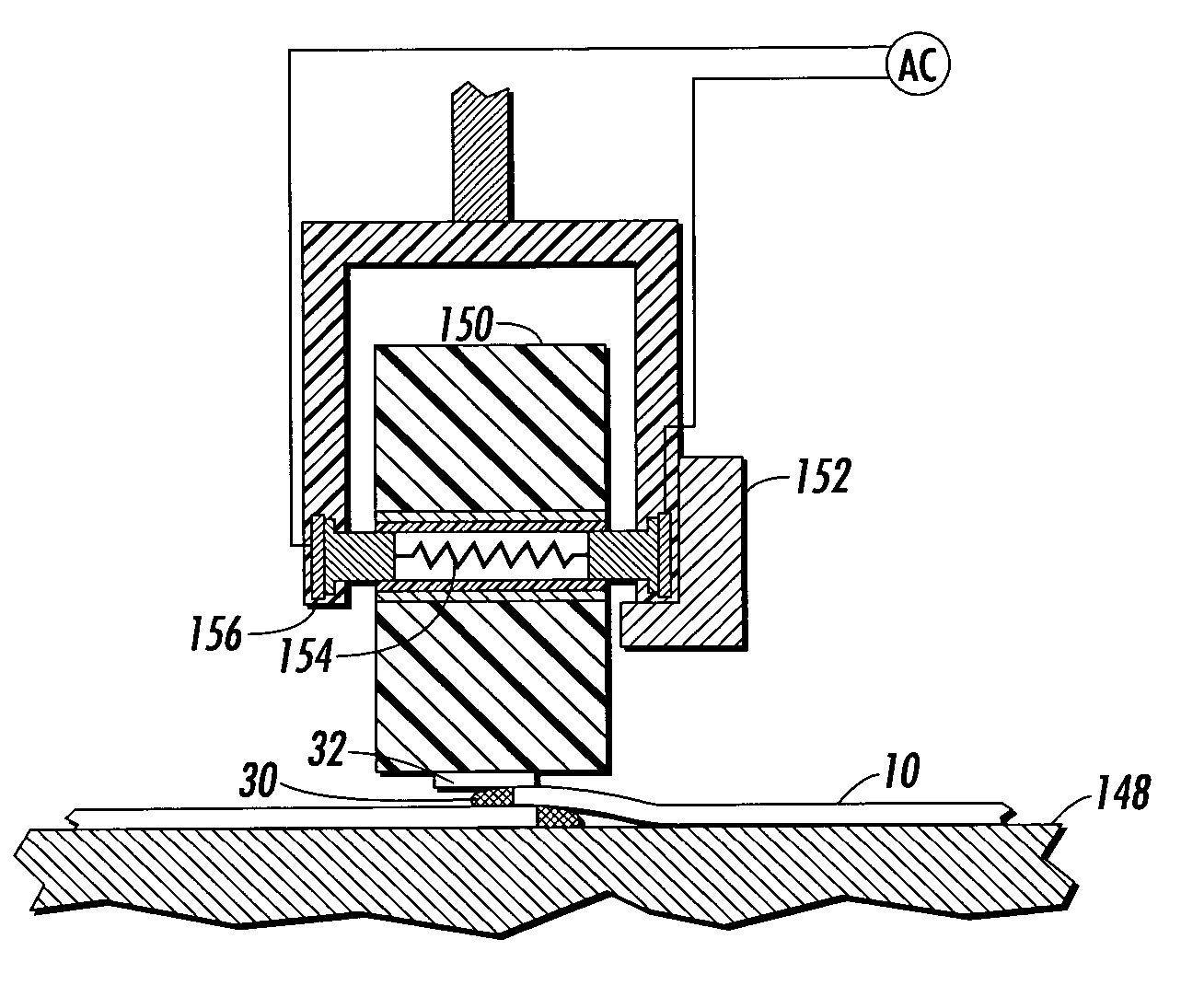

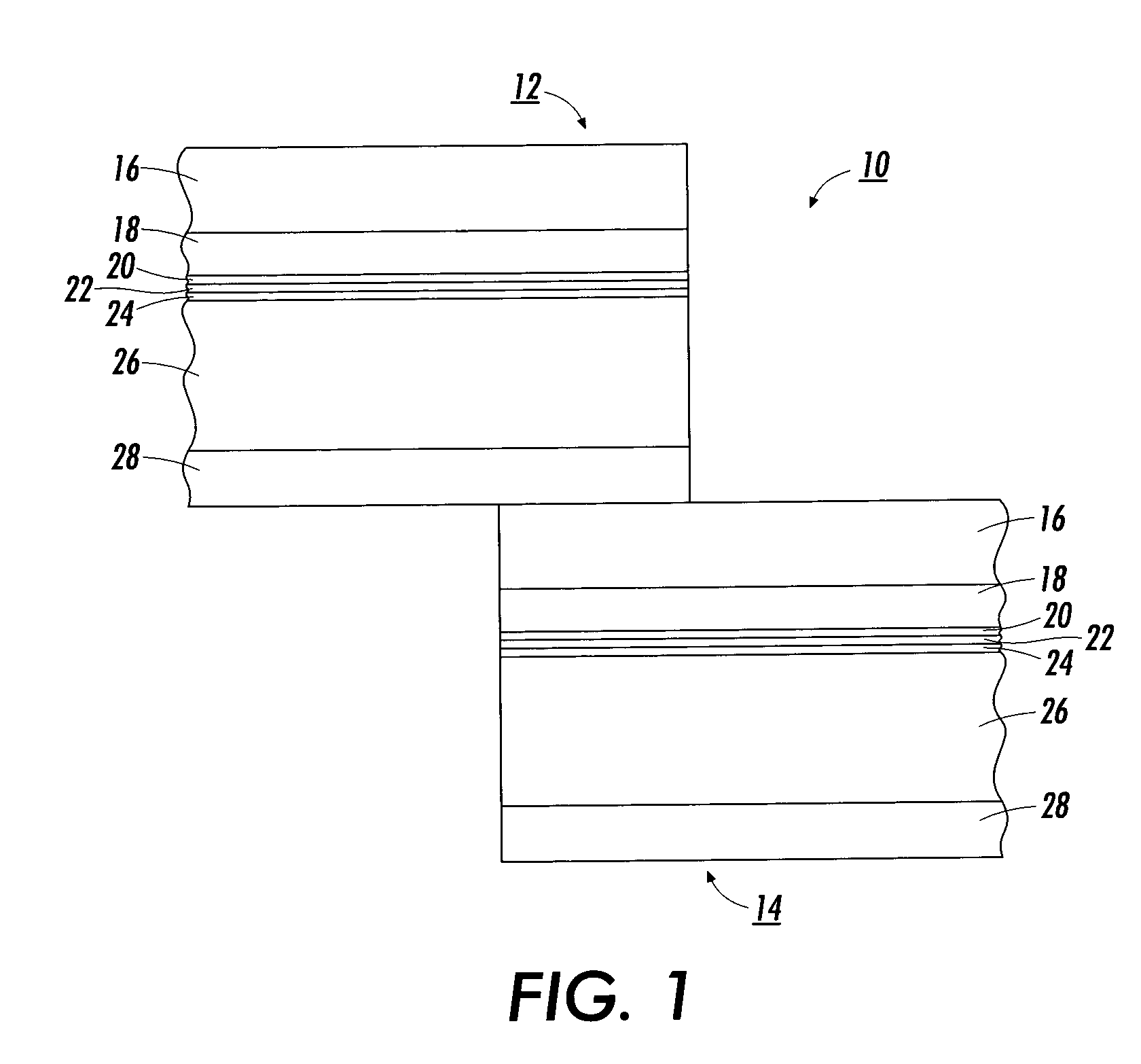

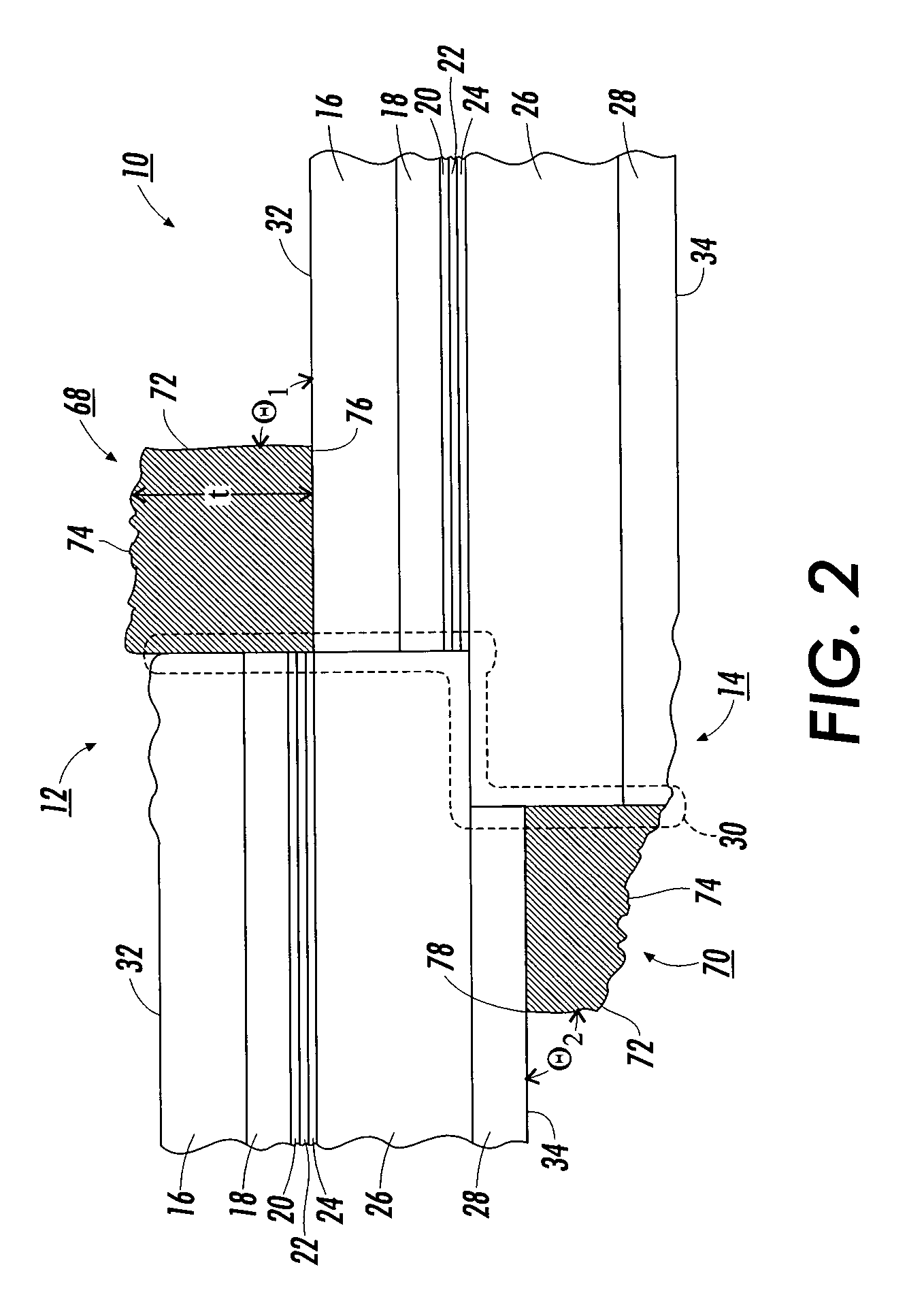

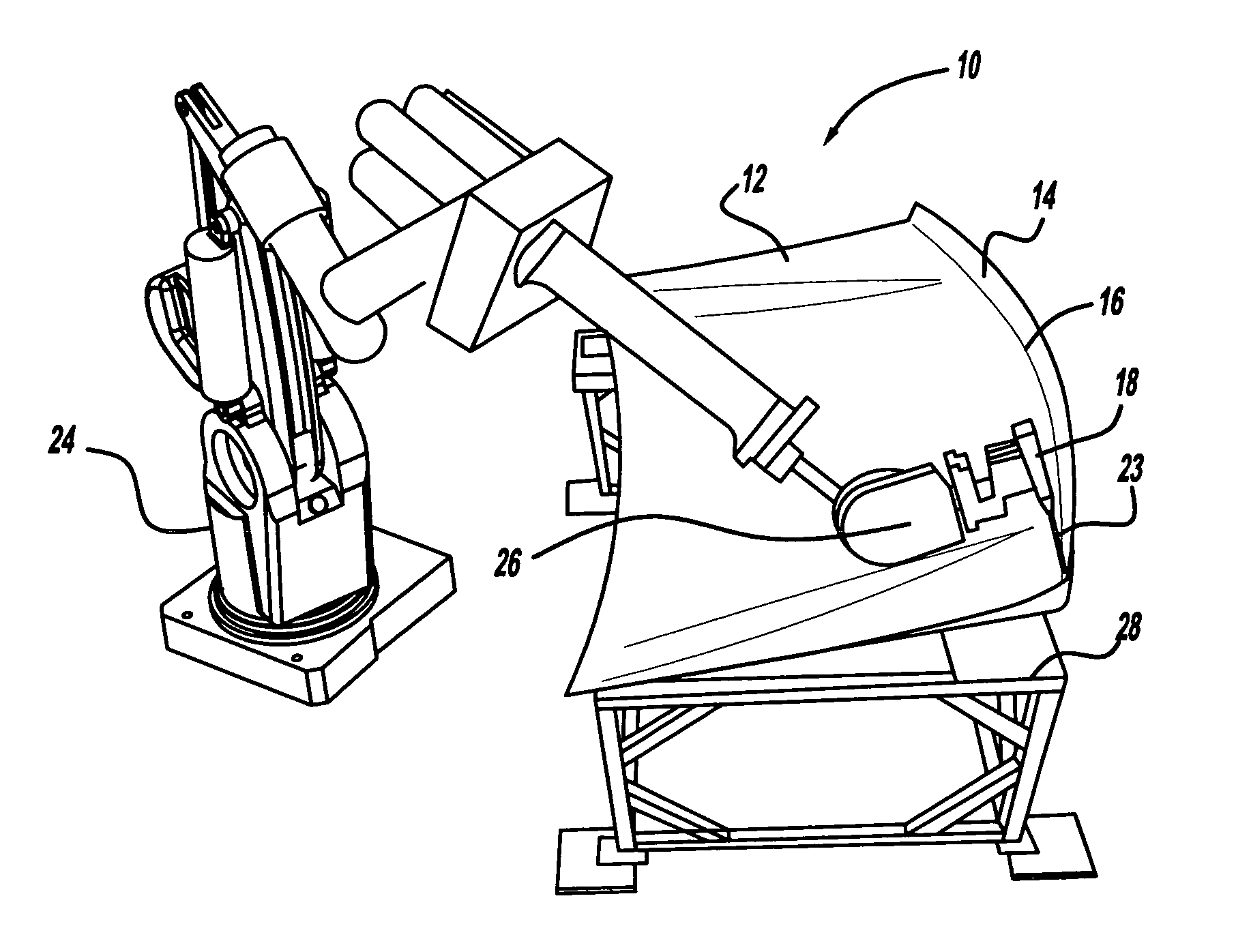

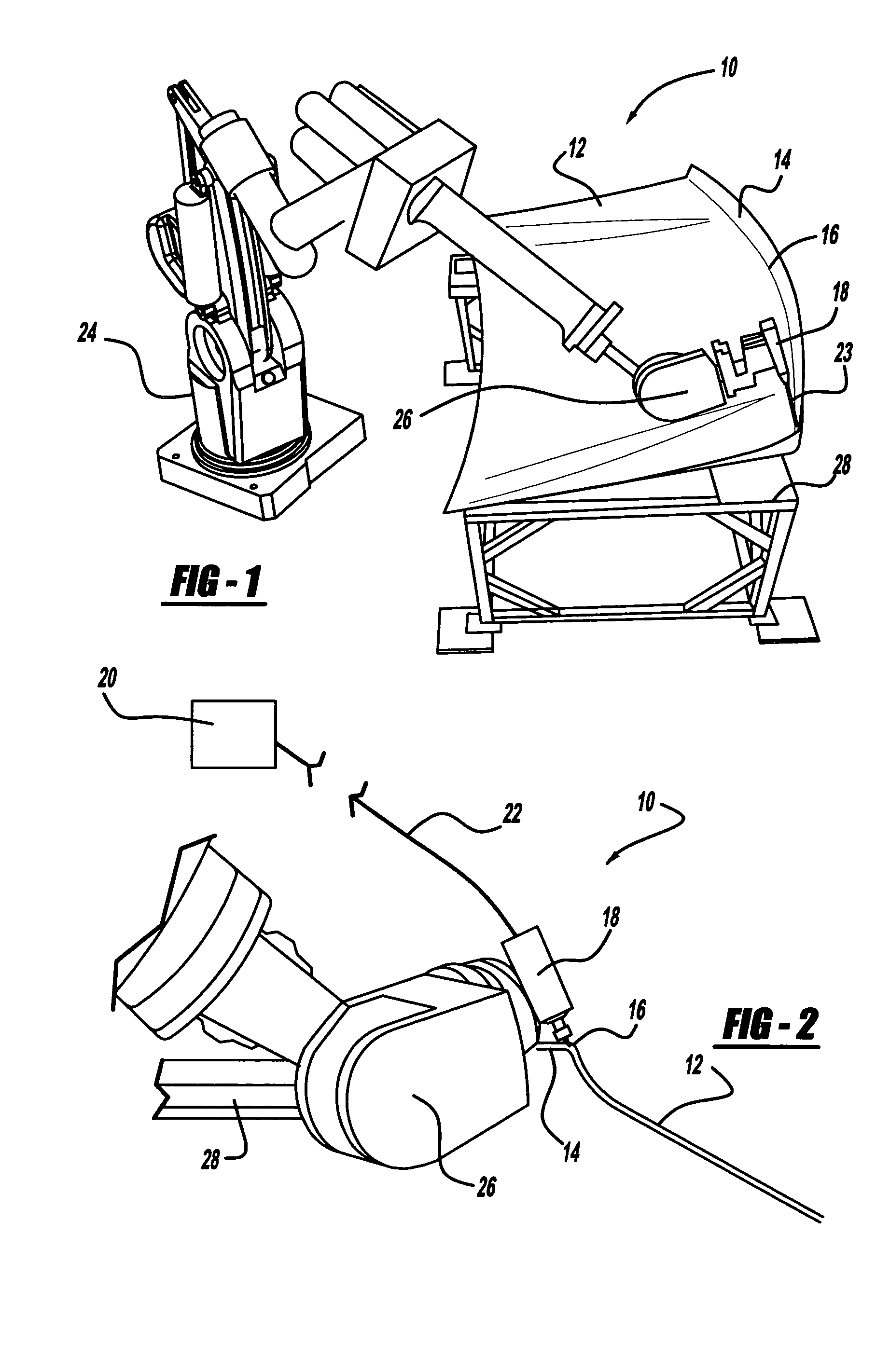

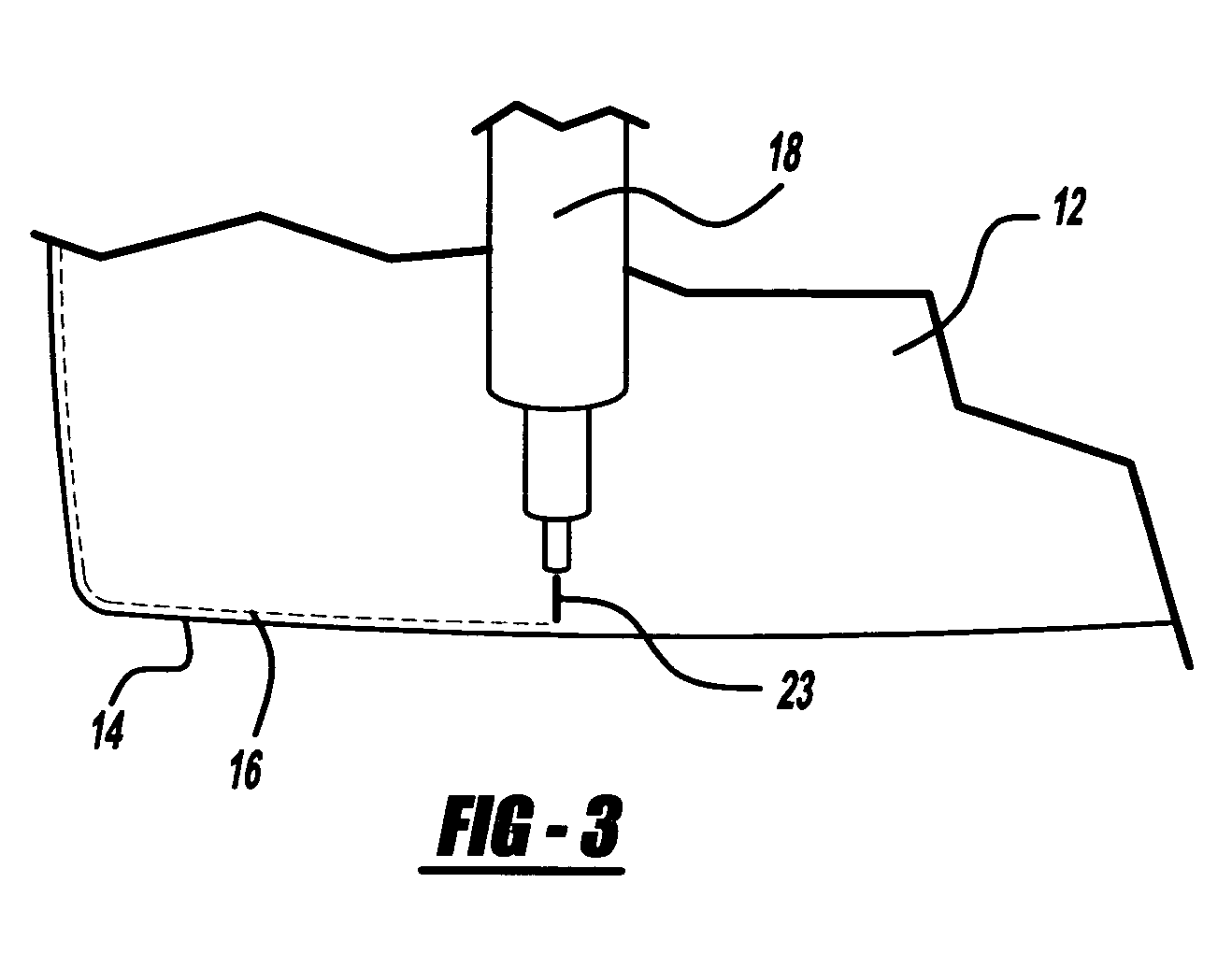

Flexible imaging member seam treatment apparatus

InactiveUS6803549B2Short lifePremature mechanical failureElectrography/magnetographyDomestic articlesMechanical engineeringSmooth surface

A belt seam treatment apparatus includes a support element with a smooth surface that supports the seam region of the belt and a heat and pressure source that heats a treatment strip and the belt seam region and that forces the treatment strip against the belt seam region. The support element can be a tube over which the belt hangs and can include a vacuum belt hold system that secures the seam region against the tube during treatment. The heat and pressure source can be a heated pressure bar engaging the entire seam region or a heated pressure wheel traversing the seam region of the entire belt width.

Owner:XEROX CORP

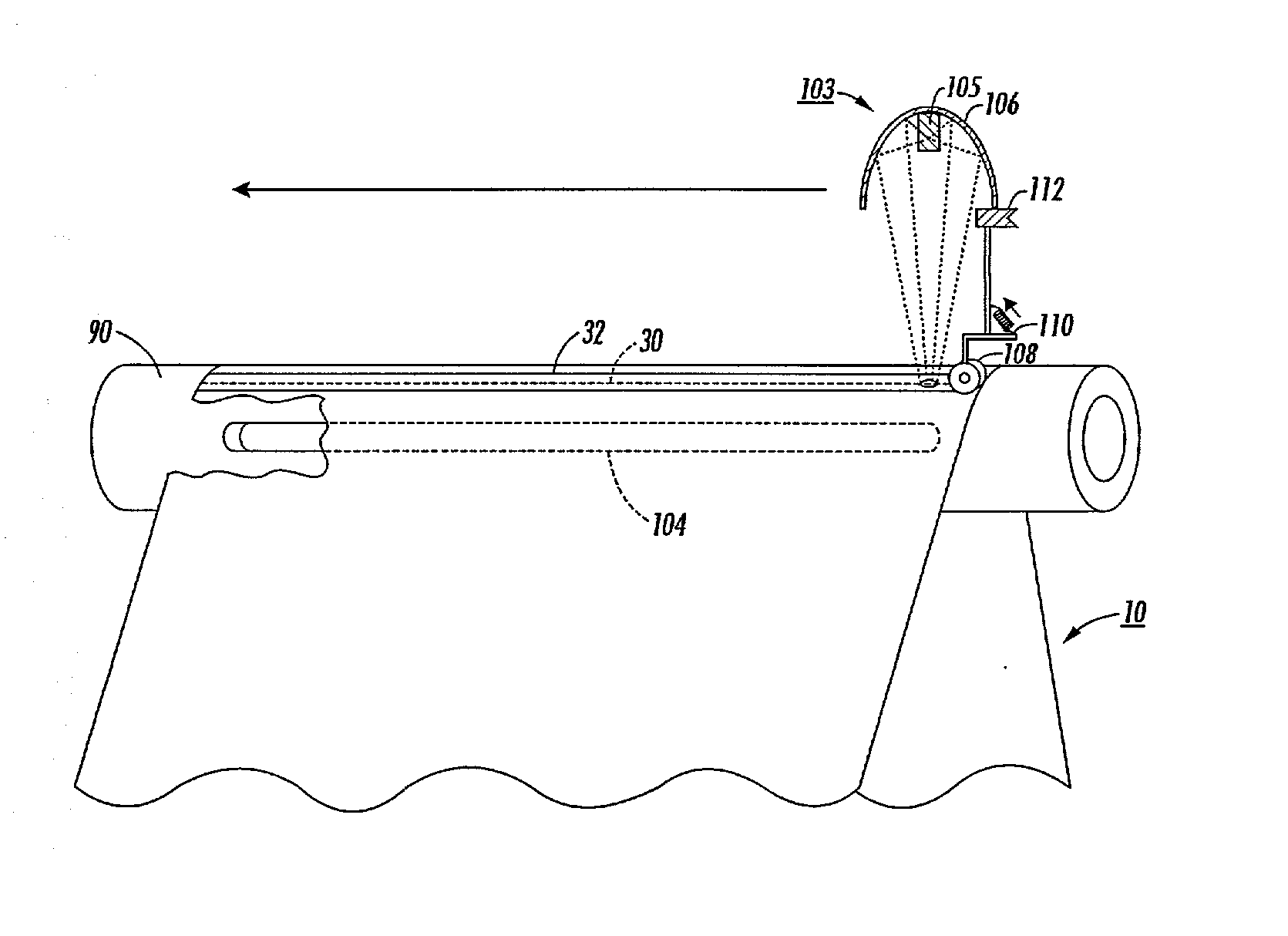

Flexible imaging member seam treatment apparatus

InactiveUS20030221785A1Good seam region physical continuityImprove surface morphologyMechanical working/deformationFilament handlingInfrared lampEngineering

A belt seam treatment apparatus includes a support element with a smooth surface that supports the seam region of the belt, a heat source that heats a treatment strip and the belt seam region, and a pressure applicator that forces the treatment strip against the belt seam region. The support element can be a tube over which the belt hangs and can include a vacuum belt hold system that secures the seam region against the tube during treatment. The heat source can be an infrared laser or an infrared lamp. Optics form a heat spot or a heat line on the strip and seam region, and a pressure wheel traverses the seam region after heating to compress the strip and seam and bond a thermoplastic polymer of the strip to the seam region of the belt.

Owner:XEROX CORP

High-strength wear-resistant paint

ActiveCN103773227AIncrease the degree of cross-linkingHigh scratch resistanceCoatingsWear resistantSilicon oxide

The invention discloses a high-strength wear-resistant paint which is prepared from the following raw materials in parts by weight: 20-30 parts of tetraethoxysilane, 15-25 parts of methyl trimethoxysilane, 15-20 parts of calcium naphthenate, 3-5 parts of silica sol, 10-15 parts of crystallized silicon oxide, 7-13 parts of graphite powder and 15-20 parts of auxiliary material, wherein the particle size of the silica sol is 4-9 nm, the particle size of the crystallized silicon oxide is 25-35 mu m, the weight ratio of the silica sol to the crystallized silicon oxide is 2:(5-6), and the weight ratio of the tetraethoxysilane to methyl trimethoxysilane is (1-2):1. The high-strength wear-resistant paint is excellent in crocking resistance, good in adhesion property with a substrate, and lower in cost.

Owner:ANHUI JINDUN PAINT

Flexible imaging member seam treatment apparatus

InactiveUS20030222078A1Good seam region physical continuityImprove surface morphologyElectrography/magnetographyDomestic articlesEngineeringMechanical engineering

A belt seam treatment apparatus includes a support element with a smooth surface that supports the seam region of the belt and a heat and pressure source that heats a treatment strip and the belt seam region and that forces the treatment strip against the belt seam region. The support element can be a tube over which the belt hangs and can include a vacuum belt hold system that secures the seam region against the tube during treatment. The heat and pressure source can be a heated pressure bar engaging the entire seam region or a heated pressure wheel traversing the seam region of the entire belt width.

Owner:XEROX CORP

Flexible imaging member seam treatment apparatus

InactiveUS20040056014A1Short lifePremature mechanical failureOhmic-resistance heatingElectrography/magnetographyEngineeringMechanical engineering

A belt seam treatment apparatus includes a support element with a smooth surface that supports the seam region of the belt and a heat and pressure source that heats a treatment strip and the belt seam region and that forces the treatment strip against the belt seam region. The support element can be a tube over which the belt hangs and can include a vacuum belt hold system that secures the seam region against the tube during treatment. The heat and pressure source can be a heated pressure bar engaging the entire seam region or a heated pressure wheel traversing the seam region of the entire belt width.

Owner:XEROX CORP

Wear-resisting coating

The invention discloses a wear-resisting coating. The wear-resisting coating comprises the following raw materials in parts by weight: 20-30 parts of vinyl triisopropoxysilane, 3-5 parts of silicon dioxide aerogel, 15-20 parts of trioxane, 5-9 parts of water, 3-7 parts of acetic anhydride, 10-15 parts of acetylcholine, 0.1-0.3 part of polyoxyethylene anhydro-sorbit monoglyceride, 10-15 parts of crystallizing silicon oxide, and 7-13 parts of graphite powder, wherein the porosity of the silicon dioxide aerogel is 75-79%, and the weight ratio of silicon dioxide aerogel to vinyl triisopropoxysilane is 1:(5-7). The wear-resisting coating can improve the degree of crosslinking of a coating and enhance the resistance to scratching, and has low cost.

Owner:ANHUI JINDUN PAINT

Decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating

InactiveCN108384338ALow thermal conductivityReduce stress crackingFireproof paintsPentaerythritolDefoaming Agents

The invention provides a decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating. The decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating comprises the following raw material components in parts by weight: 20-30 parts of a styrene-acrylic emulsion, 2-4 parts of hollow glass microbeads,8-12 parts of titanium dioxide, 20-30 parts of ammonium polyphosphate, 8-12 parts of tripolycyanamide, 5-8 parts of pentaerythritol, 0.2-0.5 part of a silane coupling agent, 3-6 parts of a dispersingagent, 2-4 parts of a thickening agent, 0.2-0.5 part of a defoaming agent, 1.0-2.5 parts of a film-forming aid, 0.1-0.3 part of a wetting agent, 0.2-0.5 part of an OP-10 emulsifying agent and 20-30 of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

Aqueous metal anticorrosive, rustproof and thermal insulation coating

InactiveCN110172285AUniform stress distributionReduce stress crackingAnti-corrosive paintsPolyurea/polyurethane coatingsIron oxideEmulsion

The invention discloses an aqueous metal anticorrosive, rustproof and thermal insulation coating, which is prepared from the following raw materials: nanometer tungsten trioxide dispersion, ammonium carbonate, hollow glass microbeads, a silicone defoaming agent, iron oxide red, zinc phosphate , aluminum tripolyphosphate, silicon benzene emulsion, aluminum tripolyphosphate, mica powder, titanium dioxide, talc, an anionic wetting agent, a dispersant, a film forming aid, a thickener, an antifreeze agent, deionized water, a coupling agent, an anti-settling agent and a nonionic hydrophobically modified polyurethane block copolymer. The coating disclosed by the invention not only has good salt water resistance, acid resistance, alkali resistance, neutral salt spray resistance and high adhesion,but also has the advantages of good reflectivity, heat insulation, environmental protection, decoration, corrosion resistance and rust resistance properties.

Owner:大余松瀛化工有限公司

Root puncture resistant filler for waterproof roll and production method thereof

The invention discloses root puncture resistant filler for a waterproof roll and a production method thereof. The root puncture resistant filler is prepared by adding 10-95 percent by weight of calcium carbonate powder, 10-85 percent by weight of talcum powder, 2-50 percent by weight of wollastonite powder, 1-30 percent by weight of glass microsphere and 2-30 percent by weight of zinc oxide powder into a dry method ball miller, fully mixing for 2-3 hours and bagging. By being mixed with the glass microsphere, calcium carbonate and several other components, the compound filler can effectively improve the tension strength, the ductility and the tear strength of various waterproof rolls and reduce the maintenance frequency and the maintenance expense of the roof waterproof operation, and has higher social and economic benefits.

Owner:北京立高科技股份有限公司 +1

Preparation method of liquid-proof coating adopting gradient increasing structure

ActiveCN106835075AReduce stress crackingGood barrier protection performanceChemical vapor deposition coatingChemistryNitrogen gas

The invention discloses a preparation method of a liquid-proof coating adopting a gradient increasing structure, belongs to the technical field of plasma chemical vapor deposition. The preparation method comprises the following steps: firstly, putting a base material into a reaction chamber of a plasma chamber, continuously vacuumizing the reaction chamber till the vacuum degree of the reaction chamber is 10-200 millitorrs, and inflating an inert gas or nitrogen gas; secondly, inflating first monomer steam, second monomer steam and third monomer steam at the same time; starting plasma discharge, and performing chemical vapor deposition; after discharge, turning off a plasma power supply, stopping inflation of the first monomer steam, the second monomer steam and the third monomer steam, continuously vacuumizing, inflating atmosphere till an atmospheric pressure after the vacuum degree of the reaction chamber is kept at 10-200 millitorrs for 1-5 min, and then taking out the base material. Through inflation of the first monomer steam, the second monomer steam and the third monomer steam at the same time, and through control over increase in the flows of the first monomer steam, the second monomer steam and the third monomer steam at different speeds, the prepared coating has gradient changing structural toughness and hardness, can reduce stress cracking and deformation, and has a relatively high barrier protection performance.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Ceramic grouting forming method and mold thereof

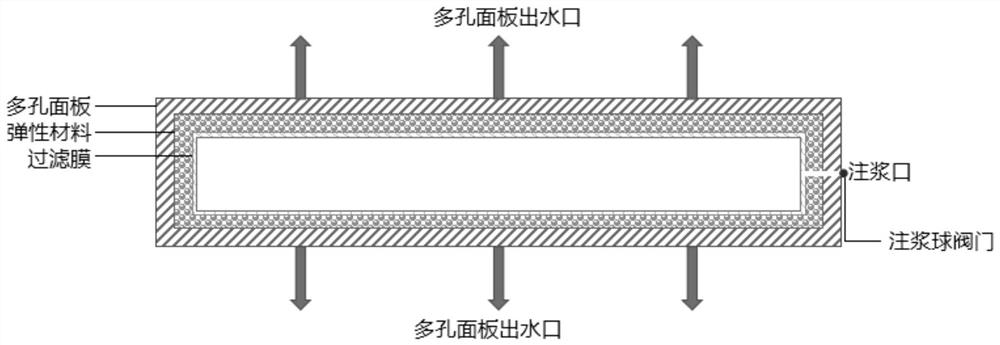

InactiveCN113967961ALarge deformationUniform deformationMould auxillary partsSlip casting mouldsMold removalCeramic materials

The invention relates to a ceramic grouting forming method and a mold thereof, and belongs to the technical field of material forming. An elastic material layer and a filtering film layer are sequentially laid on the inner surface of a porous panel, and after mold closing, pressurized grouting and pressure maintaining are conducted on a mold through a grouting opening; after pressure maintaining is completed, a grouting valve is closed, and drying, demolding and sintering are conducted. In the pressurized grouting and pressure maintaining process, the elastic material layer in the mold is pressed to elastically deform, and the elastic material layer rebounds after pressure is removed; inward compression force is evenly provided for a grouting blank, and uniform distribution and uniform density of the grouting blank are achieved; and therefore the blank is prevented from being layered or cracked. In the drying process, the elastic material can retain a part of moisture, the surface and the center of the blank are in a humidity balance state in the drying process, and the stress cracking phenomenon caused by different humidities of the surface and interior of the blank is reduced.

Owner:CHONGQING GENORI IND CO LTD

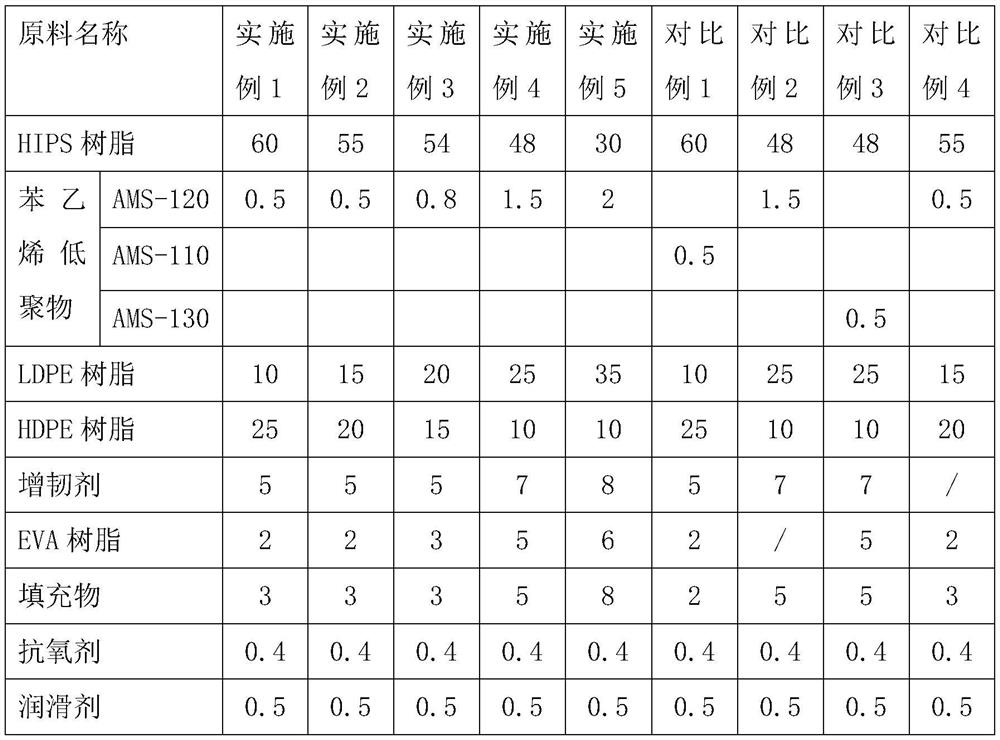

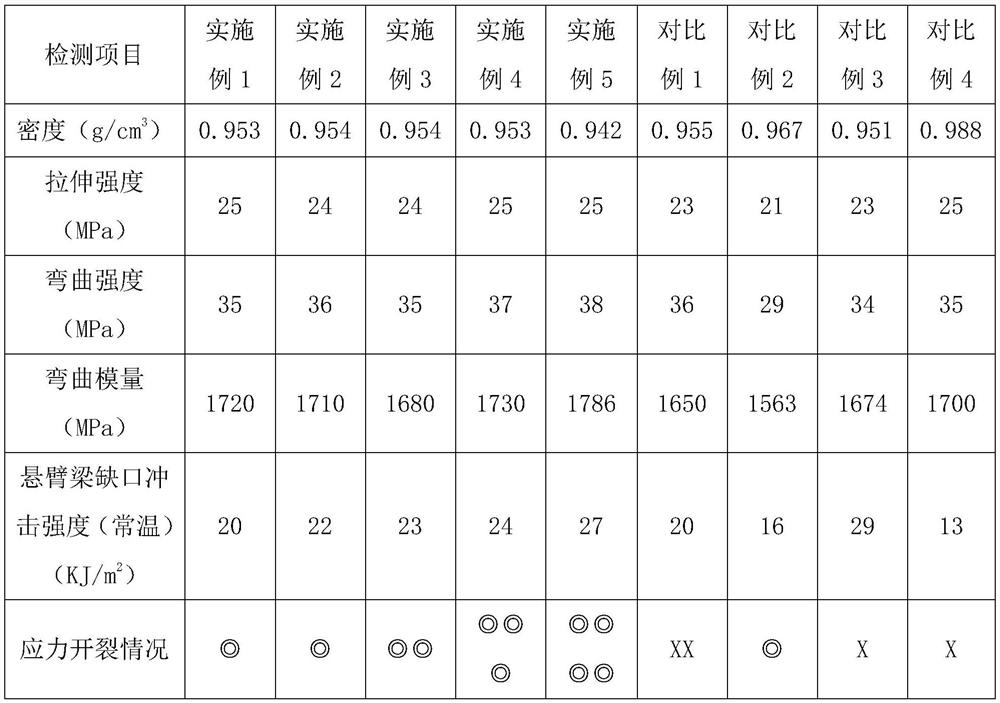

HIPS composite material as well as preparation method and application thereof

The invention provides an HIPS composite material as well as a preparation method and application thereof. The composite material comprises the following components in parts by mass: 30-60 parts of HIPS resin, 0.5-2 part of a styrene oligomer, 10-35 parts of a HDPE resin, 10-35 parts of an LDPE resin, 2-10 parts of an EVA resin, 2-10 parts of a filler, 5-10 parts of a toughening agent, and 0.5-1.5parts of a processing aid. The PS composite material provided by the invention has the characteristics of low density, high toughness and low stress cracking.

Owner:TIANJIN KINGFA NEW MATERIAL

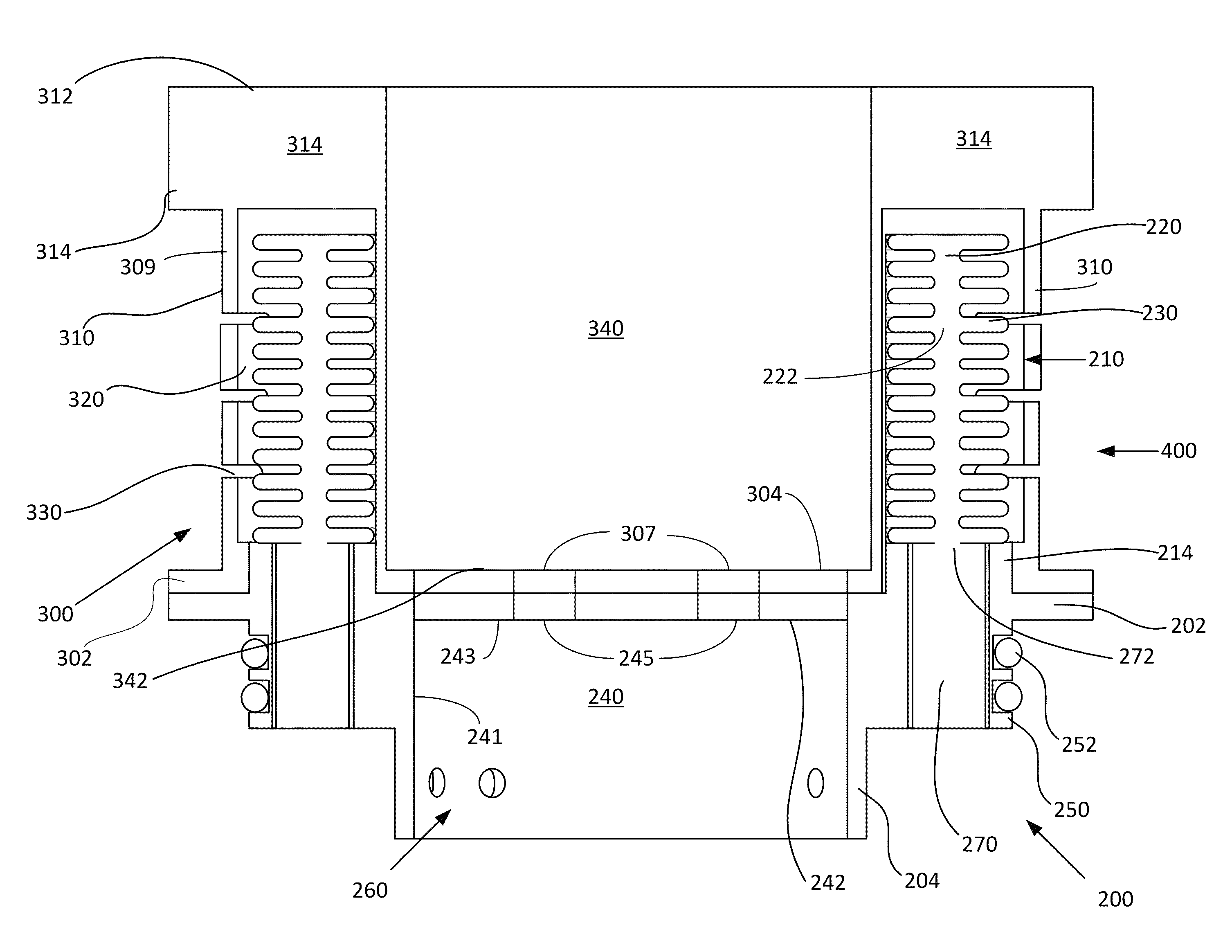

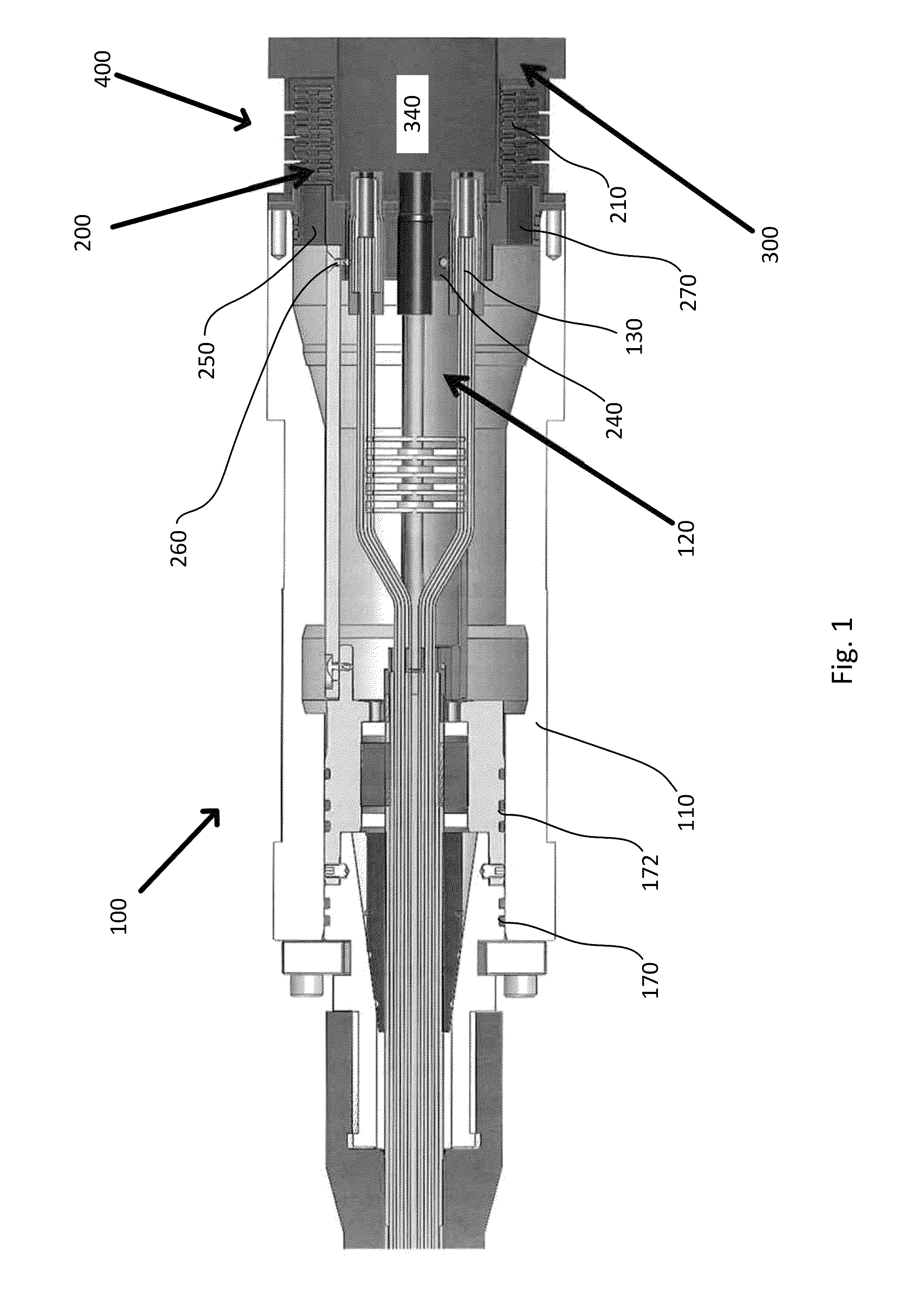

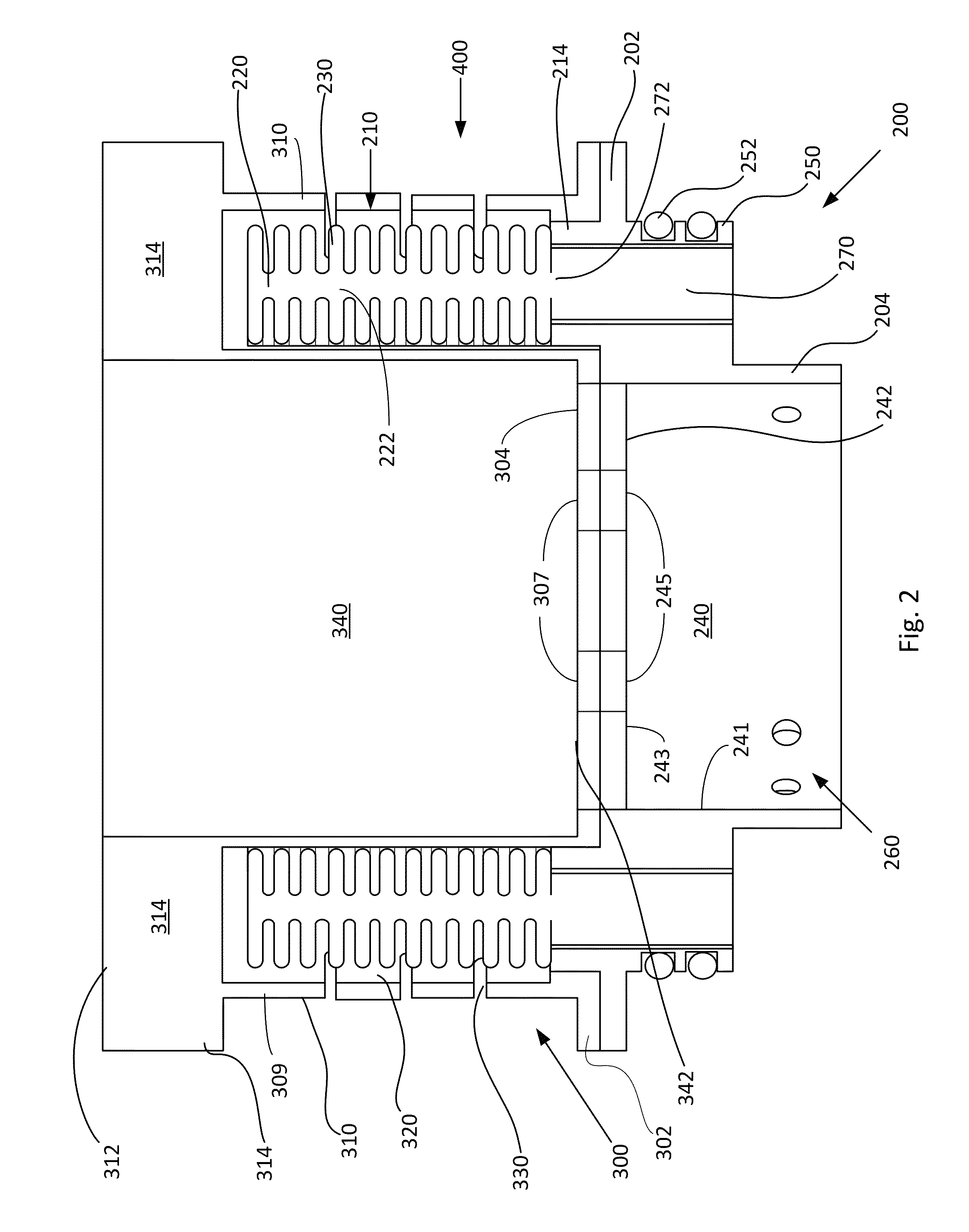

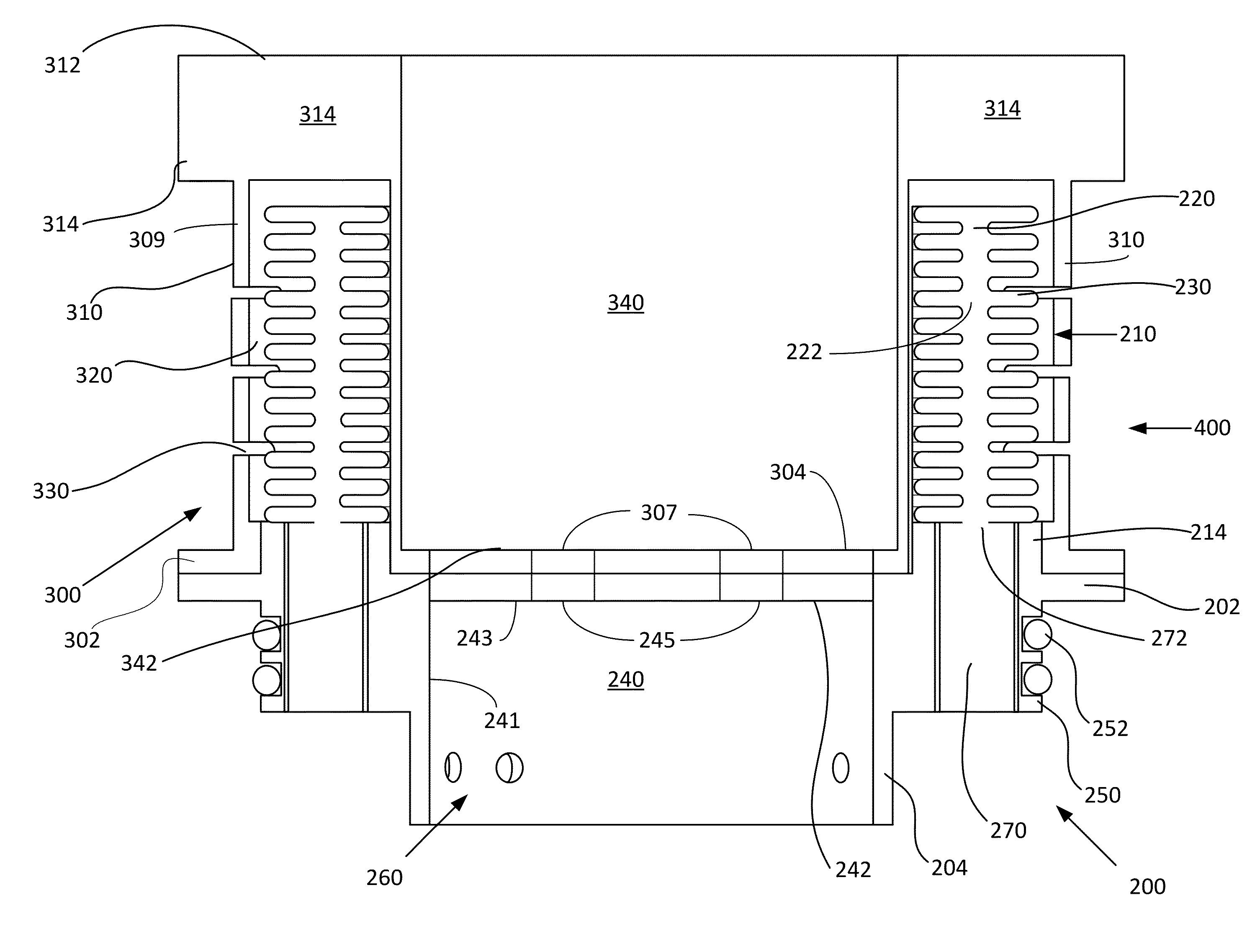

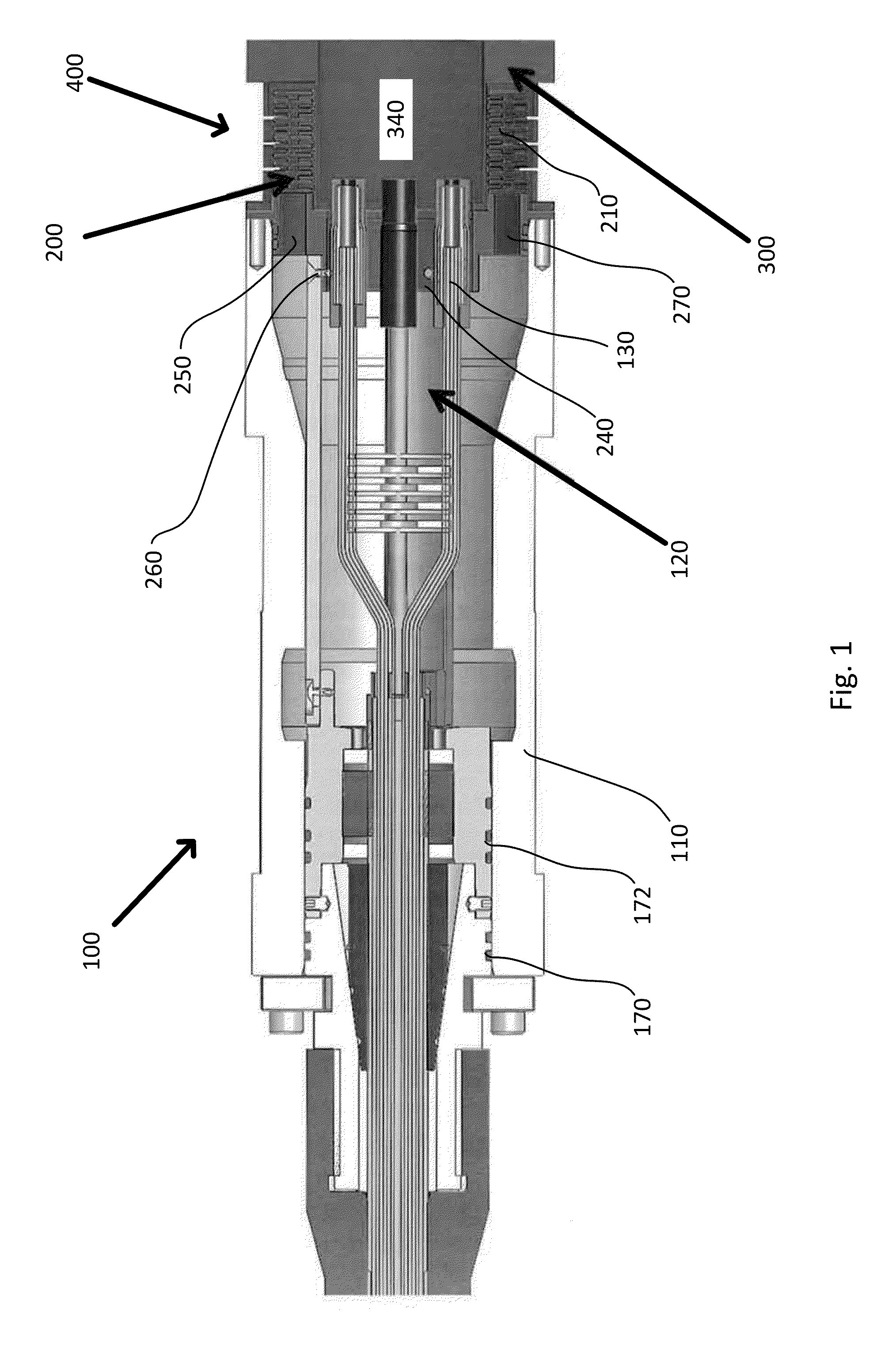

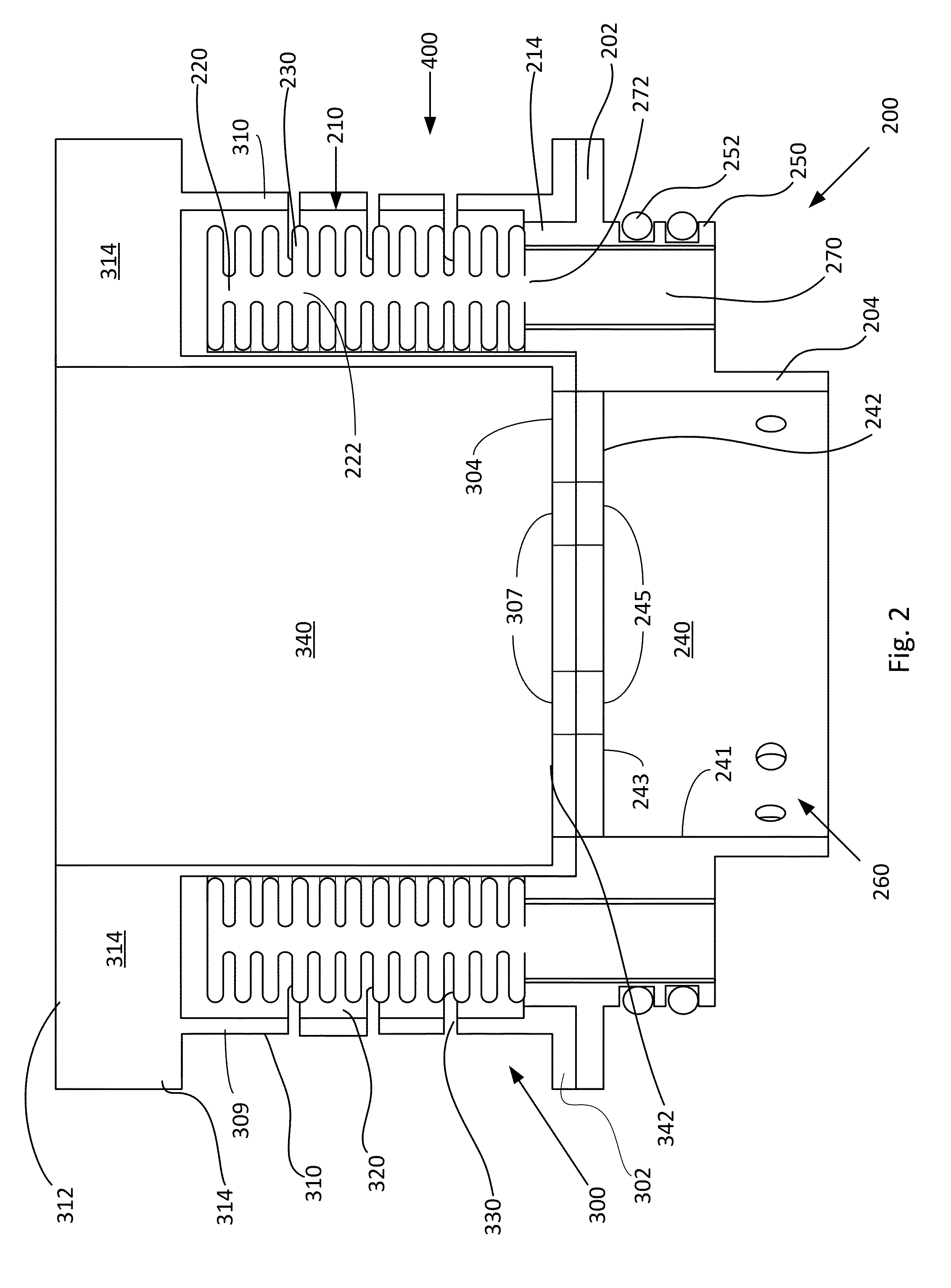

Harsh environment pressure compensator for inline cable termination

ActiveUS9388643B1Quantity minimizationLow compressibilityDrilling rodsCoupling device detailsOcean bottomAmbient pressure

The present invention generally relates to an inline pressure compensator that compensates for volumetric changes within Field-Assembled Cable Termination (FACT) structures when exposed to high pressures and extreme subsea depths by transferring a pressure compensating fluid into the internal cavity of the FACT. The present invention may comprise a flexible internal component and an outer shell-like component. The inner component may comprise two concentric rings of edge-welded bellows that are joined together and wrapped around inner components of the termination or of the inner portion of the outer component. The inner void in the bellows may be filled with pressure-compensating fluid. The pressure compensating fluid diffuses directly into the fluid-filled cavity of the termination assembly. The exterior component may comprise a housing adapted to protect the interior bellows component and provide for seawater to fill the space around the periphery of the bellows arrangement.

Owner:TELEDYNE INSTR INC

Harsh environment pressure compensator for inline cable termination

ActiveUS20160201402A1Quantity minimizationLow compressibilityDrilling rodsCoupling device detailsOcean bottomEngineering

The present invention generally relates to an inline pressure compensator that compensates for volumetric changes within Field-Assembled Cable Termination (FACT) structures when exposed to high pressures and extreme subsea depths by transferring a pressure compensating fluid into the internal cavity of the FACT. The present invention may comprise a flexible internal component and an outer shell-like component. The inner component may comprise two concentric rings of edge-welded bellows that are joined together and wrapped around inner components of the termination or of the inner portion of the outer component. The inner void in the bellows may be filled with pressure-compensating fluid. The pressure compensating fluid diffuses directly into the fluid-filled cavity of the termination assembly. The exterior component may comprise a housing adapted to protect the interior bellows component and provide for seawater to fill the space around the periphery of the bellows arrangement.

Owner:TELEDYNE INSTR INC

A high-strength wear-resistant coating

Owner:ANHUI JINDUN PAINT

Green and environment-friendly UV coating and preparation method thereof

The invention discloses a green and environment-friendly UV coating. The composition comprises the following components in parts by weight: 25-35 parts of polymerized water-soluble hyperbranched polyamide, 10-15 parts of N, N-dimethylformamide. N, N'-bis(2-ethoxyl)-N, N'-bis(trimethoxysilylpropyl)-ethylenediamine / 2, 3'-difluoro fumarate oligomer, 1-2 parts of 2-(5-phenyl-1H-tetrazole-1-base)-3-thiophene-crylic acid, 3-5 parts of an aqueous photoinitiator, 10-20 parts of inorganic filler, 0.5-1.5 parts of a dispersing agent, 0.3-0.6 parts of a flatting agent, 0.4-0.8 parts of a defoamer, 1-2 parts of an emulsifier and 10-20 parts of water. The invention further discloses a preparation method of the green and environment-friendly UV coating. The green and environment-friendly UV coating disclosed by the invention is excellent in comprehensive performance, good in mechanical property, performance stability, weather resistance, water resistance and fire resistance, high in adhesive force to a base material, safe to use and environment-friendly.

Owner:肇庆英克斯化工有限公司

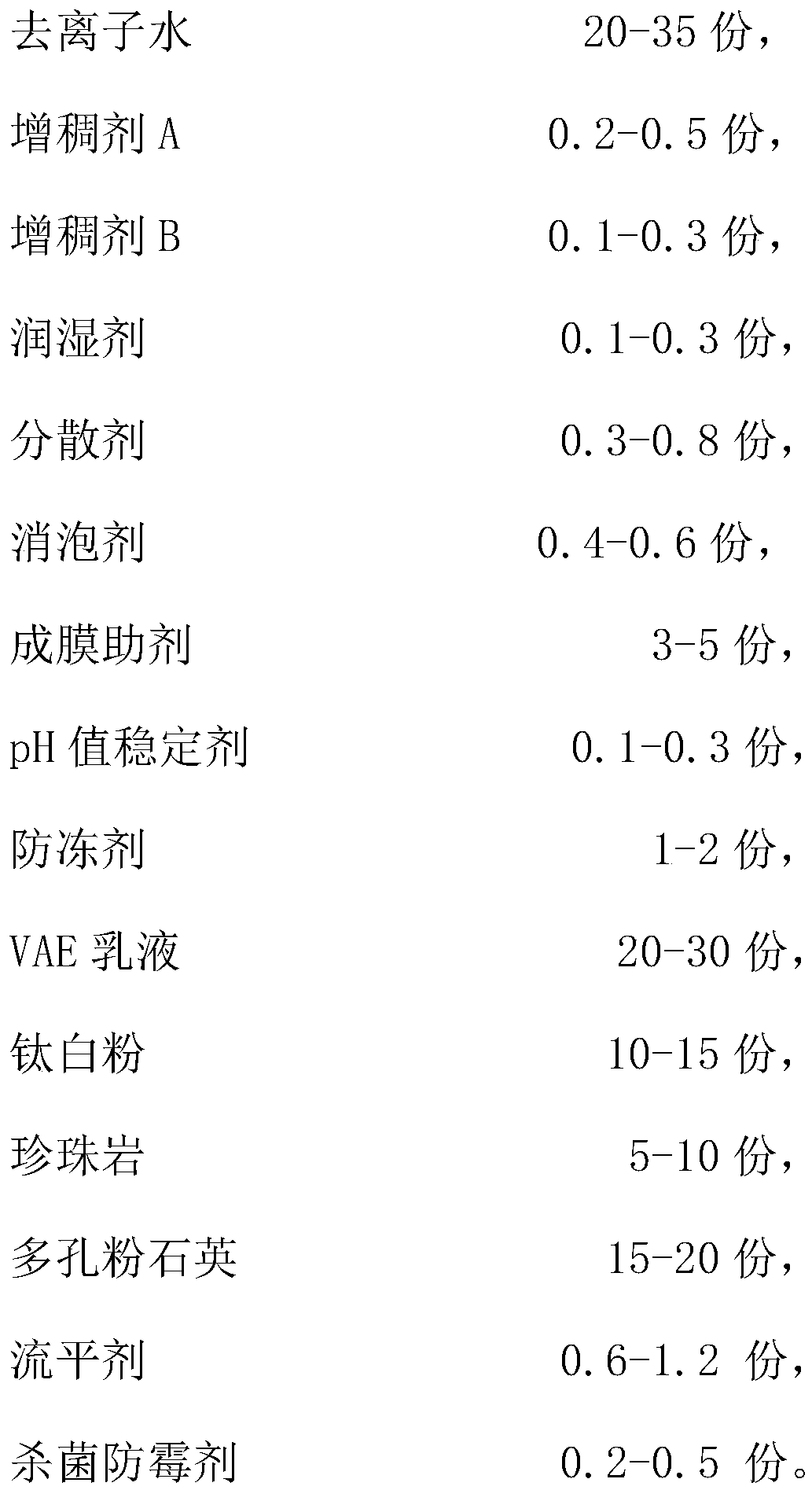

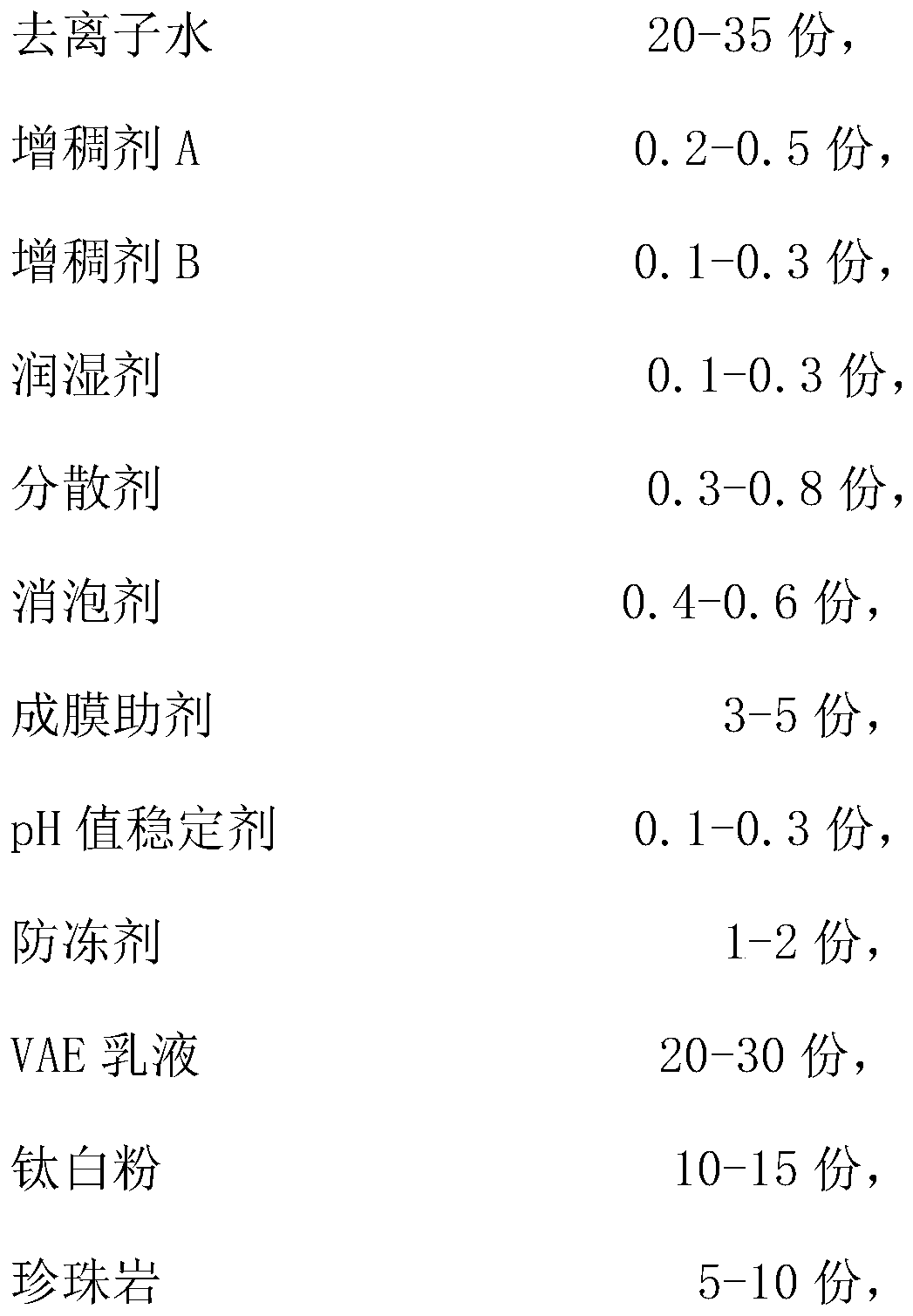

Water-based sound-absorbing heat-insulating fireproof coating and preparation method thereof

InactiveCN111100515AEffective dispersionNo bubblesFireproof paintsReflecting/signal paintsEmulsionMildew

The invention discloses a water-based sound-absorbing heat-insulating fireproof coating and a preparation method thereof. The invention belongs to the technical field of indoor coatings. The coating is prepared from the following components in parts by mass: 20-35 parts of deionized water, 0.2-0.5 parts of a thickening agent A, 0.1-0.3 parts of a thickening agent B, 0.1-0.3 parts of a wetting agent, 0.3-0.8 parts of a dispersing agent, 0.4-0.6 parts of a defoamer, 3-5 parts of a coalescing agent, 0.1-0.3 parts of a pH value stabilizer, 1-2 parts of an anti-freezing agent, 20-30 parts of VAE emulsion, 10-15 parts of titanium dioxide, 5-10 parts of perlite, 15-20 parts of porous powder quartz, 0.6-1.2 parts of a leveling agent and 0.2-0.5 parts of a bactericidal mildew preventive. The product is non-toxic, harmless, low in cost, free of environmental pollution, high in covering power and excellent in heat insulation, sound absorption and fire prevention effects.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Nano-silica modified styrene-acrylic external wall composite thermal insulation coating and preparation method thereof

InactiveCN108504203AImprove insulation effectWith sound insulationAntifouling/underwater paintsPaints with biocidesAluminum CarbonateEmulsion

The invention provides a nano-silica modified styrene-acrylic external wall composite thermal insulation coating and a preparation method thereof. The coating is prepared from the following componentsin parts by weight: 50-70 parts of styrene-acrylic emulsion, 10-20 parts of xonotlite powder, 5-8 parts of hollow glass beads, 8-12 parts of titanium dioxide, 4-5 parts of ultrafine aluminum carbonate powder, 10-20 parts of talcum powder, 2-4 parts of nano-silica, 0.8-1.2 parts of an anti-mildew bactericide, 0.4-0.8 parts of a wetting agent, 0.3-0.5 part of a dispersant, 0.5-0.9 parts of a defoamer, 1.5-2.5 parts of a coalescing agent, 0.8-1.2 parts of a thickener, 4-8 parts of an antifreezing agent, 0.1-0.3 parts of a PH regulator and 30-50 parts of deionized water.

Owner:邹奇峰

Strong-strength abrasion-resistant coating

The invention discloses a strong-strength abrasion-resistant coating. The coating is characterized in that the coating is prepared from the following raw materials in parts by weight: 20 parts of tetraethyl orthosilicate, 15 parts of methyltrimethoxy silane, 15 parts of calcium naphthenate, 3 parts of silicon dioxide sol, 7 to 13 parts of graphite powder, 15 parts of auxiliary, 5 parts of carbon fiber powder and 6 parts of silicon carbide, wherein the particle size of the silicon dioxide sol is 5nm, the particle size of silicon oxide crystals is 25 mu m, the weight ratio of the silicon dioxide sol to the silicon oxide crystals is 2:3, and the weight ratio of the tetraethyl orthosilicate to the methyltrimethoxy silane is 2:1. The strong-strength abrasion-resistant coating disclosed by the method is high in abrasion resistance and lower in cost, and the adhesion performance of the strong-strength abrasion-resistant coating with a substrate is high.

Owner:李青玉

Method for laser annealing

A method for laser annealing a part includes the steps of providing automated tooling, providing a laser, and providing a metal part to be annealed. The method also includes the steps of moving either one of the laser or metal part by the automated tooling relative to a stationary one of the other laser or metal part. The method further includes the steps of supplying power to the laser to heat a portion of the metal part to a predetermined temperature to anneal the portion of the metal part as the laser and metal part move relative to each other.

Owner:GM GLOBAL TECH OPERATIONS LLC

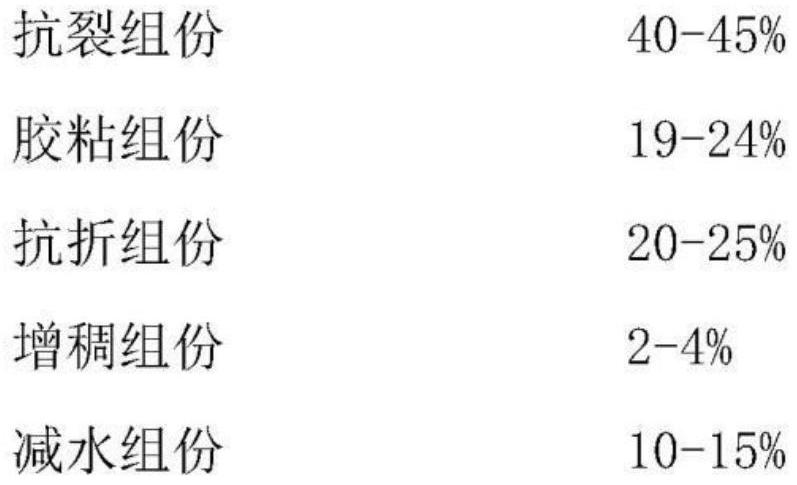

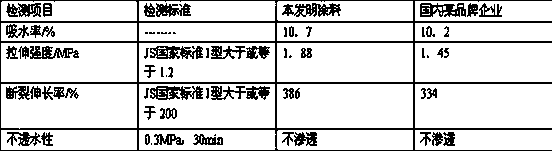

A special reinforcing agent for ready-mixed permeable concrete and its preparation method

ActiveCN108751784BPrevent shrinkage fractureReduce stress crackingStructural engineeringPervious concrete

The invention provides a special reinforcing agent for ready-mixed pervious concrete and a preparation method thereof. The special reinforcing agent for the ready-mixed pervious concrete includes thefollowing raw materials by mass: 40-45% of anti-cracking component, 20-25% of flexural component, 2%-4% of thickening component, 19-24% of adhesive component and 10-15% of water reduction component. The dosage of the special reinforcing agent in the pervious concrete is 2-3% of the mass of a cementing material. The reinforcing agent can not only effectively prevent the late shrinkage of the pervious concrete and reduce the stress cracking, but also significantly improve the flexural resistance and the frost resistance of the pervious concrete, ensures the mechanical property and the durabilityof pervious concrete pavements, and enhances the water retention and the slump retention of the previous concrete to meet the construction requirements of the ready-mixed concrete. The reinforcing agent is beneficial to prepare the premixed medium and high strength pervious concrete.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Waterproof thermal-insulation coating with organosilicon-modified styrene-acrylic emulsion

InactiveCN108395776ALow thermal conductivityReduce stress crackingFireproof paintsReflecting/signal paintsThermal insulationTalc

The invention provides a waterproof thermal-insulation coating with organosilicon-modified styrene-acrylic emulsion. The waterproof thermal-insulation coating is prepared from the following componentsin parts by weight: 80-100 parts of organosilicon-modified styrene-acrylic emulsion, 20-25 parts of hollow glass bead, 8-15 parts of diatomite, 5-10 parts of nano titanium dioxide, 30-40 parts of cement, 20-30 parts of talcum powder, 20-30 parts of quartz powder, 0.2-0.5 part of silane coupling agent, 3-6 parts of dispersing agent, 2-4 parts of plasticizer, 0.2-0.5 part of defoaming agent, 1.0-2.5 parts of film-forming additive, 0.1-0.3 part of lubricant, 0.2-0.5 part of preservative and 20-30 parts of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

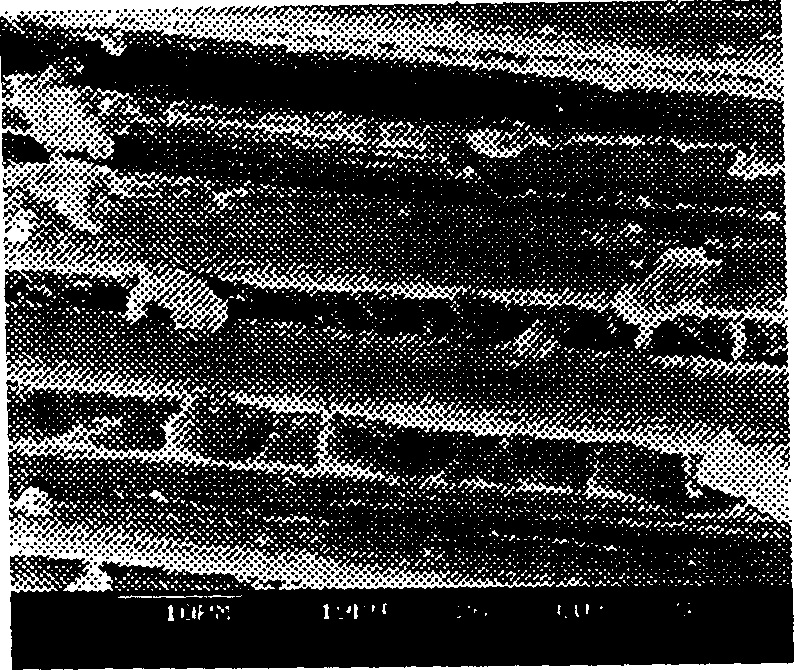

Continuous sucker rod made of fiber reinforced composition and its making method

InactiveCN1252370CIncreased transverse splitting strengthImprove local abrasion resistanceDrilling rodsLayered productsGlass fiberPolymer science

Owner:胜利油田孚瑞特石油装备有限责任公司 +1

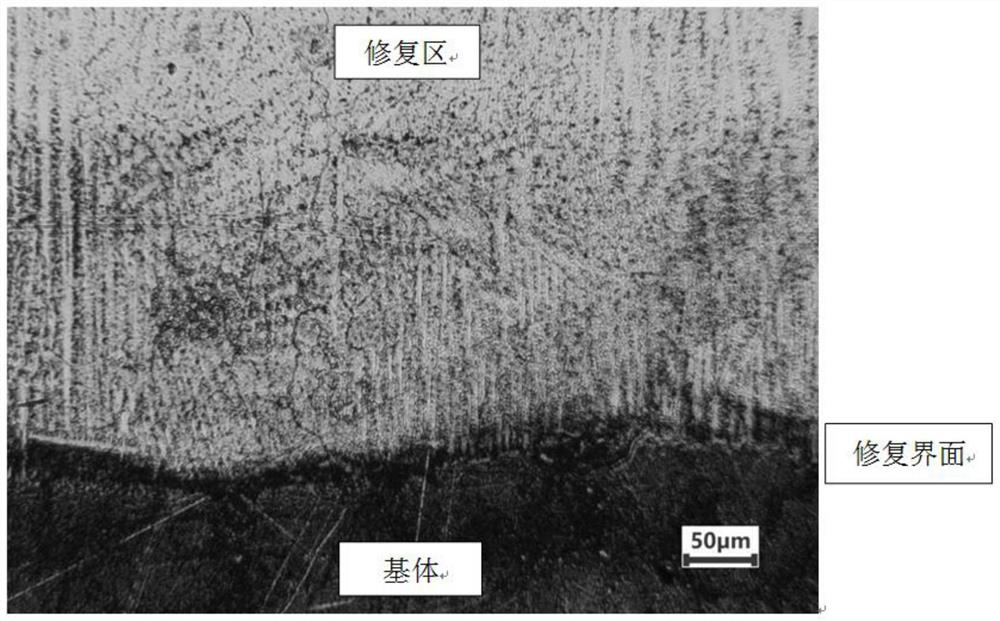

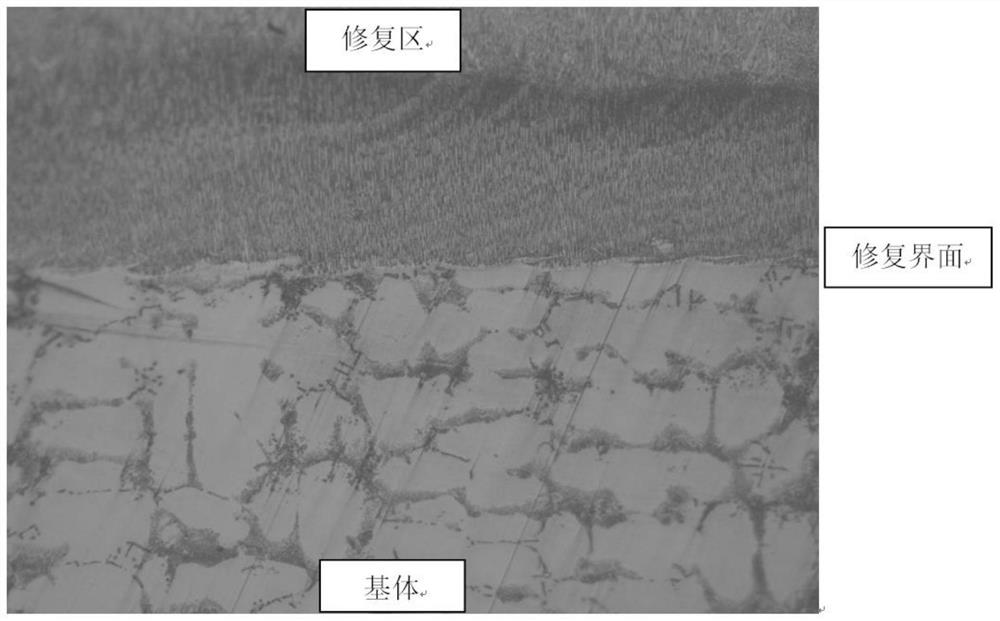

Nickel-based high-temperature alloy repair material and preparation method thereof

ActiveCN113337756AAvoid crackingImprove grain boundary crackingMetallic material coating processesMo elementSuperalloy

The invention discloses a nickel-based high-temperature alloy repair material. On one hand, the problem that a high Al + Ti nickel-based high-temperature alloy is melted by a high-energy beam to generate cracks is solved, and the crystal boundary cracking phenomenon at an interface is improved; due to the fact that the repair material does not contain the Ti element, and the Al element is controlled within a range, hard and brittle phases containing Ti, Al and the like in the repair process are avoided; in addition, interface carbide is diluted by adding the Co element, and the stress cracking phenomenon caused by matrix carbide is reduced; generation of liquefied cracks in a laser repair area is avoided through structure component optimization, and the defect-free repair effect is successfully achieved; on the other hand, the content of the molybdenum element is greatly increased, a matrix and a cladding material form an infinite solid solution of nickel and molybdenum, the cracking tendency is eliminated, the use temperature of the alloy is further increased, and the alloy has high strength under the high-temperature condition; and titanium and aluminum of the matrix material and the cladding material form a gamma' precipitation phase, and the mechanical property after repair is further improved.

Owner:西安空天机电智能制造有限公司

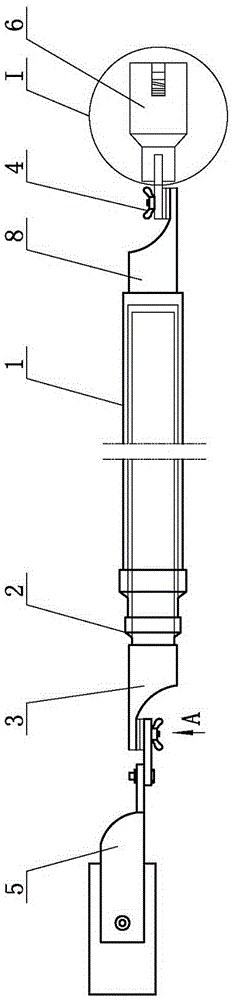

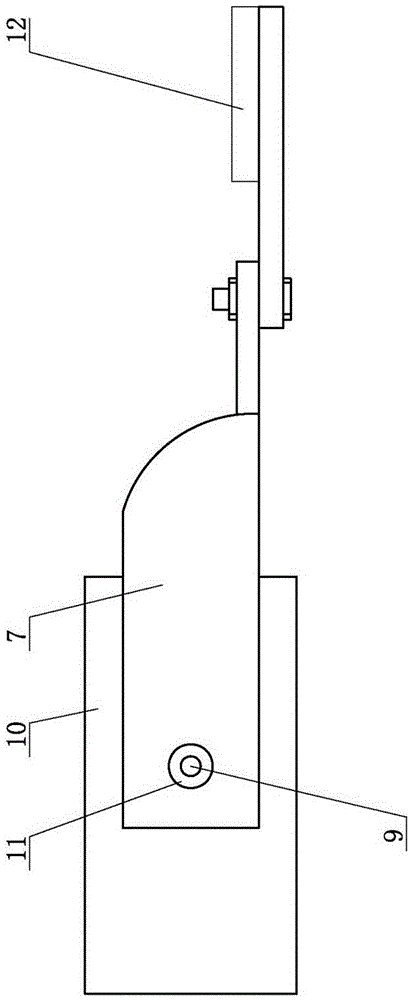

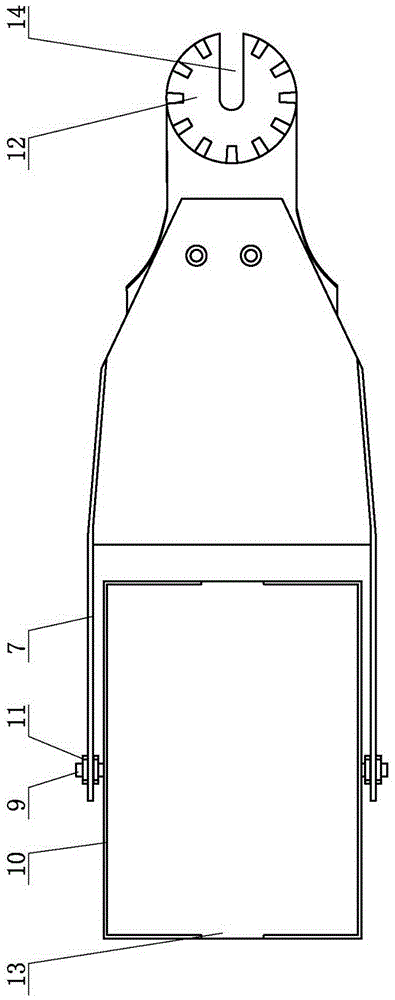

Stretchable type general local discharge detection sensor mounting tool

PendingCN106645821ALightweight replacementReplacing different types of placement with lightweightTesting dielectric strengthCoatingsControl theoryUltrahigh frequency

The invention relates to a stretchable type general local discharge detection sensor mounting tool which comprises an expansion link, wherein a fixing base is arranged at one end of the expansion link; a first steering head is arranged on the fixing base; an ultrahigh frequency type placement base is arranged on the first steering head; a second steering head is arranged at the other end of the expansion link; steering head end-toothed discs are respectively arranged on the first steering head and the second steering head; and a through hole is formed at the center of each steering head end-toothed disc. Through the replacement for different kinds of placement bases, the mounting tool can adapt to both of an ultrasonic local discharge detection method and an ultrahigh frequency local discharge detection method; the structure design is smart, so that the placement bases can be easily replaced; a stretchable operation rod is adopted by the mounting tool, so that the length of the operation rod can be accurately adjusted according to the height of the onsite to-be-detected equipment; and the stretchable structure design is space-saving, so that a local discharge tester can conveniently carry the mounting tool.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com